LOADMASTER ELITE Series User manual

ELITE SERIES

OPERATORS MANUAL

LOADMASTER

100 WEST ELEVENTH AVENUE

PO BOX 186

NORWAY, MICHIGAN 49870

PHONE 906- 63-9226

TOLL FREE 800-433-2768

FAX 906- 63-9800

E-MAIL: [email protected]

12-1-2001

REV 06-01-2004

TABLE OF CONTENTS ELITE

Section 01 SAFETY PRECAUTIONS

Sec01-pg03 thru sec01-pg08

Section 02 OPERATOR’S MANUAL

Sec02-pg09 thru sec02-pg30

{Include/study all of the SECTION 01:

SAFETY PRECAUTIONS}

Warning…Although many ELITE’s are setup on chassis’ that do NOT require the operator to possess a

“CDL”…this does NOT imply that

this

manuals numerous SAFTEY PRECAUTIONS are less valuable or less

important to understand and follow than any other REAR LOADER.

All of the same rear-loader

hazards

exist in the Elite rear-loader, even if it happens to be smaller and lighter

than some other rear-loader.

Read, understand, and follow all of the information in this manual (including but not limited to all the Safe

Operation, Safe Maintenance, and Safe Repair information) before approaching an ELITE.

Be sure all operator’s, maintenance people, repairers, washers, lubers, etc. are trained for ELITE

operation

so

that each person can SAFELY perform their assigned tasks.

Sec01-pg01 (contents page)

Section 01

SAFETY PRECAUTIONS

IMPORTANT SAFETY INFORMATION

READ AND UNDERSTAND THIS ENTIRE MANUAL

BEFORE OPERATING, REPAIRING, OR ADJUSTING THE

EXCEL REAR-LOAD REFUSE PACKER. PEOPLE WHOM

USE OR MAINTAIN THIS EQUIPMENT MUST BE

THOROUGHLY TRAINED AND FAMILIAR WITH THE

MACHINE. IF INCORRECTLY USED OR MAINTAINED,

THIS EQUIPMENT CAN CAUSE SEVERE INJURY OR

DEATH.

Keep this manual where the people who maintain or

operate the ELITE can have ready access to it.

Additional copies are available by contacting

LOADMASTER or a LOADMASTER dealer.

Some service operations may require special tools or

blocking devices (such as the raised tailgate). If you

require information on these items, contact

LOADMASTER.

THE SAFETY PRECAUTIONS ARE FOR YOUR OWN

PROTECTION!

DO NOT OPERATE OR MAINTAIN OR REPAIR THE ELITE

UNTIL YOU HAVE READ THIS ENTIRE MANUAL AND

UNDERSTAND ITS CONTENTS CLEARLY. PLEASE CALL

LOADMASTER (906-563-9226) IF YOU REQUIRE

ASSISTANCE!

If the operator of this machine or the servicer of this machine

has trouble reading, then he/she must be assigned a

mentor/trainer who will read and explain to such individual the

entire contents of this manual as well as the safety precautions

and the danger, warning, caution, and notice decals and

placards affixed to the ELITE. SUCH INDIVIDUAL CAN NOT BE

ALLOWED TO OPERATE OR MAINTAIN THE ELITE UNTIL

HE/SHE COMPLETELY UNDERSTANDS ALL OF THESE

MATERIALS. FAILURE TO DO THIS CAN RESULT IN SERIOUS

INJURY OR DEATH!

SAFETY AND SAFE METHODS MUST BE ADHERED TO AT

ALL TIMES. OSHA LOCKOUT PROCEDURES MUST BE

FOLLOWED WHEN MAINTAINING THE LEGACY3. If you

are not familiar with OSHA lockout procedures, contact

the LOADMASTER or OSHA office.

This DANGER symbolism precedes information

pertaining to specific immediate hazards, which

if

disregarded

, WILL result in severe personal injury or

death of the user or others.

This WARNING symbolism precedes information

pertaining to hazards or unsafe practices which COULD

result in severe personal injury or death.

This CAUTION symbolism precedes information

pertaining to potential hazards or unsafe practices,

which if disregarded, may result in a lesser personal

injury or damage to the equipment.

This notice symbol will precede information which is vital

to the proper operation or maintenance of the

equipment.

Sec01-pg02

FOLLOW ALL LOCKOUT/TAGOUT PROCEDURES AS DEFINED IN THIS

MANUAL, AS WELL AS WELL AS DEFINED BY YOUR SPECIFIC SHOP

(EMPLOYER) AND OSHA! FAILURE TO HEED THIS WARNING OF

DANGER MAY RESULT IN SERIOUS PERSONAL INJURY OR DEATH.

BEFORE ENTERING THE BODY, ALWAYS SHUTDOWN THE

DIESEL, PLACE THE IGNITION KEYS IN YOUR POCKET AND

ATTACH A SIGN TO THE STEERING WHEEL THAT SAYS “DO

NOT START ENGINE”! PERFORM YOUR SHOP’S DETAILED

LOCKOUT/TAGOUT PROCEDURE. THE EJECTOR BLADE

COULD MOVE UNEXPECTEDLY CAUSING SERIOUS INJURY OR

DEATH.

IF ENTERING THE FORWARD (CAB) SIDE OF EJECTOR, FIRST

EXTEND THE EJECTOR BLADE ALL THE WAY REARWARD

(TOWARDS TAILGATE) AND “PARK” IT THERE. THEN DO YOUR

COMPLETE LOCKOUT/TAGOUT PROCEDURE.

STAY CLEAR OF MOVING HOPPER BLADES AND THE HOPPER

LOADING SILL WHEN BLADES ARE MOVING! IF YOU OR A WORK

PARTNER IS CAUGHT IN THE BLADE ACTION, SERIOUS INJURY OR

DEATH WILL RESULT.

BEFORE ENTERING THE LOADING HOPPER, ALWAYS

SHUTDOWN THE DIESEL, PLACE THE IGNTION KEYS IN YOUR

POCKET AND ATTACH A SIGN TO THE STEERING WHEEL THAT

SAYS “DO NOT START ENGINE”! DO YOUR SHOP’S DETAILED

LOCKOUT/TAGOUT PROCEDURE.

THE BLADES COULD UNEXPECTEDLY AND SUDDENLY BEGIN

MOVING WHICH WILL CAUSE SERIOUS INJURY OR DEATH.

WHEN REPAIRING THE TAILGATE’S RUBBER SEAL, ALWAYS

PROVIDE

THREE DISTINCT MEANS

OF SUPPORT FOR THE

PARTIALLY RAISED TAILGATE! TAILGATE COULD SUDDENLY

FALL CAUSING SERIOUS INJURY OR DEATH IF TAILGATE IS

NOT SUPPORTED IN THREE SEPARATE WAYS.

SEE THE REPAIR TOPIC CALLED “INSTALLING A FRESH

TAILGATE SEAL” IN THE REPAIR SECTION OF THIS MANUAL

FOR A DETAILED EXPLANATION OF BLOCKING AND

PROPPING OF TAILGATE BEFORE BEGINNING SEAL

REPLACEMENT.

NEVER WORK BENEATH A RAISED TAILGATE THAT HAS A

HYDRAULIC CYLINDER REMOVED!

NEVER WORK BENEATH A RAISED TAILGATE THAT HAS A

TAILGATE LIFT CYLINDER’S HOSE, FITTING, OR VALVE

COMPONENT REMOVED!

TAILGATE MAY SUDDENLY FALL CAUSING SERIOUS INJURY

OR DEATH

EVEN IF

THE TAILGATE IS MECHANICALLY

PROPPED AND BLOCKED UP. THE TAILGATE LIFT CYLINDERS

SYSTEM

MUST BE

PROVIDING

ONE OF THE THREE

MEANS OF

SUPPORT BEFORE

WORKING BENEATH

A RAISED TAILGATE.

