5

2. Safety instructions

A fog machine is not a toy!

•Make sure, that all persons who work with the tank and the gas are professio-

nals. Incorrect use can cause the risk of suffocation!

•Carbon dioxide is not toxic but may cause asphyxiation in high concentrations.

•Carbon dioxide is heavier than air. The highest concentration is therefore at

floor level. The maximum allowed concentration is 0.5 % by volume (MAK:

5.000 ppm).

•Ensure adequate ventilation.

•Ensure that all national/local regulations for handling and storage of liquid

carbon dioxide (CO2) are observed.

•Extreme temperatures at the nozzle (hot/cold). Danger of burning/frostbite.

•Occasionally very hot droplets of fluid may escape when in operation.

Never aim at persons directly and keep a minimum distance of 10 ft from the

nozzle.

•Never touch the nozzle when in operation. Danger of getting burnt.

•The location for the machine must be non-flammable, non-combustible and

not sensitive to heat. It must be twice as big as the machine.

•Keep a minimum distance of 24 in to all flammable, combustible objects and

objects sensitive to heat.

•Glycol is alcohol and burns with a slightly bluish, almost invisible flame. Never

point the fog at strong sources of ignition like fire or pyrotechnic effects.

•Never open the machine and leave the machine unattended when connected

to a power supply.

• The visibility must be more than 6 ft in rooms where people walk around.

•Do not swallow the fog fluid. Keep it away from children. In case of eye contact,

rinse with a lot of water. Consult a doctor should you accidentally swallow

some fluid.

•Spilled fluid or splashed fluid droplets can cause slip hazard. Mop up the fluid

and dispose of it according to regulations.

•Fog may activate smoke detectors.

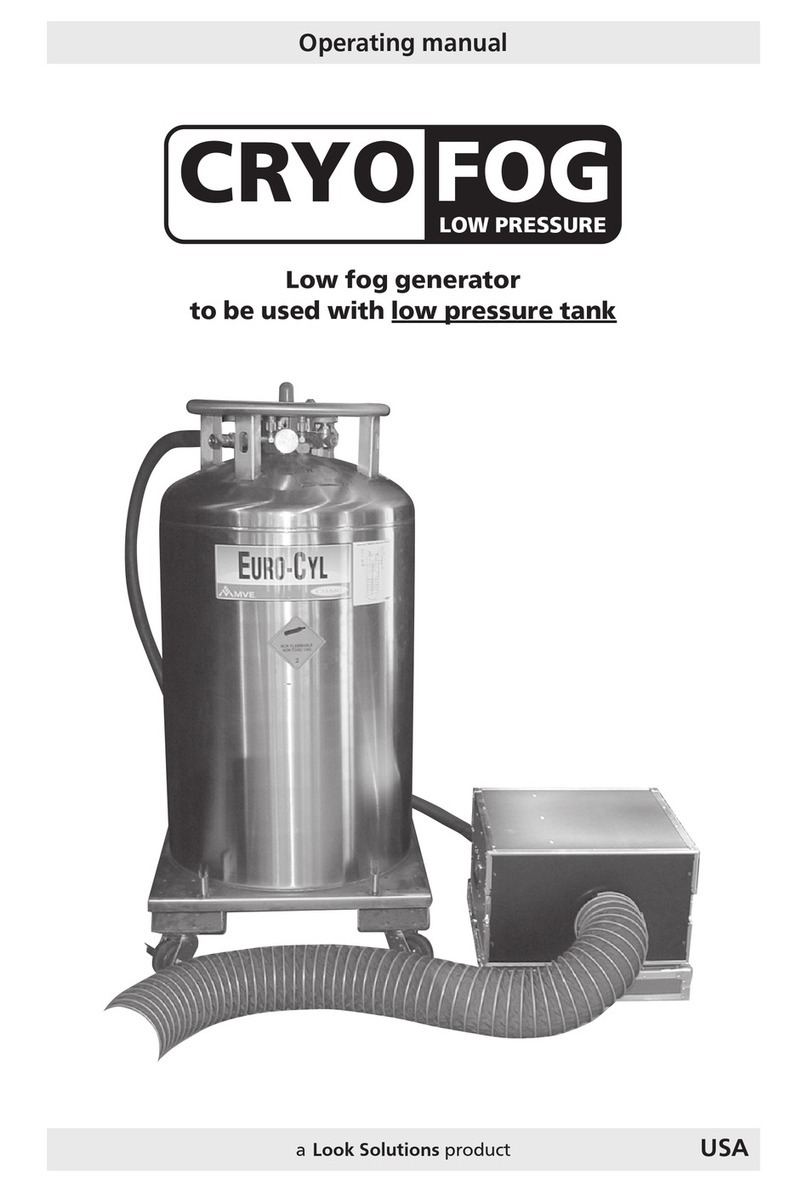

Artificially-made fog can be produced in many different ways. The method

used here to produce fog, with a device which works according to the vaporizer

principle, is the most harmless one.

No case has so far been reported in which a healthy human being has been

harmed because of using our device to produce artificial fog. However, this can

only be guaranteed if the professional fog generators are used appropriately, i.e.

at the correct vaporization temperatures as well as with the correctly mixed fog

fluid.

We, however, recommend: People with health problems or problems of the

respiratory tract or with an inclination for allergies should avoid any contact

with artificially-made fog.