3 | P a g e

PRINTING THIN-WALL MODELS

Desktop 3D printers are perfectly capable of producing great-flying R/C models durable enough to withstand

hangar rash and general use. However, aircraft designs contain a unique mix of thin surfaces and intricate solid

supports that require some practice to print perfectly. Keep the following tips in mind when printing your model.

QUALITY FILAMENT

Using good quality filament can be the key to successful thin-

wall prints. PLA is the filament of choice for these prints due to

its low warp and high interlayer bond strength. While most PLA

may seem identical, there’s a lot of variation in diameter

tolerance, moisture content, pigment consistency, and melting

properties. With poor quality filament, you may notice surface

imperfections, underextrusion on thin walls, and stringing

between interior features. We’ve had great results with eSun

PLA+ (sometimes sold as PLA Pro) and strongly recommend it for

printing Lofted Aero models.

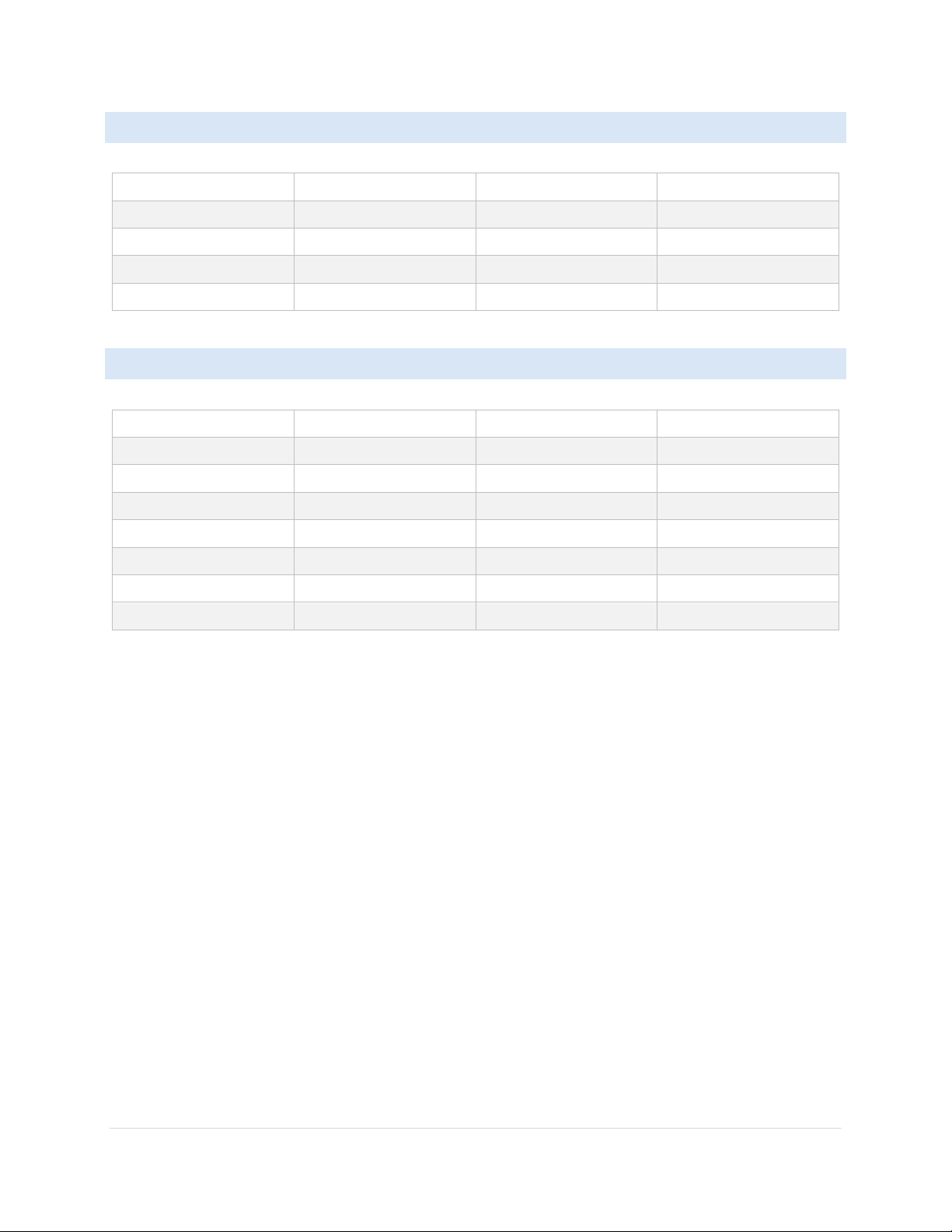

SLICING SETTINGS

The supplied pre-built gcode files are the safest bet to achieve properly-sliced parts. These files were prepared for

a printer with the following characteristics:

•1.75mm filament

•Direct-drive extruder

•0.4mm nozzle

•200mm x 200mm x 150mm print volume (or greater)

If your printer setup is different, Lofted Aero recommends using the Simplify3D slicer and the provided factory

files. Simplify3D includes many features ideal for thin-wall printing, including allowing multiple processes per print,

control over the layer start location, and good control of retraction settings. Additionally, the slicing process

organization scheme makes it easy to modify the processes in the provided files to suit your machine.

If you choose to try slicing the STL files with a different slicer, there are a few things to keep in mind:

•Most parts should be sliced with only 1 perimeter, no solid top & bottom layers, and no infill

•“Solid” parts (landing gear components, hatch latch, wing nut holders) should be sliced with 3 perimeters,

3 solid top & bottom layers, and ~40% infill

•Nozzle temperature should be 210-220 degrees with no cooling fan

•Bed temperature should be 50-60 degrees

•Retraction should be just enough to prevent stringing between features

•Extra length on restart should be just enough to prevent sparse extrusion at layer start

•Extrusion ratio should be adjusted until print weight equals the suggested part weight