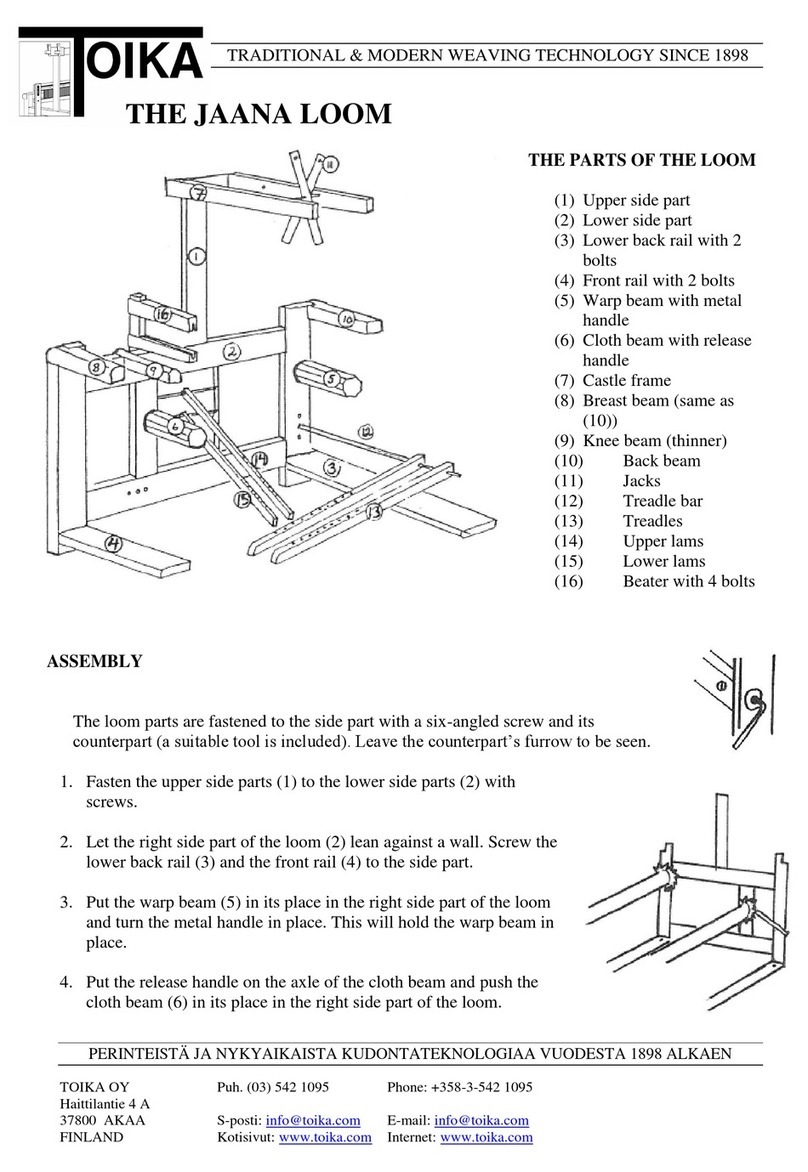

1

Assembly tips and information

Please read all the text of these instructions completely. The pictures may seem clear enough to

assemble the loom; however, the text also contains useful information about operating David 2.

Barrel nuts

To connect parts, barrel nuts are used. These cylinder shaped nuts have a slot on one of the flat

sides. Always insert the barrel nut into the wooden part, so that the side with the slot is visible. The

slot shows the direction of the threaded hole in the nut. With a flat screwdriver you can turn the

barrel nut so that it is positioned properly to catch the bolt. If it is hard to catch the bolt, it usually

helps to turn the barrel nut 180 degrees. If you inserted a barrel nut incorrectly into the wood, a

magnet can be used to remove it.

Wood screws

Where wood screws are used, we have predrilled holes in the wood. The screw will cut its own

thread into these holes. The screws are very sharp and will cut their own hole if you miss the

predrilled hole during assembly. If this happens, you will find that after a couple of turns, the screw

will be very difficult to turn. You may even shear the head off of the screw. Also, the parts will be

assembled in the wrong location.

If you have to disassemble and assemble again, makes sure that the wood screw turns in the

same thread again which was cut the first time. Otherwise, after assembling several times, the

thread will be destroyed.

You can find the existing thread by turning the screw counter clock wise, while pushing it into the

wood. When you feel the screw snaps into the thread, turn clock wise. When the screw turns

easily, you know that you have found the thread.

The Texsolv system

Each shaft of the David 2 is provided with one hundred Texsolv heddles (28 cm long). The ties of

these bundles are included and can be used to tie bundles again. A bundle of Texsolv heddles is a

continuous line of 100 heddles folded into a zig zag. Each bundle is fastened in four places. This

makes it easy to pass the shaft bars through the loops of the heddles. If you want to cut the

heddles apart, use a sharp pair of scissors to cut the loops at the top and bottom of the shafts.

Before removing heddles from a shaft, tie them into a bundle. Do not remove the ties from the

bundles, until the heddles have been slipped onto the shaft bars or the loops of the bundles are

inserted by sticks, to protect the heddles from becoming entangled.

Practically, Texsolv cord consists of two cords, which are connected every 12 mm, forming loops

between them. If needed, the cord should be cut between the two loops. To prevent unraveling, the

ends should be singed with a match or lighter. When we talk about the first or last loop in these

instructions, the loop we mean is the one beside the loop where the cord is cut. The loop that

remains after cutting has no strength and should not be used.

The Texsolv cord is adjustable in length by 12 mm

steps (ca.1/2”), according to the loops. For fine

adjustment, plastic pegs are used, inserted into the

loops of the cord. Each peg through the cord will

shorten it about 1.5 mm (1/16”).

You will not need more than 7 pegs in a cord,

because with 8 pegs the cord becomes one cord

loop shorter and you can just as well shorten the

cord one loop. In hardware bag 3 are 50 spare pegs.