7

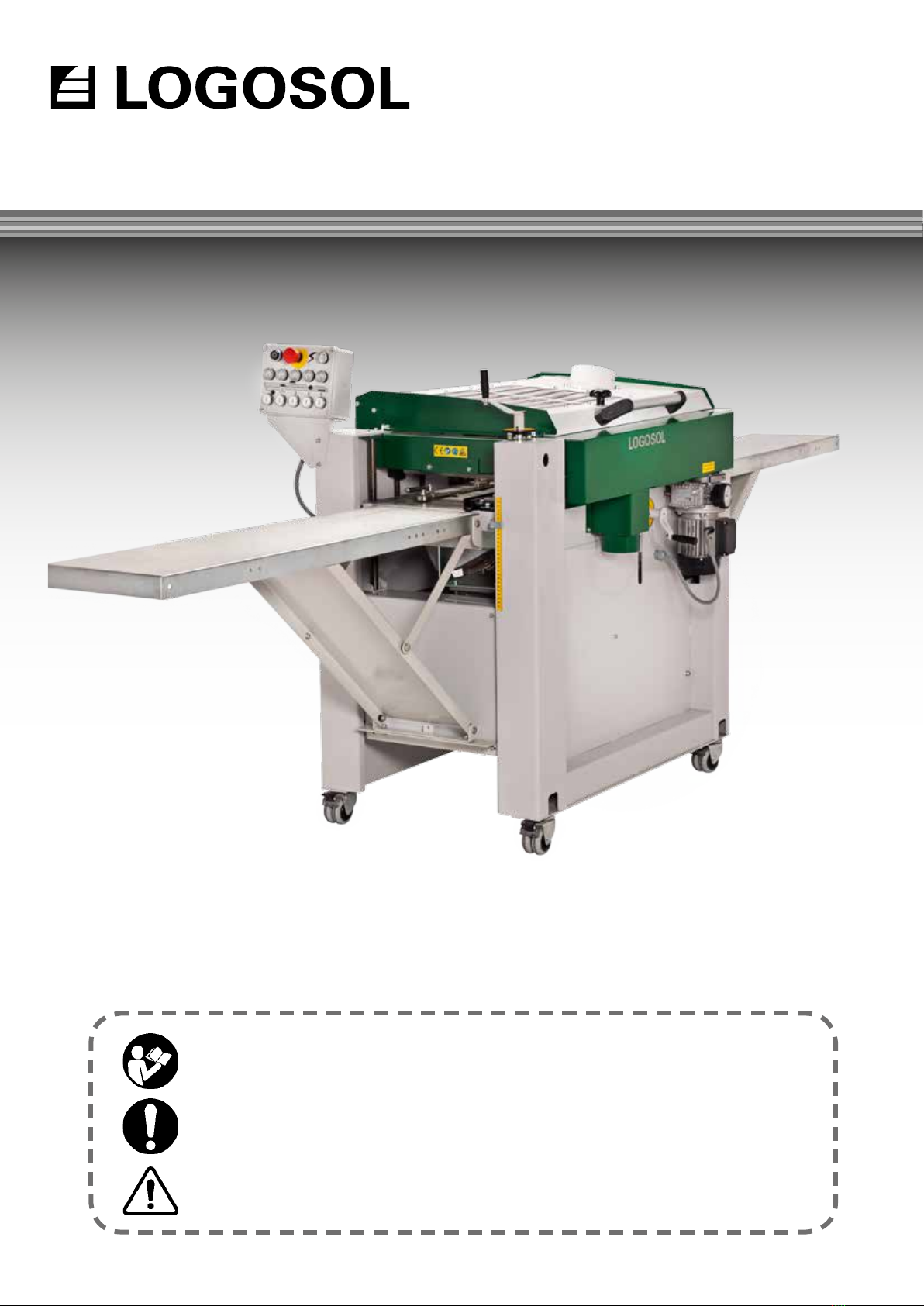

List of Components

Pos. Description Ref. no.

1 Crank for machine table, compl. 7502-001-0210

Crank 7502-001-1221

2 Protective plate, in-feed 7502-001-0007

3 Feed roller, grooved (4) 7502-001-0370

Bearing seat, compl. (10)

