78

Flowrate

Dispensing

Disp Vol 2.02mL:

Copy No. 10:

Disp Vol:

2.02 mL

Copy No.:

10

4.Footswitch G:

5.Back T. 1 2:."

Footswitch:

Gated Trigger

Back Time :

"1.2

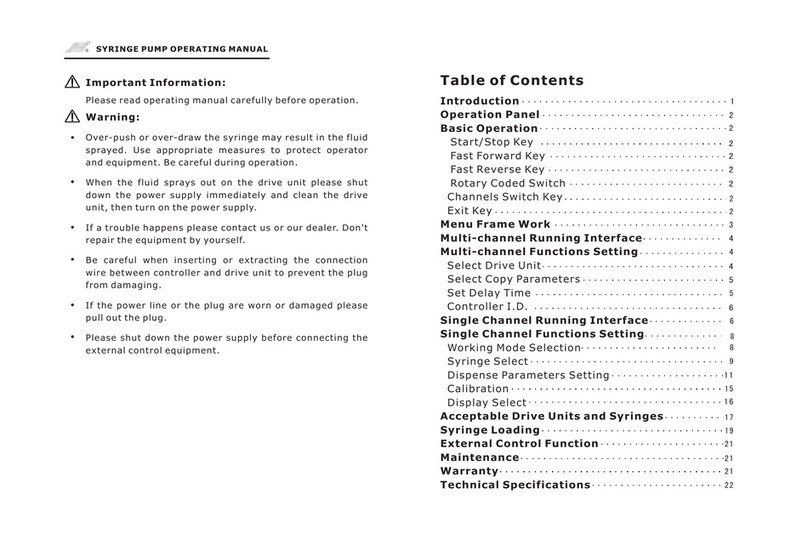

1.System Setting

2.Control Mode

1.System Setting

2.Control Mode

4.Footswitch G:

5.Back T. 1 2:."

1.System Setting

2.Control Mode

1.System Setting

2.Control Mode

3.Disp Setting

4.Calibration

1.System Setting

2.Control Mode

3.Disp Setting

4.Calibration

Disp Vol 2.02mL:

Copy No. 10:

Footswitch Setting

Footswitch has two kinds of working status.

Press footswitch, the pump starts running; Press footswitch again,

the pump stops.

The pump runs as long as the footswitch is pressed.

Set Footswitch

Press and turn to highlight the Footswitch line. Press to enter next

interface. Turn to select or , then press to confirm or

press to cancel the selection and return to previous menu.

The pump identifies the Longer Footswitch automatically. When the pump

connects the footswitch, the Key on operating panel is invalid no

matter the remote control is on or off.

Trigger:

Gated:

Knob Knob

Trigger Gated Knob

Exit Key

Note:

Start/Stop

Knob

Press and turn Knob

Press and turn Knob

Back Suction Time Setting

In dispensing and filling state, to prevent the liquids from dropping to cause

error when the filling stops, the pump will back-turn a suction angle to suck

back the liquids. The back suction is the same for each filling operations, it

doesn't influence the filling accuracy.

Set :

Press and turn to highlight the back suction time line. Press the to

enter next interface, turn to adjust , press to

confirm or press to cancel the adjustment and return to previous

menu.

Back Suction Time

Knob Knob

Knob Back Suction Time Knob

Exit Key

Control Mode

The pump has two kinds of working mode: and .

Set

Press and turn the to highlight control mode line. Press to enter next

interface, turn Knob to select control mode, press to confirm or press

to cancel the selection and return to previous menu.

Flowrate Dispensing

Control Mode:

knob Knob

Knob Exit

Key

Dispensing Setting

Before dispensing process, the parameters including Pump Head, Tubing,

Dispensing Volume, Copy number, Flow Rate and Pause time must be set.

Dispensing Volume: the volume that the pump dispenses between every time

interval.

Press and turn to highlight dispense setting line. Press to highlight

dispensing volume line. Press again to highlight the value of the volume.

Turn to select Dispensing Volume. Press to confirm or press

to cancel the selection and return to previous menu.

Knob Knob

Knob

Knob Knob Exit Key

Copy No.: the total filling number. Its range is 0 to 9999.

Press to highlight copy number line. Press Knob to enter next interface

Turn to select copy number. Press to confirm or press to

cancel the selection and return to previous menu.

If the is “0”, the dispensing process of the pump will continue until

press key or turn off the pump to stop dispense process.

form

Knob .

Knob Knob Exit Key

Copy No.

Start/Stop

BT100-1F OPERATING MANUAL BT100-1F OPERATING MANUAL