Table of Contents

1 Important Safety Instructions............................................................................................................................................2

2 Product Overview.............................................................................................................................................................3

2.1 Product description............................................................................................................................................... 3

2.2 Product features.................................................................................................................................................... 3

2.3 Working principle ..................................................................................................................................................4

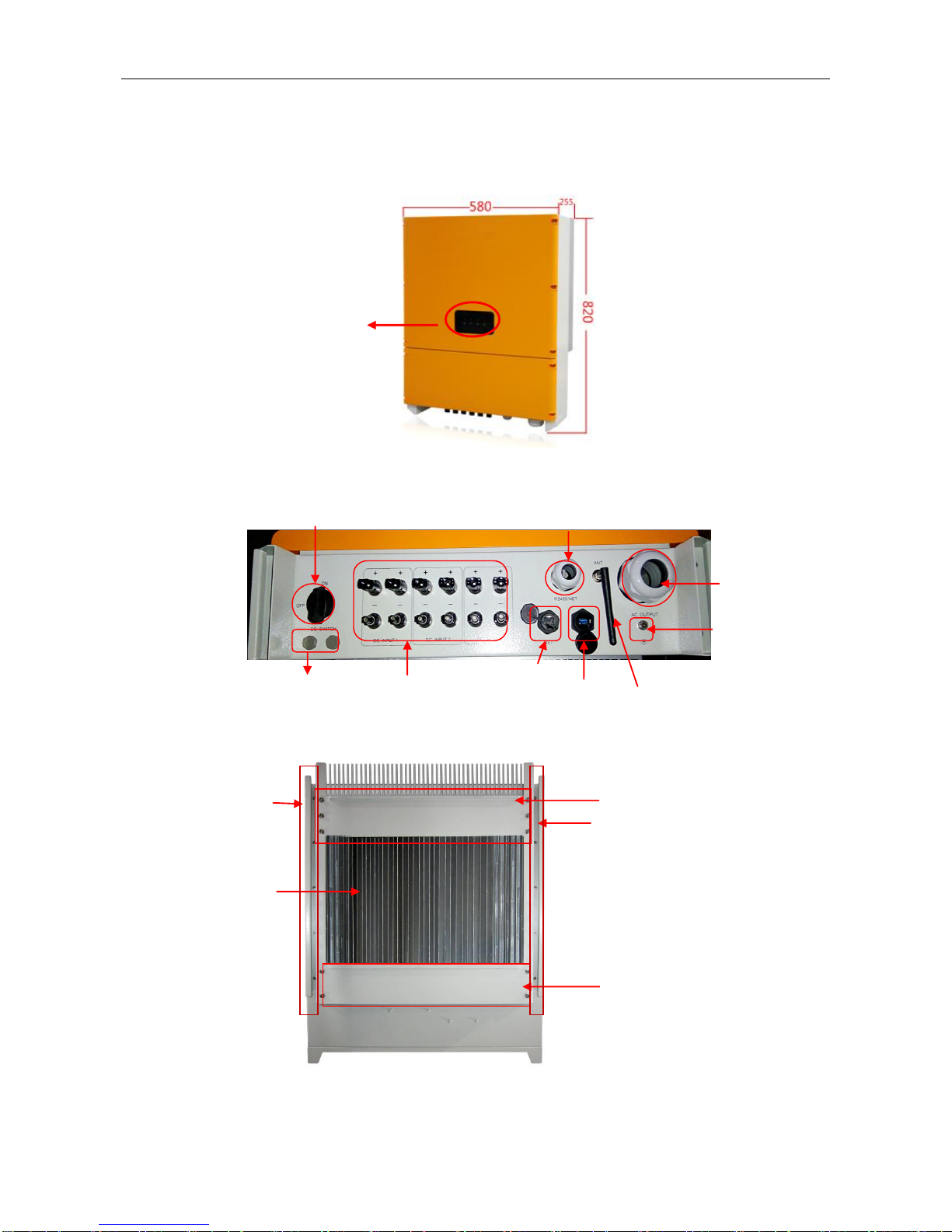

2.4 Product view .........................................................................................................................................................5

