8

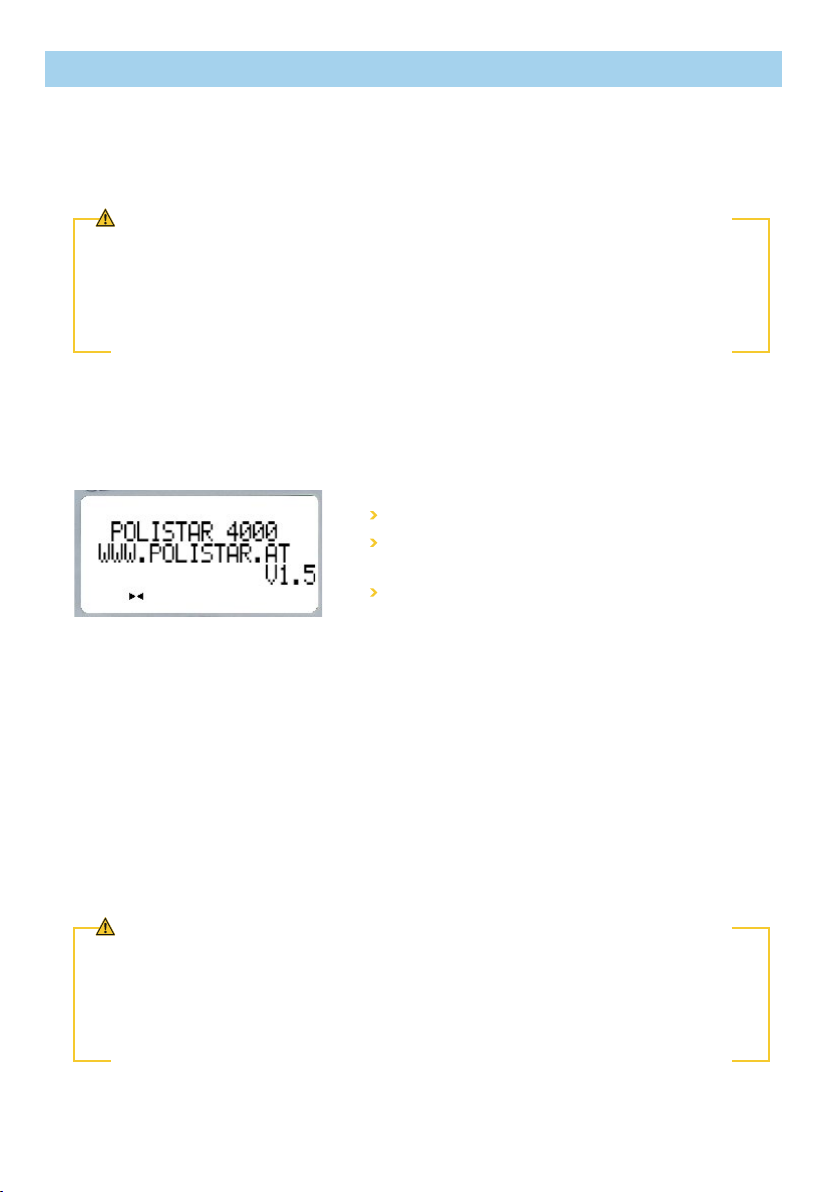

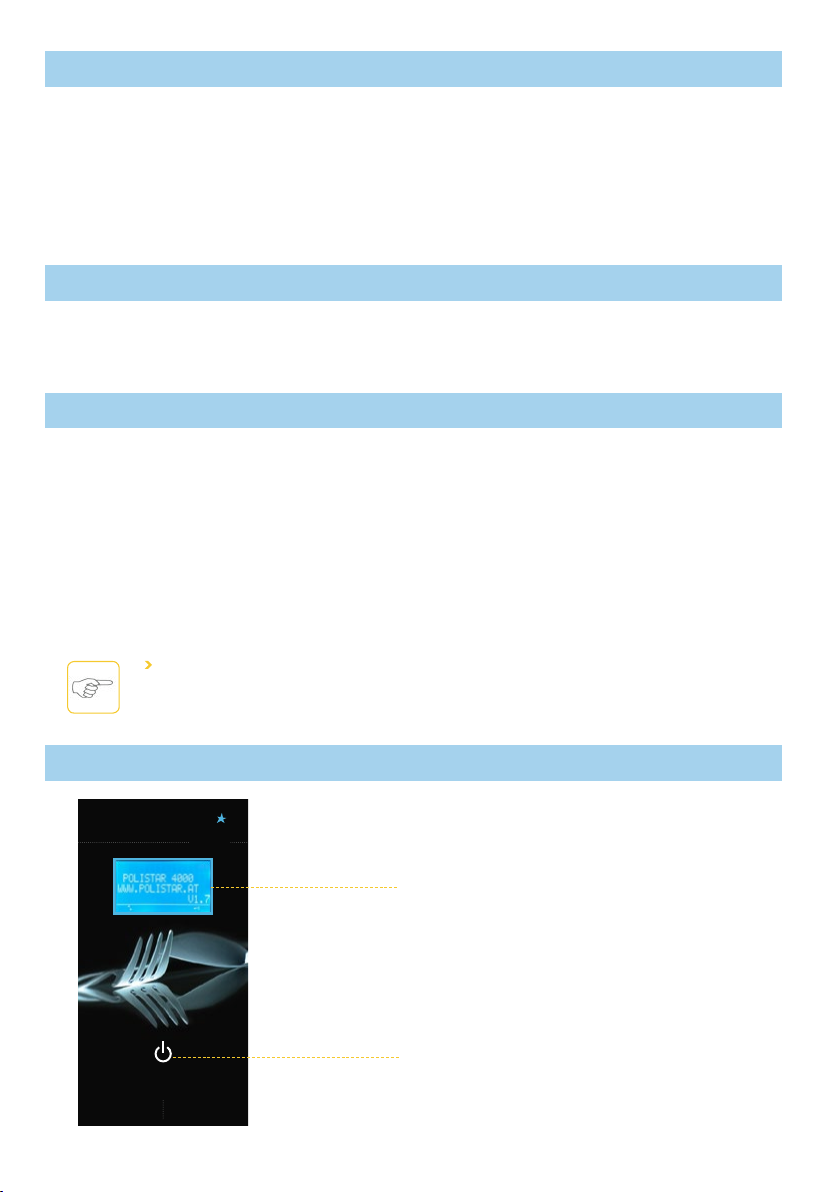

1st Line: Display of the model name

2nd Line: Display of the web site of the product

manufacturer

3rd Line: Display of the software version

4. IMPORTANT INFORMATION

Non-authorized and unqualified persons must not start, operate or repair the machine. The

integrated safety equipment must not neither be changed nor dismantled. Please adhere to

these operating instructions when performing all activities in connection with the flatware

polishing machine POLISTAR 4000.

When ordering spare parts or in case of technical inquiries, always provide the model name and

the serial number. The above information and the machine data can be found on the name plate,

which is attached at the inside of the cover. Information about the date, time, model name and

software version is shown on the display as soon as you close the cover again.

Please note that only original spare parts may be installed into the machine, because the warranty

claim expires otherwise.

In addition to the original spare parts, the POLISTAR 4000 also offers accessories. LUGAMA

offers POLIDRY (article number 204ZB00002) polishing granulate, POLICLEAN (article number

208ZB00002) cleaning alcohol as well as flatware transport carts in stainless steel (with PVC

tub and four steering rollers) at an optimal work height for the flatware insertion and discharge.

Please ask your authorized specialty retailer.

The machine is equipped with an UVC lamp. The light of the UVC lamp sterilizes the surfaces in

the flatware and the granulate.

ATTENTION!

Objects must not be placed on the machine! Neither the inside nor the surface of the machine must

be subjected to a gush of water, because water penetration can damage the electronics (see item

12.1 Cleaning). Under no circumstances must the machine be cleaned with jet water (hose) or a high

pressure cleaner. Do not use abrasives, acids, lyes, steel wool or steel brushes for cleaning, because

the machine would be damaged by these materials.

ATTENTION!

The radiation of this UVC lamp is dangerous for eyes and skin. For your safety, the machine is designed

in such a way that the UVC lamp switches off automatically if the machine cover is opened.

The flatware polishing machine will be heated to 115 °C. Let the machine cool down for a few minutes

before you start cleaning the inside of the machine. During operation, please do not perform any

grabbing actions into the inside of the machine or into the polishing granulate.