Table of Contents

1 / Safety Precautions

3

2 / Module Introduction5

3 / Modules Transpo and Storage10

4 / Unloading and Storage14

5 / Unpacking18

18

18

21

6 / Module Installation22

5

7

2.1 Schematic diagram of module structure

2.2 Module identication

5.1 Conrmation of mounting system before unpacking modules

5.2 Unpacking requirements

5.3 Unpacking steps

22

22

22

23

23

24

24

25

25

26

26

26

27

28

28

29

29

29

6.1 Storage precautions before installing modules

6.2 Precautions for handling modules prior to installation

6.3 General safety

6.4 Electrical peormance safety

6.5 Operation safety

6.6 Installation conditions

6.6.1 Installation site and working environment

6.6.2 Selection of tilt angle

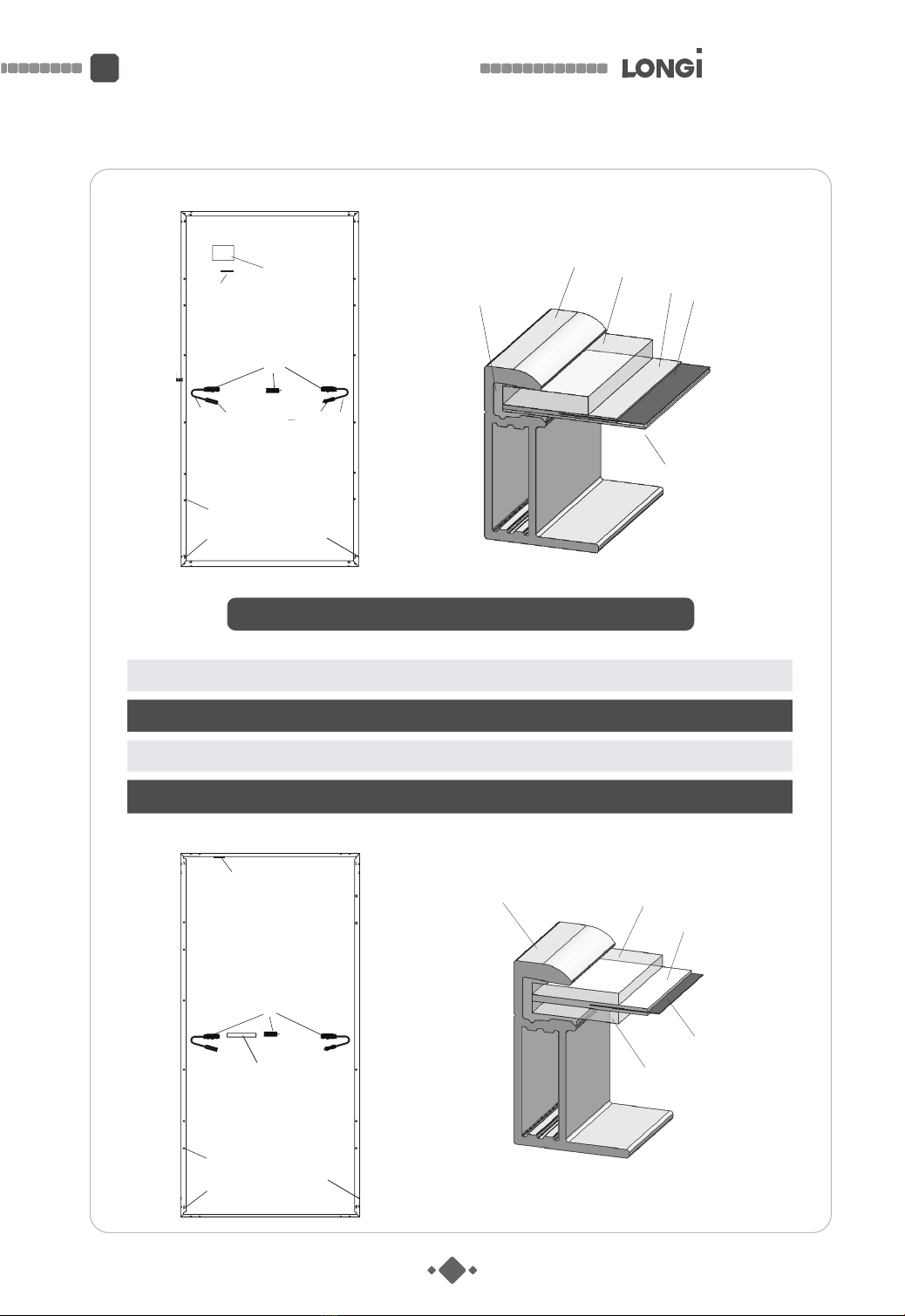

6.7 Mechanical installation

6.8 Installation method

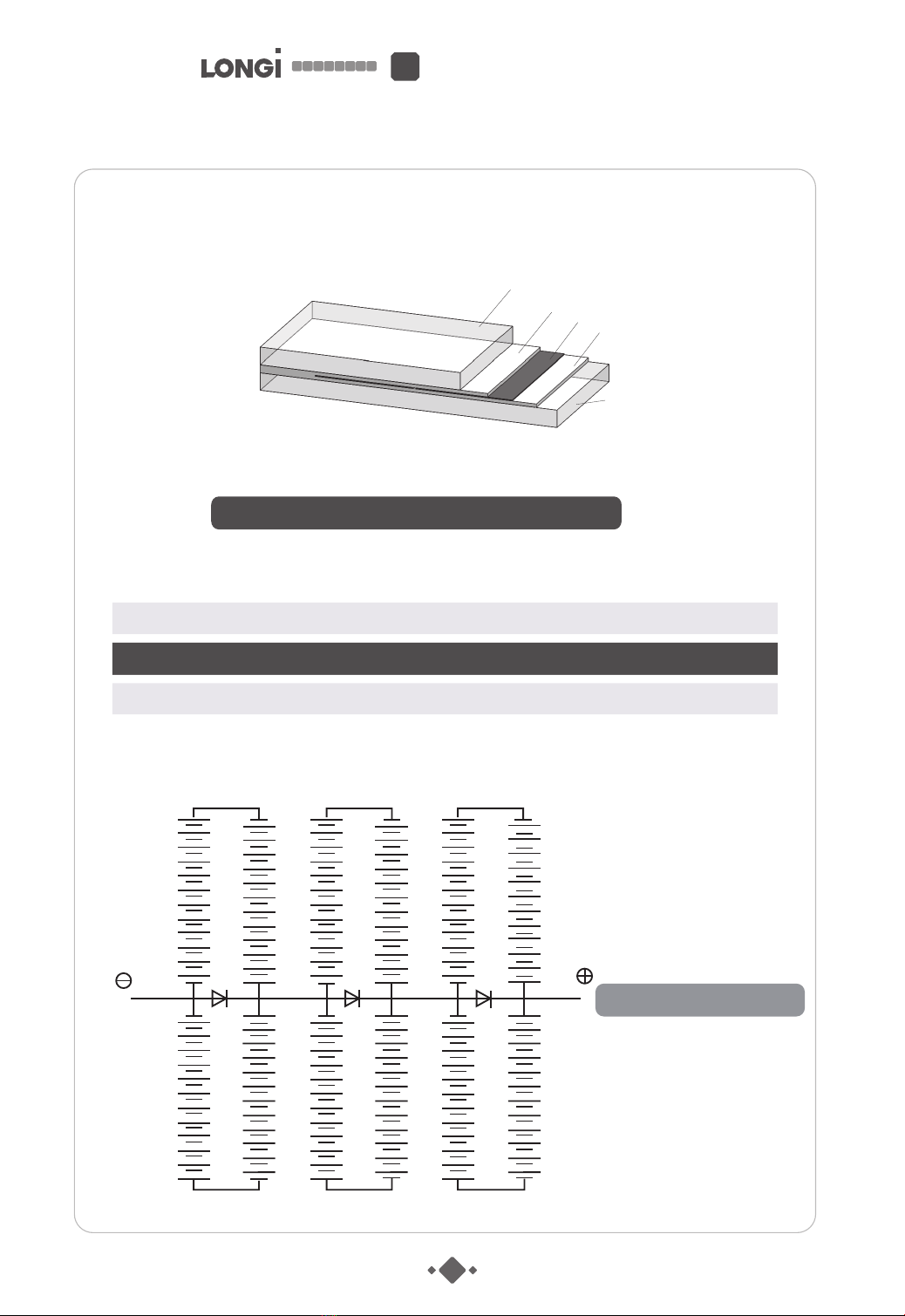

6.9 Electrical installation

6.9.1 Electrical peormance

6.9.2 Cables and wiring

6.9.3 Connecting cable

6.9.4 Bypass diodes

6.9.5 Safety of electrical connections

6.10 Grounding

6.10.1 Grounding clamp

10

13

3.1 Transpo and storage requirements

3.2 Notes on claims for cargo damage in transit