4 Bearing holder (8)

5 Switch pin 7502-001-0022

Main switch 7502-001-0024

6 Cover 7502-001-0480

Plexiglas 7502-001-0026

Aluminium front piece

hinge

Sealing strip 7502-001-0032

Handle 7502-001-0034

Locking handle, compl. 7502-001-0036

7 Cutter 2

Vertical cutter spindle, right thread 7502-001-0000

Spindle nut, right thread 7502-001-0010

Set of spacers 7502-001-0230

Universal cutter 7000-000-9092

Upper track bearing 7502-001-0052

Lower track bearing 7502-001-0152

Track ring, sga30 7502-001-0048

8 Cover support 7502-001-0056

9 Chip deector, cutter 2 7502-001-0058

10 Carriage, cutter 3 7502-001-0062

11 Cutter 3

Vertical cutter spindle, left thread 7502-001-0020

Spindle nut, left thread 7502-001-0030

Set of spacers 7502-001-0230

Universal cutter 7000-000-9092

Upper track bearing 7502-001-0052

Lower track bearing 7502-001-0152

Track ring, sga30 7502-001-0048

12 Carriage shaft (2) 7502-001-0410

13 Chip outlet, upper section 7502-001-0064

14 Upper horizontal cutter, 410 7502-001-0066

Planing knife, 410 7000-002-8410

Chip breaker, 410 7502-001-0140

Track bearing 7502-001-0152

15 Chip outlet, lower section 7502-001-0068

16 Feed roller, rubber 7502-001-0380

Bearing seat, compl. 7502-001-0075

17 Protective plate, exit 7502-001-0074

18 Bearing bracket 7502-001-0076

19 Trapezoidal thread bar 7502-001-0082

20 Table 7502-001-0084

Plastic runners (4)

21 Carriage locking handle 7502-001-0092

22 Belt gear housing, cutter 2 and 3 7502-001-0096

23 Belt gear, cutter 2 and 3

Poly V belt pulley, motor 7502-001-0300

Poly V belt pulley, spindle 7502-001-0154

Poly V belt 7500-001-2005

24 Electric motor, cutter 2 and 3 7502-001-0350

25 Lower bearing washer (4) 7502-001-0142

Bronze bushing 7502-001-0112

26 Chain sprocket, trapezoidal

thread bar (4) 7502-001-0114

27 Chain, table 7502-001-0116

Chain lock 7502-001-0118

Pos. Description Ref. no.

28 Electric motor, upper horiz. cutter 7502-001-0340

29 Motor support 7502-001-0122

30 Control panel

Control box 7502-001-0124

Control box cover (lid) 7502-001-0126

Emergency stop 7502-001-0128

Control button, ON, black 7502-001-0132

Lamp holder with cap 7502-001-0134

Lamp 7502-001-0138

31 Control box bracket 7502-001-0147

32 Trapezoidal thread bar with crank 7502-001-0144

33 Bearing bracket 7502-001-0146

34 Lower horizontal cutter, 300 7502-001-0500

Planing knife, 300 7000-002-8300

Chip breaker, 300 7502-001-0150

Track bearing 7502-001-0152

35 Chip outlet, lower horizontal cutter 7502-001-0156

36 Motor support bracket

Motor support 7502-001-0158

37 Electric motor, lower horiz. cutter 7502-001-0340

38 Case 7502-001-0162

39 Upper bearing washer (2) 7502-001-0164

40 Upper bearing washer (3) 7502-001-0166

41 Chain tensioner, compl. 7502-001-0168

42 Crank for carriage, cutter 3 7502-001-1220

Threaded bar, carriage, cutter 3 7502-001-0174

43 Chip outlet, cutter 3 7502-001-1172

45 Inner chipoutlet, cutter 3 7502-001-0176

46 Pressure roller 7502-001-0178

47 Cover for belt drive 7502-001-0173

48 Belt pulley, upper horizontal cutter 7502-001-0300

49 Support, carriage opening

50 Worm gear, motor 7502-001-0190

Strut, feeder motor 7502-001-0197

51 Feed chain 4 (model 3 & 4) 7502-001-2391

Feed chain 4 (older models) 7502-001-0391

52 Feed chain sprocket (8) 7502-001-0392

53 Feed chain 3 7502-001-0180

54 Fence 2 7502-001-0100

55 Fence bracket 7502-001-0080

56 Fence axle 7502-001-0196

57 Cover for feed roller chain 7502-001-0198

58 Chip channel, cutter 2 7502-001-1390

59 Chain 2 7502-001-0202

60 Chip deector, cutter 2 7502-001-0204

61 Chain 1 7502-001-0391

62 Fence 1 7502-001-0090

63 Pointer, height adjustment scale 7502-001-0206

Scale 7502-001-0208

64 L bracket 7502-001-0070

65 Flexi hose, cutter 3 7502-001-0240

66 Bracket 7502-001-0212

67 Electric box 7502-001-0214

68 Side roller 7502-001-0228

69 Adjusting plate 1 mm 7502-001-0310

Adjusting plate 1 mm 7502-001-0320

Adjusting plate 2 mm 7502-001-0330

70 Belt gear, lower cutter

Poly V belt pulley, motor 7502-001-0300

Poly V belt pulley, spindle 7502-001-0154

Poly V belt 7500-001-2007

71 Screw for belt tensioning 7502-001-0232

72 Screw for locking the belt tension