User Guide for SpeedControl 1047

• LS Control A/S • Industrivej 12 • DK –4160 Herlufmagle Page 3

Product Description

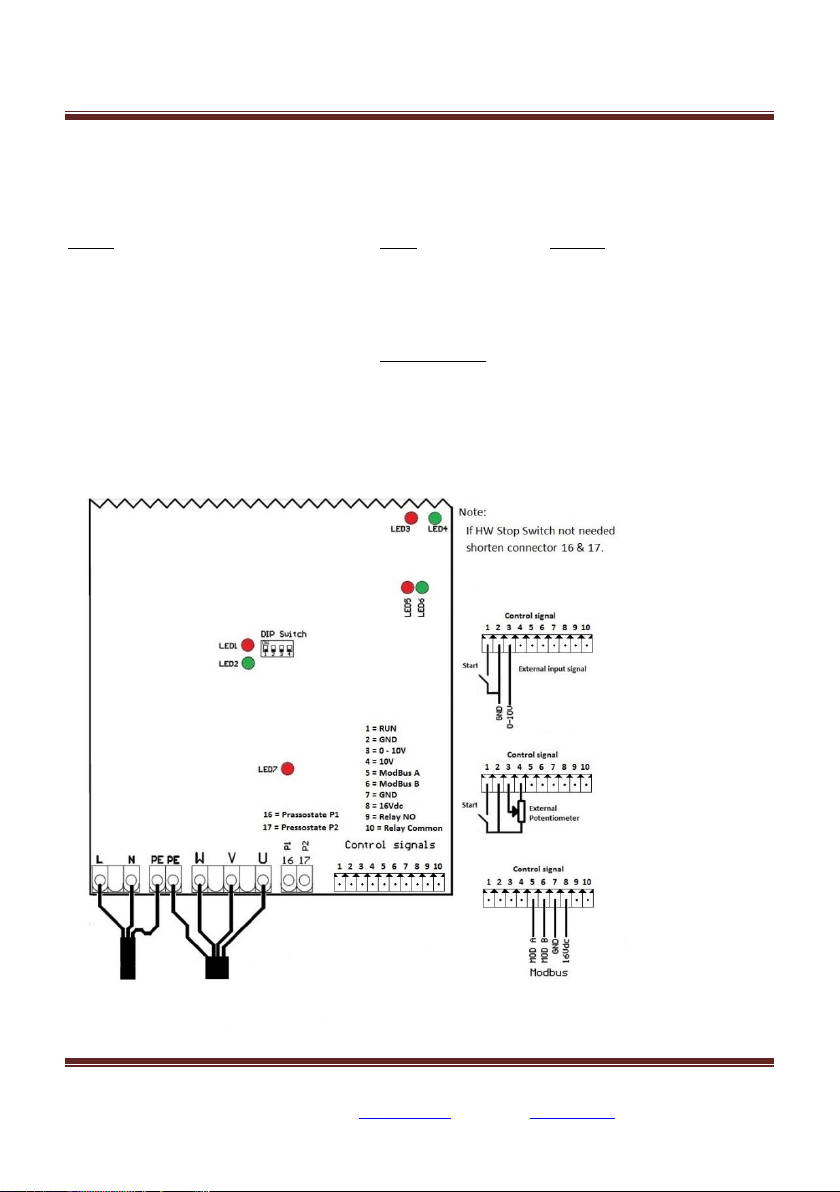

SpeedControl 1047 is a frequency converter for control of 3-phase EC, PMSM and BLDC motors up to

1500W/5.5A with single phase supply. SpeedControl 1047 is delivered enclosed in an IP 54 metal housing for

demanding environments or without enclosure for build-in constructions. The compact construction offers

many mounting options. The construction is not equipped with active cooling, the sound level is very low,

and the frequency converter is maintenance free.

•Descrete light grey color for reduction of heat absorption.

•Silent and reliable with an advanced self protection feature.

•Provided with a user-friendly interface for quick and easy installation.

•Designed for use in many different applications, including compressor applications. Depending on

motor profile.

•For special applications, please contact us for further information.

Considerations for Compressor use

For each compressor, the compressor data from the manufacturer datasheet must be hard wired into the

frequency converter software by LS Control. Afterwards the specific compressor is selected by means of dip

switches. Since the compressor parameters change with changing loads, LS Control must carry out a

performance test on each individual compressor to select the best parameters covering the widest range of

operating patterns ensuring that the compressor will be able to operate at high loads as well as low loads.

The result of the performance test will give a new max. current and new max. RPM for correct operation of

the compressor in question.

Rule of thumb! When using a compressor with a frequency converter, make sure that the input power to

the compressor is below the maximum power of the frequency converter and that the frequency converter

can deliver the required current for the compressor.

Application considerations with compressors

To choose the right compressor for your specific application, it is important to compare the compressor

data with the frequency converter data. Make sure that both the frequency converter and the compressor

can supply the required power and current for your application.

At high loads the frequency converter may become extremely warm. Therefore, if the compressor is

operated at high loads and high ambient temperatures, active cooling might be necessary. Please refer to

chapter Electrical / Mechanical installation.

NB! It is your responsibility to ensure that the installation in all meets the EMC standards applying for your

specific installation and the environment in which it is installed.