2

Table of ContentsTable of Contents

TABLE OF CONTENTSTABLE OF CONTENTS................................................................................................................................ 22

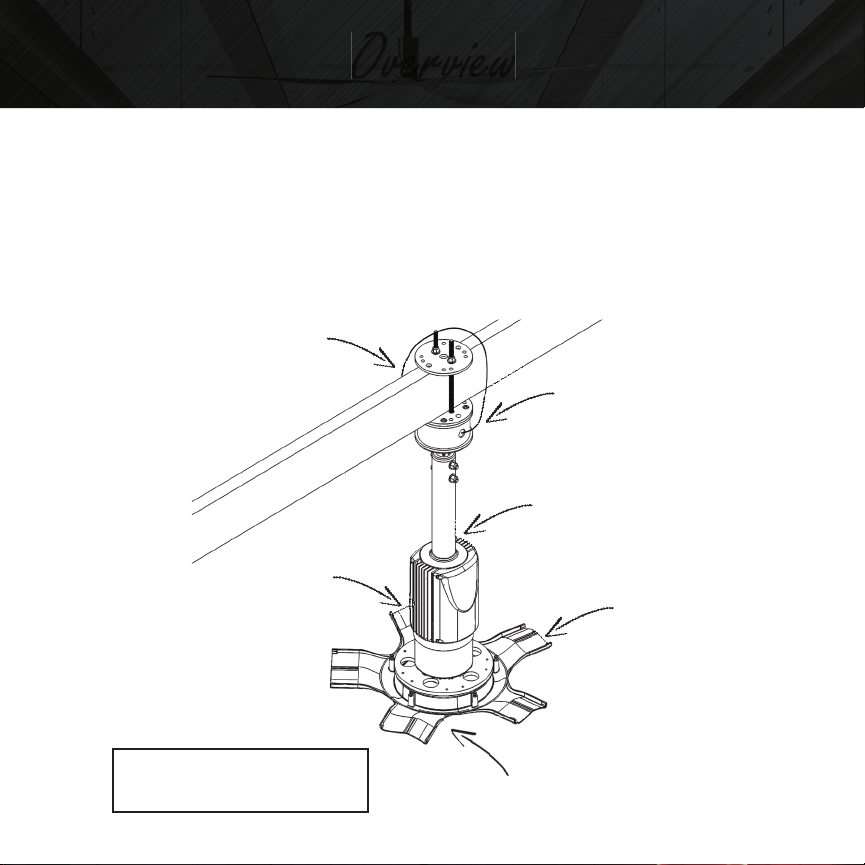

OVERVIEWOVERVIEW.................................................................................................................................................................. 44

COMPONENTS ....................................................................... 4

TECHNICAL DATATECHNICAL DATA .......................................................................................................................................... 55

FUSING & THERMAL LIMITINGFUSING & THERMAL LIMITING .................................................................................................. 77

FUSES...................................................................................... 7

THERMAL LIMITING................................................................ 7

SAFETYSAFETY.............................................................................................................................................................................. 88

ELECTRICAL SAFETY................................................................ 8

GENERAL SAFETY.................................................................... 9

CLEARANCES .......................................................................... 10

INSTALLATION PREPARATIONINSTALLATION PREPARATION.................................................................................................... 1212

PREPARATION ........................................................................ 12

TOOLS REQUIRED .................................................................. 13

ITEMS INCLUDED ................................................................... 14

HARDWARE INCLUDED ......................................................... 14

INSTALLATION PROCEDUREINSTALLATION PROCEDURE.......................................................................................................... 1616

INSTALLATION OF THE MOUNTING HARDWARE ................ 16