Loadrite LP950 User manual

LP950

Data Printer

MANUAL

OPERATORS

Data Printer

Model LP950

Document No. MAN-LP950-03

Issue Date: June 2004

Distributed Worldwide by:

)8 Walls Road, PO Box 12-607, Penrose, Auckland, New Zealand

+64-9-5257006

℡+64-9-5257373

www.loadritescales.com

Designed & Manufactured by:

www.actronic.com

This manual is copyrighted with all rights reserved. Under copyright laws, this manual may not be

copied in whole or in part or reproduced in any other media without the express written permission

of Actronic Ltd. Permitted copies must carry the same proprietary and copyright notices as were

affixed to the original. Under the law, copying includes translation into another language.

Please note that while every effort has been made to ensure that the data given in this document is

accurate, the information, figures, illustrations, tables, specifications, and schematics contained

herein are subject to change without notice.

Actronic Ltd assumes no liability in connection with the use of any Loadrite branded product.

© 2004 ACTRONIC LIMITED

i

Contents

1 General Description ...................................................................................................................1

2 Installation...................................................................................................................................2

Printer ............................................................................................................................................... 2

Electrical Connection .................................................................................................................... 3

Use with Data Capture System................................................................................................... 3

3 Printer Controls and Indicators.................................................................................................4

Function Of Buttons ...................................................................................................................... 4

Function Of Indicators.................................................................................................................. 4

Paper Roll Replacement ............................................................................................................... 5

Ribbon Casette Replacement......................................................................................................6

Baud Rate ........................................................................................................................................ 7

4 Specifications ..............................................................................................................................8

LP950 OPERATORS MANUAL

1

1 General Description

The LOADRITE LP950 printer is an accessory to the Loadrite weighing

system and is used to provide a permanent record of the weighing

operations as they are performed.

A detailed description of the 'print-outs' available is given in the Loadrite

Operating Manual.

The LP950 printer is supplied complete with:

• a fully adjustable mounting bracket

• a cable which may be plugged between the LP950 and the PRINTER/EDP socket at

the rear of the Loadrite Weigh Indicator.

• a spare ink-ribbon cartridge

Printing is performed by the dot-matrix impact method, utilising a

replaceable ink-ribbon cartridge, on to either:

• standard 57mm calculator plain paper or

• 2 layer NCR paper, (if a duplicate copy is required).

LP950 OPERATORS MANUAL

2

2 Installation

Printer

The LP950 printer should be installed at the appropriate mounting angle,

orientation and location to provide optimal conditions of use by the operator.

The following important rules should be observed:

1. The printer should not be located in direct sunlight or near any engine

compartments which can become excessively hot. (If necessary a

screen should be provided to shade the unit from direct heat and

sunlight).

2. To reduce the risk of entry of dust or moisture into the printer case -

• The unit should be mounted with the mouth of the paper exit slot in

a downwards direction.

• Care should be taken that externally accumulated dust, water and

oil etc. does not enter when the lid is opened to replace the paper

roll.

3. The printer should be located in such a way that it does not hinder the

normal operation of the machine controls or the visibility of the operator.

4. The printer should be located in a position where:

• The hinged lid can be opened without restriction, for replacement of

the paper roll or ribbon cartridge. [The lid is secured with a sprung

(not hinged) plastic clip. Bending this clip back too far may result in

its breakage.]

• The operator has easy access to the printer to operate the printer

controls.

LP950 OPERATORS MANUAL

3

Electrical Connection

All power supply and signal connections to the printer are contained within

the cable and connector assembly. No other connections are required.

Connection is made by plugging the cable between the socket located at

the rear of the LP950 and the PRINTER/EDP socket located at the rear of

the Loadrite Weigh Indicator. The power supply to the printer is switched

ON and OFF by the main power ON/OFF switch on the side of the Loadrite

indicator.

Ensure that the printer and cable are securely fastened and the cable

routed to avoid accidental physical damage. Special care is needed when

routing cable to avoid physical damage.

Use with Data Capture System

The Loadrite weighing system may be operated with both an LP950 Printer

and a Data Capture System.

