Contents

Safety rules 1

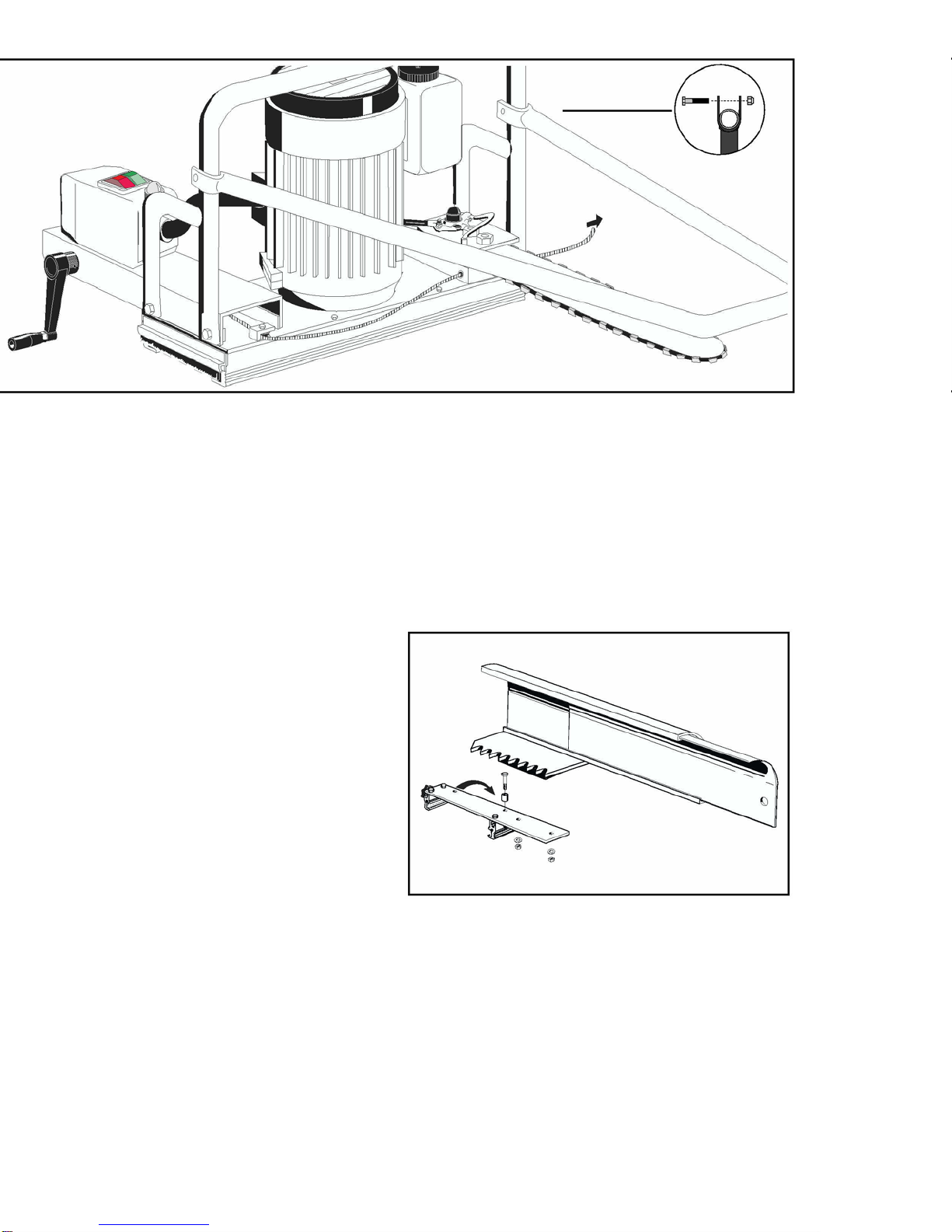

Assembly 2

Assembling bar and chain 3

Chain lubrication 4

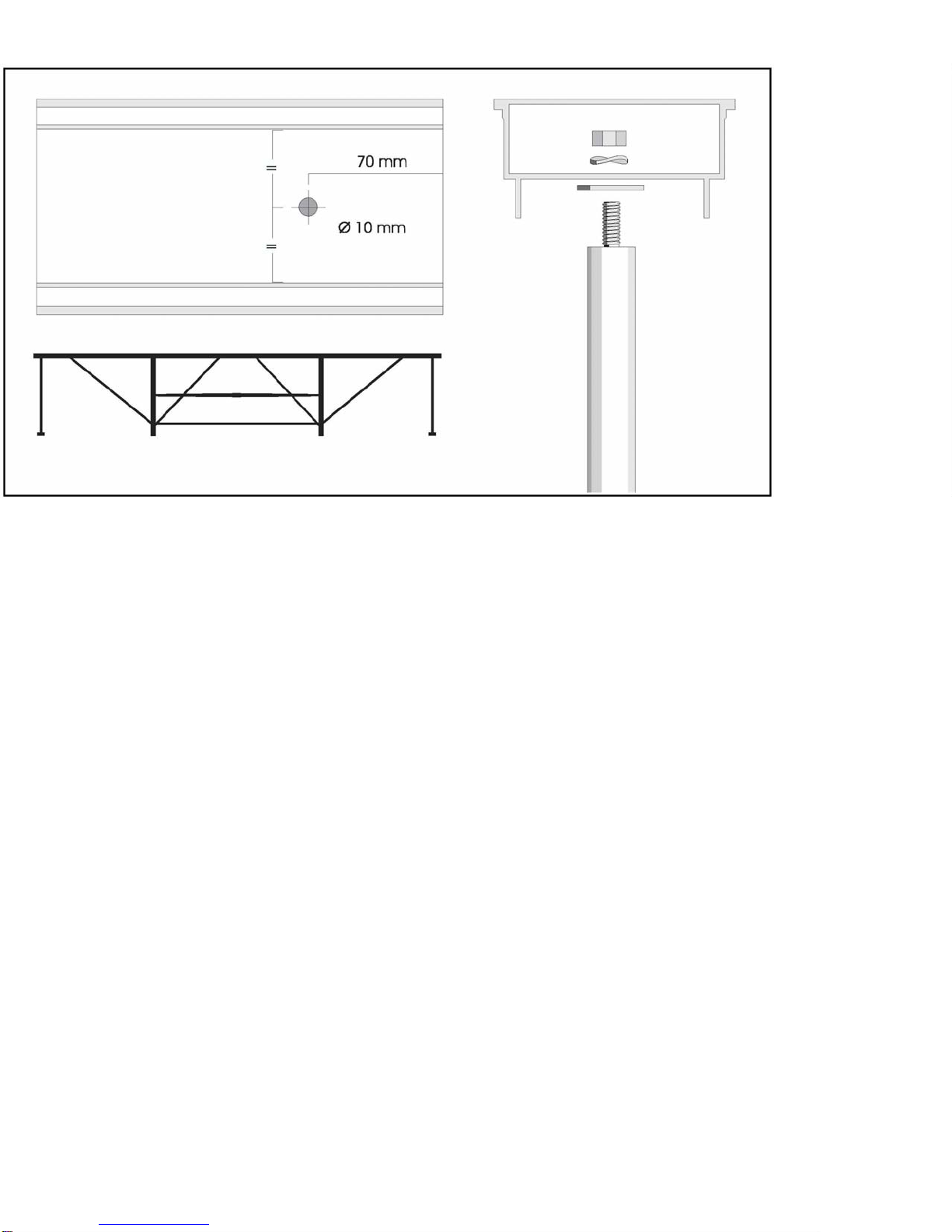

Frame support 5

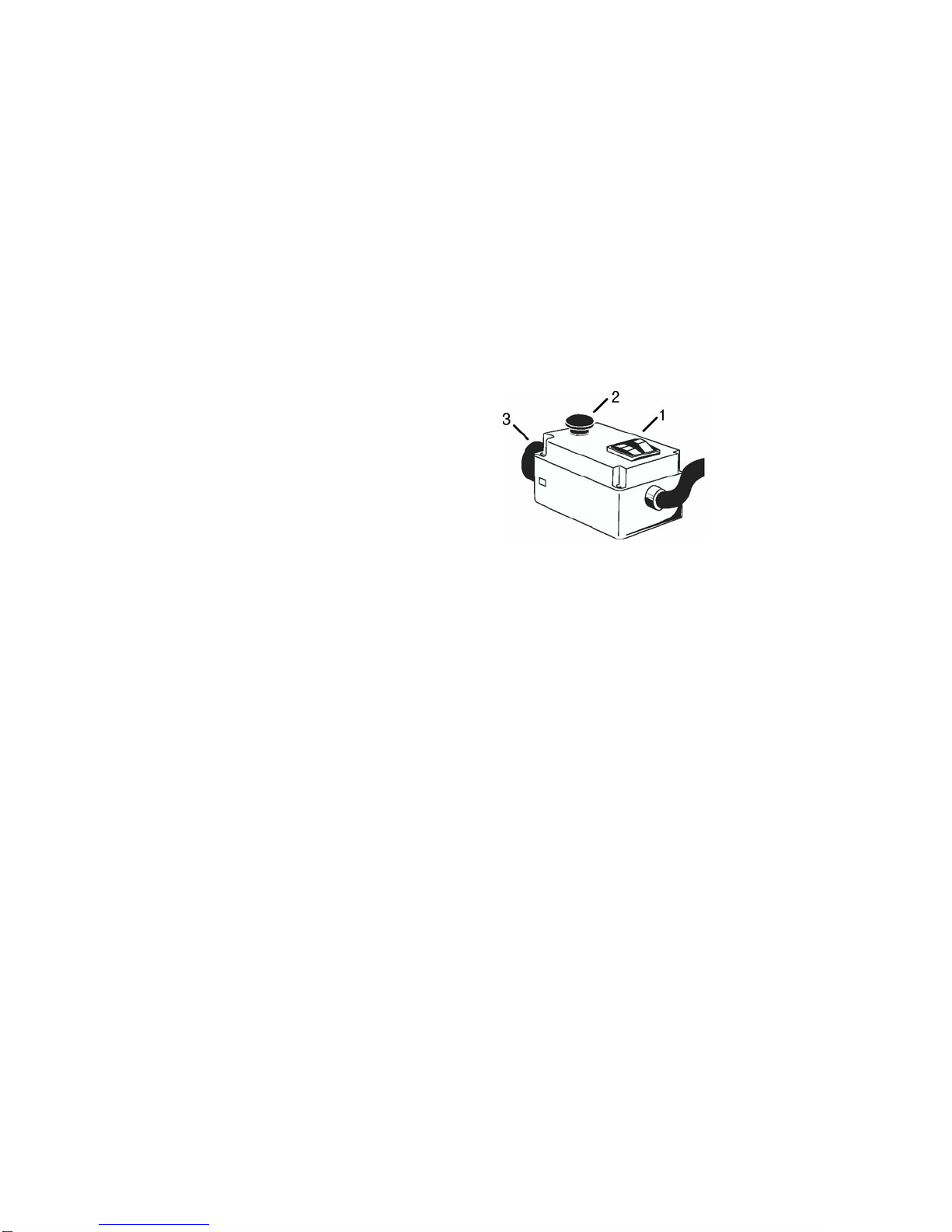

Control light and electric system 6

Cutting equipment 6

Maintenance 7

Belt tension 7

