Page 3 of 30

1. GENERAL SAFETY INSTRUCTIONS

The correct use of pneumatic

equipment within a system is the

responsibility of the system designer

or the person who determines its

technical specifications.

The use of safety guards is

recommended to minimize the risk

of injury to persons; pay close

attention to the fact that

compressed air may lead to the

explosion of closed containers, and

vacuum may lead to the implosion

of closed containers. The vacuum

generator, even if silenced, makes

noise: if necessary, wear suitable

protection. In the event that,

contrary to indications, dusts, oil

mists, fumes, etc. are suctioned,

these will be mixed with the

discharge air of the vacuum

generator and expelled via the

discharge conduit; use suitable,

approved air filters to avoid possible

intoxications. The discharge air has a

high output speed. Do not obstruct

the discharge of the gripper module.

Ensure that the components are

properly secured; regularly check

that connections are in good

working order, as high cycles or

vibrations may cause them to

loosen. Consider the possibility of

pressure drops in the pneumatic

supply line: then provide for a safety

system that, in order to prevent

injury to the operator or damage to

the machine prevent the risk of the

piece being released.

Consider the possibility the electrical

or pneumatic supply is interrupted,

to protect persons and systems.

Consider the emergency stop when

designing the system.

Pneumatic supply and connection

The supply pressure should not

exceed the recommended one of 7

Bar. (102 psi)

If the compressed air contains

impurities, the components may

malfunction. Install a filter upstream

of the component; the filter grade

should be at least 5 µm. Air

containing excessive quantities of

condensate may cause the

components to malfunction.

Installing condensate drains or

dryers prevents these malfunctions.

For more information, see the

Installation and Commissioning

section.

Electric connection

Connect the cables separately from

power or high voltage lines,

avoiding parallel wiring or wiring in

the same conduit of the same lines.

Control circuits that include sensors

and coils may malfunction due to

the noise from these other lines.

Carefully follow the electrical wiring

instructions, paying close attention

to avoiding the short-circuiting of

loads.

Assembly

Compressed air may be dangerous

if used by unskilled personnel.

Assembling, using and maintaining

systems should solely be carried out

by experienced and specially trained

personnel. Both for fastening and

supplying, solely use the bores and

methods provided by the

manufacturer. Prior to

assembly/disassembly of the

components, cut off voltage and

pressure. Install and maintain the

components only after thoroughly

reading and understanding this

manual.

Maintenance

Maintenance must be carried out in

accordance with the instructions in

this manual. Prior to any

maintenance work, check the

conditions to prevent the sudden

release of pieces, then suspend

pneumatic/electrical supply, and

discharge residual pressure.

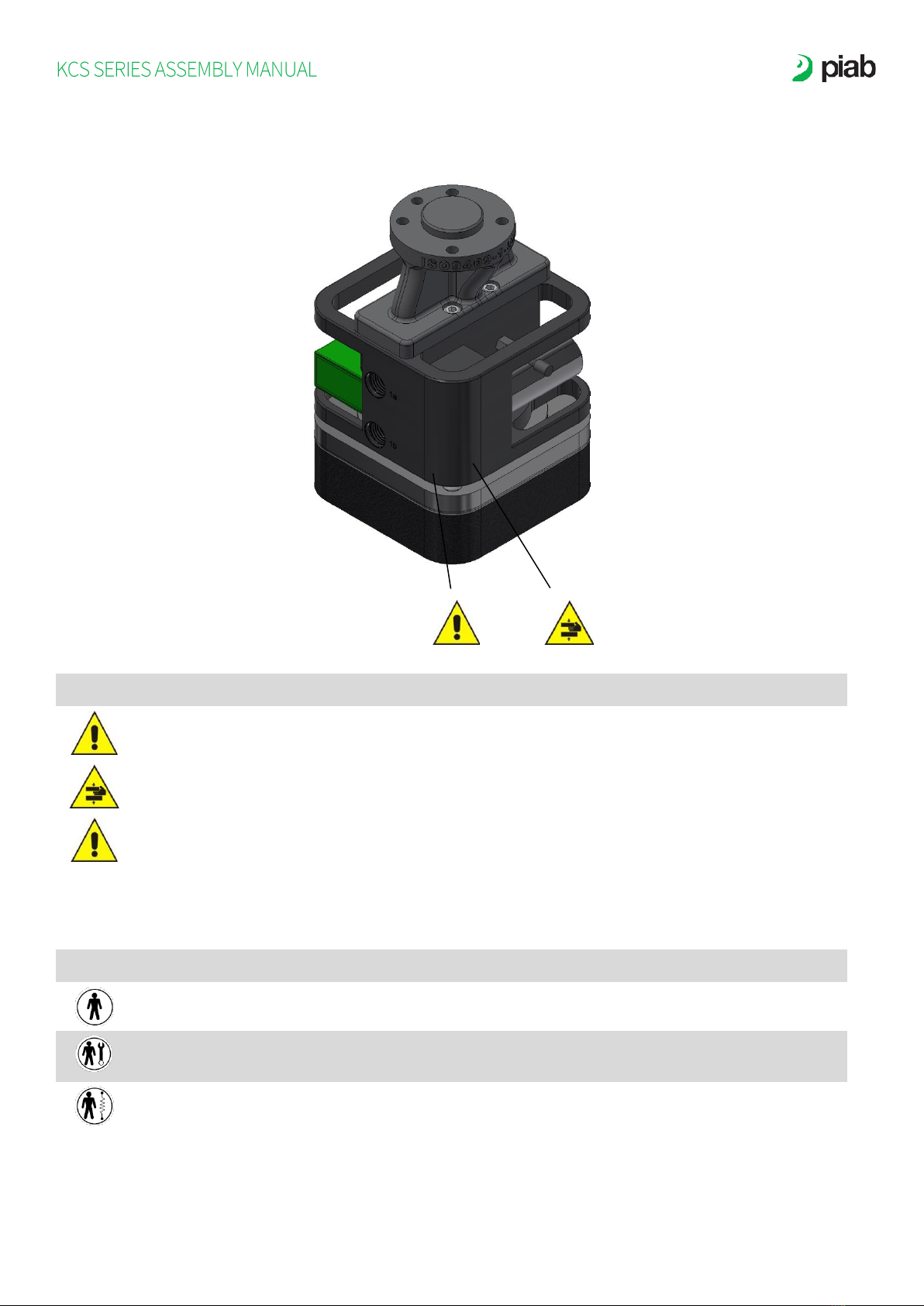

Safety instructions

Handle the components with care.

During installation and maintenance,

cut off voltage and pressure.

Modifying the components is

prohibited.

Cleaning the environment and place

of use is recommended.

Follow the installation and

commissioning instructions.

The electrical and pneumatic

connections should be permanently

connected to the component.

Storage

For a correct storage of the system

or its spare parts, we recommend:

Exclude outdoor areas, areas

exposed to the elements or with

excessive humidity or exposed to

direct sunlight.

The environment must be

sufficiently clean, arrange the system

almost in such a way that it has a

stable base of support and make

sure that there is no risk of

unexpected movements.