3

Contents

1.0 Before the rst lift... ............................................................................................ 4

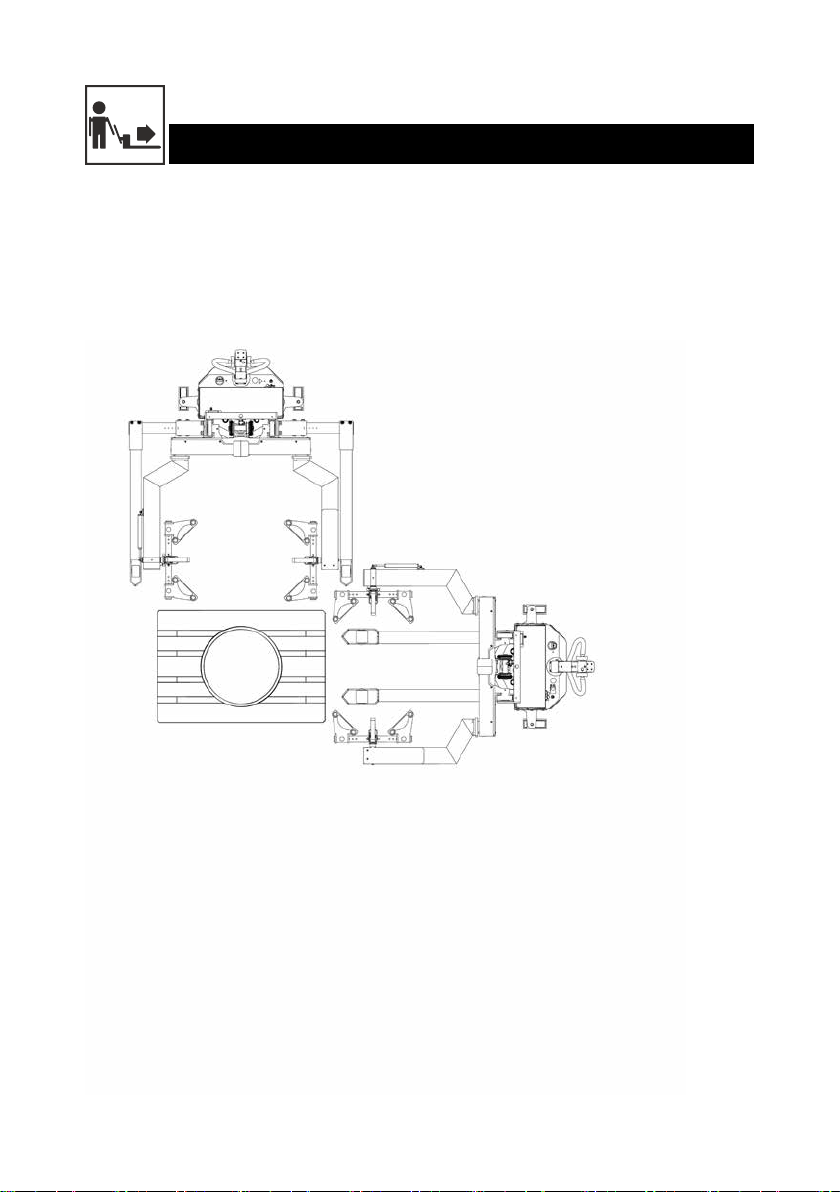

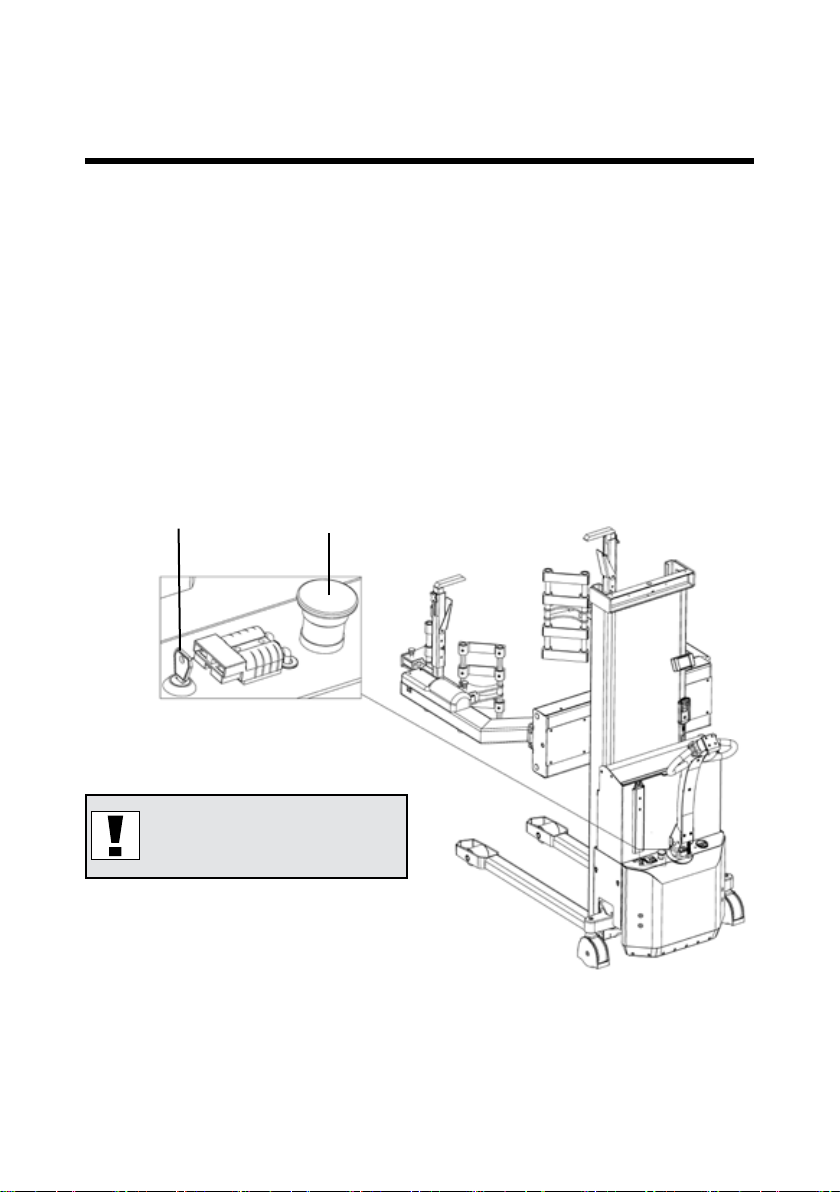

2.0 Functions and identications .......................................................................... 5

3.0 How to operate Multi drum turner ................................................................ 6

3.1 Handling of drums ............................................................................................................... 6

3.2 Use of the Multi drum turner................................................................................................ 7

