LOADMASTER EXCEL Series Operating instructions

800−433−2768

100 west eleventh avenue

Norway, M ch gan 49870−0186

po box 186

tel 906−563−9226 tel

fax 906−563−9800 fax

LOADMASTER

….Your Waste Equipment Partner

EXCEL SERIES

Maintenance & Repair Manual

General Body & Hydraulics

General Body & HydraulicsGeneral Body & Hydraulics

General Body & Hydraulics

Released June28, 2007

This manual is publication 7700043

TABLE OF CONTENTS Excel

Maintenance & Repair…general

“body and “Hydraulics

Hydraulics Manual…w/ Hydraulics

Repair

Schematics…Hydraulics & Electrical

Nomenclature “LoadMaster lingo

Pgs a & b

Section 01 Hydraulics… how the system works

Sec01-pg01 thru sec01-pg08

Section 02 Hydraulics…Checking & Adjusting

the various Hydrau settings

Sec02-pg01 thru sec02-pg08

Section 03

Trouble shooting…

Sec 03-pg01 thru sec03-pg04

Section 04 Repairs (various)

Sec 04-pg01 thru sec04-pg08

Section 05 Schematics…

Hydraulics

Sec05-pg01 thru sec05-pg02

Section 06 Schematics…

Electircal

Sec06-pg01 thru sec06-pg04

June 2007

This is the Maintenance/ Repair manual for the

“Excel”.

It includes eneral body Maintenance & Repair

AND is the Hydraulics Manual as well.

The information contained in this Manual

applies ONLY to the EXCEL.

See other manuals for other LOADMASTER

products.

For the Excel Product…

There are 3 manuals for a complete set:

1- the OPERATOR’S MANUAL with Preventive

Maintenance Manual…which also includes

some schematics.

2- The Parts Manual

3- This Maintenance & Repair Manual

Which includes the Hydraulics

800-433-2768

EXCEL

{page date 06-19-07}

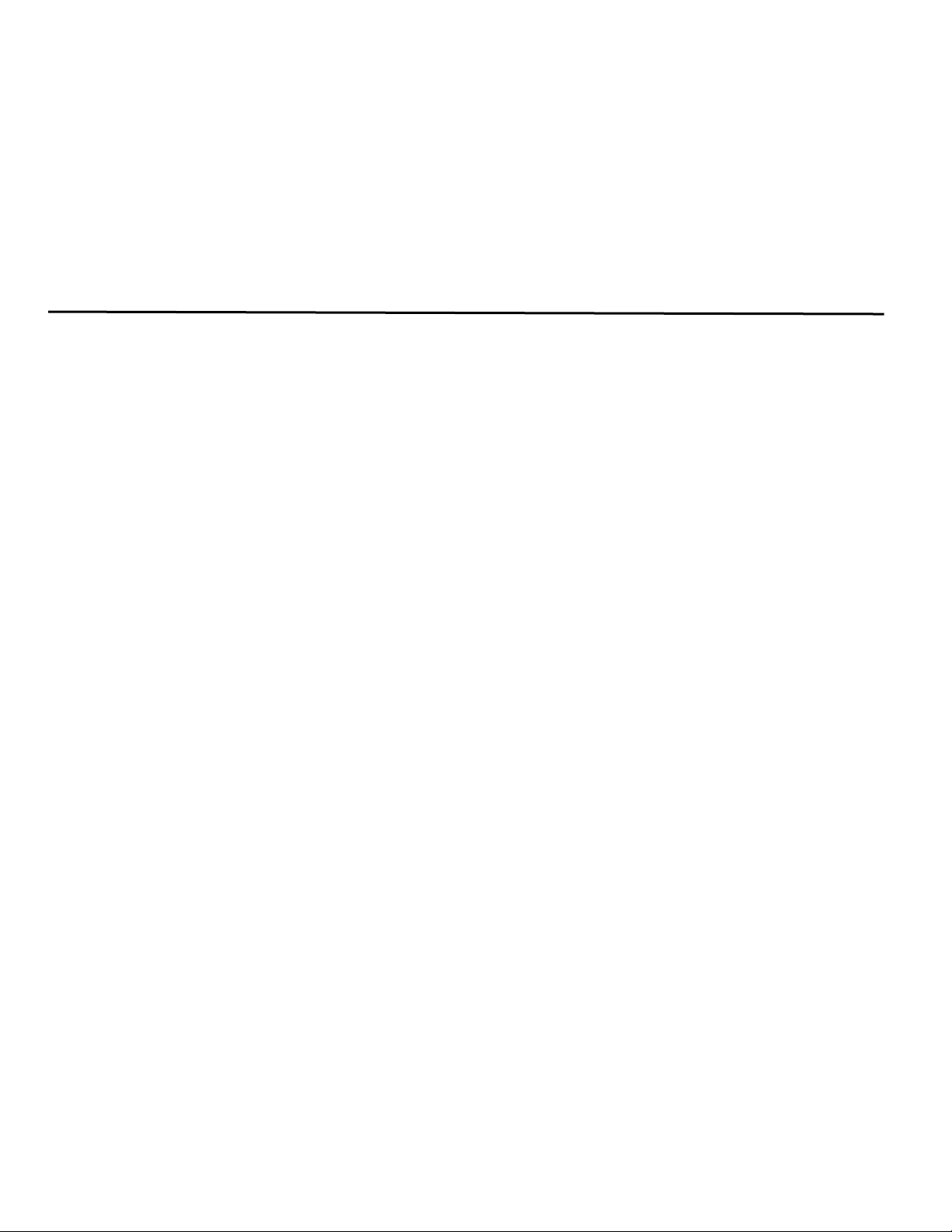

Some NOMENCLATURE…the “words” Loadmaster uses…l ngo to “talk”

The Hopper

Throttle-Advance Limit Switch

Upper Light Pod

“Tailgate

-

Mounted Valve”

The bod ’s Face

Ejector Blade

Under sill

“light

bar

Sweep

Blade

Hopper Sill

Riding S

tep

G

ate lift

c linders

Telescopic C linder

Slider

Blade

The “Chassis”

The “T

ailgate”

or

just “Gate”

The “bod ”

“Bod -Mounted Valve”

Main Wrist Pivot

Sweep C linder

C linder

’s Rod

Slider Shoes

Slider c linder

Slider Shoes

Slider Track

800-433-2768

EXCEL

{page date 06-19-07}

Some NOMENCLATURE…the “words” Loadmaster uses

Mud Flap

Gate’s main “Hinge”

Ladder rung

TurnB

uckle

Gate Ajar Switch

Knobbed Lever

s

Tail-side Controls

Bod Access Door

“Decals”

Gate

-

Ajar Lite

(red)

“Bod

-

Mount”

“Button” Switches

“PTO-Engaged” LIte (red)

Return Filter Lite (amber)

Pressure Filt

er

(opt)

Lite (blue)

Gate Lift

C linder

Section 01

rel june 28, 2007

HOW IT WORKS..THE HYDRAULICS

This section of the manual is an overview of the various

individual hydraulic components and how they all work

together as a “system” Reading this section will have

value to you because it will increase your overall

understanding of “how your EXCEL works”, which will

increase your problem solving skills and speed up any

troubleshooting

The components…

Most EXCEL’s are equipped with a

CHELSEA

PTO

When the PTO is engaged on, the pump

will begin to rotate The PTO may have a drive ratio of

1:1 3 (ratio may vary per

specifc

chassis) This means if

the diesel is rotating at 1200 RPM, the pump itself will

be rotating at 1530 RPM The EXCEL pump is typically a

COMMERCIAL INTERTECH P365 SERIES This is a

modern "journal bearing” gear pump that handles higher

speeds and pressures well Since it is a simple gear

pump, any time the pump is rotating it will create flow in

proportion to its rotational speed (RPM) The EXCEL

uses a 6 4 cubic inch per revolution pump The circuit

therefore is about a 42 GPM flow at a

diesel

speed of

1200 RPM

The

body-mounted valve

is a 2-spool GRESEN V20 The

lowermost cover is the

inlet cover

The inlet cover is

closest to the pump and directly connects to the pump

by the

pump pressure hose

The inlet cover holds the

main relief

and has a

gauge stem

from which all of your

pressure gauge readings will be recorded The EXCEL’S

main relief setting is 2900-2950 psi @ throttle advanced

The inlet cover also connects the

auxiliary return hose

to

tank This auxiliary return provides a path to tank for the

body-mtd valve’s functions, since the outlet of the body-

mtd valve has a

power beyond sleeve

that allows

pressurized fluid to be available downstream to the

tailgate-mounted valve

The first spool section is the

tailgate section,

which is a

single-acting (tailgate is powered up and gravity down)

spool in the case of the EXCEL This work section has

no

port devices installed (such as a port relief;

no

port

reliefs used in tailgate section)

