8

V50 Ram Installation Procedure

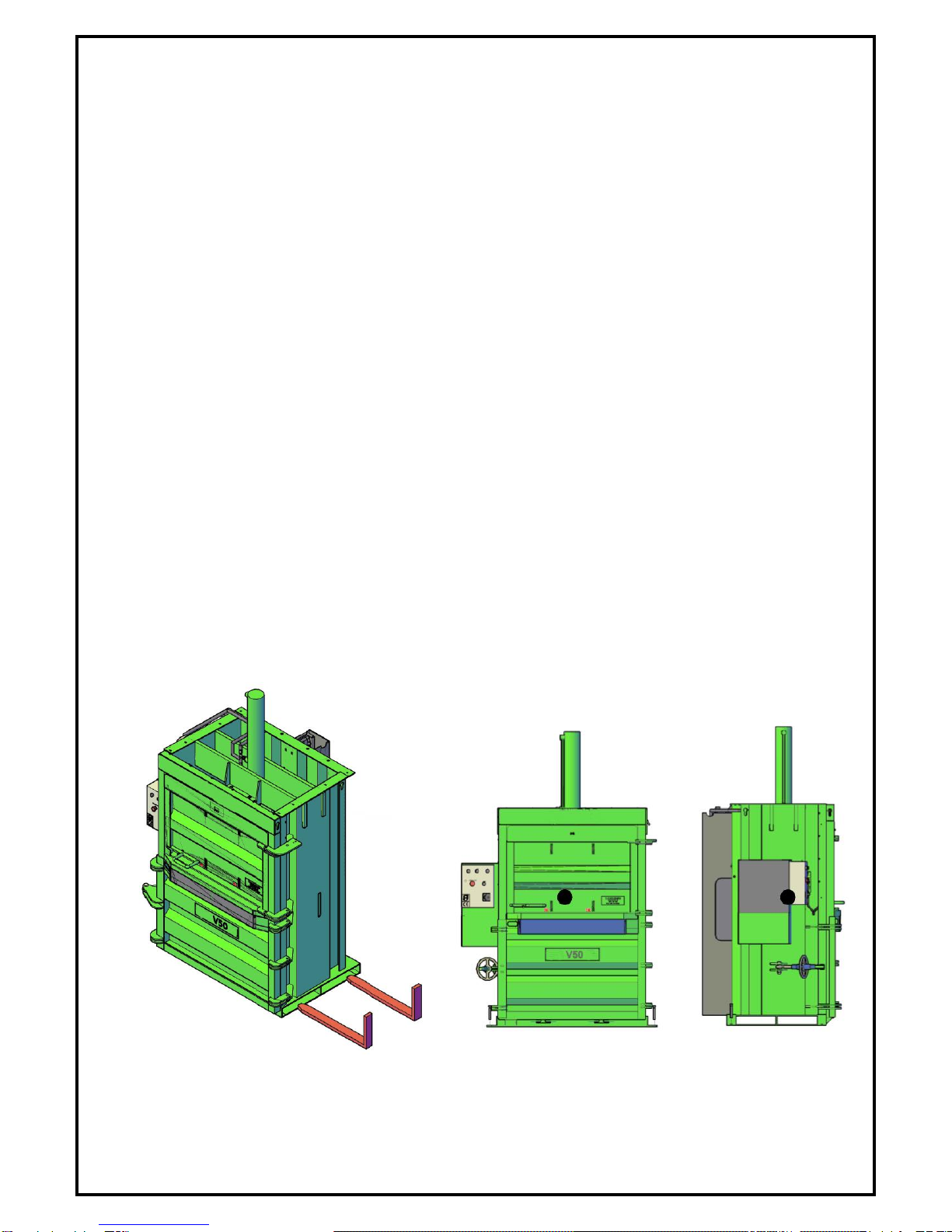

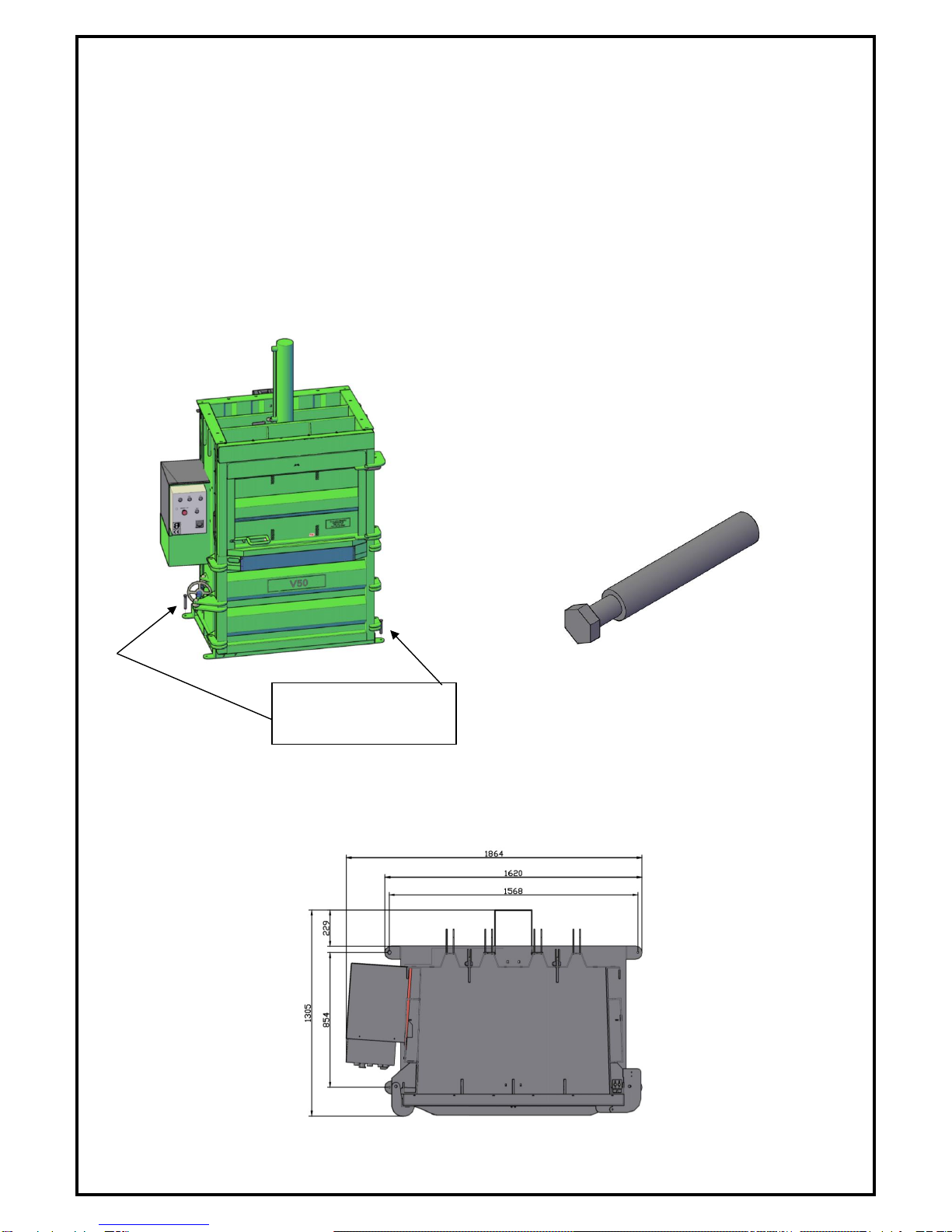

When you receive your V50 machine, the ram will be dropped into the machine’s chamber for

transport purposes (Fig 1). This procedure outlines the steps to be taken to re-fit the ram and

centreplate back into its operating position. It also outlines the steps to be taken to lower the ram

and centreplate if the machine has a requirement to be transported again for any reason.

To fit the ram back to its housing, carry out the following steps;

1) Plug in machine and turn on. (Check motor rotation is correct or machine will only run but not

develop pressure)

2) Make sure the doors are closed.

