31-Open

Rigging Manual

Page:

3 of 15 Total Task Time:

N/A

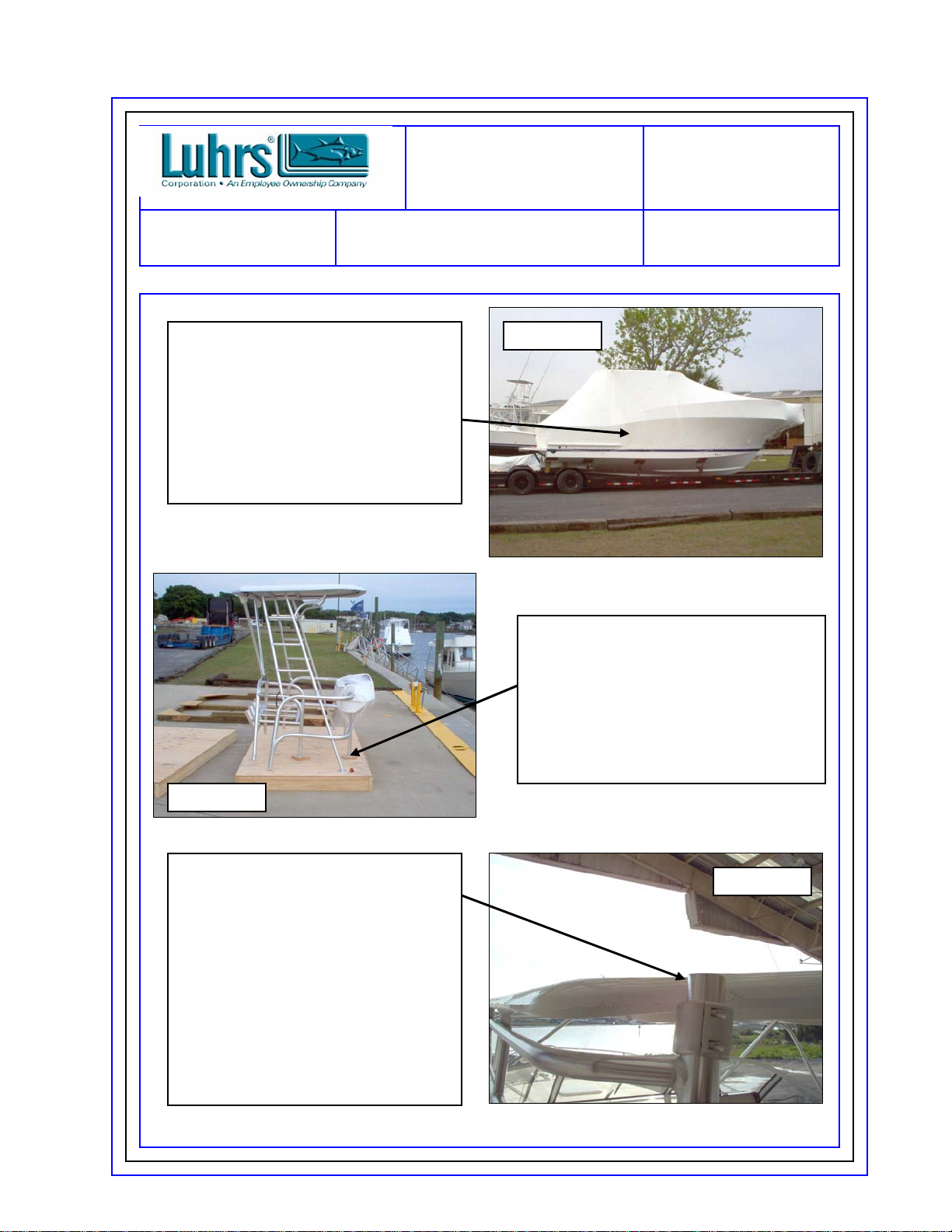

Once all lines are pulled snug as

shown in figure: 4.The console and

sunshade are ready to be put on

top of the hardtop. The whole

upper station can be picked up as