The second spool section (highest from body floor) is

the

ejector section

which known as double acting The

ejector

telescopic

cylinder’s

extend (base-side) workport

has a fixed port relief set at 2400psi (“crack flow”)

This

relief will relieve (@2400 psi) during route compaction

only during the telescopic’s smallest stage (aka,

“plunger” stage…the

first

stage to drift closed during the

ejector’s on-route “automatic drift” (towards the cab)

[Sec01-pg01]

The EXCEL uses a valve called the

synkpak

valve to

control the ejector blade/tellescopic cylinder’s

automatic

drift forward (towards the cab) on the route See the

very next topic labeled “EXCEL SYNKPAK” for a detailed

description of how the Synkpak works

The final section of the body-mounted valve is the

outlet

cover

The

power beyond sleeve

is mounted into the

outlet cover

of the body-mounted valve The

PB sleeve

allows for feeding of pressurized fluid

downstream…through the

roof tubing

and to the

tailgate-mounted valve

The

tailgate-mounted valve

controls the blade actions

and most of the optional equipment, such as a roof

mounted “reever” or the “kick bar” It is a PARKER

VG35 valve that usually has 3 or more working sections

and hangs from the tailgate’s roof (The sections with

the “spools” are called “work sections” )

The first section of the tailgate-mounted valve is the

inlet cover

This inlet receives the flow from the roof

mounted pressure tube It also is the origin of the

return

line

since the cover on the other side is a plugged

turnaround outlet cover

The next sections are the option work sections such as

the “2-10 reever” and the “kickbar” Work sections have

“spools” which are spring centered and are manually

shifted in or out to direct flow to a desired function

Typically there are no workport devices used for options

on the EXCEL (see Kart Dumper exception later)

The

blade

section closest to the pump is the

sweep

blade work section

, and it always comes next, (which is

“upstream” of the slider blade work section) This

spooled section has a

knockout positioner

This knockout

postioner is a device that is controlled by one pressure

“’trip” setting for both directions of spool shift When the

spool is manually shifted, the KO mechanically

holds

the

spool shifted until the next time the pressure

rises

to its

setting, whereupon it releases the spool and the spool

knocks-out to centered-neutral position This pressure

rise typically occurs when the cylinders “bottom-out”

This sweep section has a port relief mounted to the

sweep cylinders

base-side, known as the

secondary port

relief

This secondary port relief can allow the sweep

blade to “unwrap” a little if the pressure induced should

exceed “critical” structural loads This important port

relief protects the structure from

excessively

high loads

that could otherwise cause structural damage or

componentry damage

Opposite the

secondary port relief

(at the opposite work

port) is an

anticavitation check

that allows some

“makeup oil” to go into sweep’s rod-side during this

slight blade unwrap Whenever the secondary port relief

is actually relieving, this anticavitation check precludes

powerful suction effects that could extrude the sweep

cylinder’s piston seals

The last working section (the one with the

throttle

advance switch

trigger) is the

slider blade section

This

slider blade section has no port mounted devices The

slider section also has a

knockout positioner

directly

coupled to one end of its spool

The two hopper blade work sections have an internal

flow path known as “tandem center” When a V40’s

tandem center spool section is shifted to do a function,

it blocks the valve’s power core on the

downstream side

This characteristic is important in terms of proper blade

sequence

Since the start of the first half and second

half of the semi-automatic blade cycle is the

“simultaneous” shifting of

both

blade spools, the

sweep

blade

will always move first since its spool is

tandem

center

and it is

upstream

(closest to pump)

of the slide

blade spool

The last section of the tailgate-mounted valve is the

outlet cover

In the case of the EXCEL, this cover’s outlet

port is actually plugged but this section is casted to be a

turnaround

cover The actual return hose is then

connected to an outlet port of the

inlet cover

Leaving the tailgate-mounted valve, the oil flows

through the

roof return tube

to the

return filter

The return filter is a 5-micron (MICROGLAS) with a 25

PSI bypass valve It is a in-tank element and has a

condition

indicator

affixed to the head casting

The

hydraulic reservoir

if fully dressed with a

level gauge

with thermometer, magnet type drain plug, filler/media

breather,

and

cleanout cover

The suction side of the tank has a 100 mesh replaceable

suction filter

It has a 3-PSI bypass valve built into it

The tank has a baffle that separates the suction side

from the return side to promote settling of dirt and

entrained air

The open loop…

When no functions are being

performed (all valve spools in their centered, neutral

position); the oil flow follows a path known as the “open

loop” It originates at the oil tank’s

suction line filter

,

through the

suction hose

, to the

pump

, through the

pump

pressure hose

, to the

body-mounted valve

, up the

roof tube pressure

, to the

tailgate-mounted valve

, back

through the

roof return tube

, through the

return line

filter

and back at the

tank

again As long as none of the

spools are shifted, the oil will flow in this simple open

loop

[Sec01-pg02]

The t ilg te up/down function…

The EXCEL’s

tailgate is power-up and gravity-down (known as

“single-acting”) The lowermost spool section of the

body-mounted valve is the “tailgate” section and is

plumbed to the tailgate lift cylinders

When the hand lever is pulled

outward

the spool itself

also moves outward and the pump’s output flow is

connected to the gate cylinders “up” port (which is the

“base-end” cylinder port) At this very same moment,

the same spool will also connect the “rod-side” ports to

tank So the gate will “raise” If the hand lever labeled

tailgate is pushed

inward

, the tailgate cylinder will

connect to tank and the gate will lower by the force of

gravity

Since the tailgate spool section has no

port

relief at all,

its

only

pressure-limiting device is the main relief of the

body-mounted valve

The tailgate cylinders have orifice restrictors built into

each port (at the cylinder itself) This purposeful

restriction precludes the tailgate from “over-running” the

pump flow when lowering the gate, allowing the gate to

lower smoothly

Never st nd or cross underne th r ised

t ilg te!! T ilg te m y unexpectedly nd

suddenly f ll c using serious injury or de th.

