Obere Schloßstr.131

D-73553 Alfdorf

+49 7172/93730-0

Fax +49 7172/93730-22

E-Mail: info@lorenz-sensors.com

Technical changes under reserve

Internet: www.lorenz-sensors.com

1 Contents

1Contents ..............................................................................................................................................................................2

2Imprint .................................................................................................................................................................................3

3References in this Text.......................................................................................................................................................3

4Read First ............................................................................................................................................................................4

4.1 Safety and Caution Symbols....................................................................................................................................4

4.2 Intended Use ...........................................................................................................................................................4

4.3 Dangers...................................................................................................................................................................4

4.3.1 Neglecting of Safety Notes..........................................................................................................................4

4.3.2 Remaining Dangers ....................................................................................................................................4

4.4 Reconstructions and Modifications...........................................................................................................................4

4.5 Personnel ................................................................................................................................................................4

4.6 Warning Notes.........................................................................................................................................................5

5Term Definitions..................................................................................................................................................................5

5.1 Terms ......................................................................................................................................................................5

5.2 Definition of the Pictograms on the Torque Sensor ..................................................................................................5

6Product Description............................................................................................................................................................6

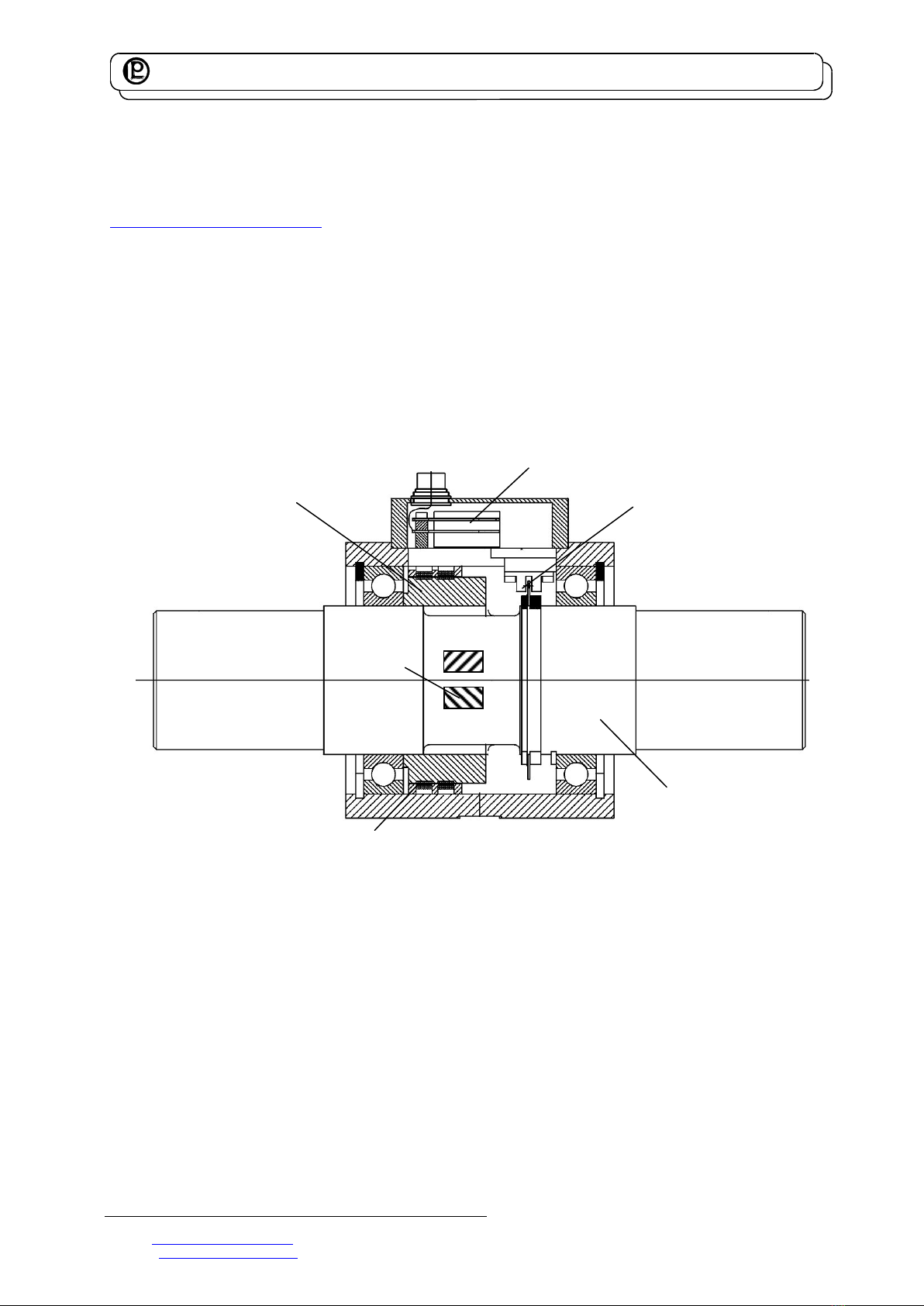

6.1 Mechanical Setup ....................................................................................................................................................6

6.2 Electrical Setup........................................................................................................................................................6

6.3 Angle of Rotation- and Speed Measurement............................................................................................................7

6.4 Sensor Communication............................................................................................................................................7

7Mechanical Assembly.........................................................................................................................................................8

7.1 Couplings ................................................................................................................................................................8

