LS600 Installation and Operation Guide 3

www.leadsolarenergy.com

Contents

Notes 4

1.1 Validity.................................................................................................................................................. 4

1.2 Symbols used...................................................................................................................................... 4

1.3 Safety Instructions.............................................................................................................................. 4

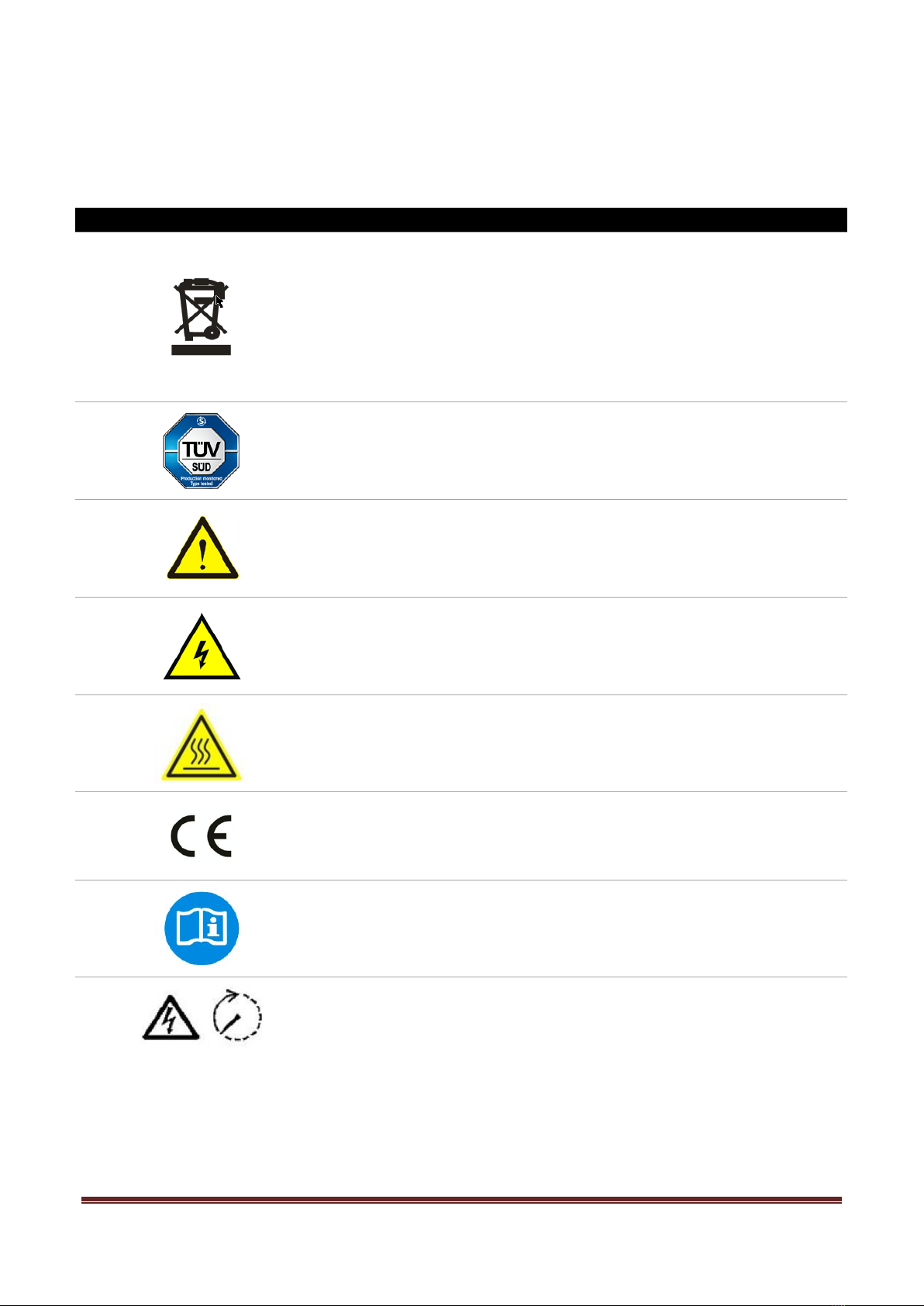

1.4 Explanation of Symbols ..................................................................................................................... 5

Introduction ................................................................................................................................................................. 6

2.1 LeadSolar Smart Solar: More Flexibility, More Productivity......................................................... 6

2.2 Reliability.............................................................................................................................................. 7

2.3 System Monitoring & Easy Maintenance ........................................................................................ 7

2.4 Simple Design & Easy Installation ................................................................................................... 7

Installation ................................................................................................................................................................... 8

3.1 Compatibility & Capacity.................................................................................................................... 8

3.2 Packaging ............................................................................................................................................ 8

3.3 Microinverter Identification ................................................................................................................ 9

3.4 Required Parts & Tools...................................................................................................................... 9

3.5 Lightning Surge Suppression............................................................................................................ 9

Installation Procedure................................................................................................................................................ 10

4.1 Preparation ........................................................................................................................................ 10

4.2 Installation.......................................................................................................................................... 10