The auxiliary return hose provides the return path to

tank during tailgate raising or lowering

The ejector function…

The

telescopic cylinder

actuates the ejector blade The upper work section of

the body-mounted valve controls the ejector’s telescopic

When the telescopic is fully

extended,

the ejector blade

is fully rearward, towards the tailgate The ejector blade

does two jobs When the tailgate is fully raised at the

landfill or transfer station, the ejector blade is used to

“push-out” the payload This job requires the telescopic

cylinder have available 2000 PSI @ throttle advanced

When the EXCEL is on the route (tailgate fully lowered

and latched, of course), the ejector blade starts parked

at rear of body and then slowly automatically drifts

forward (towards cab) as the garbage is collected and

the payload builds This

drift

will occur automatically as

a pressure head is continuously maintained at the

extend

side of the telescopic This second

on-route

job is

to provide a resisting, yet drifting, front surface for the

hopper blades to compress garbage against This

resistance is created by hydraulic pressure on the

extend-side of telescopic as the telescopic

retracts

toward the cab (blade drifts forward towards the cab)

This head of pressure is controlled by the action of the

synkpak

valve (see next subject, labeled EXCEL

SYNKPAK for description of how it works)

[Sec01-pg03]

The compact blades function…

Two of the

tailgate-

mounted valve’s

working sections controls the two

compaction blades The blade that pivots (rotates) is

called the

sweep blade

The blade that slides in the track

channels is the

slide blade

If the tailgate-mounted valve

has more than two working sections (the sections with

moveable “spools”), the extra work sections are for the

“optional equipment” Work sections for the “options”

are always “in front” (upstream; closest to the pump) of

the blades work sections

The sweep blade’s work section is always upstream of

the slider blade’s work section These two blade sections

have a casted flow path known as

tandem center

A V40

“tandem center” work section has the “power core”

internally blocked

downstream

…this means that the

shifted spool

closest to the pump

(the upstream sweep

section) will consume

all

of the available pump flow with

any downstream spools that are also shifted (the slider

spool) getting no flow

until

the upstream section (the

sweep)

shifts back to neutral

This creates a simple function “sequencing” effect Since

the correct operator’s method of cycling the blades is to

shift and release

both

spools’ hand levers

simultaneously, the sweep blade rotates (sweeps)

first

while the slide blade sits motionless waiting for the

sweep’s spool to knock-out to neutral At the very

moment the sweep’s spool automatically shifts to

neutral, all of the pump’s flow is then directed to the

slider blade’s cylinders and the slider blade begins to

move

As mentioned earlier, both the sweep and the slider

work sections have knock-out positioners These

knockouts, when teamed with the plumbing scheme and

the “tandem” center section castings, provide for the

sequencing of the semi-automatic cycling of the

compaction blades The blades must

both

sequence in

their specific order and they must move distinct and

separate of each other to be functioning normally

The knockout positioner is the device that holds the

blade spools shifted until the hydraulic pressure in that

particular section

rises

to the knockouts

pressure

setting

When this setting is reached, the spool is

released and it shifts to neutral (spool centered)

position The pressure setting specification for the

EXCEL is…sweep knockout spec is 2200 PSI @ throttle

advanced and the slider knockout spec is 2700 PSI @

throttle advanced The pressure

rise

typically occurs

when each pair of cylinders bottom-out at the end of

their stroke

Having said all of this, the compact blades do a semi-

automatic compaction cycle as follows…The cycle begins

with both spools (via hand levers linkage controls)

manually simultaneously shifted outward and released

Both knockout positioners grab and hold the spools

shifted The

sweep

cylinders begin to move first with all

of the pump’s flow going to the sweep cylinders (The

sweep’s valve section is closest to the pump and its

internal casted passages are “tandem-center”, which

means all of the pump oil goes to its own workport and

nothing goes downstream ) The sweep blade continues

to rotate until its cylinders complete their stroke and

they bottom-out This bottoming-out causes a rapid rise

in sweep pressure and the sweep knockout will knockout

the sweep spool to

neutral

centered

Meanwhile, the

slider spool has been held shifted with no pump flow

available to it At the very moment the sweep spool

knocks-out to neutral, all the pump flow is

now

available

to the slider spool which begins directing the flow to the

slider cylinders The slider blade

now

begins to move

and it continues to move until its cylinders bottom-out

and the pressure rises to its setting The slider knockout

then knocks the spool to centered neutral and the first

half

of the semi-automatic blade

cycle

is complete

Both

spools are now at their centered neutral position The

blades are said to be stopped at their cycle

interrupted

position This is correct and normal functioning

The second half of the semi-automatic cycle begins

(after the operator visually assures it is safe to do so)

with both hand control levers being pushed inward

simultaneously The sweep blade again moves first (its

valve section is still upstream of slider, of course) and

the second half of the cycle occurs the same way but in

the opposite direction of the first half

The second ry port relief system…

As mentioned

earlier, the sweep work section has a port relief on the

sweep cylinders extend-side (cylinder’s base-end) and

an anti-cavitation check opposite of it (on the retract-

side; the rod-side) Acting together, these two port

mounted cartridges are a

system

that can relieve the

portion of the structural loads that are above allowable

amounts (This would be seen as a slight

unwrapping

of

the sweep blade when the slider blade is nearly all the

way up) In some applications this situation will rarely

occur and in others it may sometimes occur when the

EXCEL body is near its full capacity

The EXCEL sweep’s secondary port relief is set to 3800

PSI @ “crack” (Crack being 2 GPM)

When the slider blade is travelling upward (“compacting”

the garbage), the sweep blade has already been fully

rotated down to “capture” the hopper’s garbage and the

sweep worksection will be in its centered neutral

position The compacting action of the slider blade

travelling upward will necessarily

induce

a hydraulic

pressure on the sweep cylinders base-side The

only

relief located to relieve the excessive

portion

of this

induced load is the relief on the cylinder

ports

side…the

secondary port relief (This is because the sweep spool

is in its centered neutral position and the spool itself

[Sec01-pg04]

blocks

any inlet cover mounted relief from “seeing” the

induced pressure on the work port side)

The anti-cavitation check simply allows for oil to be

drawn into the sweep cylinder rod-side

during

any port

relieving that may occur This prevents any powerful

suction

effect from damaging cylinder seals

This secondary port relief

system

prevents expensive

component and structural failures by preventing blade

loads and pressures from exceeding allowable values

LOADMASTER uses a fixed, non-adjustable secondary

port relief that is set to the

correct

value for the EXCEL

Do not shim djust ny of LOADMASTER’s non-

djust ble reliefs.

[Sec01-pg05]

The optional equipment

… Most EXCEL’S will have an

optional attachment or two The option work-sections

are in the tailgate-mounted valve just upstream of the

hopper blades worksections

These option work sections are simple manually shifted

spools that must be held shifted for their function to

occur The “kickbar option”, the “2-10 reever”, or

“winch” may be installed options They are always

double-acting and the work sections may or maynot

have port reliefs/orifices See separate “chart”

Some options require

orifices

to be installed at the

tailgate-mounted valves option work sections’ work ports

(both ports) to reduce the flow This list identifies which

options use work port restricting orifices:

Kart dumper(s) yes

1-2 option yes

kickbar yes

drum winch no

2-10 reever no

Option l Regener tion…

The “regen” valve is a

available

option

that reduces the hopper blades’ “total

cycle time” It increases the

slider

blade speed in the

downward

(non-packing) direction only The schematic

below is the EXCEL hydraulic circuit with the regen valve

installed

Whenever the EXCEL is equipped with the

regeneration

option…the total hopper blade cycle time can not be

allowed to be less than 22-23 seconds For

example…if you “stopwatch” the total blade cycle time

to be, say, 19 seconds…it is

too f st

and the diesel’s

throttle advance must be reprogrammed to a

lessor

RPM

until the total cycle time is 22-23 seconds (a

slower

speed of blade movement)!