THE TAILGATE’S HYDRAULIC LIFT SYSTEM MUST BE IN GOOD

WORKING CONDITION (AND TWO ADDITIONAL MECHANICAL

BLOCKING AND PROPPING MEANS SECURELY INSTALLED)

BEFORE WORKING BENEATH A RAISED TAILGATE.

ALWAYS FULLY LOWER THE TAILGATE BEFORE REMOVING A

TAILGATE LIFT CYLINDER OR ANY OF IT’S PLUMBING COMPONENTS

(VALVES, TUBES, FITTINGS, and HOSES)! DO NOT RELY

ONLY

ON

MECHANICAL BLOCKING AND PROPPING TO SUPPORT A PARTIALLY

RAISED TAILGATE! TAILGATE MAY SUDDENLY FALL CAUSING

SERIOUS INJURY OR DEATH.

THE ELITE’S TAILGATE LIFT SYSTEM IS FULLY SERVICABLE WITH

TAILGATE

FULLY LOWERED

.

NEVER STAND UNDERNEATH OR WALK BENEATH A MOVING

TAILGATE! THE TAILGATE MAY BE LOWERED UPON YOU OR MAY

SUDDENLY FALL CAUSING SERIOUS INJURY OR DEATH.

A COMPONENT FAILURE (SUCH AS HOSE END “BLOW-OFF”) COULD

CAUSE TAILGATE TO SUDDENLY FALL.

NEVER STAND UNDERNEATH OR WALK BENEATH A RAISED

(OR PARTIALLY RAISED) TAILGATE WHEN SUPPORTED

ONLY

BY ITS HYDRAULIC SYSTEM!

TAILGATE MAY SUDDENLY AND UNEXPECTEDLY FALL

DOWNWARD CAUSING SERIOUS INJURY OR DEATH.

SHOULD A HYDRAULIC COMPONENT FAIL, SUCH AS A HOSE-

END “BLOW-OFF”, THE TAILGATE WILL SUDDENLY FALL.

Sec01-pg03

KEEP THE BODY SIDE ACCESS DOOR CLOSED WHEN EJECTOR

BLADE IS IN MOTION! THE EJECTOR BLADE MOVES PAST

THE DOOR OPENING AND COULD CAUSE INJURY.

YOU MUST NOT OPERATE THE ELITE UNLESS:

YOU ARE QUALIFIED BY TRAINING AND EXPERIENCE IN THE

SAFE OPERATION OF THIS MACHINE.

TRAINING INCLUDES COMPLETE KNOWLEDGE OF YOUR EMPLOYER’S

WORK RULES, ALL GOVERMENTAL REGULATIONS, AND

MANUFACTURER’S OPERATOR’S MANUAL RELATIVE TO THIS

MACHINE’S SAFE USE.

AN UNTRAINED OPERATOR SUBJECTS HIMSELF/ HERSELF

AND OTHERS TO SERIOUS INJURY OR DEATH.

YOU MUST NOT SERVICE, MAINTAIN, OR REPAIR THE ELITE UNLESS:

YOU ARE QUALIFIED BY TRAINING AND EXPERIENCE IN THE

SAFE

OPERATION

OF THIS MACHINE.

TRAINING INCLUDES COMPLETE KNOWLEDGE OF YOUR

EMPLOYER’S WORK RULES, ALL GOVERMENTAL

REGULATIONS, AND MANUFACTURER’S OPERATOR’S MANUAL

RELATIVE TO THIS MACHINE’S SAFE USE.

A SERVICE TECHNICIAN WHO IS UNTRAINED IN THE SAFE

OPERATION

OF THE ELITE SUBJECTS HIMSELF/HERSELF AND

OTHERS TO SERIOUS INJURY OR DEATH.

YOU MUST NOT SERVICE, MAINTAIN, OR REPAIR THE ELITE

UNLESS YOU ARE THOROUGHLY KNOWLEDGEABLE OF YOUR

SHOP’S (YOUR EMPLOYER’S) DETAILED LOCKOUT/TAGOUT

POLICIES AND PROCEDURES.

LOADMASTER HAS INCLUDED THE OUTLINE OF A SKELETON,

BARE BONES LOCKOUT/TAGOUT PROCEDURE IN THIS

MANUAL. IT IS THE RESPONSIBILITY OF THE OWNERS,

SUPERVISORS, MAINTAINERS, AND OPERATORS OF THE

LEGACY3 TO FULLY DEVELOP A “DETAILED”

LOCKOUT/TAGOUT PROCEDURE/POLICY THAT SUITS YOUR

SHOP’S SPECIFIC CIRCUMSTANCES.

THE RIDING STEP SHALL NOT BE USED WHEN:

SPEEDS EXCEED 10 MPH

DISTANCE OF TRAVEL IS MORE THAN 2 TENTHS OF A

MILE

VEHICLE IS MOVING BACKWARDS (IN REVERSE)

TO PREVENT POSSIBLE INJURY, DEATH, OR PROPERTY

DAMAGE, DO NOT USE THIS VEHICLE TO “TOW” OTHER

EQUIPMENT. IT IS NOT INTENDED, DESIGNED OR EQUIPPED

FOR TOWING.

DO NOT ENTER UNDER OR CRAWL UNDER THE CHASSIS

UNLESS THE DIESEL IS SHUTDOWN, THE IGNITION KEYS ARE

IN YOUR POCKET, AND A SIGN HAS BEEN PLACED ON THE

STEERING WHEEL THAT SAYS “DO NOT START ENGINE”! DO

YOUR SHOP’S DETAILED LOCKOUT/TAGOUT PROCEDURE

INCLUDING WHEEL CHOCKING!

THE VEHICLE WILL RUN YOU OVER CAUSING SERIOUS

INJURY OR DEATH. YOU MAY BECOME ENTANGLED IN THE

EXPOSED VEHICLE DRIVETRAIN OR THE ROTATING PUMP-

PROPELLOR SHAFTING CAUSING SERIOUS INJURY OR

DEATH.

DO NOT OVERLOAD THE PACKER AND CHASSIS. DO NOT

EXCEED THE CHASSIS MANUFACTURER’S POSTED GROSS

VEHICLE WEIGHT RATINGS (OVERALL AND “PER AXLE”).

GROSS VEHICLE WEIGHTS MUST ALSO MEET APPLICABLE

FEDERAL, STATE, AND LOCAL WEIGHT LAWS. FAILURE TO

COMPLY COULD CAUSE POOR HANDLING AND OUT OF

COMPLIANCE BRAKING AND CAUSE SERIOUS INJURY OR

DEATH.

Sec01-pg 04

THE IN-CAB MASTER ROCKER SWITCH LABELED “THRTL”

(THROTTLE) MUST BE IN THE “OFF” POSITION WHEN THE

TRUCK IS BEING DRIVEN ABOVE 10MPH!

SHOULD THE THROTTLE ENGAGE DURING TRAVEL, LOSS OF

VEHICLE CONTROL COULD OCCUR RESULTING IN SERIOUS

INJURY OR DEATH.

ALWAYS BE CERTAIN THE THROTTLE ADVANCE CAN

NOT

AUTOMATICALLY ADVANCE THE DIESEL RPM UNLESS THE

VEHICLE TRANSMISSION IS IN

NEUTRAL

!

AUTOMATIC ADVANCEMENT OF THROTTLE WHILE VEHICLE IS

IN A DRIVE OR REVERSE GEAR COULD RESULT IN LOSS OF

VEHICLE CONTROL AND CAUSE SERIOUS INJURY OR DEATH.