Step 1: Measure Grid AC Voltage at Electrical Utility Connection ............................................................ 11

Step 2: Attach Microinverter to PV Racking .............................................................................................. 11

Step 3: Connect Microinverter’s AC Cable ................................................................................................ 12

Step 4: Terminate Unused end of AC Cable for Each Branch .................................................................... 12

Step 5: Install AC Branch Circuit Junction Box........................................................................................... 14

Step 6: Ground the System & Microinverter............................................................................................. 14

Step 7: Completer the Installation Map .................................................................................................... 15

Step 8: Install the Link nearby the AC Main .............................................................................................. 15

Step 9: Connect the PC Modules ............................................................................................................... 15

Step10 Register Microinverter .................................................................................................................. 16

LeadSolar Microinverter System Operation Guide .................................................................................................... 17

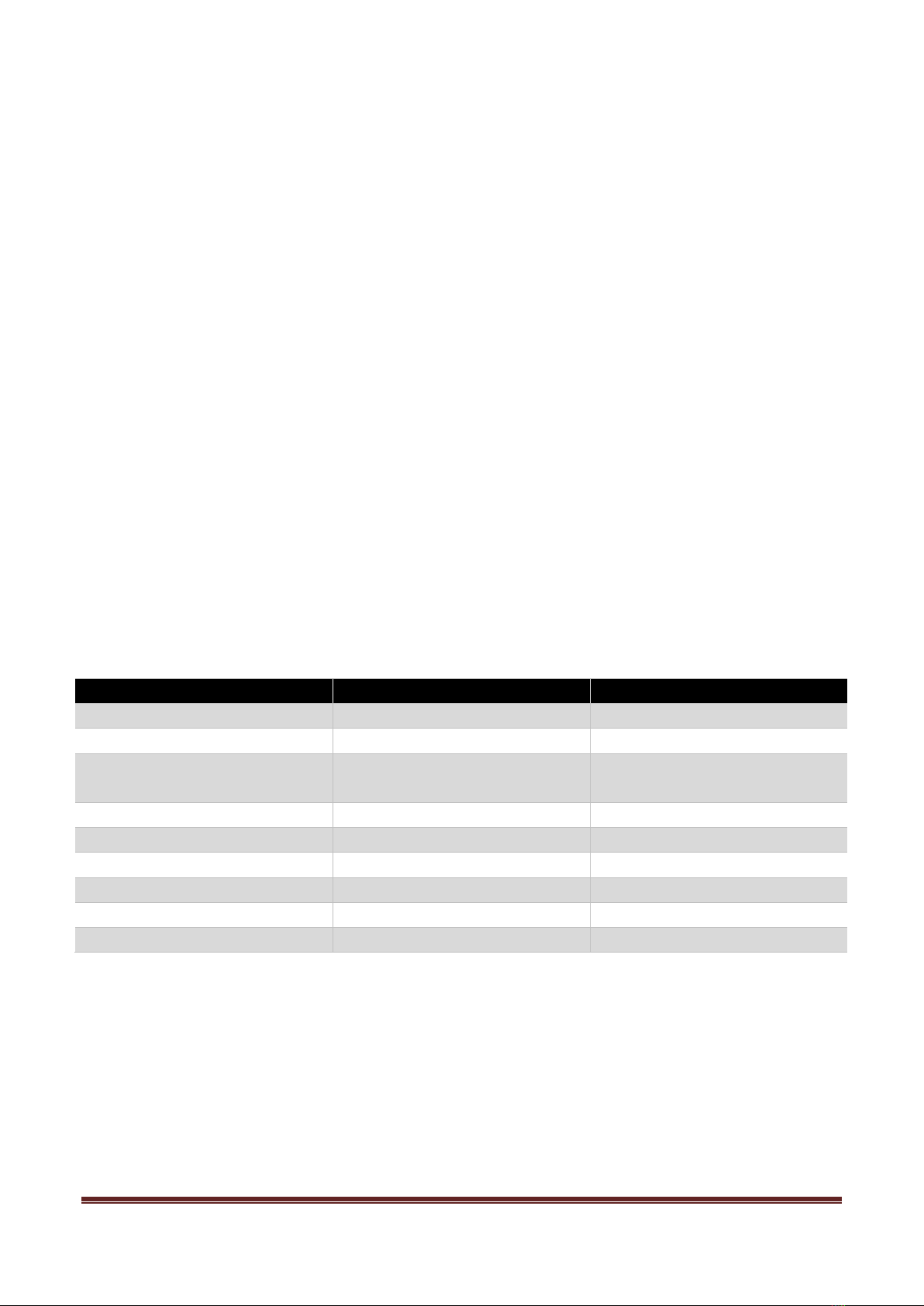

Microinverter System Trouble Shooting Guide.......................................................................................................... 18

Replacing or Adding a Microinverter ......................................................................................................................... 19

Technical Data............................................................................................................................................................ 20

8.1 Technical Considerations................................................................................................................ 20

8.2 Specifications .................................................................................................................................... 20

Appendix.................................................................................................................................................................... 22