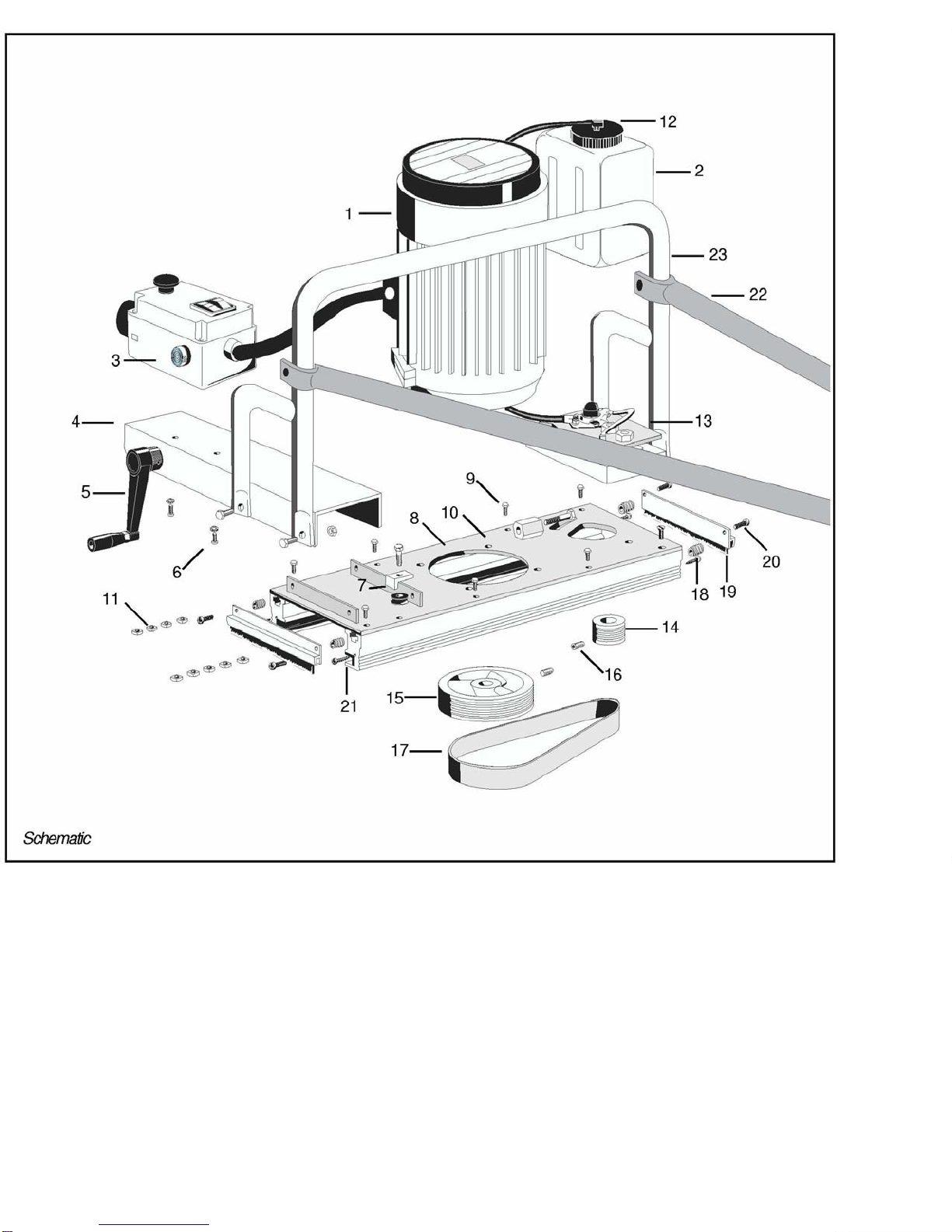

Schematic 8

Parts list 9

Circuit diagram 10

Technical specifications 11

EU manufacturer's declaration 11

Safety rules

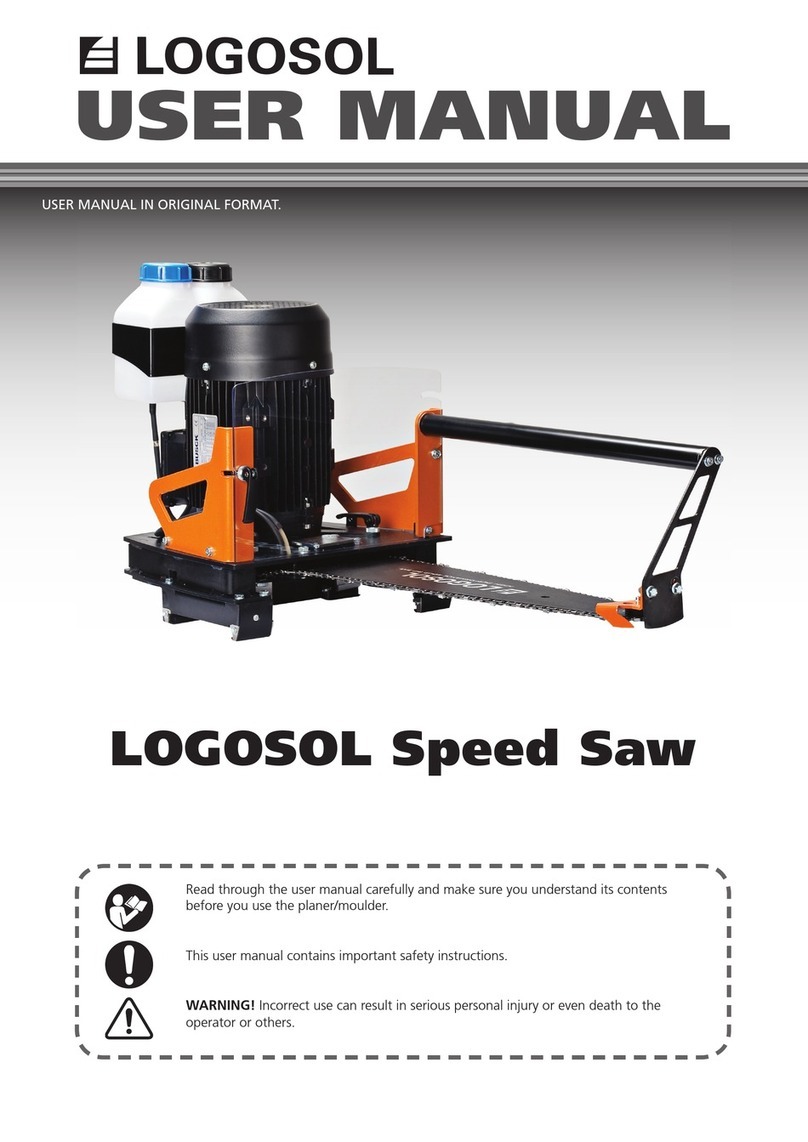

•The LOGOSOL E 5000 may only be

used for cross cutting in combination

with the LOGOSOL mini-saw mill.

Incorrect use can cause severe

injury. Always concentrate fully and

work carefully with the sawing unit.

•Attach support legs under the saw

mill guide rail before you attach the

sawing unit. Otherwise the saw mill

may tip over when there is no load

on the log bed.

•Do not wear loose clothing, scarves

and the like which can get caught in

the saw.

•Always check that the saw is solidly

fitted on the guide rail before

plugging in the cable. ln order to

prevent the saw from pitching off the

guide rail when started, ensure that

both plastic strips attach firmly to the

guide rail flange.

•Check that the electric cable runs

free along the entire sawing bed. Do

not step on the cable.

•Turn the saw off after each cut.

•in order to prevent unauthorized

use, never leave the saw

unattended when plugged in.

•Pull the plug out

- before replacing, adjusting and

cleaning the chain, or carrying

out any other maintenance.

- before touching any moving

parts.

- before removing the saw from

the sawmill.

