3

CHAPTER 1

AIRCRAFT DESCRIPTION

GENERAL

The C-130, manufactured by the Lockheed Company, is a medium range tactical transport

powered by four T-56 turboprop engines. The C-130 can operate from short, unprepared

surfaces, can back up under its own power, and has been adapted for many missions, with cargo

hauling, airdrop, and medical evacuation as the most common. The aircraft has been in

continuous production since 1955 with over 2,300 examples delivered by 2009.

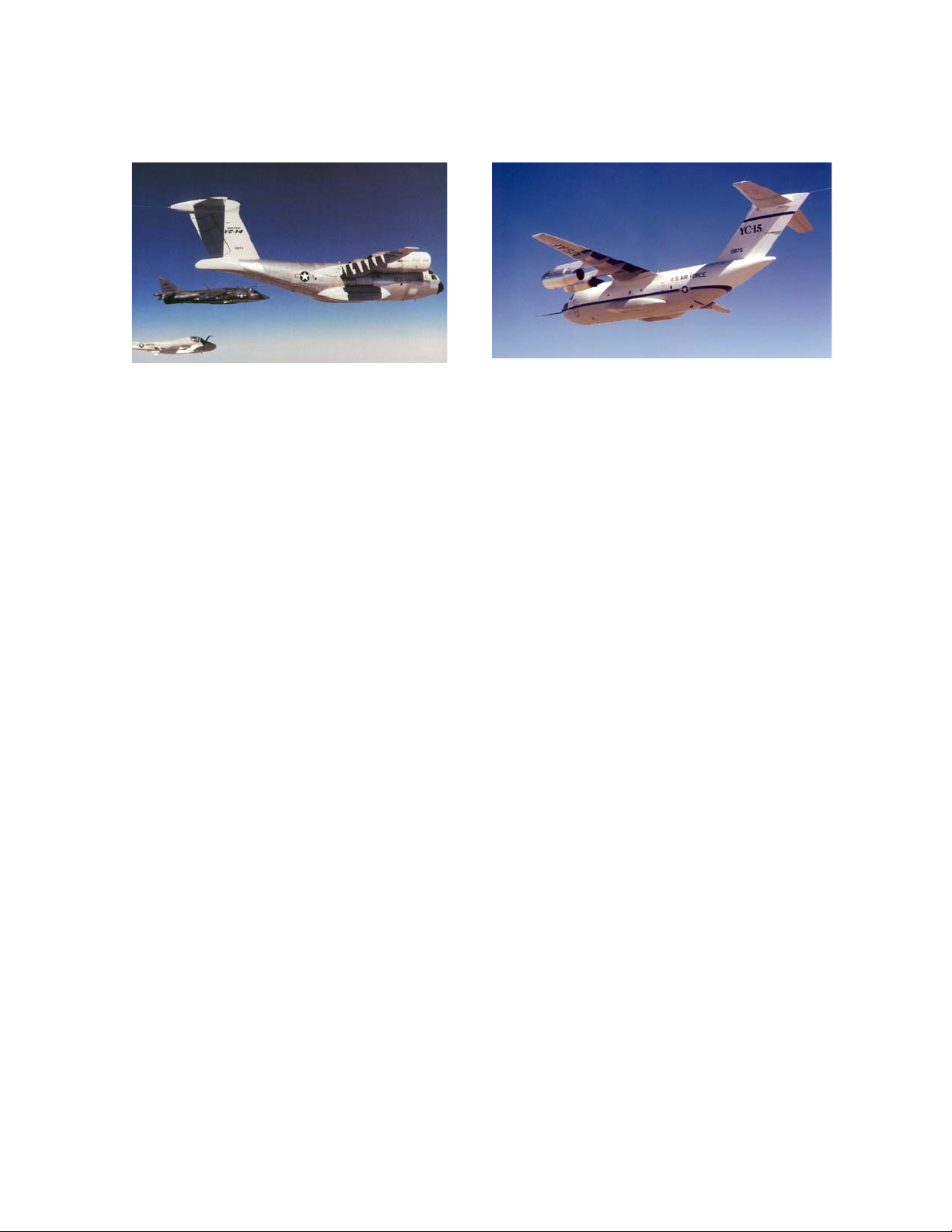

Development of the C-130 was a direct result of the Korean War, as the propeller powered

transports left over from WW II were unable to accomplish short take off and landings with

useful loads. A development contract was awarded to Lockheed, who produced the YC-130

prototype that first flew on 23 August 1954 from Burbank to Edwards AFB. Unlike transports

derived from passenger airliners, the C-130 was to be designed from the ground-up as a combat

transport with loading from a ramp at the rear of the fuselage. While the appearance of the C-130

was unremarkable, the design was innovative in introducing 3000 psi hydraulic boosted flight

controls, turboprop propulsion, and the high lift capabilities of the Lockheed-Fowler type wing

flaps.

DIMENSIONS

Wing span .............................................................................132 feet

Length .....................................................................................98 feet

Tail height ...............................................................................38 feet

WEIGHTS

Maximum combat weight ........................................ 175,000 pounds

Max normal start taxi...............................................155,000 pounds

Max landing weight ................................................. 155,000 pounds

Normal landing weight ............................................130,000 pounds

Representative operating weight................................88,000 pounds

Fuel capacity ..............................................................61,364 pounds

While not considered a true short takeoff and landing (STOL) aircraft, the C-130 can be operated

from runways as short as 3,000 feet, and can operate from unimproved surfaces. At weights less

than 135,000 lbs, up to 100 passes are permissible on an unimproved surface with a California

bearing ratio of 6 – soil consistency of a golf course fairway. The turboprop engines have

excellent foreign object damage (FOD) tolerance, and allow the aircraft to back up on its own

power, which is important for operations at airfields with limited ramp space. The low cargo

floor and ramp allow the aircraft to easily loaded, to include driving vehicles directly into the

cargo compartment and combat offloads – offloads of palletized equipment using the aircraft’s

own power.

The aircraft is normally flown with a crew of four; pilot, copilot, flight engineer, and loadmaster.

The flight engineer runs the aircraft systems, and the loadmaster runs the cargo compartment, to

include loading, unloading, center of gravity and weight calculation, passenger minding, and

airdrop rigging.