Longevity WeldMax 164i User manual

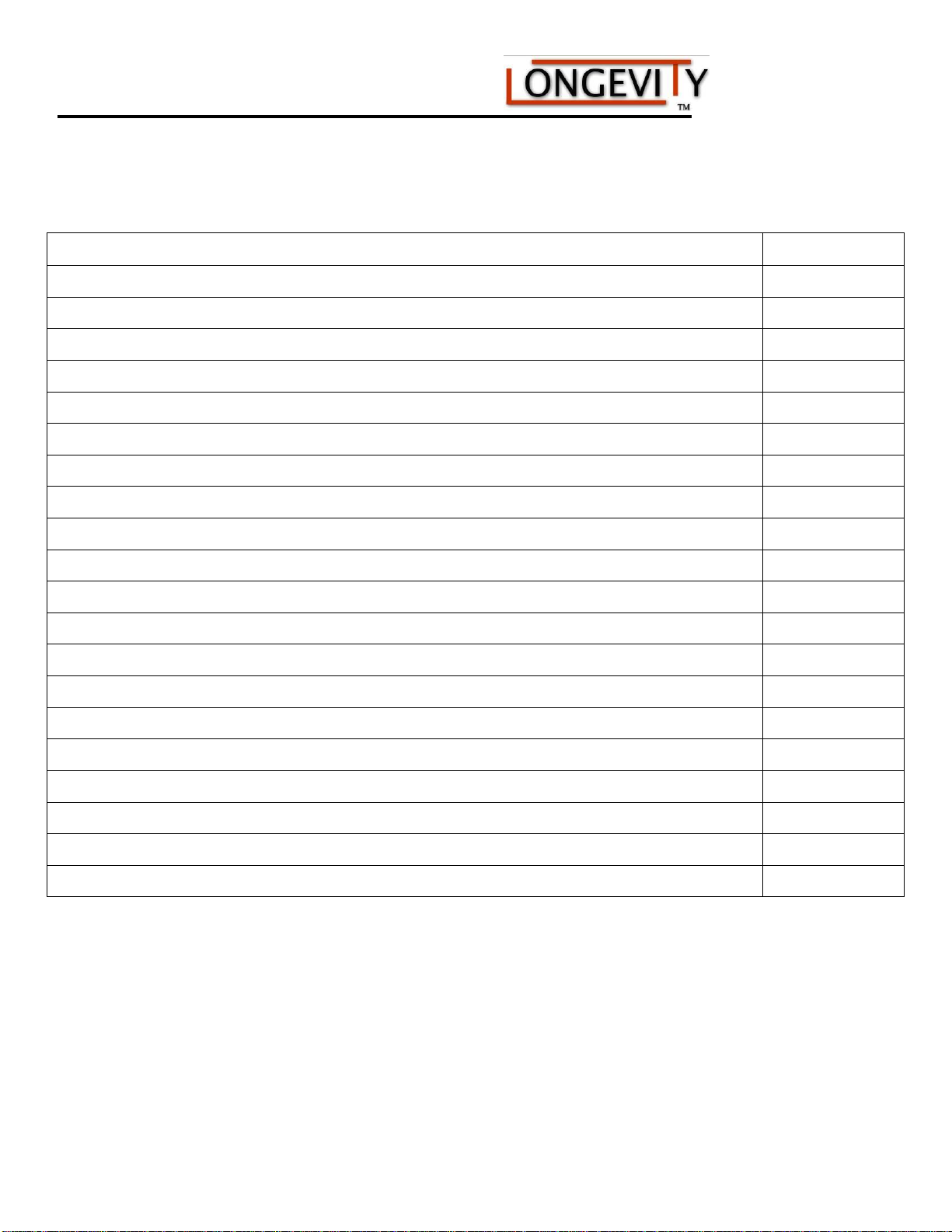

Other Longevity Welding System manuals

Longevity

Longevity MigWeld 100 User manual

Longevity

Longevity Forcecut 40D User manual

Longevity

Longevity ForceCut LP-100 User manual

Longevity

Longevity MIGWELD SPOOLGUN 140 User manual

Longevity

Longevity ProMTS 252i User manual

Longevity

Longevity STICKWELD 140STL User manual

Longevity

Longevity Forcecut 40D User manual

Longevity

Longevity WeldMax 185i User manual

Longevity

Longevity TigWeld 200EX User manual

Longevity

Longevity WeldAll 200P User manual

Longevity

Longevity MigWeld 140 User manual

Longevity

Longevity Forcecut 40D User manual

Longevity

Longevity ForceCut 42i User manual

Longevity