SHOULD THIS MALFUNCTION EVER OCCUR, PARK THE

VEHICLE IMMEDIATELY AND REPAIR

NEUTRAL

INTERLOCK

OF THE THROTTLE ADVANCE SYSTEM.

NEVER OPERATE, MAINTAIN, OR REPAIR THE VEHICLE OR

THE ELITE WHILE UNDER THE INFLUENCE OF ALCOHOL OR

DRUGS! WORKERS UNDER THE INFLUENCE PRESENT A

HAZARD TO THEMSELVES AND OTHERS AND CAN CAUSE

SERIOUS INJURY OR DEATH.

DO NOT OPERATE, MAINTAIN, OR REPAIR THE VEHICLE OR

THE ELITE UNLESS YOU ARE ALERT, CLEAR-HEADED AND

WELL RESTED. IF YOU ARE FEELING TIRED, DO OTHER WORK

CHORES THAT DO

NOT

REQUIRE YOU TO BE NEAR A

HYDRAULICALY-POWERED MACHINE.

DO NOT WEAR WATCHES, RINGS, AND JEWELRY WHILE

WORKING WITH MECHANICAL OR ELECTRICAL EQUIPMENT.

DO NOT WEAR LOOSE CLOTHING THAT COULD ENTAGLE YOU

INTO MOVING OR ROTATING COMPONENTS. THESE TYPES

OF THINGS WILL BE HAZARDOUS AND COULD CAUSE

SERIOUS INJURY OR DEATH IF WORN NEAR MOVING

MECHANICAL OR HYDRAULIC MACHINE PARTS.

DO WEAR PERSONAL PROTECTION ITEMS SUCH AS HARD

HATS, SAFETY GLASSES (EYE PROTECTION), HEAVY GLOVING,

AND SAFETY SHOES WHEN OPERATING OR MAINTAINING

THE ELITE OR CHASSIS. OPERATORS SHOULD WEAR VESTING

THAT HAS A BRIGHT COLORATION (ORANGE) AND

REFLECTIVE CHARACTERISTICS FOR DAY/NIGHT VISIBILITY.

FOLLOW ALL OF YOUR EMPLOYER’S REQUIREMENTS FOR

PERSONAL PROTECTIVE ITEMS.

BEFORE OPERATING THE PACKER, BE CERTAIN TO CLEAR THE

AREA OF ALL PEOPLE. ALWAYS BE ATTENTIVE WHEN

OPERATING THE CONTROLS. WATCHDOG THE AREA FOR

ACTIVITY. SCAN YOUR MIRRORS REGULARLY. NEVER BACK-

UP THE VEHICLE UNLESS YOU ARE COMPLETELY CERTAIN IT

IS SAFE TO DO SO. USE A HELPER/OBSERVER OR GET OUT

YOURSELF, IF NECESSARY, TO ASSURE YOU CAN SAFELY

BACK-UP. THOROUGHLY UNDERSTAND THE CONTROLS

BEFORE OPERATING THE PACKER. FAILURE TO DO SO COULD

RESULT IN SERIOUS INJURY OR DEATH TO YOURSELF OR

OTHERS.

ALWAYS KEEP THE IN-CAB “GATE AJAR” PILOT LIGHT IN

GOOD WORKING CONDITION. ALWAYS BE SURE THE BACK-

UP ALARM SOUNDS WHENEVER THE TAILGATE IS RAISED-UP

A FOOT OR SO. REPLACE LAMP BULB OR REPAIR ELECTRICAL

WIRE SYSTEM IMMEDIATELY. FAILURE TO DO SO COULD

LEAD TO SERIOUS SITUATIONS.

BEFORE RAISING THE TAILGATE, BE SURE THERE EXISTS

ADEQUATE CLEARANCE BETWEEN TAILGATE AND ANY

BUILDING STRUCTURE OR ELECTRICAL POWER LINES (OR

ANY OTHER OBSTACLES). ALLOWING THE TAILGATE TO

STRIKE OBJECTS OR POWER LINES COULD CAUSE SERIOUS

INJURY OR DEATH.

sec01-pg 05

ALWAYS DRIVE CAREFULLY AND DEFENSIVELY! ALWAYS BE

AWARE THE CHASSIS/PACKER IS A

HEAVY

VEHICLE AND NOT

A PASSENGER CAR. THE CHASSIS/PACKER WILL REQUIRE

SLOWER CORNERING SPEEDS AND LONGER STOPPING

DISTANCES. THE CHASSIS/PACKER WILL HAVE A HIGHER

CENTER OF GRAVITY WHICH PRESENTS A “ROLL-OVER”

HAZARD IF DRIVING HABITS ARE NOT ADJUSTED. BE AWARE

THE CHASSIS/PACKER’S HANDLING AND BRAKING

CHARACTERSITICS WILL

CHANGE

AS YOU BUILD A PAYLOAD.

FAILURE TO ACCOUNT FOR THESE FACTORS COULD LEAD TO

ROLL-OVER OR LOSS OF CONTROL RESULTING IN SERIOUS

INJURY OR DEATH.

SOME CONTAINER HANDLING “OPTIONS”, SUCH AS THE

ROOF-MOUNTED CABLE REEVER (AKA....THE “2-10”), AND

THE SPOOLING DRUM WINCH, WILL HAVE CABLES WITH A

“HOOK’ AT THE END OF THE CABLE. THERE WILL EXSIST A

BENT PEG FOR HOOK “STOREAGE”.

WHEN THAT OPTION’s HOOK IS “NOT” ACTIVELY BEING

USED, ALWAYS “STORE” THE CABLE’S HOOK ONLY AT THE

PROVIDED “BENT PEG” HOOK STORE. DO NOT STORE THE

HOOK ANYWHERE ELSE!!

NEVER, (NEVER) “STORE” THE CABLE’S HOOK BY

ATTACHING THE HOOK TO THE GATESIDE “HAND HOLDS”

(AKA ...GATESIDE “GRAB HANDLES”). THE HAND-HOLDS

ARE “ONLY” FOR THE ‘HANDS” OF THE RIDERS & OPERATORS.

WRONGLY “HOOKING’THE CABLE’s HOOK TO THE HAND-HOLD

WILL RESULT IN SERIOUS INJURY (CABLE PINCHING/

CUTTING INJURIES), IF THE CABLE’S HOOK IS “WRONGLY”

STORED AT THE GATESIDE “HANDHOLDS/ GRAB HANDLES”.

ALWAYS “STORE” ANY CABLE’s “HOOK” AT THE PROVIDED

BENT PEG STYLE OF HOOK STOREAGE ONLY.

ALWAYS EXERCISE YOUR HIGHEST SPECIAL CARE WHEN

“BACKING-UP” THE CHASSIS/PACKER!

THE CHASSIS/PACKER IS TYPICAL OF ALL REAR LOADERS IN

THAT IT HAS A “BLIND-SPOT” WHICH THE VEHICLE’S

MIRRORS CAN

NOT

PUT INTO THEIR “FIELD OF VISION”.

FAILURE TO ALWAYS USE THE MOST EXTREME CARE IN

BACKING-UP THE CHASSIS/PACKER WILL RESULT IN

SERIOUS INJURY OR DEATH TO BYSTANDER OR WORK

PARTNER.