See SEC05 for how to “stopwatch”

Option l k rt dumper(s)…

If the EXCEL is equipped

with kart dumpers, one scheme to supply the hydraulic

oil, is to use one of the tailgate-mounted valve’s option

work sections to control the kart dumper There will be

in-line adjustable orifices installed at both work ports of

the “CT worksection” to control the up/down speed of

the kart dumper function

In the case of the EXCEL, there will also be work-port

reliefs installed for the kart dumper option

Cart-tipper up direction=1800 PSI @ crack flow

Cart-tipper down direction=700 PSI @ crack flow

These “port” reliefs are necessary to assure that kart

dumper operation does not interfere with functioning of

the SYNKPAK valve (which could cause poor

payload/densification performance)

The orifice size Loadmaster uses in most cases (for options) is 7/64”

diameter drill size

[Sec01-pg06]

EXCEL SYNKPAK

revision 10-03-02

On the route, the EXCEL’s ejector blade must slowly and

automatically

drift forward (towards vehicle cab) in a

controlled, pressured fashion to generate good payloads

(good garbage densification)

The EXCEL has a valve that controls the ejector blades

forward “drift” as garbage is collected and compressed

against the ejector blade on the route This valve is

called the “synkpak” valve

This valve

synchronizes

the slow drifting action of the

ejector blade to the

pack

pressure levels occuring at the

hopper blades (specifically, the slider blade) The

“settings” of this valve are

one

important factor in the

EXCEL’S overall payload generation performance

The synkpak valve consists of

two

sequence valves , in

series, built into a aluminum body Both sequence valves

are adjustable (It is located at the front body face about

2 feet above the “body-mounted valve”…a valve “block”

mtd to a bracket) The sequence valves are “cartridge”

style, meaning they can be readily unscrewed as a

whole

pre-set

unit from the manifold body without

needing to tamper with the plumbing connections

Each sequence valve has a controlling pilot hose…

The upper (physically highest in the manifold

body) sequence valve is plumbed to the slider blades

“pack” port and is labelled “C” (C=carriage; also called

“slider” blade)

The lower (closest to the ground) sequence

valve is plumbed to the pump discharge

port…sometimes simply called the “pump pressure”

hose Perhaps strangely, this sequence valve is labelled

“B”…remember Bump=pump

The sequence valve cartridges are BOTH set to the same

SETTING of…

C (CARRIAGE) = 2500 PSI

B (PUMP) = 2500 PSI

The synkpak’s body is plumbed between the ejector’s

extend port and the tank The port marked “CYL”

connects to the ejector’s tellescopics extend port The

port marked “T” connects directly to tank Review the

schematics Since the body-mounted valves spool

section for the ejector is in its’ centered, neutral position

(when on-route, collecting garbage), it’s work ports are

blocked

Therefore, the synkpak

controls

the only

available path to tank and thusly controls the ejector’s

telescopic on-route collapse (drift towards cab)

Whenever the

pilot pressure

at a sequence cartridge is

less than that sequence cartridge’s

setting

…the

sequence cartridge will block the to-tank path

Whenever the

pilot pressure

at a sequence cartridge is

greater than that cartridge’s

setting

…the cartridge

opens

As mentioned earlier, the two sequence cartridges are in

series

Therefore

both

sequence cartridges must be

piloted open before the ejector’s tellecopic has a path to

tank and can collapse (retract) This means that both

pilot pressures must rise to the set trip points

simultaneously

Both pilots have guage coupling nipples installed The

“C” (carriage; aka slider) nipple is screwed directly onto

the synkpak valve and the “B” guage nipple is located at

the body-mounted valve’s inlet cover A third guage

nipple is located at the tellescopic’s extend port See

schematic

A orificed fitting is installed directly into the synkpak’s

“cyl” port (5/64” dia) When both sequence cartridges

have opened, the path to tank is opened and the

telescopic will suddenly retract (collapse) just enough to

relieve

some

of the force in the garbage bale

The garbage bale can be thought of as a giant spring

that

must be released

just a bit to allow the hopper

compaction blades to be able to clear the loading

hopper This orifice assures that this oil release to tank,

through the now open synkpak valve, occurs in small

controlled amounts The orifice is therefore important to

good payload performance (good garbage densification)

ADJUSTING THE SYNKPAK VALVE

The

only

reason to attempt to adjust the synkpak valve

is if your payload performance has been determined to

be below normal or the ejector blade is not

“autodrifting” Read the OPERATION & MAINTENANCE

manual topics related to “generating payload”

before

you attempt to adjust the synkpak Check and

adjust all

the other settings

before approaching the synkpak valve

The most important thing to remember is to

not

adjust

the synkpak valve until after you have checked these

other system settings (which are, in effect, “timed” to

the synkpak’s settings…

Check the system m in relief to be 2900-2950 psi at

throttle advanced (EXCEL spec)

Check the slider knockout to be at 2700-2750 psi at

throttle advanced (EXCEL spec)

Replace the sweep port relief to be 3800psi crack (

if

excessive sweep blade unwrap occuring) (p/n 8800605)

Now run the unit for a week or two while monitoring the scale

weights of the true

full

loads and confirm “good” payload

performance

[Sec01-pg07]

If the payload still seems to be below normal, only then

turn your attention to the synkpak valve

To dial in your two synkpak settings would require

monitoring 3 pressure gauges

while the unit is on the

actual route

and body nearly full of garbage Since this

is highly dangerous (be aware vehicle runovers and

traffic related accidents are serious refuse truck

accidents), LOADMASTER does not recommend this

method Trained personnel only should perform this type

of monitoring

After you have checked all of the other relevant,

payload generation factors…use the simple turn-of-the

–screw method to reset the synkpak valve Turn both

synkpak adjusters inward 1/8 TURN Then place the

truck back in service and monitor loads for another week

or two Turning

both

synkpak adjusters inward ( loosen

jamb nuts and remember to re-jamb) increases the

resistance of ejector blade and therefore will increase

your payload density Always turn the two adjustments

in unison…if you turn c inward 1/8 turn, then turn b

inward 1/8 turn (exactly)…unison

If after monitoring/weighing several true,

full

(not

partial) loads and the payload performance is still not

acceptable, you can make another 1/8 TURN “in” and

repeat the weighing of true,

full

loads (not partial loads)

This is ¼ total turns inward If payload performance is

then still

not

corrected, call LOADMASTER and order the

two cartridges from LOADMASTER in new, benchset

condition Replace the c and b cartridges

correctly…remember the cartridges will look the same

but have different settings that you will not have to

touch

The synkpak valve’s two adjusters are fairly

sensitive

…small 1/8 turns of adjuster can make big

changes in payload generation and ejector blade

behavior Do not overadjust If you dial-up too much

ejector drift resistance, the ejector will not

automatically

drift forward towards the cab This is a functional

defect…the ejector must drift automatically (If the

operator is “manually” moving the ejector blade forward,

the EXCEL will not achieve good payload performance )

Tip…after you have loosened one of the jamb nuts…get a

mental picture

of what 1/8 turn will look like

before

you

actually do your turning…once you become confused, you will

become “lost” and can not get back to where you were Do

this adjustment thoughtfully and carefully

Immediately

after

you adjusted the first cartridge, do the second exactly the

same way This can not be stressed enough…think about it

before doing it After inserting allen wrench in adjuster, use a

magic marker to create a “reference” line on valve body which

is aligned with the allen wrench…then “turn”

exact

amount

Reminder…always adjust

both

adjusters exactly the

same amount

If you become “lost”, acquire fresh

pre-set

cartridges

from LOADMASTER Then remember to install in proper

positions the settings are different Save your old

cartridges, they could be reset on the bench

W rning!!!

BEFORE ENTERING THE BODY, ALWAYS SHUTDOWN THE

DIESEL, PLACE THE IGNITION KEYS IN YOUR POCKET AND

ATTACH A SIGN TO THE STEERING WHEEL THAT SAYS “DO

NOT START ENGINE”! PERFORM YOUR SHOP’S DETAILED

LOCKOUT/TAGOUT PROCEDURE. THE EJECTOR BLADE

COULD MOVE UNEXPECTEDLY CAUSING SERIOUS INJURY OR

DEATH.

IF ENTERING THE FORWARD (CAB) SIDE OF EJECTOR,

FIRST

EXTEND THE EJECTOR BLADE ALL THE WAY REARWARD

(TOWARDS TAILGATE) AND “PARK” IT THERE. THEN DO YOUR

COMPLETE LOCKOUT/TAGOUT PROCEDURE.