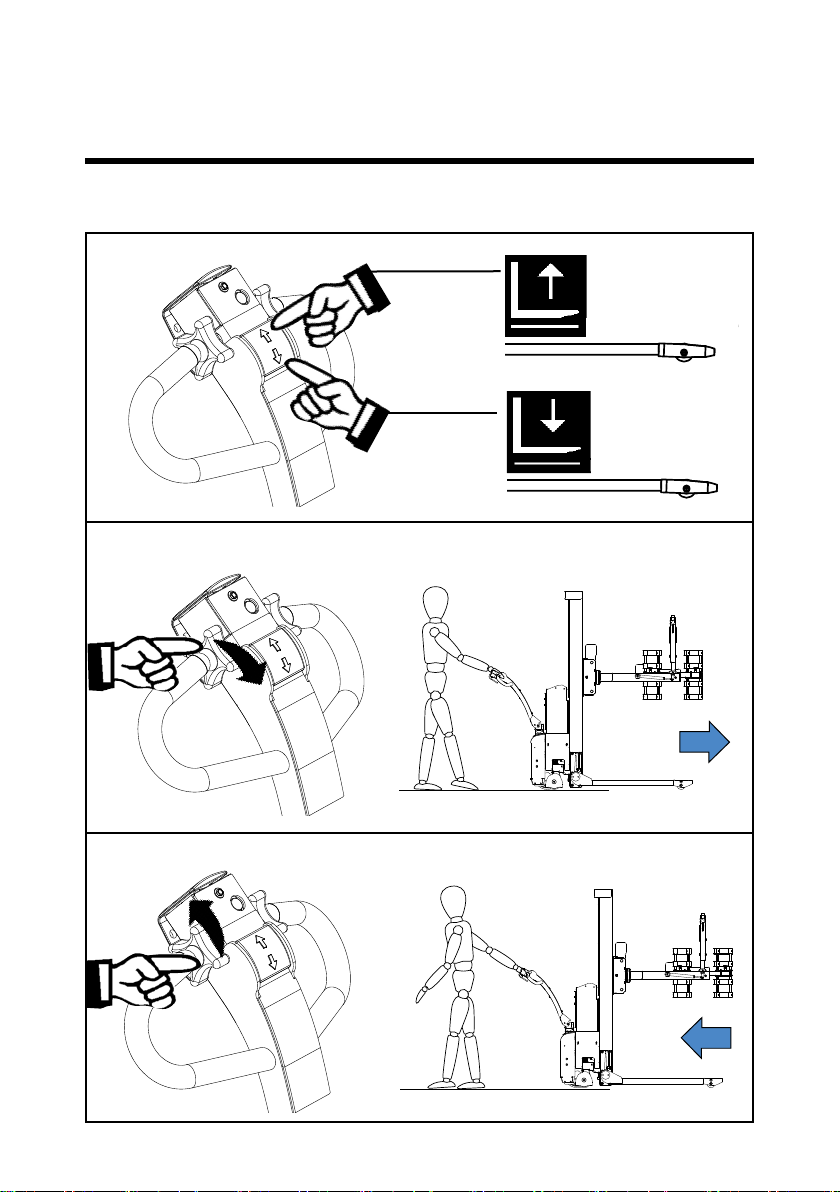

3.3 Handle functions.................................................................................................................. 8

3.4 Personal safety.................................................................................................................. 10

3.5 Remote control MR-1 / Lifting-Lowering-Rotation-Clamping..............................................11

3.6 Remote control / Lift and lower / Rotation ......................................................................... 12

3.7 Remote control / Clamping of drums................................................................................. 13

3.8 Remote control / Clamping of small drums and cans........................................................ 17

3.9 User-Interface LUI-1 Multi drum turner.............................................................................. 18

3.10 Setting up User-Interface LUI-1 Multi drum turner........................................................... 19

3.10.1 Home display................................................................................................................ 19

3.10.2 Display for Setup .......................................................................................................... 19

3.10.3 Setting of rotation speed............................................................................................... 20

3.10.4 Setting of stop position ................................................................................................. 20

3.10.5 Deleting stop positions ................................................................................................. 21

3.10.6 Setting the end stop limit for gripping arms (inner/outer).............................................. 21

3.10.7 Deleting end stop limit positions................................................................................... 22

3.11 Intended use .................................................................................................................... 23

3.12 Unintended use ............................................................................................................... 23

3.13 Unacceptable use............................................................................................................ 24

4.0 Optimum safety ..................................................................................................... 26

4.1 Safety regulations.............................................................................................................. 26

