First Startup Zenit+

10

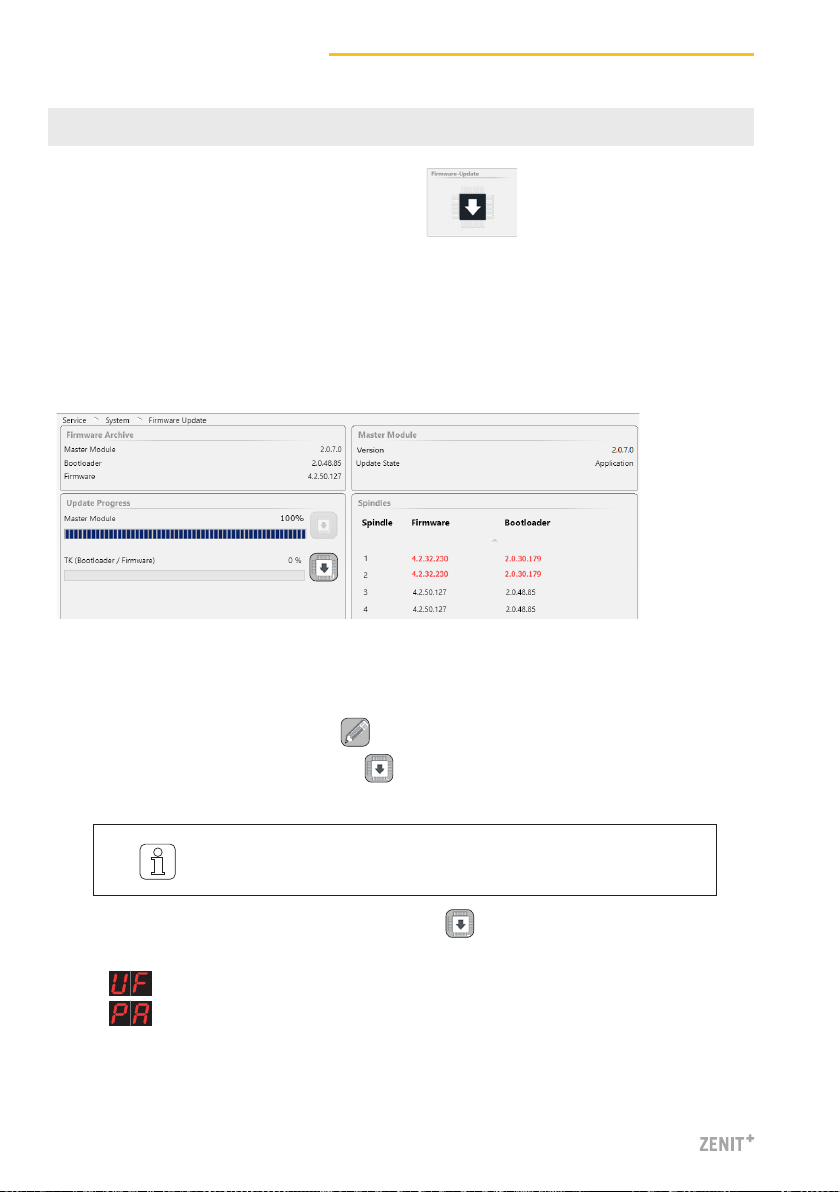

SERVICE >System >Firmware Update

7 Firmware Update

3. Start the TK (Bootloader / Firmware) update with .

»The status of the update is displayed in the progress bar.

»(Update Firmware) is displayed for all sensing heads which do not match.

»is displayed after a successful update.

4. Check firmware and bootloader version of the spindles.

5. Terminate the firmware update.

Master Module, Bootloader and Firmware Versions

The versions shown in the “Master Module” field and in the “Spindles” field must match the

versions shown in the “Firmware Archive” field.

Perform the Firmware Update

A firmware update must be performed if the versions do not match:

1. Activate the edit mode by tapping .

2. Start the Master Module update with .

»The status of the update is displayed in the progress bar.

»Red version number: versions do not match

»Grey version number: TK is offline

It can take some time (30s) until the update is terminated and the

respective next update button becomes active!