TIP: a good rule of thumb…if “lost” where adjsuter’s are

at…gently bottom out the adjuster and then “back-out” exactly

1 5/8 Turns…do it to both adjusters…this has proven to be

very close to correct settings for both

Troubleshooting tips…

If the ejector blade will not

automatically

drift forward on the route (a

functional defect)…

1-Inspect the orifice to be clear and free

2-Remove both synpak cartridges and inspect the o-ring seal at the

tip of the cartridge…if erroded seal, the synkpak can not ever open

and ejector blade can not ever auto-drift (Do one cartridge at a

time…do

not

flip-flop the cartridges!) Replace all cartridge seals

3-If both of above are “ok”’,

only then

adjust both synkpak adjusters

outward (ccw) exactly 1/8 turn (or slightly less than 1/8 turn) and then

retest the excel on the route to confirm the return of automatic ejector

drift forward After inserting a allen key in adjuster, make a magic

marker reference mark, on the synkpak’s body, that is aligned with the

allen key…then turn ccw ex cly 1/8 turn (Remember…seemingly very

small adjustments will have large effect on ejector’s drift behaviour )

[Sec01-pg08]

c pilot

c pilotc pilot

c pilot

b pilot

b pilotb pilot

b pilot

c cartridge

c cartridgec cartridge

c cartridge

b cartridge

b cartridgeb cartridge

b cartridge

tank line

tank linetank line

tank line

telly cyl line

telly cyl linetelly cyl line

telly cyl line

orifice

orificeorifice

orifice

OVERVIEW OF CORRECT EXCEL

SPECIFICATIONS…

This page lists the EXCEL specifications needed for

checking and setup These values apply only to the

EXCEL; other LOADMASTER models will have other

specifications Refer to the manual that specifically

applies to that model Alw ys p y ttention to the

diesel RPM specified…if you me sure t some

other diesel RPM, the re ding will

not

be correct!

MAIN SYSTEM RELIEF…

This is located in the inlet cover of the body-mounted

valve The body-mounted valve is the valve just inside

the body access door Take your reading at the gauge

stem provided at the inlet cover of the body-mounted

valve

Spec is 2900 PSI +/-50 PSI @throttle dv nced

SYNKPAK VALVE…

This aluminum-housing valve is mounted at the body’s

forward face about 2’ above the body-mounted valve

This valve controls the ejector blades automatic drifting

forward on-route as payload builds-up in the body It

consists of two sequence valves (in series) each with a

pilot line See schematics and separate write-up for

detailed information Spec is

C-PILOT (SLIDER PACK) 2500PSI

B-PILOT (PUMP PRESSURE) 2500 PSI

These are “cartridge-style” sequence valves that can be

replaced easily with f ctory pre-set cartridges when

needed

SWEEP KNOCK-OUT POSITIONER…

This device is directly coupled to the sweep

worksection’s spool of the tailgate-mounted valve

Spec is 2200 PSI +/-50 PSI @ throttle dv nced

This device is very fast acting and can

not

be measured

with a common glycerin-filled gauge A glycerin filled

gauge will give a reading that is very false

SLIDER KNOCK-OUT POSITIONER…

This device is directly coupled to the slider worksection’s

spool of the tailgate-mounted valve

Spec is 2750 PSI +/- 50 PSI @ throttle dv nced

This device is very fast acting and can

not

be measured

with a common glycerin-filled gauge A glycerin filled

gauge will give a reading that is very false

SECONDARY PORT RELIEF…

This cartridge type port relief is screwed into the

sweep

worksection (on the cylinder’s base-end) of the tailgate-

mounted valve (on cylinder’s base-end…pack side)

Spec is 3800 PSI @ “cr ck” flow

This setting is not adjustable (and do not “shim”)

For more detailed explanations of these specifications,

see the “check and setup” writeup that applies to each

particular specification

THROTTLE ADVANCED RPM… (“T-A”)

This is the

diesel

RPM that the diesel will raise to when

the EXCEL’s electric controls signal the need

Spec is 1150 RPM-1350 RPM (typic lly).

When the diesel speed does advance, it will be

noticeable to the ear and can be read at the cab’s

tachometer

DIESEL IDLING RPM…

This is the diesel RPM with diesel at idle

Spec is per wh tever the diesel m nuf cturer

s ys it is supposed to be; usu lly bout 750 RPM.

EVERY SPECIFICATION IS TO BE MEASURED WITH THE

GAUGE COUPLED AT THE INLET COVER OF THE BODY

–MOUNTED VALVE!

If the readings are taken at some

other spot in the hydraulic circuit, the readings will be in

error

LOADMASTER has installed the male gauge stem for

gauge coupling at the inlet cover of the body-mounted

valve as standard equipment

LOADMASTER has available the 3000 PSI glycerin filled

gauge, 2 feet of hosing, and the matching female

coupler all preassembled (Order LOADMASTER P/N

0130014)

This particular type of coupler requires that the pressure

be low to cleanly couple/uncouple Shut down the

diesel and disengage the PTO when

coupling/uncoupling the gauge to avoid having hydraulic

oil escaping

[Sec01-pg09]

OVERVIEW OF MAJOR EXCEL

COMPONENTRY…

PTO… Varies… a CHELSEA PTO that will allow the pump

to be direct coupled to the PTO Drive ratio is typically

near 1:1 3, which is to say a 30% speed increaser The

specific part number will vary depending on the type of

chassis transmission, rotation required, etc Will be

OMFB manufacture PTO if unit equipped with “Piston-

Pump”

PUMP…Usually a COMMMERCIAL-INTERTECH P350 in a

6 4 cubic inch per revolution displacement The specific

part number will vary depending on the rotational

direction needed Will be OMFB brand if “Piston-pump”

BODY-MOUNTED VALVE…A GRESEN V20 SERIES

configured to LOADMASTER’s specification This valve

always has 2 spooled work sections One worksection

controls the tailgate cylinders and the other worksection

controls the ejectors telescopic

TAILGATE-MOUNTED VALVE…A PARKER VG35

SERIES (april2004) configured to LOADMASTER’s

specification This valve has usually has 3-4 work

sections Closet to the pump will be any “option”

worksection(s), followed by the sweep worksection, and

lastly the slider worksection The sweep and the slider

worksections have devices called knockout positioners

directly coupled to their spools

RETURN LINE FILTER… A INTERNORMAN 5 micron

(nominal), tank-top filter with synthetic “microglass”

element and a condition indicator gauge

OIL RESERVOIR…In-the-body 42 gallon capacity tank

with magnetic type drain plug, fill level gauge with

thermometer, top surface clean-out cover, combo

screened filler/breather, and a full port ball valve at

suction line Inside the tank, near the bottom, is a 100

mesh suction line strainer

TELESCOPIC CYLINDER…The ejector blade is

actuated by a HYCO telescopic cylinder It is built to a

LOADMASTER dimensional specification for to suit the

EXCEL When the telescopic is fully extended, the

ejector blade is fully rearward, towards the tailgate

SWEEP CYLINDERS…A pair of rod-type hydraulic

cylinders The EXCEL uses a 5” bore x 23-5/8” stroke

with a 3” rod diameter These are internally cushioned

to reduce end of stroke pounding Premium quality

design and manufacture by PETTIBONE All of the

EXCEL’s various cylinders have zero-leak o-ring boss

ports and feature chrome plated rodding

SLIDER CYLINDERS… A pair of rod-type hydraulic

cylinders The EXCEL uses a 5” bore x 43” stroke with a

2-1/2” rod diameter These are internally cushioned to

reduce end of stroke pounding Premium quality design

and manufacture by PETTIBONE

TAILGATE CYLINDERS… A pair of rod-type hydraulic

cylinders The EXCEL uses a 4-1/2” bore x 30-1/8”