Longevity ForceCut LP-100 User manual

Longevity

Longevity ForceCut 62i User manual

Longevity

Longevity STICKWELD 140 User manual

Longevity

Longevity WeldAll 160 User manual

Longevity

Longevity TIGWELD 160SX User manual

Longevity

Longevity MigWeld 200S User manual

Longevity

Longevity WeldMax 520D User manual

Popular Welding System manuals by other brands

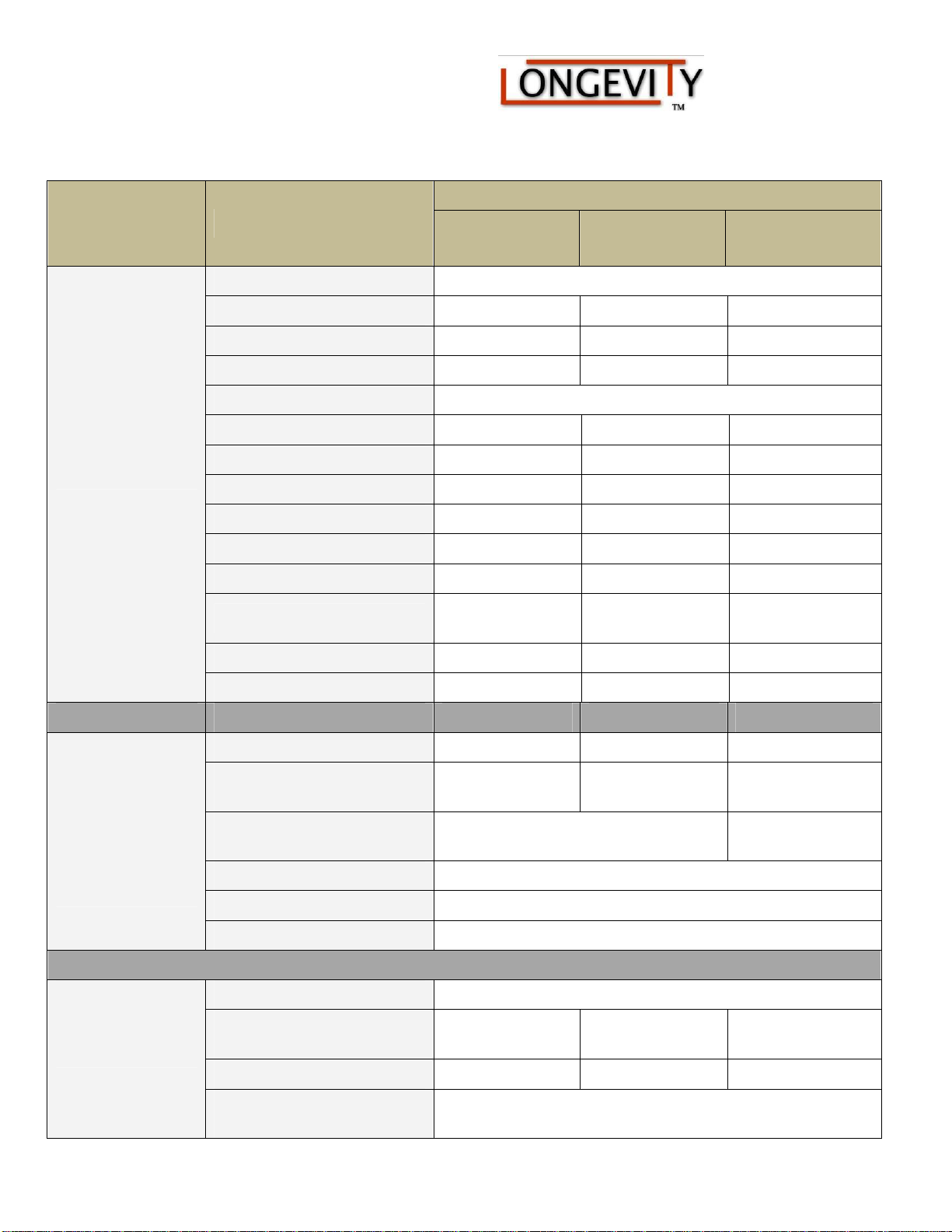

TAFA

TAFA 30*8B35 owner's manual

Lincoln Electric

Lincoln Electric INVERTEC V350-PRO CE Technical specifications

ESAB

ESAB Buddy Arc 145 instruction manual

CIGWELD

CIGWELD 636804 use instructions

Red-D-Arc

Red-D-Arc DC-400 Operator's manual

Hobart Welding Products

Hobart Welding Products Spool Gun DP 3035-10 owner's manual