Please consult your local LOADRITE dealer for the supply of the Data

Capture System.

LP950 OPERATORS MANUAL

4

3 Printer Controls and Indicators

The LP950 printer has two control buttons and three associated indicator

lights on the operator control panel.

Function Of Buttons

Paper Feed

This button is used to fast feed the paper out of the printer. It may be used

when required during paper loading.

On Line

The printer can be switched 'ON LINE' and 'OFF LINE' (i.e. print data or

don't print data) by successively pressing the ON LINE button. When the

printer is 'ON LINE' the associated indicator light will be on.

Test

If the PAPER FEED button is momentarily depressed while holding the ON

LINE button, the printer will print a test print. After printing, the printer will

be left in the OFF LINE state and the ON LINE button must be pressed

before the printer will operate.

Function Of Indicators

On Line

Indicates when the printer is 'ON LINE' and able to accept data for printing.

Ready

Indicates that the printer is ready to accept data for printing.

This indicator goes off when:

The printer is out of paper

The printer is 'OFF LINE'

The printer is busy printing and is unable temporarily to accept any

more data.

LP950 OPERATORS MANUAL

5

Paper

When the paper roll in the printer runs out, this indicator will flash on and

off. The 'READY' and 'ON LINE' indicators will go off. When the paper roll

is replaced, the 'PAPER' light will go out, but the ON LINE button must be

pressed to put the printer back 'ON LINE'.

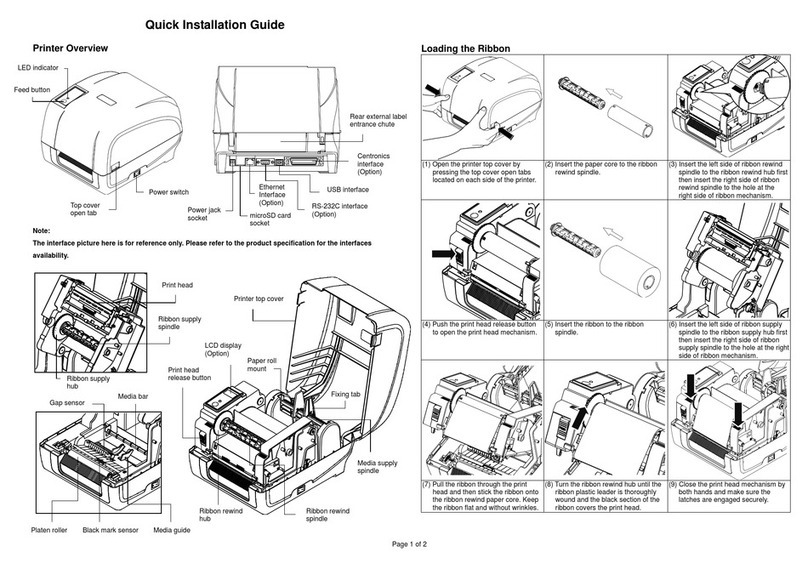

Paper Roll Replacement

IMPORTANT

Do not pull the paper roll backwards through the printer

mechanism as this will cause irrepairable damage!

The LP950 printer uses standard 57mm wide paper; either plain or 2-layer

NCR - if a duplicate copy is required.

The maximum roll diameter in either case is 57mm.

To replace the paper roll -

1.Open the hinged lid by springing the plastic clip and lift the lid wide open.

2.Remove the short length of paper remaining in the printing mechanism

by:

i) Using the PAPER FEED button, or

ii) Using the manual paper feed wheel, or

iii) Gently pulling the paper through the mechanism by hand, in the

NORMAL direction.

3.Remove the old roll core from the holding fingers and insert the new roll

with the paper direction as shown in the diagram.

PAPER LOADING PATH

FEED THROUGH

APPROX 6mm

RIBBON

CASSETTE

LP950 OPERATORS MANUAL

6

4.Free the end of the new paper roll, checking that the end is cut

reasonably square and is free from irregular or jagged tears. If

needed, trim the end with scissors.

5.Take the free end of the paper and gently push it over the plastic ramp

and into the mouth of the printer.

