Page 5C0-426-48AC Operator’s Manual

MC-425-14 Table of Contents

Contact Information.......................3

The Taylor-Dunn Corporation: .....4

Introduction 7

Who Should Read This Manual.............7

About This Manual.................................7

Glossary of Terms............................8

Conventions .....................................10

Signal Words and Their Denitions:.......10

Safety Alert Message.............................10

Responsibilities................................11

Of the Owner..........................................11

Of the Operator......................................11

Of the Passengers ................................11

Of the Service Personnel.......................11

Vehicle Modications ......................12

Replacement Parts ..........................13

Using Non-OEM Replacement

Components:..........................................13

About Your Vehicle 14

Licensing Requirements ........................14

Vehicle compliance................................14

Electric tow trucks:.................................14

How to Identify Your Vehicle .........15

Data Plate..............................................15

Where to Find Data Plate and Serial

Number..................................................15

Taking Delivery of Your

Vehicle 16

What To Do If a Problem is

Found................................................16

Driver Training 17

Driver Qualications...............................17

Vehicle Controls 18

Start Switch ..........................................18

Direction Control Switch.........................18

Headlight Switch....................................18

Hi-Low Speed Switch.............................18

Dash Display..........................................18

Emergency Stop Switch.........................19

Horn Switch ...........................................19

Dash Gauge...........................................20

Throttle Pedal.........................................21

Foot Brake Pedal...................................21

Steering .................................................21

Parking Brake, Automatic.......................21

Seat Adjustment.....................................22

Vehicle Operation 23

General Safety Guidelines.....................23

Seat Belts (optional)...............................25

All Seat Belt Types.................................26

Combination Lap and Shoulder Belts ....26

Lap Belts Only........................................26

Seat Belts While Pregnant.....................26

Safety Belt Maintenance........................26

Starting...................................................27

Driving....................................................28

Loading Cargo .......................................30

Transporting Pets...................................30

Vehicle Load Capacity, Denition...........31

Collisions or Accidents...........................31

Towing..............................................32

Draw Bar Pull (DBP), Denition .............32

Hitch Release.........................................33

Park Brake Bypass Switch.....................35

Charging Your Vehicle 36

Generic Safety Guidelines..............36

Charging Time........................................37

New Battery Break In.............................37

AC Power Source ..................................37

Storing and Returning to

Service 38

Storing Your Vehicle...............................38

Returning to Service ..............................38

Vehicle Maintenance 39

Daily Inspection......................................39

Pre-Operation Inspection.......................39

Interlock Switch Inspection............40

Start Switch ...........................................40

Operator Presence Switch.....................40

Brake Interlock Switch ...........................40

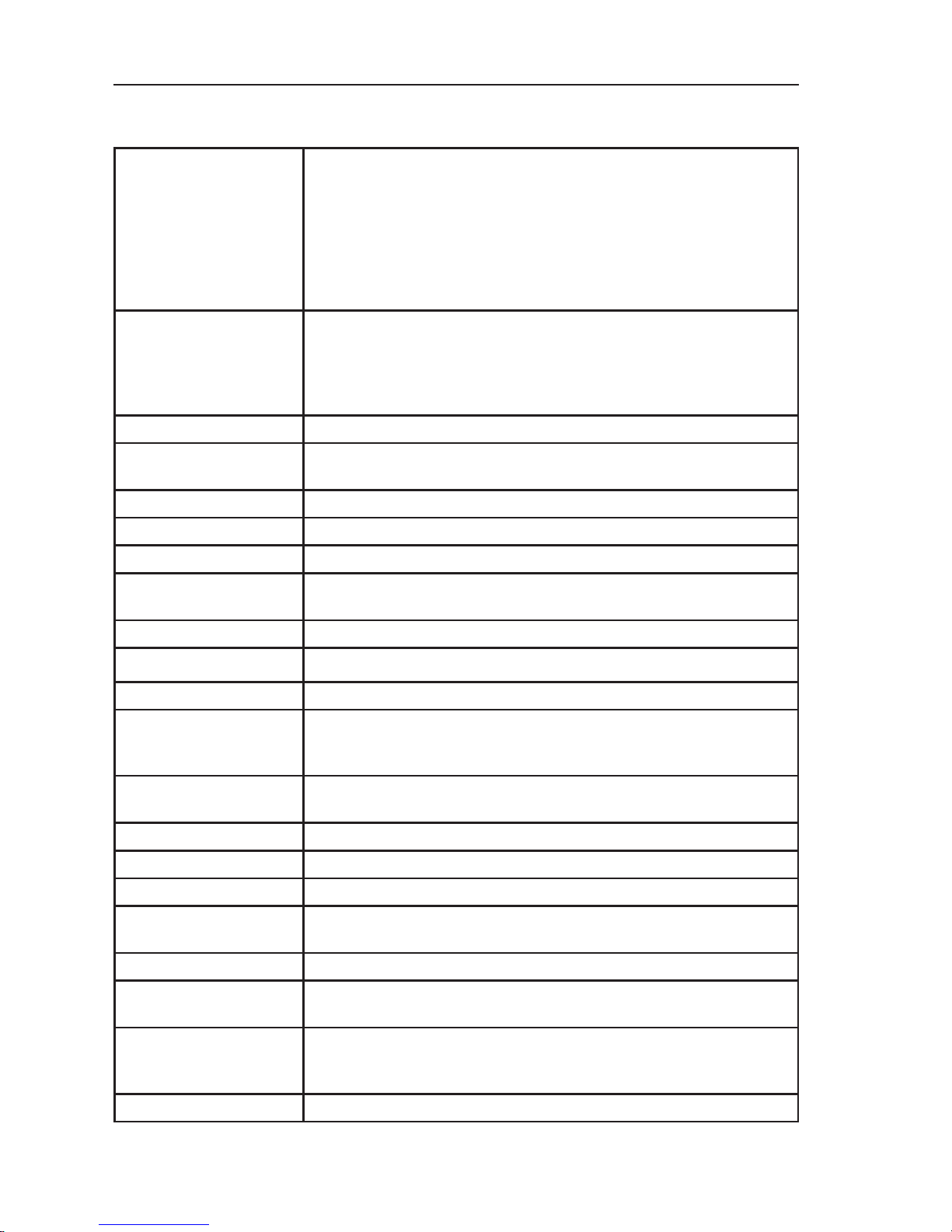

Maintenance Schedule....................41

Maintenance Guidelines for Severe Duty

Applications............................................41

Battery Maintenance.......................42

Cleaning.................................................43

Watering.................................................43