WWW.LONGS-MOTOR.COM

7

6. Adjustment of troubleshooting

1) , the status on light’s indication

PWR: green, normal work light.

ALM: red, failure light, the motor with phase short-circuit, overvoltage and under-voltage

protection.

2) Troubles

Alarm indicator

Reasons Measures

Wrong connection for power Check wiring of power

LED off turn Low-voltages for power Enlarge voltage of power

Wrong connection of stepper

motor Correct its wiring

Motor doesn’t run, without

holding torque RESET signal is effective

when offline Make RESET ineffective

Motor doesn’t run, but

maintains holding torque Without input pulse signal Adjust PMW & signal level

Wrong wires’ connection Change connection for any of

2 wires

Motor runs wrong direction Wrong input direction signal Change direction setting

Too small relative to current

setting Correct rated current setting

Acceleration is too fast Reduce the acceleration

Motor stalls Rule out mechanical failure

Motor’s holding torque is

too small

Driver does not match with the

motor Change a suitable driver

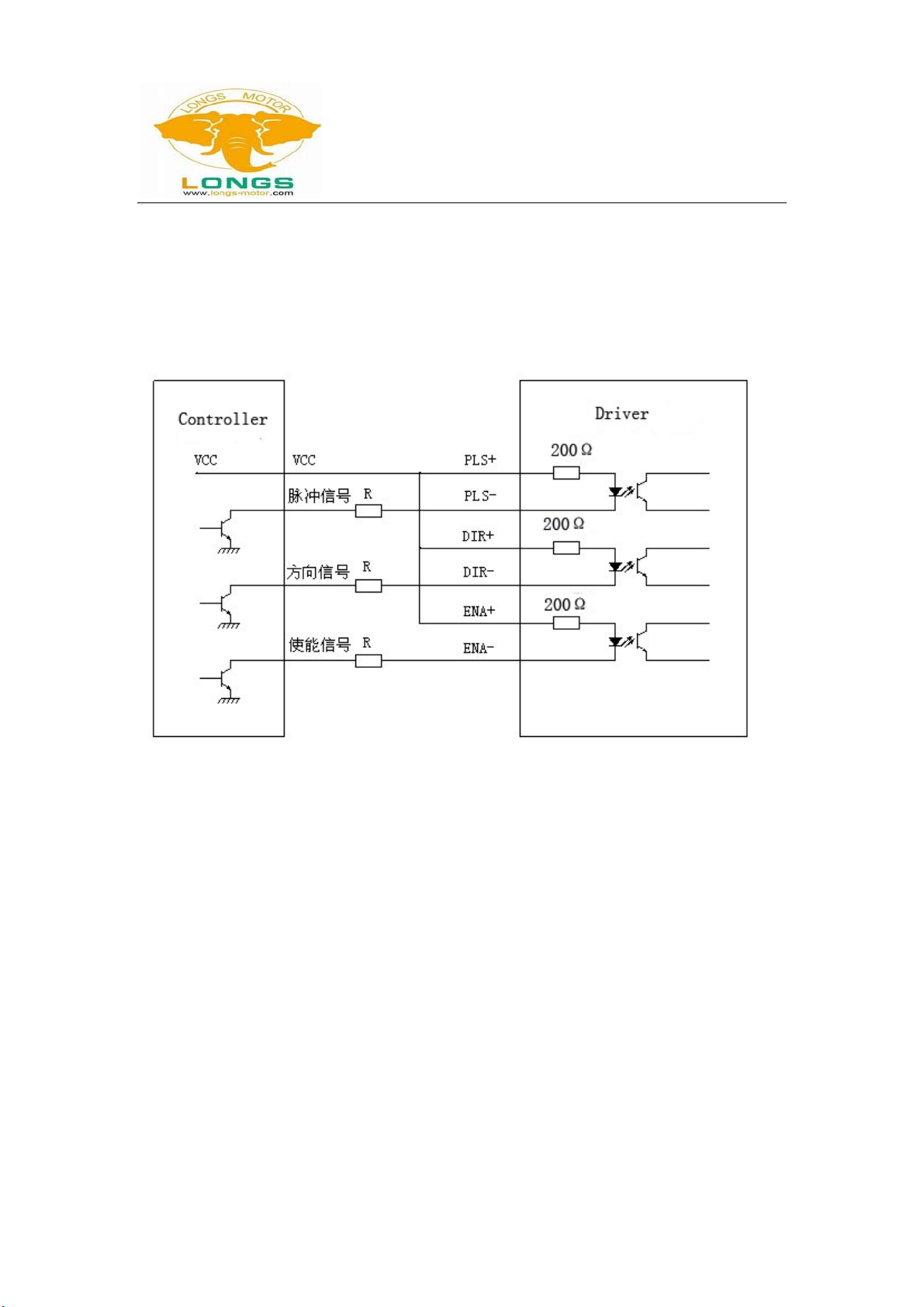

7. Driver wiring

A complete stepper motor control system should contain stepper drives, DC power supply and

controller (pulse source). The following is a typical system wiring diagram