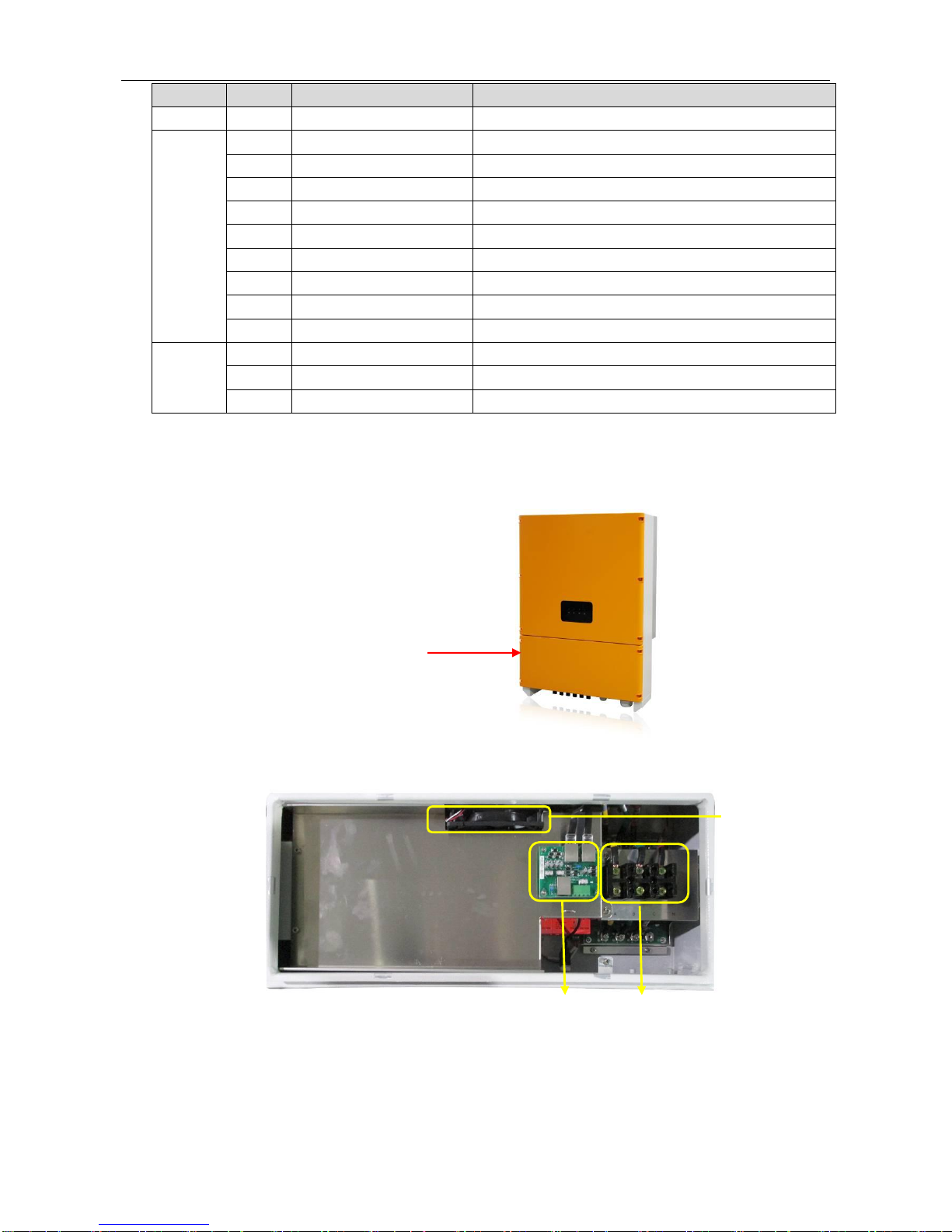

3 Installation........................................................................................................................................................................7

3.1 Inspection before installation.................................................................................................................................7

3.2 Transport............................................................................................................................................................... 7