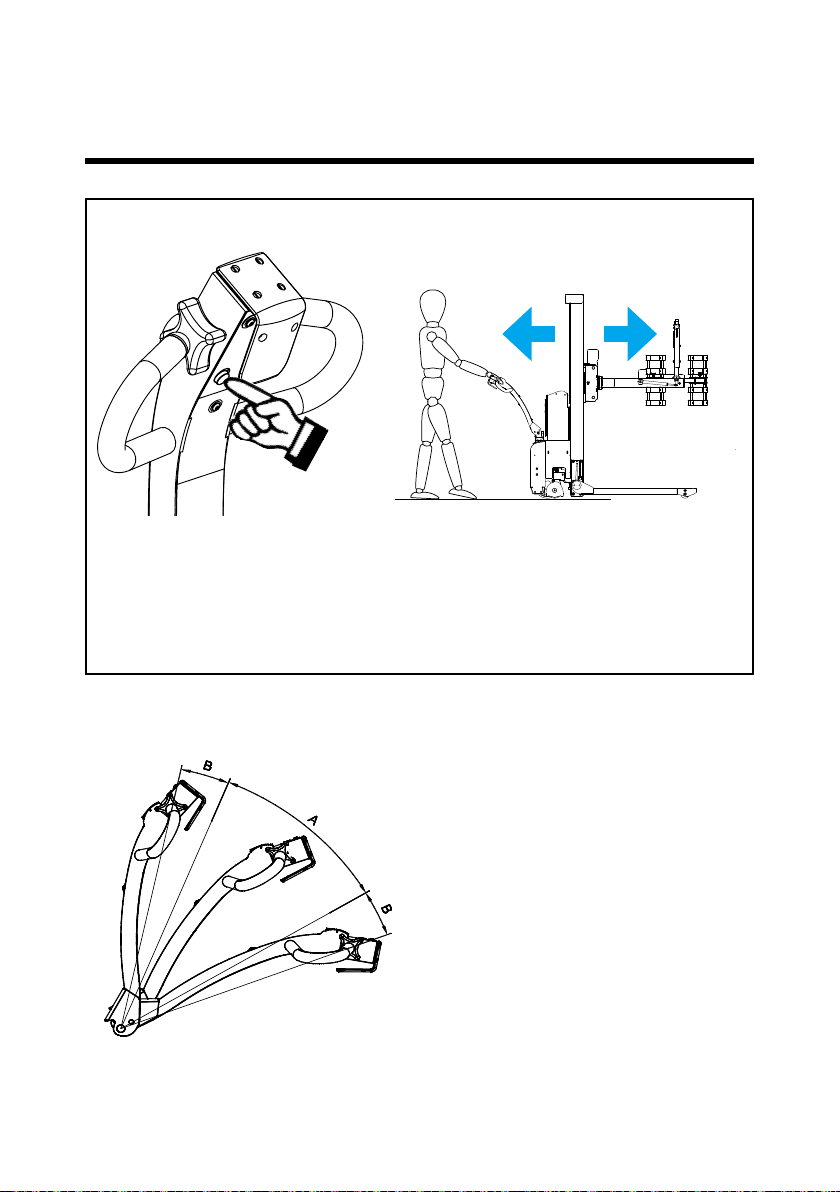

4.2 Rotation range................................................................................................................... 27

4.3 Driving loaded.................................................................................................................... 27

4.4 Rotation with load.............................................................................................................. 28

4.5 Emergency stop................................................................................................................. 28

4.6 Safety labels...................................................................................................................... 29

4.7 Additional safety advices ................................................................................................... 30

5.0 There must be a current supply... ............................................................... 31

5.1 Fuses - replacement.......................................................................................................... 31

5.2 Wirring connections........................................................................................................... 31

6.0 Maintenance............................................................................................................ 32

6.1 Cleaning ............................................................................................................................ 32

7.0 Good service after purchase ......................................................................... 33

7.1 Ordering spare parts.......................................................................................................... 33

7.2 Warranty/Compensation.................................................................................................... 33

7.3 Service and repair ............................................................................................................. 33

7.4 Warranty ............................................................................................................................ 33

7.5 Liability exemption............................................................................................................. 33