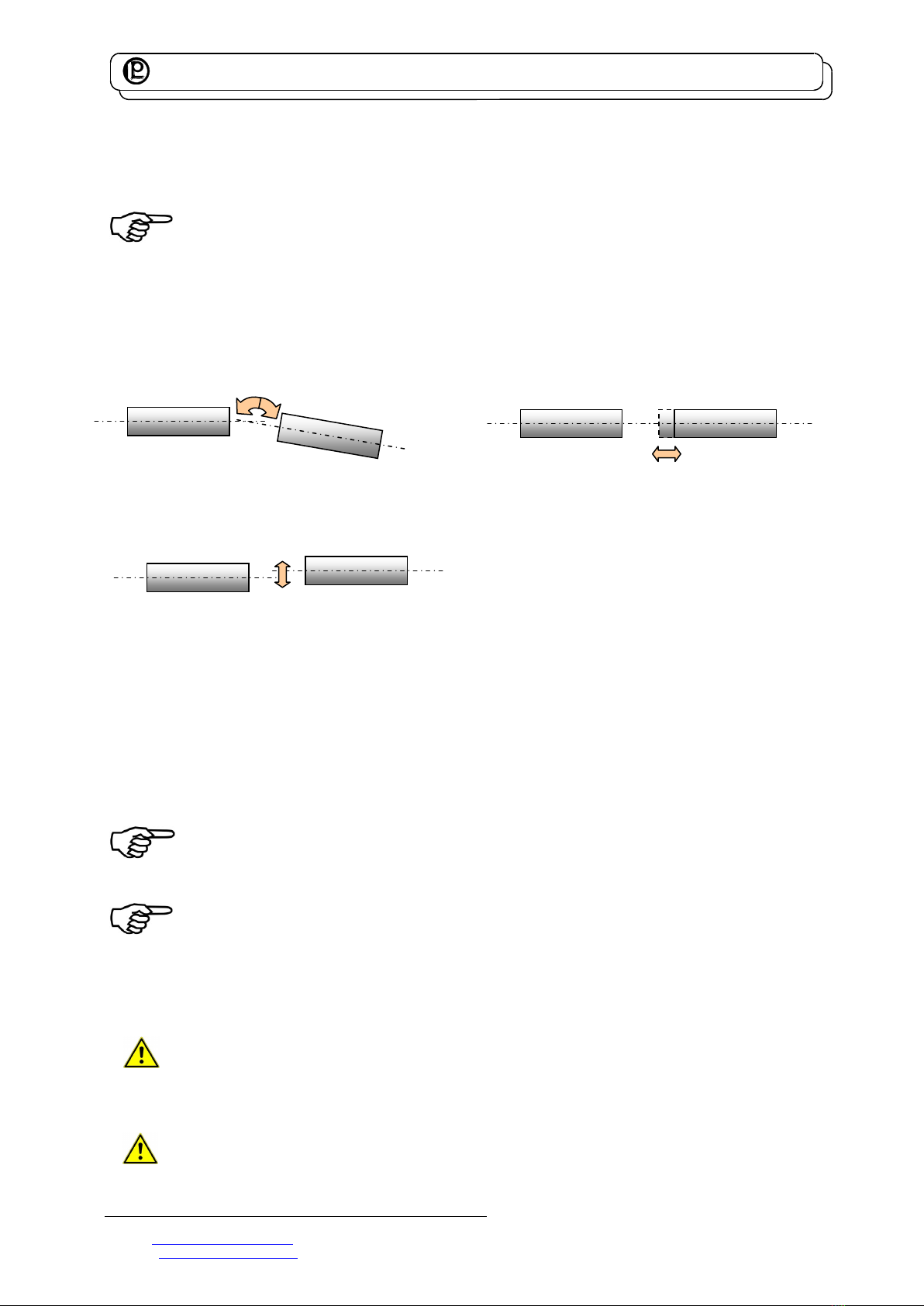

7.1.1 Misalignment Possibilities of Single-Jointed Couplings................................................................................8

7.1.2 Double-Jointed Couplings ...........................................................................................................................8

7.1.3 Alignment of the Measurement Arrangement ..............................................................................................8

7.2 General....................................................................................................................................................................8

7.2.1 Torque Sensors of 0.1 N·m to 10 N·m.........................................................................................................8

7.3 Free-floating Assembly ............................................................................................................................................9

7.4 Foot Version Assembly ............................................................................................................................................9

8Electrical Connection .......................................................................................................................................................10

8.1 USB - Cable...........................................................................................................................................................10

8.2 Shielding Connection.............................................................................................................................................10

8.3 Running of the Transmission Cables......................................................................................................................10

8.4 Drivers and Software .............................................................................................................................................10

8.5 Calibration Control .................................................................................................................................................10

9Measuring..........................................................................................................................................................................10

9.1 Engaging ...............................................................................................................................................................10

9.2 Direction of Torque ................................................................................................................................................11

9.3 Static / Quasi-Static Torques .................................................................................................................................11

9.4 Dynamic Torques...................................................................................................................................................11

9.4.1 General .....................................................................................................................................................11

9.4.2 Natural Resonances..................................................................................................................................11

9.5 Speed Limits..........................................................................................................................................................11

9.6 Disturbance Variables............................................................................................................................................11

10 Maintenance ......................................................................................................................................................................12

10.1 Maintenance Schedule (recommended).................................................................................................................12

10.2 Trouble Shooting ...................................................................................................................................................12

11 Decommission ..................................................................................................................................................................12

12 Transportation and Storage .............................................................................................................................................12

12.1 Transportation .......................................................................................................................................................12

12.2 Storage..................................................................................................................................................................13

13 Disposal.............................................................................................................................................................................13

14 Calibration.........................................................................................................................................................................13

14.1 Proprietary Calibration ...........................................................................................................................................13

14.2 DKD-Calibration.....................................................................................................................................................13

14.3 Re-Calibration........................................................................................................................................................13

15 Data Sheet .........................................................................................................................................................................13

16 Literature ...........................................................................................................................................................................13