©2014 HYSTER COMPANY

TABLE OF CONTENTS

General .....................................................................................................................................................................1

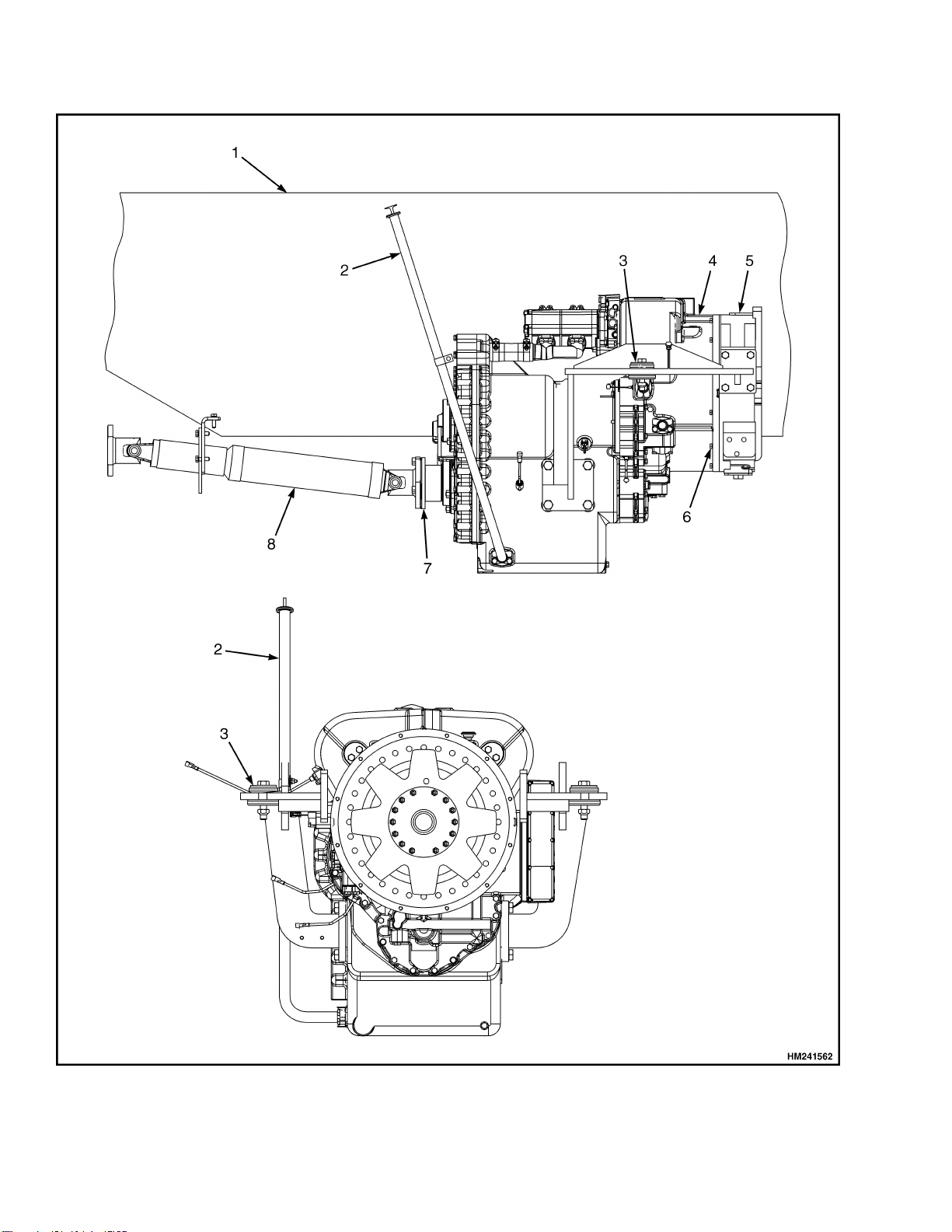

Transmission Repair ............................................................................................................................................... 1

Remove ................................................................................................................................................................ 1

Disassemble .........................................................................................................................................................4

Transmission Case, Disassemble ...................................................................................................................5

Converter Housing, Disassemble .................................................................................................................28

Reverse and Second-Speed Clutch ...............................................................................................................30

Reverse, Disassemble ...............................................................................................................................30

Second-Speed Clutch, Disassemble ......................................................................................................... 35

Forward Clutch, Disassemble ...................................................................................................................... 37

Third-Speed Clutch, Disassemble ................................................................................................................43

Fourth-Speed Clutch, Disassemble ............................................................................................................. 47

First-Speed Clutch, Disassemble .................................................................................................................50

Output Shaft, Disassemble .......................................................................................................................... 56

Turbine Shaft, Disassemble .........................................................................................................................57

Impeller and Baffle, Disassemble ................................................................................................................ 59

Impeller Cover and Turbine Assembly, Disassemble .................................................................................62

Pump Drive Gear, Disassemble ................................................................................................................... 63

Clean and Inspect ............................................................................................................................................. 64

Housings ........................................................................................................................................................64

Oil Seals and Gaskets ...................................................................................................................................65

Bearings ........................................................................................................................................................ 65

Gears and Shafts .......................................................................................................................................... 65

Assemble ............................................................................................................................................................65

Pump Drive Gear, Assemble ........................................................................................................................ 65

Impeller Cover and Turbine, Assemble .......................................................................................................66

Impeller and Baffle, Assemble ..................................................................................................................... 67

Turbine Shaft, Assemble ..............................................................................................................................70

Output Shaft, Assemble ............................................................................................................................... 72

First-Speed Clutch, Assemble ......................................................................................................................73

Fourth-Speed Clutch, Assemble .................................................................................................................. 80

Third-Speed Clutch, Assemble .....................................................................................................................85

Forward Clutch, Assemble ........................................................................................................................... 90

Reverse and Second-Speed Clutch ...............................................................................................................97

Second-Speed Clutch, Assemble .............................................................................................................. 97

Reverse Clutch, Assemble ......................................................................................................................100

Converter Housing, Assemble ....................................................................................................................106

Transmission Case, Assemble ....................................................................................................................110

Install ...............................................................................................................................................................131

Control Valve With Solenoid Cover ....................................................................................................................134

Remove ............................................................................................................................................................ 134

Install ...............................................................................................................................................................134

Control Valve Disassemble and Assemble .....................................................................................................136

Control Valve Cover Removal ........................................................................................................................ 136

Control Valve Components .............................................................................................................................136

Disassemble ................................................................................................................................................ 136

Install .......................................................................................................................................................... 136

Control Valve Cover Installation ................................................................................................................... 137

Full Flow Control Valve Repair ..........................................................................................................................138

Remove ............................................................................................................................................................ 138

Table of Contents

i