6.By using the manual feed knob (or the PAPER FEED button - if power is

connected), feed the paper through the mechanism and leave

approximately 6mm (1/4") of paper protruding from the mechanism.

Ensure that the paper lies between the ink ribbon and the cassette

housing.

7.Tighten the ink ribbon in its cassette by turning the star-shaped disc (on

right-hand end of cassette) two or three turns clockwise.

8.Close the case and secure the lid catch.

9.Press the PAPER FEED button until the paper emerges past the tear-off

edge.

10. Press the ON LINE button and the printer is now ready for operation.

Ribbon Casette Replacement

Printing on plain paper in the LP950 printer is achieved by use of an inked

ribbon which is contained in a replaceable cassette.

The ribbon will normally last for 2 to 3 rolls of paper.

To Replace the Cassette -

1. Open the lid of the printer. If there is paper in the mechanism, remove it by

cutting the paper close to the exit slot of the mechanism.

IMPORTANT

Do not pull the paper roll backwards through the printer mechanism as

this will cause irreparable damage!

2. Press down on the left-hand end of the cassette to pop the right-hand end up.

The cassette can now be lifted out.

3. The new cassette is fitted in the reverse order to removal, i.e. position the

right-hand end of the new cassette in the mechanism and gently push the left-

hand end home.

4. Ensure that the paper lies between the ink ribbon and the cassette housing.

LP950 OPERATORS MANUAL

7

Baud Rate

The LP950 printer communicates with the Loadrite weigh indicator at a

communication speed of 9600 baud. Earlier printers communicated at the

slower speed of 1200 baud.

If the LP950 printer is used with an LR810 indicator, the LR810 should

have the Baud Rate setting changed to 9600 baud. (Ask your Loadrite

dealer for details).

If the Baud Rate of the printer needs to be changed, your Loadrite dealer

can provide an instruction sheet.

LP950 OPERATORS MANUAL

8

4 Specifications

Case - Injection moulded polycarbonate.

Silicon rubber 'O' ring sealed.

UV resistant polyester front panel membrane

pushbuttons.

Environmental - Operating ambient temp. -10°C to +50°C.

The unit must not be operated in direct

sunlight.

Relative humidity 20% to 90%

Splashproof to IP52 (water from above only).

Weight - With mounting bracket : 1.6kg

Print Method - Dot matrix impact on plain paper.

Inking by auto-feed, replaceable, ribbon

cassette.

Paper - Standard plain calculator paper, 57mm wide,

up to 57mm diameter roll.

Optional - 2 layer NCR paper for duplicate

copy.

Print Format - 24 columns, 5 x 8 dot matrix characters, 1.7 x

2.7mm with one dot (0.37mm) descender.

Printable

Characters -

Full ASCII character set, plus extended set.

Print Speed - 1.7 lines/second typical

Paper Feed - 4.0 lines/second typical

Test Print - All printable alpha-numeric characters are

printed.

Indicator Lamps - LED type; On Line, Out of Paper, and Ready.

Control Buttons - On front panel - On/Off Line, Paper Feed,

Test Print Facility

Data Input - Serial ASCII, RS232 protocol with 'printer

ready' handshake. (Ready line goes 'low'

when buffer full or printer printing).

Baud Rate - 1200 or 9600 Baud set by internal jumper.

Data Buffer - 1 line (24 character) Printing of line initiated

when buffer full (24 char.) or LF, CR, CRLF

received. CR and LF are treated as a CRLF

pair.

LP950 OPERATORS MANUAL

9

Power

Requirements -

11.2 to 32V DC.

Average Current when Printing:

0.75A @ 12V DC input

0.4 A @ 24V DC input

Peak Current when Printing:

3.0A @ 12V DC input

1.3A @ 24V DC input

Standby Current:

100mA max

40mA typ. @ 24V

Power Input

Protection -

Series diode to protect against reverse

voltage. Input filter and high voltage pre-

regulator into switch-mode main regulator to

protect against "load-dump" and automotive

transients.

LP950 OPERATORS MANUAL

10

Notes

Other manuals for LP950

1

Table of contents

Other Loadrite Printer manuals