stroke with a 3-3/4” rod diameter These cylinders are

single-acting since the EXCEL has a gravity lowered

tailgate These have integral,port-mounted orifices

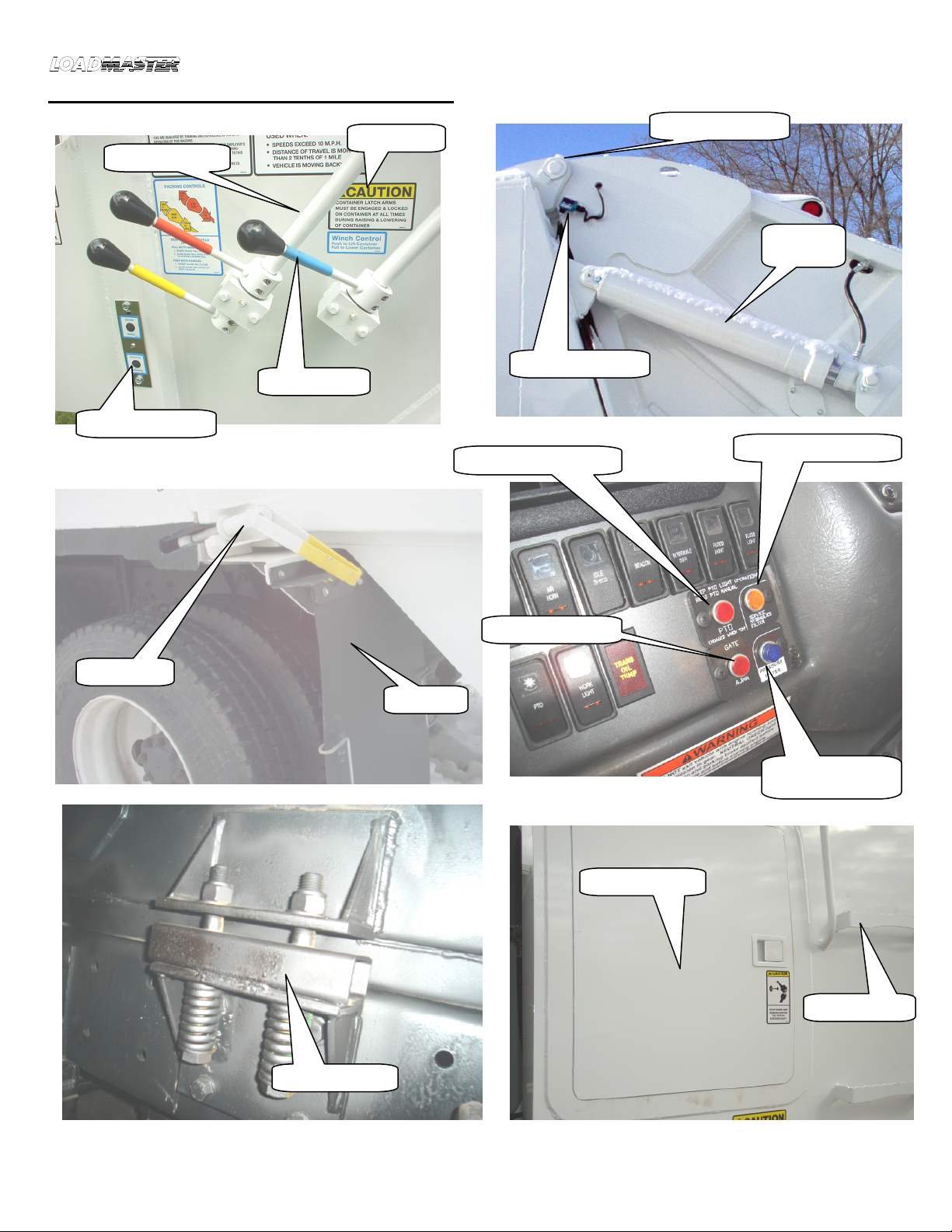

IN-CAB ROCKER SWITCH PANEL…The various

switched electrical circuits will have their “inside the cab”

switches grouped together here A switch is “on”

(closed) if the red color band is visible This switch panel

is typically located just to the left of the steering wheel

FUSE BLOCK…All of the various branch circuits

originate at this ATO style fuse block which is typically

located nearly under the dash in a protected location

near the operator’s left foot

IN-CAB RELAYS…Some EXCEL’s require relays to

control the “throttle advance” or other functions The

exact number of relays on any particular EXCEL is

dependent upon factors that include the particular

chassis used LOADMASTER uses IDEC brand quality

relays These relays are the yellowish, transparent “ice

cube” relays that are typically located in a protected

“inside-the-cab” spot usually somewhere near the

driver’s left foot

FIREWALL TERM STRIP…Every EXCEL has a term

strip mounted to the firewall located “under the hood”

ahead of the driver’s side The color-coded, labeled

wires “pass through” this strip LOADMASTER includes

this as a “troubleshooting” feature to speed up finding

the source of an electrical circuit malfunction

HARNESSES…The electrical wires are bundled, labeled,

colorized, and protectively covered in a “harness” The

overall electrical harnessing is made up of several

independent

subharnesses

connected together at

strategic locations with premium quality DEUTSCH

metallic body multi-pin connectors

LIMIT SWITCHES…The throttle advance limit switch

and the tailgate ajar switch is the same switch The

throttle advance switch is wired N 0 (and closes

whenever the slider spool is shifted out of neutral) and

the tailgate ajar switch is wired N C (and is held open by

a lowered tailgate) This switch is a MICROSWITCH

brand wobble stick with sealed body A cable connector

seals the cable as it enters the switch

BUTTON SWITCHES…The “buzzer signal” and

“throttle” advance switches are fully encapsulated and

mounted to a stainless steel panel with a stainless

unpainted

grounding post Has a “click” feel when it

switches

[Sec01-pg10]

Section 02 Checks and Setups

CHECK and SETUP… BLADES

“

CYCLE T ME”

rel June 2007

“CYCLE TIME” IS THE TOTAL NUMBER OF SECONDS IT

TAKES THE SLIDE AND SWEE BLADES TO COM LETE

ONE ACK CYCLE, WHILE THE DIESEL IS AT ADVANCED

THROTTLE R M.

The EXCEL specification is 26-27seconds without

optional regeneration and with the diesel’s RPM

advanced to 1150-1350 RPM. (The specific diesel

rpm will vary with pump/pto options.) The

hopper blade cycle time W TH OPT ONAL

REGENERAT ON specification is 21-23 seconds.

One complete pack cycle is to start with both blades at

“home” position and end up also at “home” position.

Checking Procedure:

1- Both the slider and sweep blades are parked in

“home” position.

2- Diesel running; Transmission in neutral; ark Brake

is applied on; TO is engaged on; Throttle Rocker

switch is on (red band will show)…

3- This is a two person task. One person with a stop

watch and one person manning the blade’s hand

control levers.

4- ull both control levers outward simultaneously

(and release them) as stop watch is triggered on

spoken “go”.

5- The person manning the controls must be in a state

of ready to “push in” (and release) the hand control

levers at the very instant that both levers are seen

to kick-out to neutral. (This is the “interrupted” or

half-way point of the automatic cycle.) This

interruption must be kept as brief as practical to

correctly measure the “cycle time”. Meanwhile, the

stop watch has continued to run.

6- Now the stop-watch holding person must be alert to

stop the watch at the exact moment the blades are

both back to home position (both hand levers will

have “kicked-out” to neutral).

7- Record this number of seconds and repeat the time

measuring process a total of three times for best

confidence of accurate measurement.

STAY CLEAR OF MOV NG HOPPER BLADES AND THE HOPPER

LOAD NG S LL WHEN BLADES ARE MOV NG! F YOU OR A

WORK PARTNER S CAUGHT N THE BLADE ACT ON, SER OUS

NJURY OR DEATH W LL RESULT.

To adjust the cycle time, alter the diesel’s throttle

advanced R M setting.

Do not adjust outside the

previously specified range….damage to componentry

may occur.

Most diesels today are “E-DIESELS”. You will most likely

need to schedule a visit to your local chassis dealer since

the

advanced throttle R M

is a programmed setting and

will require a programming device that you will most

likely not posses.

If you do adjust the diesel’s advanced throttle to 1300-

1350 R M (maximum allowable EXCEL R M) and the

measured “cycle time” is still “slow”, see troubleshooting

section for identifying and remedying other causes of

“too slow” blade movements.

REGENERAT ON OPT ON AND CYCLE T ME

If your EXCEL is equipped with the

optional

regeneration

valve…the correct hopper blades

total cycle time

will be

21-23 seconds (excel specification).

