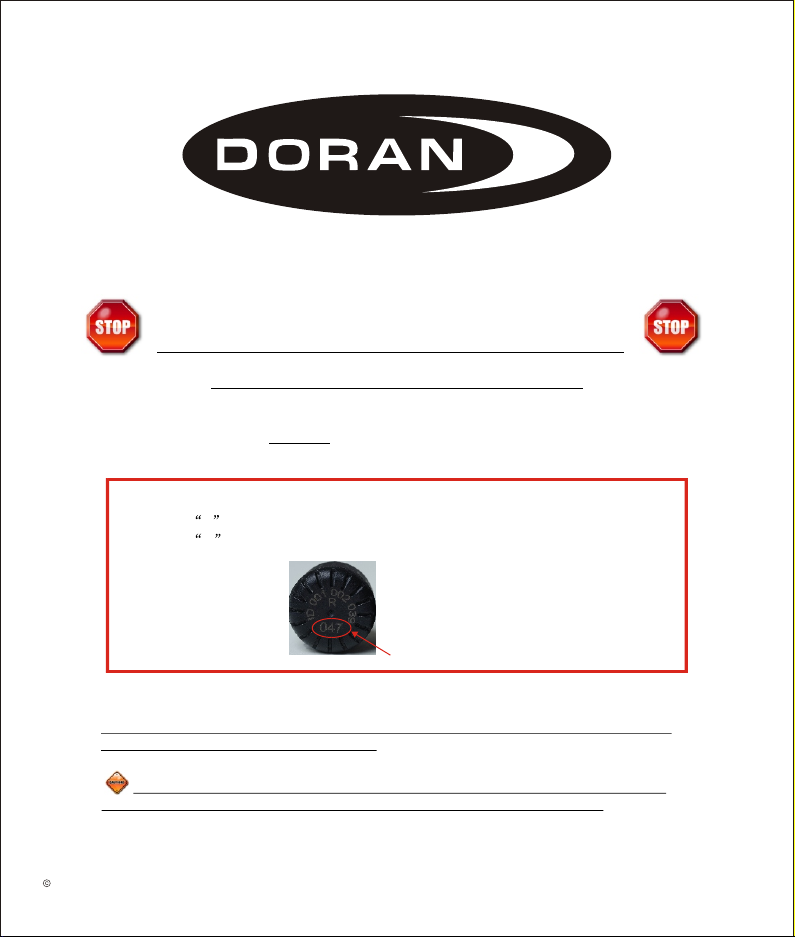

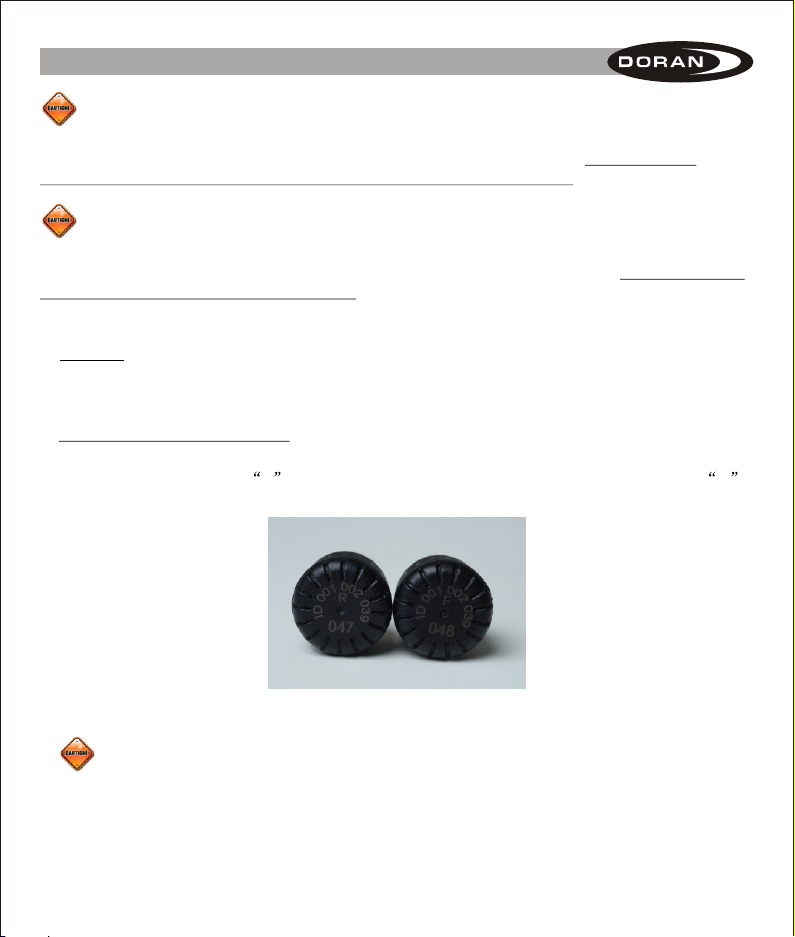

IMPORTANT: BEFORE GOING ANY FURTHER, PLEASE WRITE DOWN THE LAST THREE

DIGITS OF THE SERIAL NUMBERS OF EACH SENSOR ON THE FRONT PAGE OF THIS

MANUAL FOR YOUR FUTURE REFERENCE.