ALWAYS FOLLOW YOUR EMPLOYER’S “SAFEST WAY TO BACK-

UP” PROCEDURES/POLILCIES. THESE SHOULD INCLUDE:

PLANNING YOUR COLLECTION ROUTES TO MINIMIZE

THE NEED FOR BACK-UPS

USING A HELPER/OBSERVER TO GUIDE THE PERSON

BEHIND THE STEERING WHEEL WHEN BACKING-UP

HELPER/OBSERVER MUST ALWAYS BE OFF TO THE SIDE

OF THE CHASSIS/PACKER AND WITHIN THE MIRRORS’

FIELD OF VISION

NEVER EXCEEDING ¼ MPH WHEN IN REVERSE

ALWAYS KEEPING THE BACK-UP-ALARM IN TOP

WORKING CONDITON…(KEEP IN MIND THAT

JUST

HAVING

A FUNCTIONAL BACK-UP-ALARM IS

NOT

ENOUGH TO ASSURE SAFEST “BACKING-UP”).

ANYTHING ELSE YOU AND YOUR EMPLOYER DEEM

HELPFUL TO BACKING-UP WITH EXTREME SAFETY

HYDRAULIC SYSTEMS ARE HOT! DO NOT TOUCH ANY

HYDRAULIC COMPONENTS OR YOU MAY BURN YOURSELF.

ALLOW THE HYDRAULICS SYSTEM TO COOL DOWN TO 100

DEGREES FAIRENHEIGHT (OR LESS) BEFORE DOING ANY

HYDRAULIC MAINTENANCE OR REPAIR ACTIVITIES.

WHEN REPLACING A HYDRAULIC “PLUMBING” COMPONENT

SUCH AS A HOSE, TUBE, OR A FITTING, BE CERTAIN YOU USE

ONLY AN EQUIVALENT PRESSURE RATING (OR HIGHER)

REPLACEMENT PART! FAILURE TO HEED THIS WARNING

COULD RESULT IN SUDDEN FAILURE (BURSTS OR FORCEFUL

LEAKS) OF THE INFERIOR REPLACEMENT AND COULD CAUSE

SERIOUS INJURY OR DEATH.

HIGH PRESSURE OIL STREAMS CAN CAUSE SERIOUS BURNS

OR CAN PENETRATE TISSUE. FIRE CAN OCCUR IF THE

ESCAPING OIL HITS A HOT SURFACE (SUCH AS VEHICLE

EXHAUST SYSTEM). MACHINE COMPONENTS COULD

SUDDENLY FALL OR OTHERWISE MOVE UNCONTROLLABLY.

THE CORRECT LENGTH OF HOSE MUST ALSO BE USED. CALL

LOADMASTER IF IN ANY DOUBT ABOUT CORRECT

REPLACEMENT PARTS FOR YOUR ELITE.

GETTING YOUR REPLACEMENT HYDRAULIC PLUMBING

COMPONENTS FROM LOADMASTER WILL ASSURE CORRECT

SPECIFICATIONS. IF YOU MUST PROCURE IT IN YOUR

LOCALITY, USE ONLY NAME BRAND PARTS AND USE A

REPUTABLE HYDRAULIC HOSE/FITTING ASSEMBLY HOUSE.

DO NOT ALLOW THE “MIXING” OF DIFFERENT BRANDS AS

THEY WILL NOT CORRECTLY MATE.

Sec01-pg06

THE HYDRAULICS SYSTEM MAY HAVE “TRAPPED” HIGH-

PRESSURES EVEN WHEN DIESEL IS OFF. ALWAYS RELIEVE

THESE TRAPPED PRESSURES BY RATTLING THE CONTROL

LEVERS ABOUT THEIR CENTERED-NEUTRAL POSITIONS

(WITH THE DIESEL SHUTDOWN) BEFORE LOOSENING ANY

SYSTEM CONNECTIONS.

SOME MACHINE COMPONENTS COULD HAVE GRAVITY

PULLING ON THEM AS THEY ARE HYDRAULICALLY HELD IN

PLACE. ALWAYS STOP AND THINK FIRST IF A BLADE OR

OTHER MACHINE COMPONENT NEEDS TO BE REPOSITIONED

TO ITS “DEAD END” (OR OTHER POSITION) SO IT WILL NOT

MOVE BY GRAVITY

WHEN A HYDRAULIC CONNECTION IS

LOOSENED FOR REPAIR.

THE HYDRAULIC CYLINDERS COULD BE HOLDING A

PARTICULAR COMPONENT (SUCH AS A “BLADE”) IN A

PARTICULAR POSITION WHEN THE DIESEL IS OFF. AN

EXAMPLE OF THIS IS WOULD BE THE SLIDER BLADE HELD

UPWARD IN ITS “HOME” POSITION BY THE OIL “LOCKED”

INSIDE ITS CYLINDERS WITH DIESEL OFF. IF A HYDRAULIC

HOSE OR FITTING IS THEN WORKED-ON, GRAVITY

WILL

MOVE

THE COMPONENT TO A NEW POSTION IN A

UNCONTROLABLE FASHION. FAILURE TO ACCOUNT FOR THIS

FACT COULD RESULT IN SERIOUS INJURY OR DEATH.

OFTEN YOU CAN PURPOSEFULLY MOVE THE COMPONENT TO A

POSITON WHERE GRAVITY CAN NOT MOVE IT

BEFORE

WORKING ON THE HYDRAULICS.

SOMETIMES YOU WILL NEED TO SECURE THE COMPONENT IN

PLACE BY WELDING TEMPORARY STEEL “BLOCKING” OR

“STOPS” ONTO THE PACKER.

CALL LOADMASTER IF YOU HAVE ANY DOUBTS ABOUT THE

CORRECT AND SAFEST METHODS OF DOING THIS.

HYDRAULIC HOSES AND TUBING MUST BE INSPECTED ON A

DAILY BASIS FOR LEAKS, CUTS, ABRASIONS, DAMAGE,

RUBBING (NO CLEARANCE IN ROUTING), BEFORE THE TRUCK

IS PUT IN SERVICE. IF YOUR INSPECTION DISCOVERS SUCH

ADVERSE CONDITIONS, THE SITUATION MUST BE

CORRECTED BEFORE TRUCK CAN BE PLACED IN SERVICE.

LOADMASTER RECOMMENDS YOU REPLACE

ALL

OF YOUR

RUBBER HOSES AND THE CLAMPING AT LEAST EVERY THREE

YEARS.

FAILURE TO CLOSELY INSPECT AND MAINTAIN YOUR ELITE

AND CHASSIS COULD LEAD TO SERIOUS INJURY.

NEVER OPERATE THE HYDRAULIC SYSTEM IF ANY LEAK IS

PRESENT. SERIOUS INJURY MAY RESULT.

ALL OF THE ELITE’S PRESSURE GUAGE READINGS ARE TO BE

TAKEN AT THE GAUGE STEM LOCATED AT THE INLET COVER

OF THE BODY-MOUNTED VALVE! USE A GLYCERIN FILLED

GUAGE ON THE END OF A 24” HOSE (1/4” DIAMETER WITH

3000 PSI WORKING PRESSURE RATING) THAT ALLOWS YOU

TO BE FULLY OUTSIDE THE BODY WITH BOTH FEET ON

GROUND AND THEN TAKE THE GAUGE READING. DIESEL

MUST BE SHUTDOWN AND KEYS IN YOUR POCKET BEFORE

ENTERING THE BODY THROUGH THE ACCESS DOOR TO

COUPLE THE GAUGE COUPLER.

NEVER ATTEMPT TO READ A GLYCERIN-FILLED GAUGE WHICH IS

ATTACHED TO THE INLET COVER OF THE

TAILGATE

-MOUNTED

VALVE. ALWAYS COUPLE YOUR GLYCERIN FILLED GAUGE TO THE

BODY-MOUNTED VALVE’S GUAGE STEM. ALL LOADMASTER PRESSURE

SPECS ARE CHECKED/ADJUSTED AT THE BODY-MOUNTED VALVE’S

GAUGE STEM.