The regeneration valve will “speed up” the movement of

the slider blade during slider blade

downward

travel

(only). (The regeneration valve does

not

affect the

speed of any other blade movement.)

If your EXCEL has regeneration, the diesel’s throttle-

advanced setting must be programmed to assure that

the hopper blades total cycle time

does not exceed

the

22-23 seconds! This may require programming the

diesel throttle advance parameter to a value as low as

1150 rpm.

Never allow the EXCEL to operate with a hopper

blades

total cycle time

at value less than the 21-

22 seconds (which is to say…”faster” blade

movements).

For example, if you stopwatch the

EXCEL

and it

times to 19-20 seconds (too “fast”)…then you must

immediately have the diesel’s throttle advanced setting

reprogrammed to a lower R M value that results in a

timing of 22 to 23 seconds.

[Sec02-pg01]

BLADES AT

BLADES ATBLADES AT

BLADES AT

THEIR

THEIRTHEIR

THEIR

HOME POSITION

HOME POSITIONHOME POSITION

HOME POSITION

CHECK and SETUP…THE “MA N

REL EF” OF BODY-MTD VALVE

rev12-01

THE MAXIMUM OVERALL HYDRAULIC SYSTEM

RESSURE IS REGULATED BY THE “MAIN RELIEF”

VALVE, WHICH IS A CARTRIDGE TY E VALVE SCREWED

INTO THE INLET COVER OF THE EXCEL’S BODY-

MOUNTED VALVE.

The EXCEL specification is 2,950 PS +/- 50 PS

@ Throttle Advanced RPM (usually about 1400

rpm).

To check the setting of the system “main relief”, do the

following procedure.

Checking Procedure:

1- Shut down diesel, place the ignition keys in your

pocket and a sign on the steering wheel that says

“DO NOT START”.

2- Connect a 0-3000 SI glycerin filled pressure gauge (on a

¼” hose about 2 feet long) to the body-mtd valve’s gauge

stem that you will find at this valve’s inlet cover. (The

“body mounted valve” is the 2-section stack valve located

just inside the body’s access door). Exit the body and get

your feet back on the ground.

3- Start Diesel running; Transmission in Neutral; ark Brake

is engaged on; Throttle Rocker switch is on; Tailgate fully

down and fully

latched on both

sides…

4- Extend the ejector blade fully rearward (all the way

towards the tailgate) if it isn’t already and leave it there.

5- Depress and hold the nearby

“throttle”

advance button

switch…diesel R M will be heard to raise to the advanced

R M.

6-

Shift “tailgate” hand lever to

“raise”

position (refer to the

decal that is affixed to the body) and hold (soak)…read

the gauge while

still holding throttle advanced

. This is the

“setting” of the main relief valve. Release the hand lever

labeled “tailgate” and then repeat taking a reading for a

second time.

If the main relief setting needs adjustment to be brought

within the above specification, follow this procedure.

Adjustment Procedure:

1- Shutdown diesel, place ignition keys in your pocket

and a place a sign on the steering wheel that says

“DO NOT START”.

2- Open body side access door and enter the body.

3- Remove the acorn nut, which acts as a cover over the

adjuster stem.

4- Loosen (ccw) the jambing nut.

5- Use a hex key to turn the adjuster…start with about 1/8

turn. Turning adjuster inward (cw) will increase the

setting. Turning the adjuster outward (ccw) will decrease

the setting.

6- Tighten jamb nut and install acorn nut cap.

7- Never exceed the LOADMASTER specification. Expensive

component failures and/or structural damage can occur.

Also, if the main relief is set too low, loss of compaction

and/or functional performance can occur.

8- Exit the body (your feet back on the ground) and restart

diesel. Diesel running; Transmission in Neutral; ark Brake

on; TO engaged on; Throttle Rocker switch on…

9- Recheck the main relief’s setting again using previously

listed procedure. It is worth mentioning again that you

must

advance the throttle

to accurately check this relief

setting. If it is within specification, you are done.

Otherwise repeat the checking and adjusting until it is “to

spec”.

TI ….Throughout this manual you will notice that all the pressure

settings are stated at a certain diesel R M speed. It is important that

you check the setting at the stated R M since pump flow is dependent

on diesel’s R M. One “setting” of the main relief will measure

differently @diesel idle (typically about 750 R M) versus @ diesel

throttle advanced (typically about 1400 R M).

BEFORE ENTER NG THE BODY, ALWAYS SHUTDOWN THE

D ESEL, PLACE THE GN T ON KEYS N YOUR POCKET AND

ATTACH A S GN TO THE STEER NG WHEEL THAT SAYS

“DO

NOT START ENG NE”!

PERFORM YOUR SHOP’S DETA LED

LOCKOUT/TAGOUT PROCEDURE. THE EJECTOR BLADE

COULD MOVE UNEXPECTEDLY CAUS NG SER OUS NJURY OR

DEATH.

F ENTER NG THE FORWARD (CAB) BODY S DE OF EJECTOR,

F RST EXTEND THE EJECTOR BLADE ALL THE WAY REARWARD

(TOWARDS TA LGATE) AND “PARK” T THERE. THEN DO YOUR

COMPLETE LOCKOUT/TAGOUT PROCEDURE.

[Sec02-pg02]

0130014

CHECKING AND ADJUSTING THE KNOCK-OUT

POSITIONERS

The EXCEL’s correct knock-out specifications are…

SLIDER 2700-2750 PSI @ THROTTLE ADVANCED

(will advance” automatically during procedure)

SWEEP 2200-2250 PSI @ THROTTLE ADVANCED

(A second person will have to hold depressed a t-

adv button switch for sweep).

The

EXCEL’s

correct system main relief specification is

2900-2950 PSI @ THROTTLE ADVANCED

“CHECKING” WHERE THE

EXCEL’S

SLIDER’S KNOCK-

OUT POSITIONER (”K-O”) IS PRESENTL SET…

This procedure will identify the knockout-positioners present

setting. (See separate procedure below to adjust” a k-o.) You will use

the system main relief’s adjustment feature to identify where the k-o is

set. This relief is located at body-mounted valve’s” inlet.

1- Move the ejector blade fully rearward (towards tailgate) and

leave it there.

2- Attach a 0-3000 psi glycerin filled gauge on a 2-foot hose with

the female coupler…to the gauge stem that exists at the body-

mounted valve’s inlet cover. <FIG 1>

3- Loosen jamb nut at main relief. Arbitrarily turn outward (CCW)

the main system relief 2 to 3 turns to lower its setting a great deal.

<FIG 2>

4- Diesel running; PTO to engaged; Throttle’s in-cab, master

rocker switch to ON (red band will show)

5- Go the tailgate; move the orange slider control lever to shifted

position (push for up”) and let go of lever. <FIG 3>

The lever should not knockout to neutral because the main

relief is very low and therefore undercutting the K-O. (Many

people will call this soaking” the relief.) The throttle should

be automatically advancing to 1200-1300RPM.

6- Go back to the body-mounted valve. Affix your eyes upon the

pressure gauge. Hold the gauge in one-hand so you can clearly

read it…. the slider is still soaking”.

7- Begin slowly turning upward (cw) the main relief’s hex key

adjuster…slowly and smoothly. All the while, keep your eyes

affixed upon the gauge. Soon you will feel and hear the slider’s

knock-out kick to neutral. Memorize and jot down on paper the

gauge reading that occurred at the very moment it kicked-out.

This is the present slider k-o setting.

8- Repeat steps 3-7 again…until you have confidence your

reading” is accurate…jot this down on paper

.

[This procedure will also work for checking the sweep’s k-o, but a

second person must hold pressed a throttle-advance button switch.]

Important! Always remember to return the main system re ief to

its correct specification of 2900-2950 PSI @ throttle advanced

when you are finished identifying what the knock-out is set to.