READ ALL OF THESE INSTRUCTIONS BEFORE INSTALLATION

Introduction

Installation

When you receive your new system:

Sensor IDs are already preprogrammed to your monitor

Baseline pressures are already set to 35 psi

Attach monitor and sensors per instructions.

Read all instructions carefully for complete system operations.

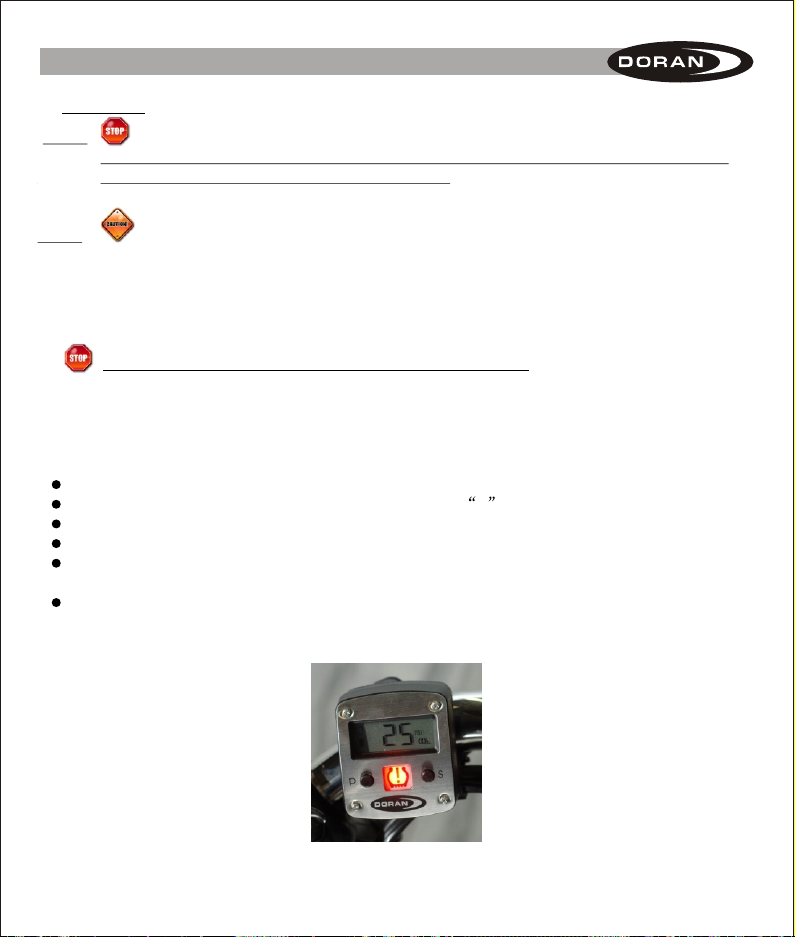

A. Monitor

We recommend that the monitor be placed in front of and in clear view of the driver at

all times.

The installation of the DORAN 360M is quite easy!

1. Locate a mounting position of your choice and attach the monitor to the vehicle. Included in

your kit is a handle bar mounting bracket and double-sided adhesive pads that you can use to

attach the monitor.

Option: If you prefer your monitor to be less noticeable, you may want to use the remote LED

warning light, which will also provide a low-pressure warning. This can be attached to

the mirror, fairing, or other part of the motorcycle. When a warning is received, the

light will blink and you can retrieve the pressures by looking at the monitor when you

stop to check the tires.

2. Connect the ( ), positive wire to a 12-volt positive connection, and the (black) negative wire

to a good ground connection. The monitor is fused internally so you will not need to install a

fuse in-line. You may want to connect the positive wire to a switched connection so the unit

is only operational when the vehicle is running. This will save battery power when the vehicle

is not being used, but with this method, alerts that are transmitted while the monitor is

turned off will not be updated until the ignition switch is turned on. It could take up to

six minutes for the sensors to report in to the monitor for present updates.

red

2