Sec01-pg07

Section 02

OPERATORS MANUAL

This operator’s manual describes how a person will

do the useful tasks needed to collect garbage using

the LOADMASTER packer. The user/operator will

often “command” the LOADMASTER packer by

moving a knobbed control lever, or flipping a rocker

switch, or depressing a button switch. This manual

describes these operator-input

actions and the

resulting

output

reactions of the machine.

Throughout this OPERATORS MANUAL there will be

safety precautions. Section 01 SAFETY

PRECAUTIONS must be read and re-read until you

thoroughly understand them and can follow them.

Some (but not all) of the SAFETY PRECAUTIONS

will be repeated throughout this booklet where

they apply. Call LOADMASTER if you have any

doubt about the safe ways to operate your

LOADMASTER packer. The LOADMASTER packer

will have been mounted on a chassis…refer to the

operators manual for the chassis for

its

safe

operation instructions.

ATTENTION OPERATORS, USERS, MAINTAINERS,

REPAIRERS OF THE LOADMASTER PACKER!!!

READ AND UNDERSTAND SECTION 01 SAFETY

PRECAUTIONS AND SECTION 02 OPERATORS

MANUAL BEFORE OPERATING THE LOADMASTER

REFUSE PACKER. PEOPLE WHOM USE OR

MAINTAIN THIS EQUIPMENT MUST BE

THOROUGHLY TRAINED AND FAMILIAR WITH THE

MACHINE. IF INCORRECTLY USED OR

MAINTAINED, THIS EQUIPMENT CAN CAUSE

SERIOUS INJURY OR DEATH.

This DANGER symbolism precedes information

pertaining to specific immediate hazards, which

if

disregarded

, WILL result in severe personal injury or

death of the user or others.

This WARNING symbolism precedes information

pertaining to hazards or unsafe practices which COULD

result in severe personal injury or death.

This CAUTION symbolism precedes information

pertaining to potential hazards or unsafe practices,

which if disregarded, may result in a lesser personal

injury or damage to the equipment.

This notice symbol will precede information which is vital

to the proper operation or maintenance of the

equipment.

Sec02-pg08

Operation of the LOADMASTER packer can be

divided into separate areas of activity. This

operator’s manual covers:

STARTUP

of the machine. This includes the pre-

startup checklist.

TRAVELING

to the area where you will pickup the

garbage.

ON-THE-ROUTE

garbage collection.

YOU MUST NOT OPERATE THE LOADMASTER PACKER UNLESS:

YOU ARE QUALIFIED BY TRAINING AND EXPERIENCE IN THE

SAFE OPERATION OF THIS MACHINE.

TRAINING INCLUDES COMPLETE KNOWLEDGE OF YOUR EMPLOYER’S

WORK RULES, ALL GOVERMENTAL REGULATIONS, AND

MANUFACTURER’S OPERATOR’S MANUAL RELATIVE TO THIS

MACHINE’S SAFE USE.

AN UNTRAINED OPERATOR SUBJECTS HIMSELF/ HERSELF

AND OTHERS TO SERIOUS INJURY OR DEATH.

TRAVELING

to the landfill or transfer station.

UNLOADING

your collected payload at the landfill

or transfer station.

Parking and

SHUTTING-DOWN

the machine.

Some LOADMASTER’S will have

OPTIONS,

such as

a 2-10 reever or a kickbar.

DO

NOT

WEAR WATCHES, RINGS, AND JEWELRY WHILE

WORKING WITH MECHANICAL OR ELECTRICAL EQUIPMENT.

DO NOT WEAR LOOSE CLOTHING THAT COULD ENTAGLE YOU

INTO MOVING OR ROTATING COMPONENTS. THESE TYPES

OF THINGS WILL BE HAZARDOUS AND COULD CAUSE

SERIOUS INJURY OR DEATH IF WORN NEAR MOVING

MECHANICAL OR HYDRAULIC MACHINE PARTS.

DO WEAR PERSONAL PROTECTION ITEMS SUCH AS HARD

HATS, SAFETY GLASSES (EYE PROTECTION), HEAVY GLOVING,

AND SAFETY SHOES WHEN OPERATING OR MAINTAINING

THE EXCEL OR CHASSIS. OPERATORS SHOULD WEAR

VESTING THAT HAS A BRIGHT COLORATION (ORANGE) AND

REFLECTIVE CHARACTERISTICS FOR DAY/NIGHT VISIBILITY.

FOLLOW ALL OF YOUR EMPLOYER’S REQUIREMENTS FOR

PERSONAL PROTECTIVE ITEMS.

Sec02-pg09

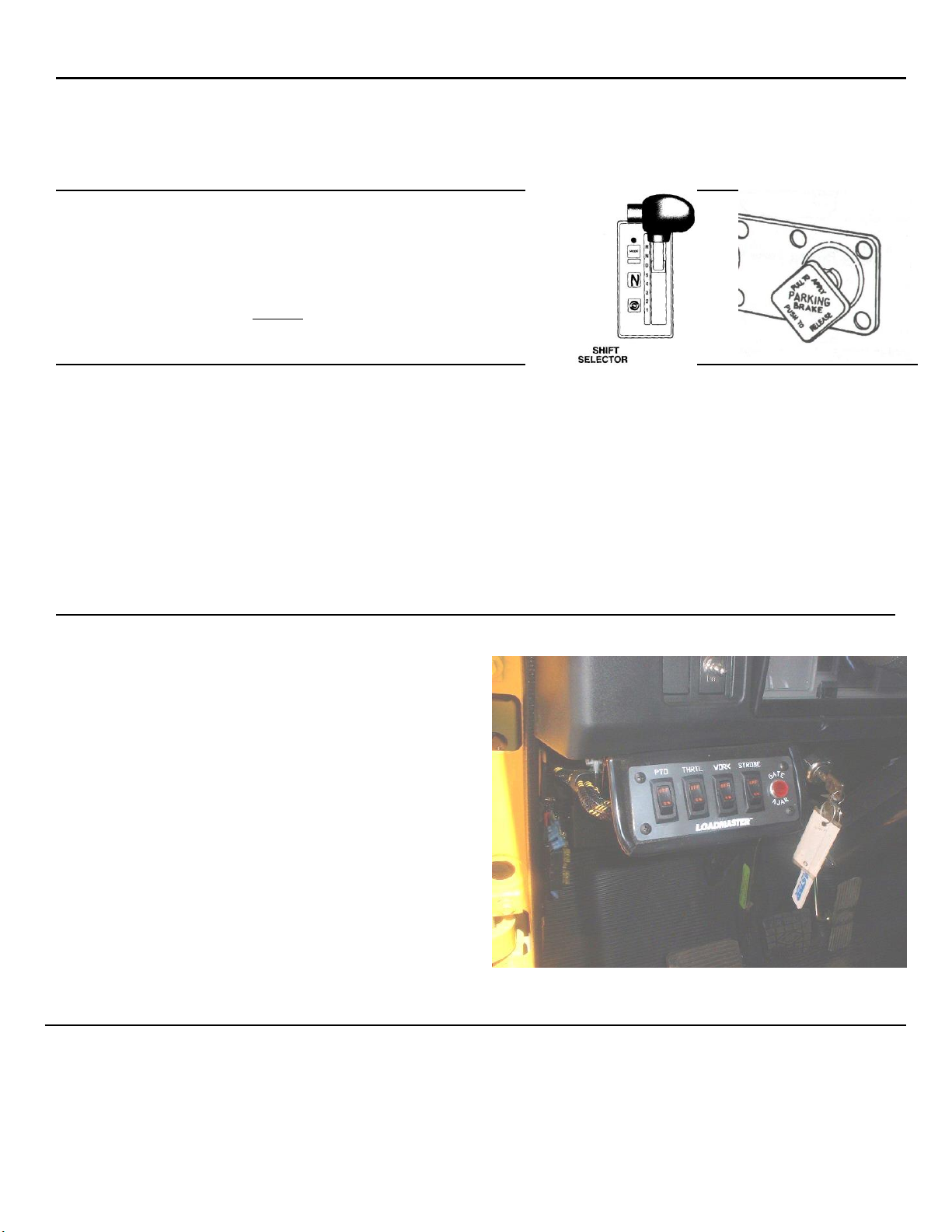

OVERVIEW OF THE CONTROLS

ROCKER SWITCH PANEL

This panel is located inside the cab and just to the

left of the steering wheel.

