• Never use the machine to saw pieces of

work that are so small that they cannot be

secured safely.

• When sawing prole sections the work

must be carried out such that the piece of

work cannot slide away and the saw blade

cannot become jammed. A proled piece

of work must lie at or be held in place by

an attachment so that toppling or sliding

during the work is prevented.

• Round pieces of work such as tubes must

be well secured, otherwise these can

revolve and the danger exists that the saw

blade catches in them. Always keep the

piece of work on the table and against

the stop using a suitable accessory or

attachment.

• Make sure that the piece of work does not

have any nails or other foreign objects in it.

User safety

• Make sure you have a clean and tidy

working environment.

• Make sure the working environment is

well lit.

• The user of the machine must be

instructed in the use, adjustment and

operation of the machine.

• Use a dust mask or dust hood to prevent

the inhalation of (harmful) dust.

• Wear gloves when you exchange the

saw blade or when rough material is to

be sawn. It is best to keep saw blades

in a separate holder to prevent anyone

getting hurt.

• When the machine is equipped with

a laser, this may not be replaced by a

dierent type of laser. Repairs may only

be carried out by the laser manufacturer

or a recognised specialist.

• The operator should wear ear protectors

to reduce any damage to hearing.

• To prevent accidents occurring by the

accidental switching on of the machine,

the plug must always be pulled out of the

socket before adjustment of the stop or

the saw head is carried out,

when changing blades or accessories, and

when maintaining the machine.

• To prevent electric shocks, when plugging

the plug into the socket the metal

pins must not be touched in any way

whatsoever.

• Never use the cord to pull the plug out of

the socket. Keep the cord away from oil,

heat and sharp objects.

• Never apply a cleaning or lubrication

agent to a saw blade that is still revolving.

• To prevent res, never use the machine in

the vicinity of ammable liquids, vapours

or gases.

• Always use original accessories: others

may cause wounding.

• Always choose the right saw blade in

relation to the material to be sawn.

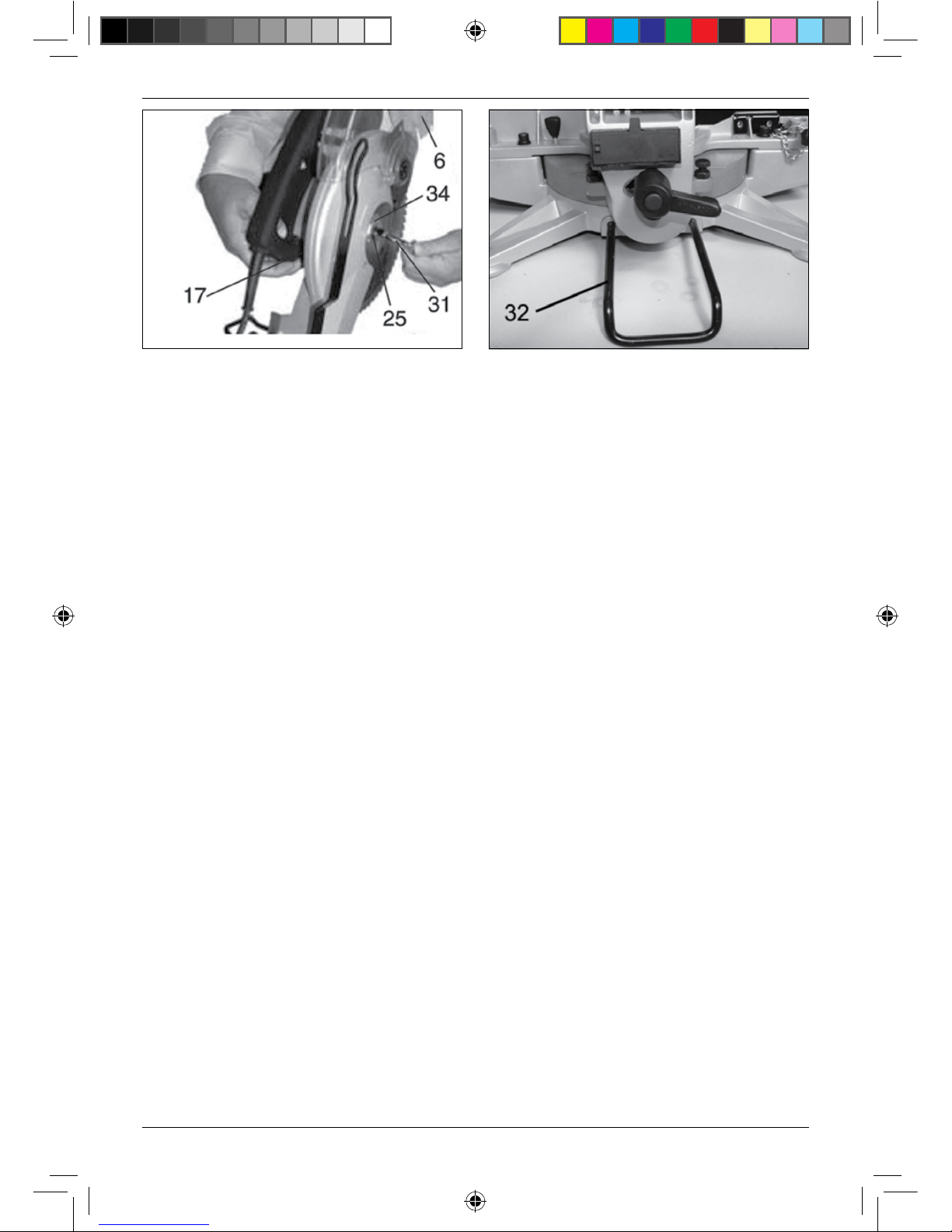

Transporting and moving

• Check that all locks and tensioning

devices are secure.

• Do not lift the machine by the extension

pieces (for the stabilisation of the saw),

but by the solid underside of the machine.

While the machine is in use

With frequent use of the machine, do not

let routine lead to mistakes. Remember that

a slight lack of concentration can lead to

serious injuries in a fraction of a second.

• Before beginning to saw, make sure

that the protective hood is in the right

position.

• Before cutting the rst cut, let the

machine run for a short while. If you hear

any unusual sounds or observe any strong

vibration, turn the machine o and take

the plug out of the socket, and then nd

the cause of the problem. Do not switch

the machine on again until the cause has

been found and the fault repaired.

• Make sure that the piece of work being

sawn o does not get stuck in place, do

not hold it or clamp it and no not secure it

against the stop. It must be able to move

freely along the side of the saw blade.