Installation/Use/Maintenance Instructions

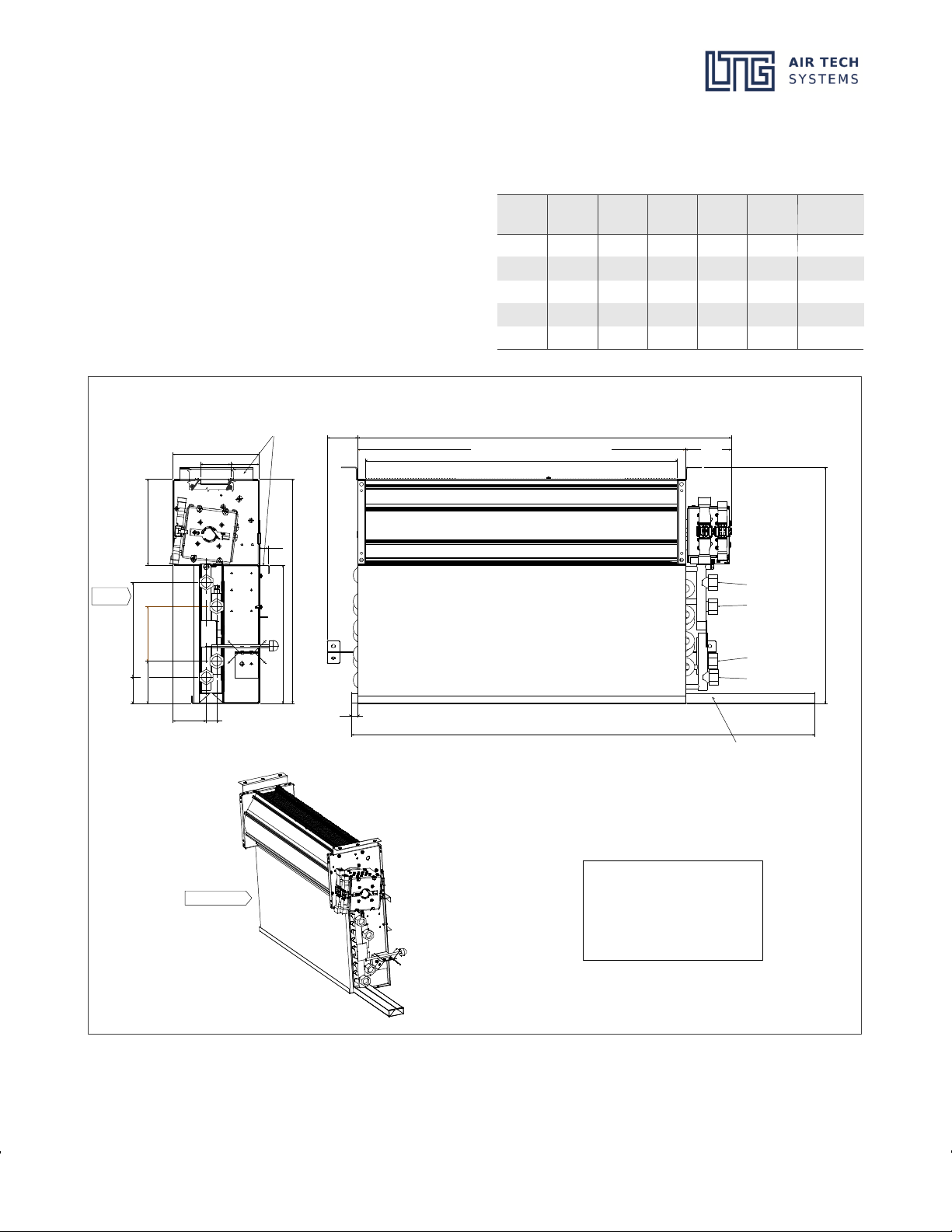

Fan coil units VFC, installation in sills

ELTG Incorporated ·PO Box 2889 ·Spartanburg, S.C. 29304, USA VFC_USA_BA (07/19)

Phone 864 599-6340, Fax -6344 ·e-mail: info@LTG-INC.net ·Internet: www.LTG-INC.net

Former editions are invalid ·Subject to technical modifications page 3 of 19

1. Safety

Assembly, dismantling and mainte

nance must be performed by trained

personnel in order to achieve reliability,

safety and best results.

1.1 Explanation of symbols and hints

Operating safety symbol

This symbol is placed alongside every

operating safety instruction in these op

erating instructions, wherever there is a

danger to life and limb. Observe these

instructions and in such cases proceed

with extreme caution. Pass on all the op

erating safety instructions to other

users. In addition to the instructions

contained in these operating instruc

tions, the generally applicable safety

and accident prevention regulations

must be observed; as shown here, for

example: Warning of hazard point.

Information symbol

This information symbol is placed

alongside those points in the manual

which must be specifically observed in

order to ensure that the guidelines, reg

ulations, instructions and correct oper

ating sequences are observed and to

prevent damage to or destruction of the

unit and/or other components in the

system.

These mandatory symbols are linked to

the operating safety instructions and

show which protective measures must

be complied with at the appropriate

workstations and therefore specifically

mandate a certain action, as shown here

as an example: Wear protective gloves.

These prohibition symbols are linked to

the operating safety instructions ban

ning a dangerous or risky action, as

shownhereasanexample:Donot

touch.

1.2 Operating safety instructions

Carefully read the safety instructions before using any LTG

fan coil unit. Always follow the safety instructions!

The units meet any pertinent safety standards.

The installation and maintenance of air

conditioning units may be dangerous be

cause of high pressures and electrical com

ponents being alive. Therefore, the installa

tion, maintenance, and repair must be per

formed by qualified and trained staff only.

In particular electrical connections are to be provided,

removed, or modified by authorized persons only ob

serving all relevant safety instructions.

Safety instructions in the technical documentation and

on unit labels must be followed at all times.

Do not open theunit for cleaning,maintenance, orrepair

and do not remove covers and casings (air diffuser) un

less all conducting lines have been completely discon

nected. Do not connect or remove the plug-in connector

when under tension.

Any work regarding the electrical equipment is to be

performed by skilled and trained staff only. Connections

to the main power supply and the safety earth terminal

must be executed exactly as described in the wiring dia

gram.

Electrical operation of the unit in a partly disassembled

condition or of individual components is not permitted

since earth terminals might be interrupted.

During continuous opera

tion the motor may reach

temperatures of up to

149 °F. If necessary, allow

the motor to cool off or wear

gloves.

In the heating mode a water

temperature of up to 176 °F

may be achieved. Water-

carrying parts may be hot

so do not touch with your

bare hands to avoid burns.

Be careful when performing

work on the heat exchang

ers. Blades and housing

parts are sharp-edged.

Wear gloves during work

and handling.