This ROCKER SWITCH PANEL groups together four

switches and one pilot light. They are:

PTO on/off switch

THRTL on/off switch

WORK light switch (optional)

STROBE light switch (optional)

GATE AJAR warning light

“BODY-MOUNTED VALVE” KNOBBED HANDLEVERS

These are located at the body’s left front corner,

just behind back of cab.

The lower knobbed handlever controls the tailgate

lift. The upper handlever controls the ejector blade.

These handlevers are spring-centered to their

neutral positions. The handlever must be “held” to

a shifted position by the operator.

“TALIGATE-MOUNTED VALVE” HANDLEVERS

These are located on the rearward, right-side of

tailgate shell.

The lower, yellow colored handlever controls the

sweep

blade. The sweep blade is the compaction

blade that “rotates” at the blades pivot.

The orange colored handlever controls the

slide

blade. The slide blade is the compaction blade that

slides in the “track” channel.

Any knobbed handlevers for

optional

attachments

will also be located near the above blade controls,

but they will

not

be colored yellow or orange. The

“2-10 reever” and the “kickbar” are examples of

optional equipment.

Sec02-pg10

SWEEP BLADE IS

YELLOW

SLIDE BLADE

IS ORANGE

TAILGATE LIFT

CONTROL

EJECTION BLADE

CONTROL

GATE

AJAR

LIGHT

OVERVIEW OF THE CONTROLS

DRIVER SIGNAL SWITCHES

There are two switches that will sound the in-cab

buzzer. They are located one on each side of the

tailgate’s shell at the very rear.

These switches are “momentary” type, which

means the operator must depress and “hold”

depressed to sound the in-cab buzzer.

THROTTLE ADVANCE SWITCHES

There are two of these switches. One is located on

the right rear of the tailgate shell. One is located at

the body’s front left corner (near body-mounted

valve). Depressing and holding these “momentary”

switches will advance the diesel’s RPM (so long as

the in-cab master switch labeled THRTL is also at

it’s ON position).

TAILGATE LATCH TURNBUCKLE

If your packer is not equipped with automatic

tailgate latches, it then will have manually operated

tailgate latches on each side. Also known as

tailgate clamps, tailgate locks, tailgate latches,

tailgate buckles, or turnbuckles. Most ELITE’s

models have the automatic-operated latches (std).

Sec02-pg11

DRIVER SIGNAL

SWITCH

THROTTLE

ADVANCE

SWITCH

STARTUP

The first step is to do a “walk-around” inspection of the

LOADMASTER packer and the truck chassis before

“cranking” the diesel.

Assure that the machine is in good, safe working

condition.

All signals and lights needed for safe street

operation are undamaged and functional

The mirrors are undamaged, clean, and

adjusted to best field of vision

Tires are inflated and have adequate treading

Cab windshield and side windows are cleaned

Assure that there is no hydraulic leakage

Check the fuel level, engine oil level, coolant

level

Check for a fully charged and accessible fire

extinguisher

Check the hydraulic fluid level

Assure that all hoses and tubes show no signs

of damage or rubbing-out spots

Assure the suction line valve is fully open

The backup alarm sounds when transmission is

shifted to reverse

The backup alarm sounds when tailgate is

raised upward about ¼ of fully raised.

The tailgate cylinder pins are retained in proper

position

The machine is clean of debris, dirt, and oils

The steps and grab handles are in good

condition

Check that the body mounts to the chassis are

in good condition

The control levers and knobs are in good

condition

Assure the body access door is securely latched

Be sure the hopper is clear of people

Be sure the general area is clear of any other

people (a passerby or a service person,

perhaps) before starting the diesel

Be certain no person is in front ,underneath,

on top of, or behind the machine

Any other “walk-around” checks your employer

has assigned

Check that the tailgate is fully down and fully

latched

The tailgate hinge pins are retained in proper

position

Assure all placards and decals are readable

Check that any work lights are in good

condition.

Check that any strobe or beacon lights work

If the LOADMASTER packer or the chassis has a

problem that needs correcting, see your supervisor

so that a trained service person will attend to the

problem.

Sec02-pg12

STARTUP

After completing the “walk-around” pre-startup

inspection, enter the vehicle’s cab.

Check that the LOADMASTER rocker switches are

all in their OFF position. A rocker switch that is ON

will show its reddish color band and a rocker switch

that is OFF will

not show

its color band.

The group of rocker switches includes 4 rocker

switches and one pilot light.

The switch labeled THRTL is the throttle master

switch. When this switch is at OFF, the throttle can

never advance because all electrical power is cutoff

at this branch circuit’s origin.

The switch labeled PTO controls whether the PTO

is engaged (hydraulic pump rotating) or

disengaged (pump uncoupled). See your specific

chassis/transmission manual for the correct

procedure for engaging/disengaging the PTO.

The switch labeled WORK turns the optional

hopper work lighting on or off.

The switch labeled STROBE will turn the optional

beacon or strobe lights on or off.

The red color warning light is labeled GATE AJAR.

This light will illuminate whenever the tailgate is

raised about a foot or so above fully closed.

Do not move truck at speeds above ¼ MPH

whenever the tailgate is raised up (fully or partially)

and “gate ajar” light is illuminated! Move only after

assuring overhead clearance is adequate and then

still move at less than ¼ MPH.

Confirm that the transmission is in Neutral and

that the park/emergency brake is applied On.

Now turn the ignition switch to ON and start-up the

diesel. Follow the instructions in the chassis

operator’s manual for starting the diesel. (Refer to

your specific chassis’ operators manual for ALL of

its operational information.)

Warm up the diesel for a few minutes and prepare

yourself to begin to travel. BUCKLE UP!

Sec02-pg13

TRAVELING

You have done your walk-around inspection, the diesel

is running, and you and your work partners are seated

and buckled up.

Ride

only in the cab

during travel to and from the

area where you will collect garbage house-to-

house.

THE RIDING STEP SHALL NOT BE USED WHEN:

SPEEDS EXCEED 10 MPH

DISTANCE OF TRAVEL IS MORE THAN 2 TENTHS OF A

MILE

VEHICLE IS MOVING BACKWARDS (IN REVERSE)

When driving on the street in the chassis/packer,

always be aware that you are driving a

heavy

truck

. The way a heavy truck handles and brakes

is different from your personal passenger car or

light truck (pickup truck). The packer requires more

distance to stop in a “panic” situation. Always allow

extra spacing in traffic. The packer is not as agile

or responsive as a typical passenger car. You will

not always be able to maneuver your way out of

difficult situations. This means you must drive extra

defensively when traveling in the chassis/packer.

Always be alert and anticipate possible traffic

hazards. Account for the size and weight of your

chassis/packer.

The center of gravity of the chassis/packer is much

higher than a passenger car. This fact must be

accounted for to avoid rolling over. Turn through

corners at slower speeds and account for the larger

turn radius the chassis/packer will require.