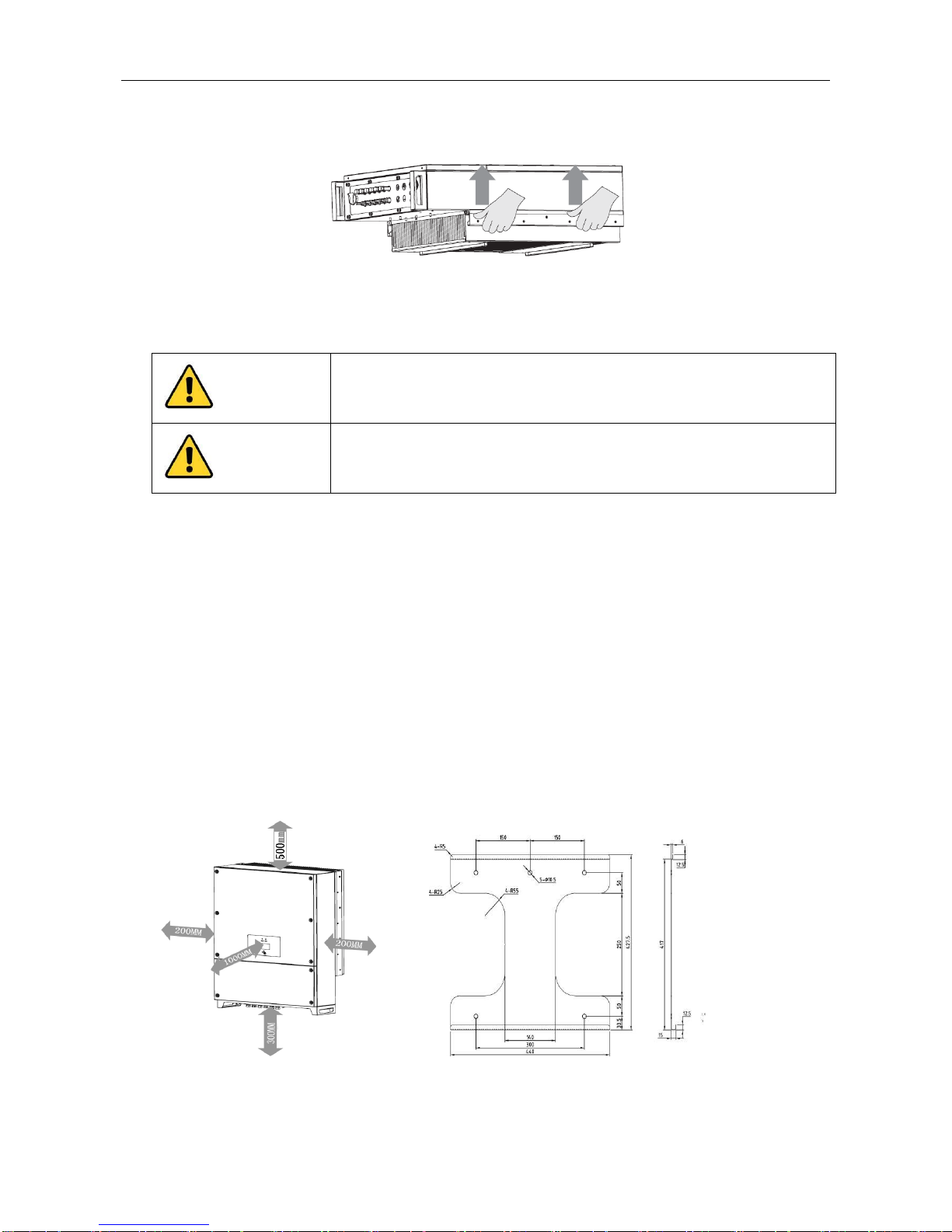

3.3 Mounting...............................................................................................................................................................8