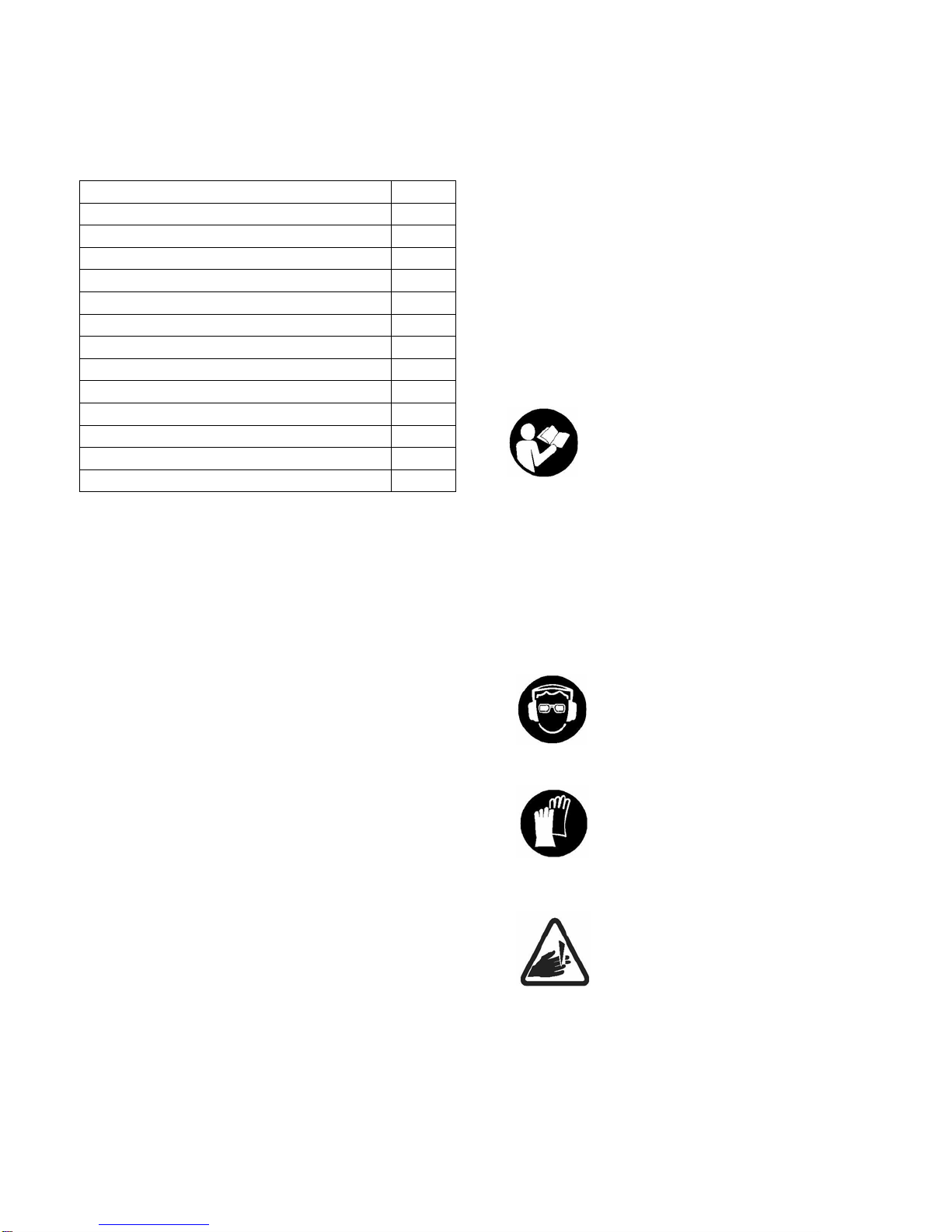

For your own safety, read ail

safety precautions carefully

and do not start the machine

before you have understood

ail of them. Do not allow

persons who have not read

the safety instructions to

operate the machine. You

should also read the

instruction manuals for the

LOGOSOL sawmill.

Use approved hearing

protection and safety glasses.

Even short exposures to high

frequency sounds can

damage your hearing.

Use gloves when you work

with the chain, as there is a

danger of cutting yourself.

Rotating saw chain: do not

insert fingers under the chain

protective cover or past the

sawmill guide rail. Always

stand behind the control arm

while sawing