Also, be aware that the full chassis/packer will

behave (brake and handle) somewhat differently

from the empty chassis/packer.

ALWAYS DRIVE CAREFULLY AND DEFENSIVELY! ALWAYS BE

AWARE THE CHASSIS/PACKER IS A

HEAVY

VEHICLE AND NOT

A PASSENGER CAR. THE CHASSIS/PACKER WILL REQUIRE

SLOWER CORNERING SPEEDS AND LONGER STOPPING

DISTANCES. THE CHASSIS/PACKER WILL HAVE A HIGHER

CENTER OF GRAVITY WHICH PRESENTS A “ROLL-OVER”

HAZARD IF DRIVING HABITS ARE NOT ADJUSTED. BE AWARE

THE CHASSIS/PACKER’S HANDLING AND BRAKING

CHARACTERSITICS WILL

CHANGE

AS YOU BUILD A PAYLOAD.

FAILURE TO ACCOUNT FOR THESE FACTORS COULD LEAD TO

ROLL-OVER OR LOSS OF CONTROL RESULTING IN SERIOUS

INJURY OR DEATH.

You must know the height of your chassis/packer

before going under any overpasses. Be sure to

allow sufficient clearance to avoid slamming into

anything overhead.

As mentioned in the “walk-around” pre-travel

inspections, be sure the tailgate is fully down and

fully latched closed. Do this by visually checking it

to be fully down in addition to monitoring the “gate

ajar” warning light periodically during road travel.

Pull over immediately should you notice the “gate

ajar” light has illuminated during travel. When you

unload (tailgate raised up), confirm that the “gate

ajar” light does indeed illuminate (proper and

normal). If not, have the “gate ajar” warning light

system repaired immediately. (Note that the “gate

ajar” light will illuminate when vehicle transmission

shifts to reverse, even with gate fully down…this is

how it is wired.)

ALWAYS KEEP THE IN-CAB “GATE AJAR” PILOT LIGHT IN

GOOD WORKING CONDITION. ALWAYS BE SURE THE BACK-

UP ALARM SOUNDS WHENEVER THE TAILGATE IS RAISED-UP

A FOOT OR SO. REPLACE LAMP BULB OR REPAIR ELECTRICAL

WIRE SYSTEM IMMEDIATELY. FAILURE TO DO SO COULD

LEAD TO SERIOUS SITUATIONS.

Never allow any person to ride in the hopper

or to ride sitting on the loading sill at any

time.

When traveling to or from your on-the–route

collection geographic area, always have the rocker

switch labeled THRTL in the OFF position (no red

color band showing). This rocker switch is a

master

kill switch which precludes any malfunction or

unintentional throttle advancing during travel

whenever it is at the OFF position.

THE IN-CAB MASTER ROCKER SWITCH LABELED “THRTL”

(THROTTLE) MUST BE IN THE “OFF” POSITION WHEN THE

TRUCK IS BEING DRIVEN ABOVE 10MPH!

SHOULD THE THROTTLE ENGAGE DURING TRAVEL, LOSS OF

VEHICLE CONTROL COULD OCCUR RESULTING IN SERIOUS

INJURY OR DEATH.

Sec02-pg14

TRAVELING

Disengage the PTO when traveling above 10 MPH.

The rocker switch labeled PTO must be rockered to

OFF position. Read the instructions for PTO

engagement/disengagement that came with your

transmission or chassis for the specific sequence of

steps.

Do not use the LOADMASTER packer/chassis as a

towing vehicle.

TO PREVENT POSSIBLE INJURY, DEATH, OR PROPERTY

DAMAGE, DO NOT USE THIS VEHICLE TO “TOW” OTHER

EQUIPMENT. IT IS NOT INTENDED, DESIGNED OR EQUIPPED

FOR TOWING.

Every chassis is tagged (often in the cab door jamb

area) by the chassis manufacturer for its maximum

allowable weight capacities. Do not exceed the

allowable tagged weight ratings.

DO NOT OVERLOAD THE PACKER AND CHASSIS. DO NOT

EXCEED THE CHASSIS MANUFACTURER’S POSTED GROSS

VEHICLE WEIGHT RATINGS (OVERALL AND “PER-AXLE”).

GROSS VEHICLE WEIGHTS MUST ALSO MEET APPLICABLE

FEDERAL, STATE, AND LOCAL LAWS. FAILURE TO COMPLY

COULD CAUSE POOR HANDLING AND OUT OF COMPLIANCE

BRAKING AND CAUSE SERIOUS INJURY OR DEATH.

NEVER OPERATE THE VEHICLE WHILE UNDER THE INFLUENCE

OF ALCOHOL OR DRUGS! WORKERS UNDER THE INFLUENCE

PRESENT A HAZARD TO THEMSELVES AND OTHERS AND CAN

CAUSE SERIOUS INJURY OR DEATH.

DO NOT OPERATE THE VEHICLE UNLESS YOU ARE ALERT,

CLEAR-HEADED AND WELL RESTED.

Plan your travel to minimize the need for “backing-

up” (reverse gear) the chassis/packer. When you

must backup, always use your highest special care

to avoid running-over people. You must keep the

back-up-alarm in good working condition and then

be aware that

this alone does not

assure safe

backing-up.

Always exercise your highest special care when

“backing up” the chassis/packer.

THE CHASSIS/PACKER IS TYPICAL OF ALL REAR LOADERS IN

THAT IT HAS A “BLIND-SPOT” WHICH THE VEHICLE’S

MIRRORS CAN

NOT

PUT INTO THEIR “FIELD OF VISION”.

FAILURE TO ALWAYS USE THE MOST EXTREME CARE IN BACKING-UP

THE CHASSIS/PACKER WILL RESULT IN SERIOUS INJURY OR DEATH

TO BYSTANDER OR WORK PARTNER.

ALWAYS FOLLOW YOUR EMPLOYER’S “SAFEST WAY TO BACK-UP”

PROCEDURES/POLICIES. THESE SHOULD INCLUDE:

PLANNING YOUR COLLECTION ROUTES TO MINIMIZE THE NEED

FOR BACK-UPS

USING A HELPER/OBSERVER TO GUIDE THE PERSON BEHIND

THE STEERING WHEEL WHEN BACKING-UP

HELPER/OBSERVER MUST ALWAYS BE OFF TO THE SIDE OF THE

CHASSIS/PACKER AND WITHIN THE MIRRORS’ FIELD OF VISION

NEVER EXCEEDING ¼ MPH WHEN IN REVERSE

ALWAYS KEEPING THE BACK-UP-ALARM IN TOP WORKING

CONDITON…(KEEP IN MIND THAT

JUST

HAVING

A FUNCTIONAL

BACK-UP-ALARM IS

NOT

ENOUGH TO ASSURE SAFEST

“BACKING-UP”).

DO “ANYTHING ELSE”YOU AND YOUR EMPLOYER DEEM

HELPFUL TO BACKING-UP WITH EXTREME SAFETY

Sec02-pg15

ON-THE-ROUTE GARBAGE COLLECTION

You have traveled to the area that will begin the

actual collection of the route’s garbage. The packer

has pulled along side the very first garbage can or

bag to be picked-up.

Shift the vehicle transmission to PARK (or

Neutral if “park” does not exist on your ELITE chassis).

Set the PARK/EMERGENCY brake to applied

ON.

These two steps must always be done by the

vehicle’s driver before he/she leaves the cab!

Position the switch labeled THRTL to ON. The

rocker switches red color band will be visible when

the switch is at ON position.

This will allow the diesel’s throttle to advance

automatically

when the compaction blades are

cycling automatically.