(Set main relief” by locking both tailgate turn buckles and

shifting tailgate raise/lower lever to raise” while holding throttle

advanced. See earlier topic in this manual.)

“RESETTING/ADJUSTING” THE

EXCEL’S

SLIDER’S K-O

POSITIONER

!DANGER! Be sure diesel is not running, ignition keys

are in your pocket, and affix a sign on steering wheel that

reads do not start”… before you enter the hopper or get

near the hopper’s blades!

Repeat these lockout/tag out steps each and every time

you must enter the hopper! (Your shop may have a more

detailed LOCKOUT/TAGOUT procedure. If so, then perform

the detailed LOCKOUT/TAGOUT procedure.)

To make a adjustment (the checking above has shown k.o. to be out

of spec”)…

1-Remove the small, rubbery hole plug from the end of the K-O

positioner’s bonnet (at the end face of it)…the adjuster” is behind

it <FIG. 4> [Sec 02-pg 03]

2-Do the checking” procedure (above) to find out where” the K-O

positioner is presently set at. (CONT’D NEXT PAGE)

TOOLS REQUIRED…

5/32” ALLEN WRENCH AND 9/16” OPEN END FOR MAIN RELIEF;

3/32” ALLEN WRENCH FOR K.O. ADJUSTMENT; 3000PSI

GUAGE & HOSE ASSY

Fig.1

Fig. 2

Fig. 3

SLIDER

CHECKING AND ADJUSTING THE KNOCK-OUT

POSITIONERS…CON’TD

3-The rule of thumb” is…1/4 turn of the k-o’s allen-head adjuster

is roughly equivalent to 100 PSI of setting change.

Based upon where the k-o positioner is presently checked” to be

set at…turn the k-o’s allen head adjuster inward (cw…raising the

pressure setting) or outward (ccw…lowering the pressure setting)

to get closer to the EXCEL specification. <FIG. 5>

EXAMPLE... The correct EXCEL spec for the slider is 2700 psi @

throttle advanced.

Your checking” procedure reveals the slider’s knock-out to be

presently set to 2500 psi @ throttle advanced.

Calculate 2700 minus 2500=200 psi on the low side”…that is ¼

turn x 2= ½ turn total needed.

Turn slider k-o adjuster’s allen-hex inward (cw; the raising”

direction) exactly ½ turn.

(The V40 knock-out adjuster has no jamming

nut…adjustment is held in place by internal friction.)

4-Now repeat the page 1” checking procedure again

(repeating steps 3-7)…jot down where k-o setting is now

set”

5-Continue if need be… using smaller /8 turn or / 6

turns next, until you are dialed” into the correct

specification.

Note : There are two k-o positioners…be sure to first correctly

identify the one you choose to work on. (The slider k-o is the

lowest one, nearest to the hopper’s loading sill; the slider work-

section has the switch trigger on its push-pull rod.)

!DANGER! Be sure diesel is not running, keys

are in your pocket, and affix a sign on steering wheel

that reads do not start”… before you enter the

hopper or get near the hopper’s blades!

Repeat these lockout/tagout steps each and

every time you must enter the

hopper!

(Your

shop may have a more detailed LOCKOUT/TAGOUT

procedure. If so, then perform the detailed

LOCKOUT/TAGOUT procedure.)

[This procedure will also work for adjusting the sweep’s k-o,

but a second person must press and hold a throttle-advance

button switch. Sweep will not have automatic throttle-advance.]

Important! Always remember to return the main system

re ief to its correct specification of 2900-2950 PSI @

throttle advanced when you are finished adjusting the

knock-out setting. (Set main relief” by locking both

tailgates turn-buckles and shifting tailgate raise/lower lever to

raise” while holding throttle advanced.)

Important! Always remember to replace the rubber hole plug

(see parts manual)…Do not allow dirt or water to enter the

knock-out device. Always keep the knock-out sealed” by

installing the rubber hole-plug.

End Knock Out check and adjust

Fig 4

Fig 5

[Sec02-pg04]

CHECK and SETUP…”SECONDARY

PORT REL EF”

THE TAILGATE-MOUNTED VALVE’S SWEE SECTION HAS A

ORT RELIEF INSTALLED ON THE BASE-SIDE OF THE SWEE

CYLINDERS AIR.

THIS “SECONDARY ORT RELIEF” IS SET SIGNIFICANTLY

HIGHER THAN THE OTHER RELIEF SETTINGS AND IS

ROVIDED TO ALLOW FOR SOME RELAXING OF “INDUCED

LOADS” THAT WOULD EXCEED THE CRITCAL ALLLOWABLE

STRUCTURAL LOADS

.

See Table of Contents for a write up of how this particular

hydraulic component functions in the system.

The EXCEL’S specification for this S.P.R. is 3800

PS @ “crack” (with crack being defined as 2

GPM).

Checking Procedure:

Actually, there is no commonly available method to field

“check” where this relief is set. This is because it is “test-stand

set” at its

crack

value of 3800 SI

@ 2 G M

. If you suspect

that this port mounted relief is not correct, it is most practical

to order from LOADMASTER a brand new bench set cartridge.

Fortunately, changing out this cartridge type valve is a

relatively fast operation and the cartridge itself is not

expensive. See the Table of Contents to locate a write-up on

change-out procedure in Repair Section. It is worth repeating

here to pay particular attention to (a) assure a clean valve

cavity (magnet wand and penlight and hooking tools) before

putting in the new cartridge, and (b) the “cartridge tip seals”

rubber 0-ring and plastic backup ring are well doped up with

axle grease when you (slowly & gently & straightly) insert the

new preset cartridge into this

cavity. All the

old junk

must

be purposefully “fished out” of cavity; it does not come

out on its own.

Sometimes it is a nicked or

extruded “tip seal” that is the

real culprit and the cartridge

(and its setting) are actually fine.

A typical “symptom” that might lead you to replace this

cartridge is that the sweep blade is “tending to unwrap” when

the body is nearing its full rated payload capacity. Be careful in

your observations here because some occasional unwrap of

sweep blade is

normal

(such as when the body

really is full

and

the payload is at its rated value).

One worthwhile

check

you can do is to physically trace the

sweep cylinder’s base side hoses to be sure the Secondary ort

Relief is correctly located on the

base-side

(not the

rod-side) of

the sweep’s cylinders.

Adjustment Procedure:

This S. .R. is

not

adjustable; it must be replaced with a totally

new preset and

fixed

cartridge.

Never “shim adjust” this port relief cartridge. Eventually this

could cause expensive structural damage and/or componentry

damage. LOADMASTER warranties are void if this is done.

Replace the entire port relief cartridge with a new

LOADMASTER preset cartridge and always replace the old

seals with new. See EXCEL parts manual.

n the unlikely event that cartridge replacement

does not solve the blade unwrapping symptom,

refer to the Troubleshooting Section of this

manual for other possible causes and remedies.

BEFORE ENTER NG THE LOAD NG HOPPER, ALWAYS

SHUTDOWN THE D ESEL, PLACE THE GNT ON KEYS N YOUR

POCKET AND ATTACH A S GN TO THE STEER NG WHEEL THAT

SAYS “DO NOT START ENG NE”! DO YOUR SHOP’S DETA LED

LOCKOUT/TAGOUT PROCEDURE.

THE BLADES COULD UNEXPECTEDLY AND SUDDENLY BEG N

MOV NG WH CH W LL CAUSE SER OUS NJURY OR DEATH.

CAUT ON!!: BEFORE REMOV NG TH S PORT REL EF, BE

SURE THE SWEEP BLADE F FULLY DOWN SO GRAV TY

CAN NOT MOVE T UNCONTROLLABLY…WHEN TH S

PORT REL EF S REMOVED…THE SWEEP BLADE W LL

BE NO LONGER HYDRAUL CALLY “LOCKED” N

POST ON.

[Sec02-pg05]

V

G

35

PORT RELIEF

SECONDARY

Other manuals for EXCEL Series

1

Other LOADMASTER Truck manuals