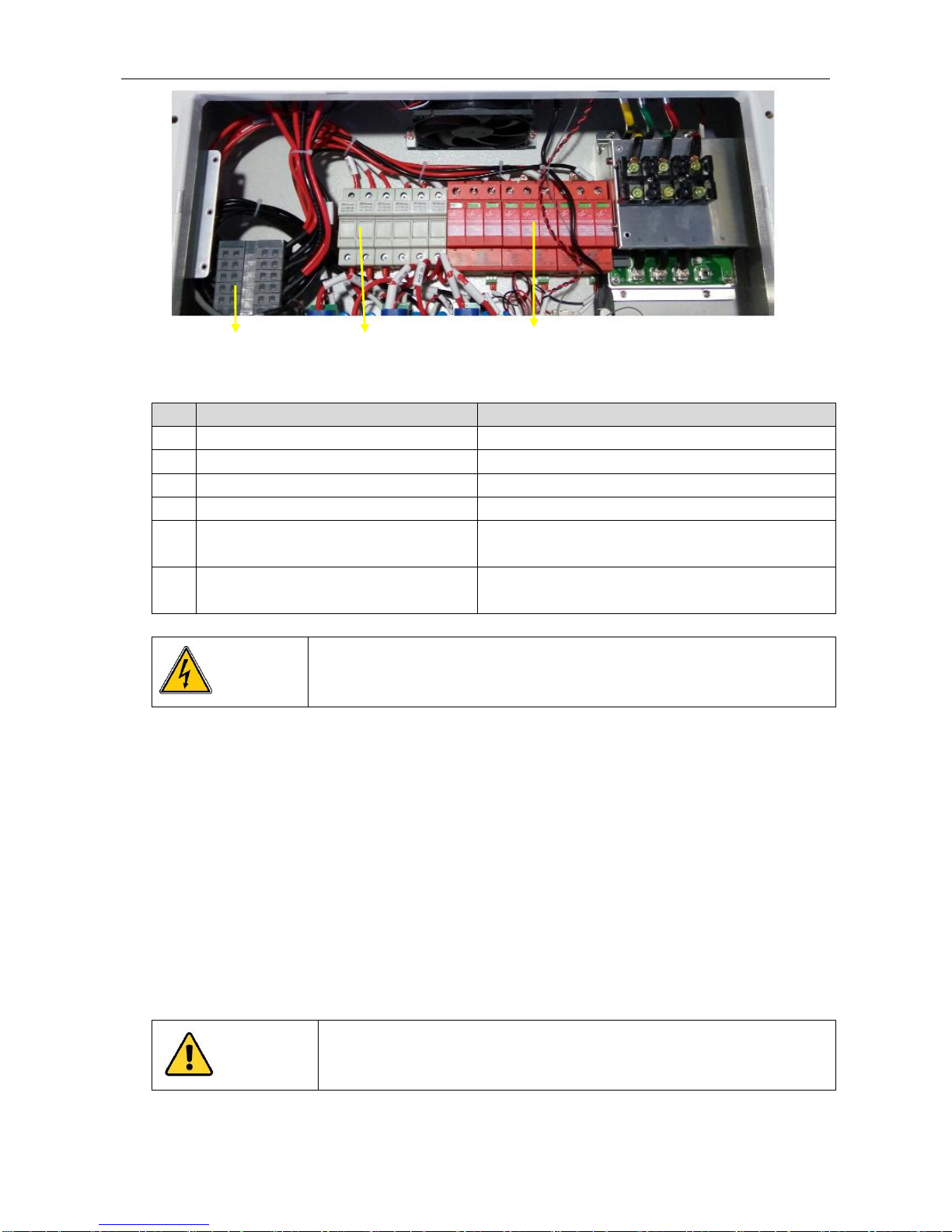

4 Electrical Connection........................................................................................................................................................9

4.1 Cable sizes ...........................................................................................................................................................9

