Pentair reserves the right to change the contents without notice page 5

AVID XA+ Control Position Monitor

Installation & Operating Instructions

5.1.2 Optional features - Falcon II

5.1.2.1 Momentary Override

Spring return momentary push type, must hold in to actuate. See Fig. 5A

5.1.2.2 Manual Locking Override

Manually depress palm button and rotate clockwise for maintained condition, must manually

disengage to return to original position. See Fig. 5B

5.1.2.3 No-Voltage Release (Latching)

With the coil first energized, the palm button is then manually moved and latched.

The inward movement of the palm button causes the valve to shift.

When the coil is de-energized, the palm button and latching mechanism are automatically

tripped, allowing the valve to return to its original position. See Fig. 5C

5.1.2.4 Hex Drive Maintained Override

Insert Allen key in hex head screw and rotate clockwise (4-5 turns) to shift spool. Valve

will stay put until hex head screw is rotated counter clockwise (4-5 turns) back to original

position. See Fig. 5D

5.1.3 Specifications

Operating pressure: 45 - 120 psig / 3.1 - 8.2 bar

Operating media: Non lubricated filtered air to 20 microns

5.1.4 Field wiring

Complete the electrical wiring in accordance with national and local electrical requirements.

The ground wire should be secure under the green screw. Check all screws for tightness.

A B

C

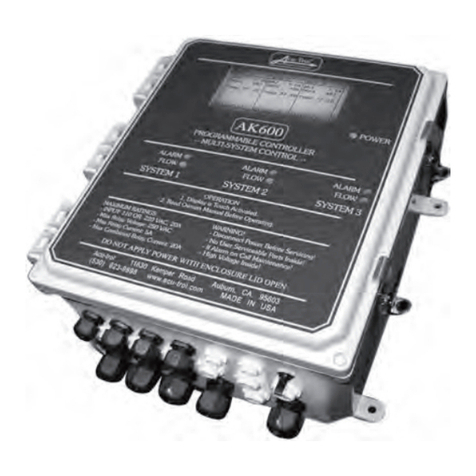

Figure 5

D

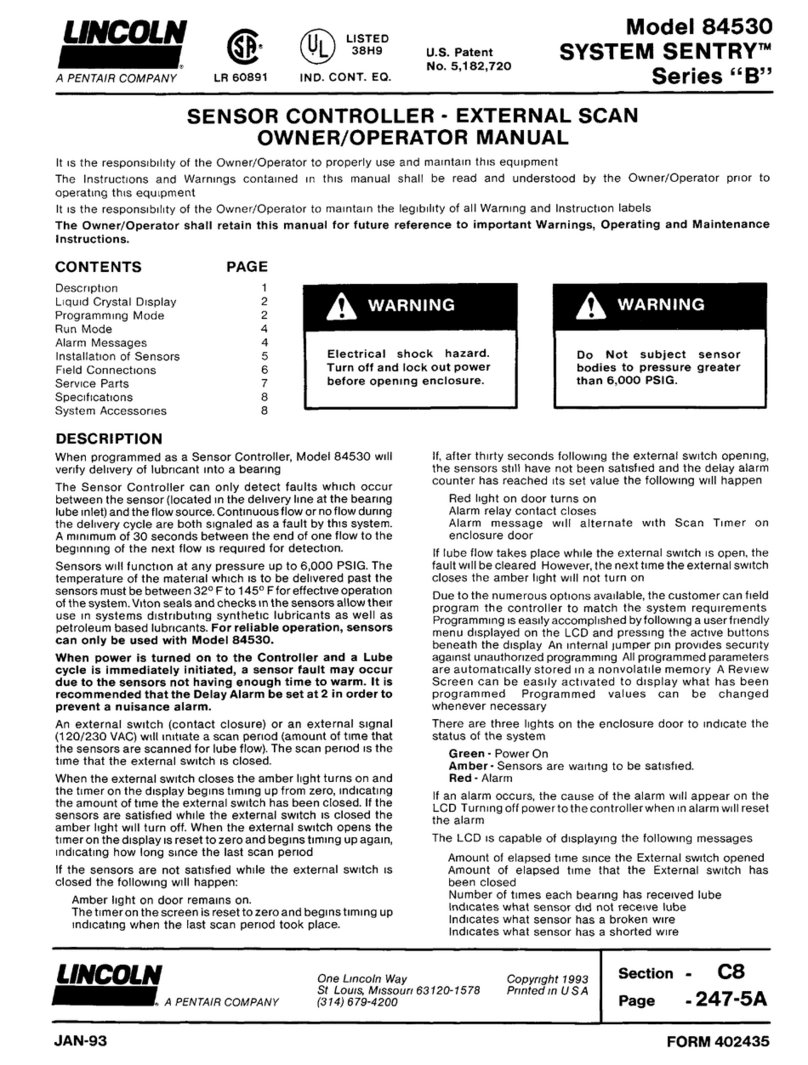

Figure 6 - Air Line Designation, 1/4” NPT or BSP air ports for inlet, outlet and exhaust

Spring Return valve

Description of operation:

Solenoid de-energized - air flows from

Outlet Port 2 to Exhaust Port 3.

Solenoid energized - air flows from Inlet

Port 1 to Outlet Port 2.

Spring Return valve

Description of operation:

Solenoid de-energized - air flows from

Inlet Port 1 to Outlet Port 2 and exhausts

from Port 4 to Port 5.

Solenoid energized - air flows from Inlet

Port 1 to Outlet Port 4 and exhausts from

Port 2 to Port 3.

Dual Coil valve

Description of operation:

Coil B de-energized - air flows from Inlet

Port 1 to Outlet Port 2 and exhausts from

Port 4 to Port 5.

Coil A energized - air flows from Inlet Port

1 to Outlet Port 4 and exhausts from Port

2 to Port 3.

A

B

5.1.5 (Air line) Installation considerations

Air mains and lines should be large enough to avoid excessive pressure loss under

conditions of maximum flow. Air lines should be installed with as few restrictions as possible

if the cost of compressed air is to be kept to a minimum. Sharp turns in piping should be

avoided for more efficient air flow and economical air power. It is advisable to pitch the

mains in the direction of air flow so that both gravity and air flow will carry the water to traps

or water legs located at frequent intervals.

To help in preventing condensed moisture from reaching the point of usage, down pipes

should never be taken directly from the bottom of air pipes or mains. Connection should be

made at the top of the main and a long radius return bend used.