This will also allow

manual

throttle advancement by

depressing and holding the button switches labeled

“throttle advance”.

Position the switch labeled PTO to ON. The

rocker switches red color band will be visible when

the switch is at the ON position.

This engages the PTO and the hydraulic pump will

begin to rotate (pump) and the hydraulic system is

now active. You will typically hear a change in the

overall sound.

You must follow the

specific engagement

instructions

given in the operation manuals for your

particular chassis/transmission/PTO-type. There are

several possible combinations that will require

somewhat different procedures for proper

engagement. If you hear nasty gear clashing

sounds, immediately revert the rocker switch to

OFF position and re-study the correct PTO

engagement procedure.

Turn on your beacon or strobe lights (and the

hopper area work lights, if needed) by

positioning the rocker switches so that the red

band is exposed.

Sec02-pg16

ON-THE-ROUTE GARBAGE COLLECTION

The compaction blades will be at their “home”

position as shown here. The hydraulic circuit has

been made active and ready to do “house-to-

house” collection. Begin tossing bagged garbage

into the hopper or dumping garbage cans into the

hopper. Fill the hopper until it is to “sill” level.

When the hopper is about full, you will need to do

a “semi” automatic blade cycle. Each blade cycle

will clear the hopper of garbage.

The blade cycle is called “semi” automatic because

it is done in two parts. The first part will begin by

pulling both

of the blades control knobs outward

(momentarily) and then releasing them.

First the sweep blade will automatically rotate open

(blade tip moves upward). When the sweep blade

is fully opened, then the slide blade will

automatically travel downward (towards hopper).

When the slide blade is fully downward and the

sweep blade’s tip is fully rotated upward, the

blades will be in their “interrupted” position as

shown here.

At this point, both blades stop moving and nothing

more will “automatically” happen. The blades will

“wait” for your next command. Before doing the

next step, be completely certain that you and

everyone else have their arms and hands well clear

of the loading sill.

The second part of the semi-automatic blades cycle

requires the sweep blade to sweep across the

sill…this is a hazardous “pinch-point” that you must

always be careful of and aware of.

This purposeful “interruption” of the blades

cycle allows the person operating the blade

controls to visually check that the hopper sill

area is clear of all people’s fingers, hands and

arms

before

beginning the second part of the

blades cycle. The person “at the controls” has

the responsibility to make sure

himself/herself is fully clear of the “pinch-

point” and that all others are fully clear as

well.

Sec02-pg17

HOPPER SILL

HOPPER

SWEEP

BLADE

SLIDE

BLADE

HOPPER

BLADES AT

INTERRUPTED

POSITION

PINCH-POINT

AT THE SILL

HOPPER’S BLADES

SHOWN AT ”HOME”

POSITION

PULL OUTWARD

BOTH SLIDE AND

SWEEP KNOBS

SIMULTANEOUSLY

ON-THE-ROUTE GARBAGE COLLECTION

After assuring that no people (or “parts of people”)

are anywhere near the hopper sill (including the

person “at the controls”),

push both

of the blade

control lever’s knobs inward (and release) to begin

the second part of the semi-automatic blade cycle.

First the sweep blade will rotate to capture the

garbage in the hopper (blade tip will move

downward). Notice the blade “tip” swept by the

hopper sill, thereby creating the pinch-point

hazard. At the very moment the sweep blade stops

rotating, the slide blade then begins sliding

upward. These actions compact the garbage into

the “body”. These actions also have cleared the

hopper. The blades are now back at their original

“home” position.

This completes one “semi-automatic” compaction

cycle.

During on-the-route, house-to-house collection you

will be doing many of these complete blade cycles.

The ejector blade will slowly and automatically drift

forward (towards the cab) as you build up a

“payload” in the LOADMASTER’S body.

Always do one

complete

blade cycle so that the

blades are always in their “home” position

whenever you are loading garbage into the hopper.

The riding steps can be used on-the-route

whenever the speeds stay below 10MPH, moving

from house-to-house, and the vehicle is not going

in reverse. Be certain the vehicle is

completely

stopped

before getting on or getting off the step.

Get a firm grip on the grab handles with both

hands and spread your feet apart to be stable.

Signal the vehicle driver (when you are stable and

secure) by sounding the in-cab buzzer by

depressing a button switch. The driver is to wait

two seconds after the buzzer stops buzzing, and

then begin to move the vehicle to the next house’s

garbage.

Do not use the LOADMASTER packer and the

chassis to tow a trailer.

STAY CLEAR OF MOVING HOPPER BLADES AND THE HOPPER

LOADING SILL WHEN BLADES ARE MOVING! IF YOU OR A

WORK PARTNER IS CAUGHT IN THE BLADE ACTION, SERIOUS

INJURY OR DEATH WILL RESULT.

THE RIDING STEP SHALL NOT BE USED WHEN:

SPEEDS EXCEED 10 MPH

DISTANCE OF TRAVEL IS MORE THAN 2 TENTHS OF A

MILE

VEHICLE IS MOVING BACKWARDS (IN REVERSE)

TO PREVENT POSSIBLE INJURY, DEATH, OR PROPERTY

DAMAGE, DO NOT USE THIS VEHICLE TO “TOW” OTHER

EQUIPMENT. IT IS NOT INTENDED, DESIGNED OR EQUIPPED

FOR TOWING.

Sec02-pg18

EJECTOR

BLADE

“THE BODY”

ON-THE-ROUTE GARBAGE COLLECTION

LOADMASTER does not recommend that you “back

pack” while on-the-route and collecting the

garbage.

Backpacking simply means pushing the ejector

blade rearward

against your payload

with the

throttle

manually advanced

(using the button

switch located near the body-mounted valve). The

compaction blades will be at their “home” position

during this “back packing”.

The LOADMASTER ELITE is designed to densify

properly to the advertised, rated payload

without

performing a single “backpacking” operation.

The valve known as the “synkpak” valve will allow

the ejector blade to

automatically

drift forward in a

controlled fashion. The operator will never need to

operate the hand-lever labeled “ejector” while

collecting garbage on the route.

When the body is “full” the ejector blade will have

drifted all the way forward (towards cab) and the

ejector’s telescopic cylinder will be seen to be

totally collapsed (retracted).

Continue

loading the

hopper until the sweep and slider blades are seen

to be not fully moving to their normal, full “home”

position. Then begin to use the slide and sweep

levers to “manually over-ride” the blade’s automatic

function. This will make extra force available to

help push the blades to their “home” positions as

the payload densification continues. Soon…even

“manually-overriding” will not get the blades “fully”

to their home positions and the loading hopper will

“shrink” quite a bit. The LOADMASTER is now truly

“full” and you must unload.

Travel to the unloading site. Follow the same

information given in the earlier section called

TRAVELING.

Remember to position the rocker

switches of OFF to disengage PTO and disable the

throttle advance.

DO NOT OVERLOAD THE PACKER AND CHASSIS. DO NOT

EXCEED THE MANUFACTURER’S POSTED GROSS VEHICLE

WEIGHT RATINGS (OVERALL AND “PER AXLE”). GROSS

VEHICLE WEIGHTS MUST ALSO MEET APPLICABLE FEDERAL,

STATE, AND LOCAL LAWS. FAILURE TO COMPLY COULD CAUSE

POOR HANDLING AND OUT OF COMPLIANCE BRAKING AND

CAUSE SERIOUS INJURY OR DEATH.

Sec02-19

EJECTOR BLADE

HAS DRIFTED

FULLY

FORWARD, but

continue to load

and pack several

hopper’s full…if

you choose to

EJECTOR

CONTROL

LEVER

Table of contents

Other LOADMASTER Truck manuals