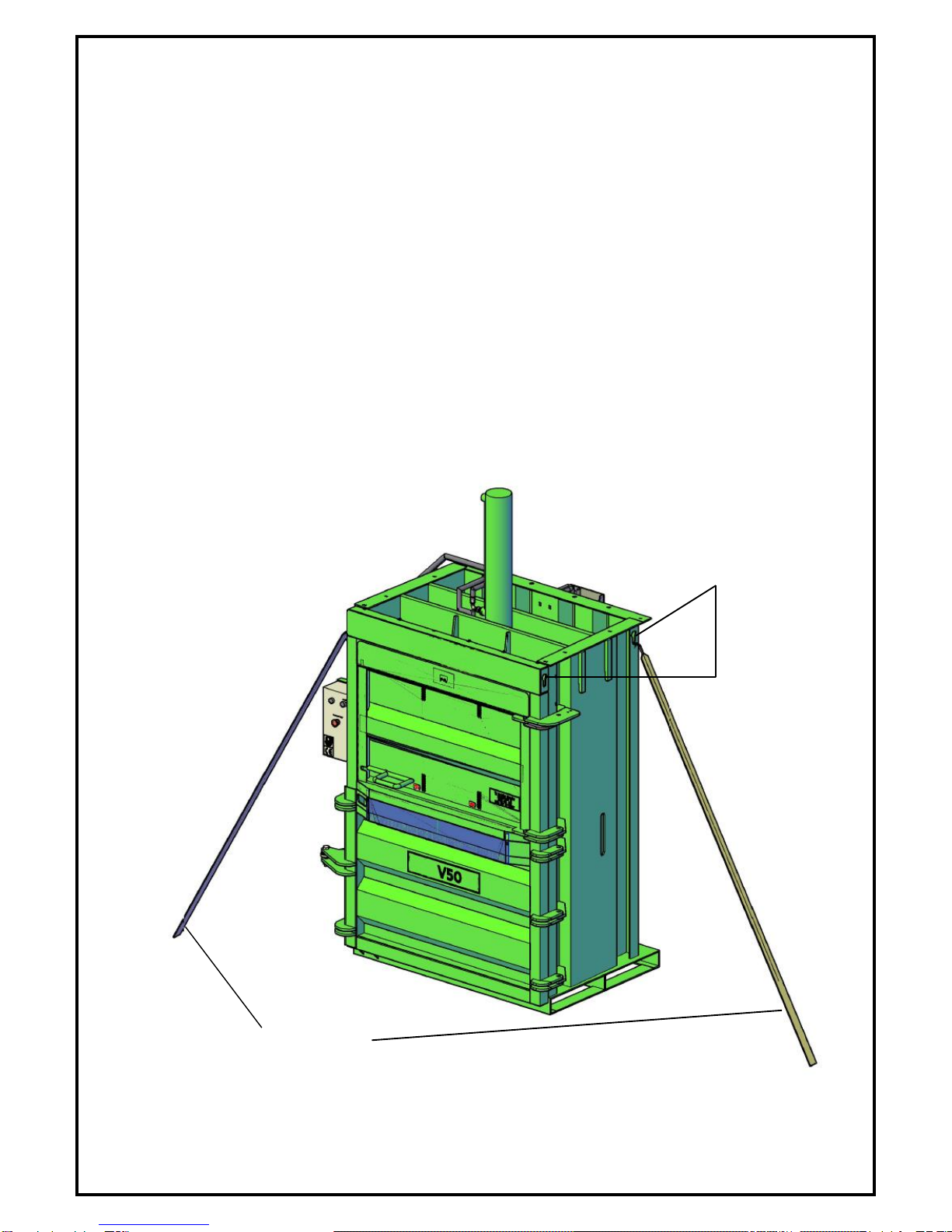

3) Before moving the centreplate, ensure the ram is orientated so that the hoses and fittings will

not get caught on the machine.