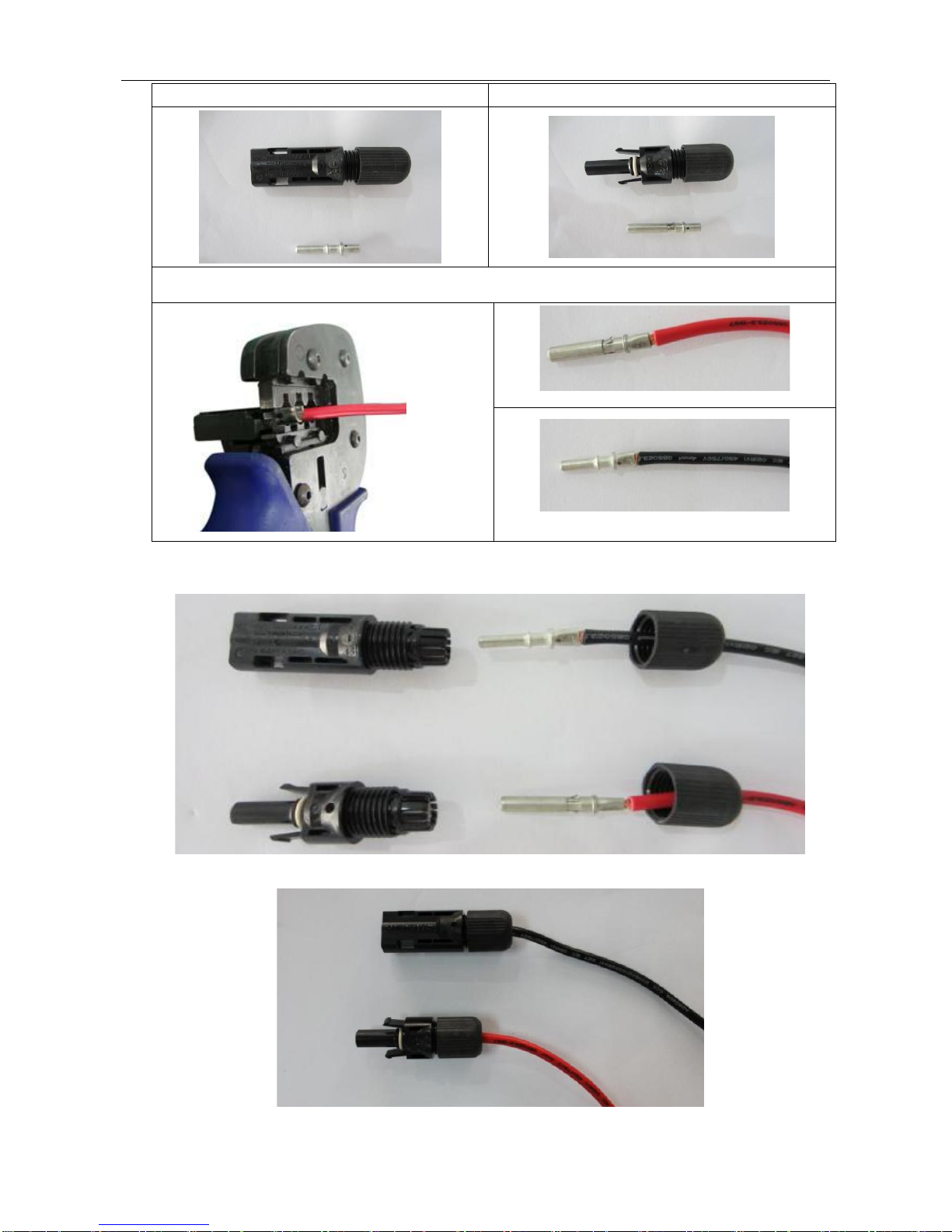

4.2 Making PV input cable and assembling connector................................................................................................ 9

4.3 Making the inverter output cable and installation instructions..............................................................................11

4.4 Making RS485 communication cable and connecting......................................................................................... 12

5 LED Indicator Lights.......................................................................................................................................................12

5.1 LED status information........................................................................................................................................ 12

5.2 View alarm information ....................................................................................................................................... 13

6 Operation .......................................................................................................................................................................14

6.1 Switching On and Off.......................................................................................................................................... 14

6.2 Operation modes ................................................................................................................................................ 15

6.3 Monitoring mode................................................................................................................................................. 16

7 Solar AssistantAPP Operation Manual ..........................................................................................................................17

7.1 Local monitoring APP (iOS &Android) installation.............................................................................................. 17

7.2 Operation of Solar Assistant APP(IOS).......................................................................................................... 18

7.3 Operation of Solar Assistant APP(ANDROID)................................................................................................ 20

7.4 How to distinguish Wi-Fi hotspot......................................................................................................................... 23

8 Troubleshooting..............................................................................................................................................................24

Appendix A........................................................................................................................................................................27