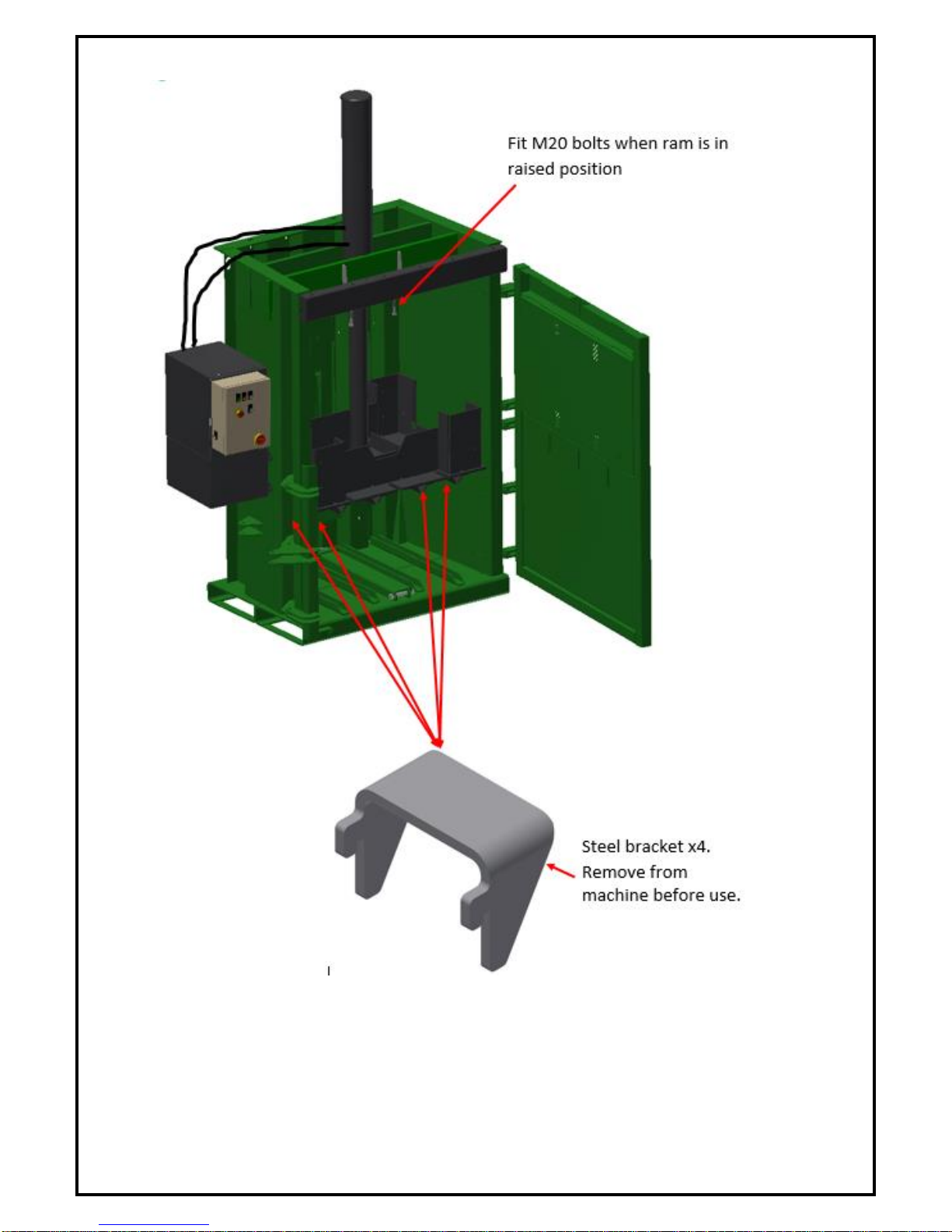

4) On the control panel press and hold the DOWN button (See page 27 for button location if

unsure.) This will move the centreplate ram up as it is resting on four steel brackets (fig 3).

Stop pressing the button every couple of seconds and open the topdoor to check ram position

(fig 2). Always keeping an eye on hydraulic pipes and making sure they do not become

trapped or get cut.

WARNING! IF THE UP BUTTON IS PRESSED THE

HYDRAULIC HOSES WILL GET DAMAGED OR CUT OFF.

5) Continue to press the DOWN button until the ram has reached the end of its travel and is

approximately 5mm away from the mounting bracket.

6) When the ram base plate has reached the end of its travel and is approximately 5mm away

from the mounting bracket, activate the emergency stop button. (See page 27 for button

location if unsure.)

7) Disconnect the power running to the machine.

Fit M20 bolts up from the bottom (nuts on top) and tighten (fig 2). You may need to adjust the ram

position to line up the bolt holes. Ensure when tightened that the ram plate is in contact with the

mounting bracket.

**Remove 4 steel brackets from machine chamber (fig 3) **

Keep brackets with machine for future use.

You are now ready to start baling. Enjoy!

Note: Engineer should not enter machine at any

stage unless machine E-stop button is pressed and

machine is completely isolated at control panel and

at the power source. (IE. Plug and switch board).