one piece. Make sure to support

the console when lifting. Best

procedure is to use a forklift and

pick up the upper station while still

on the cradle and slide upper

station off cradle once you get it

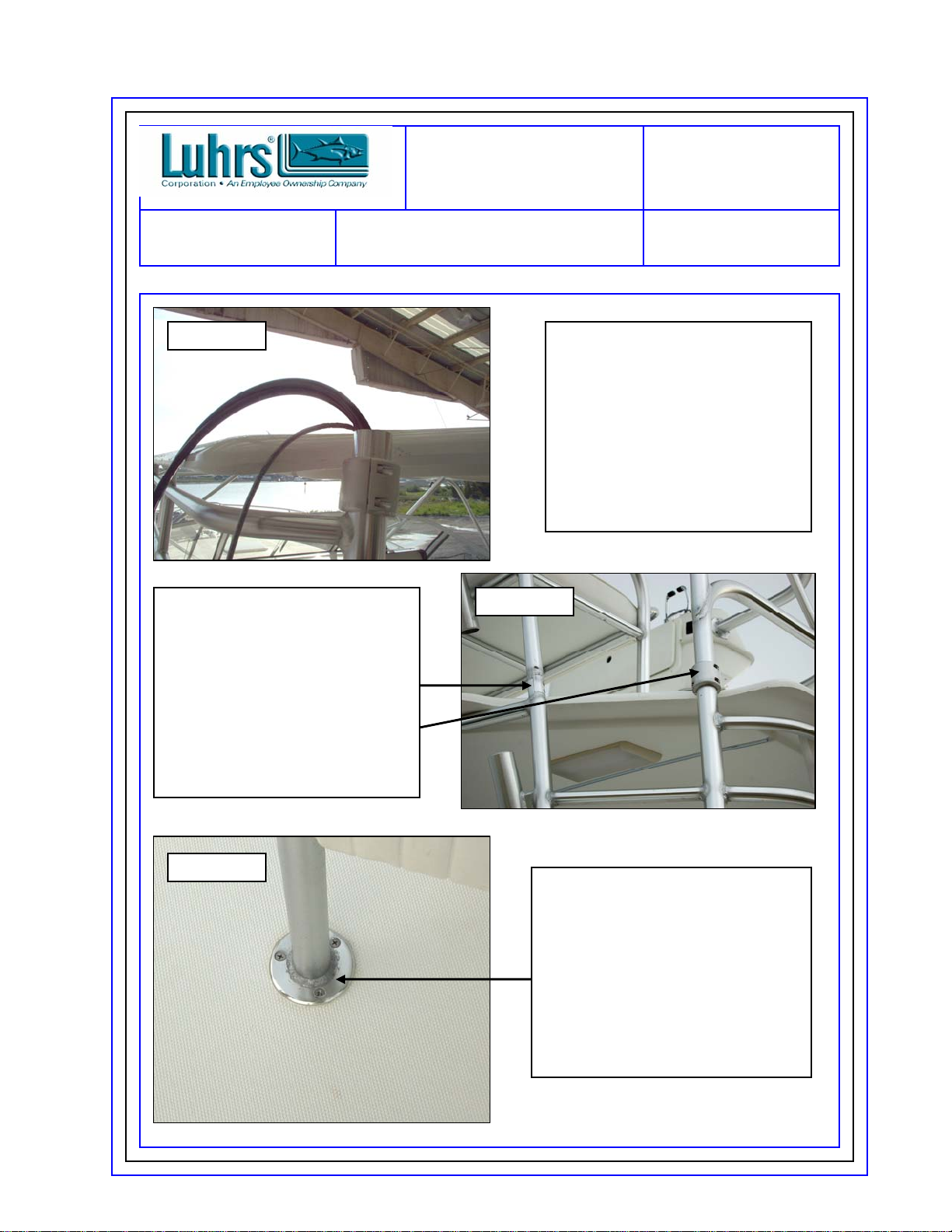

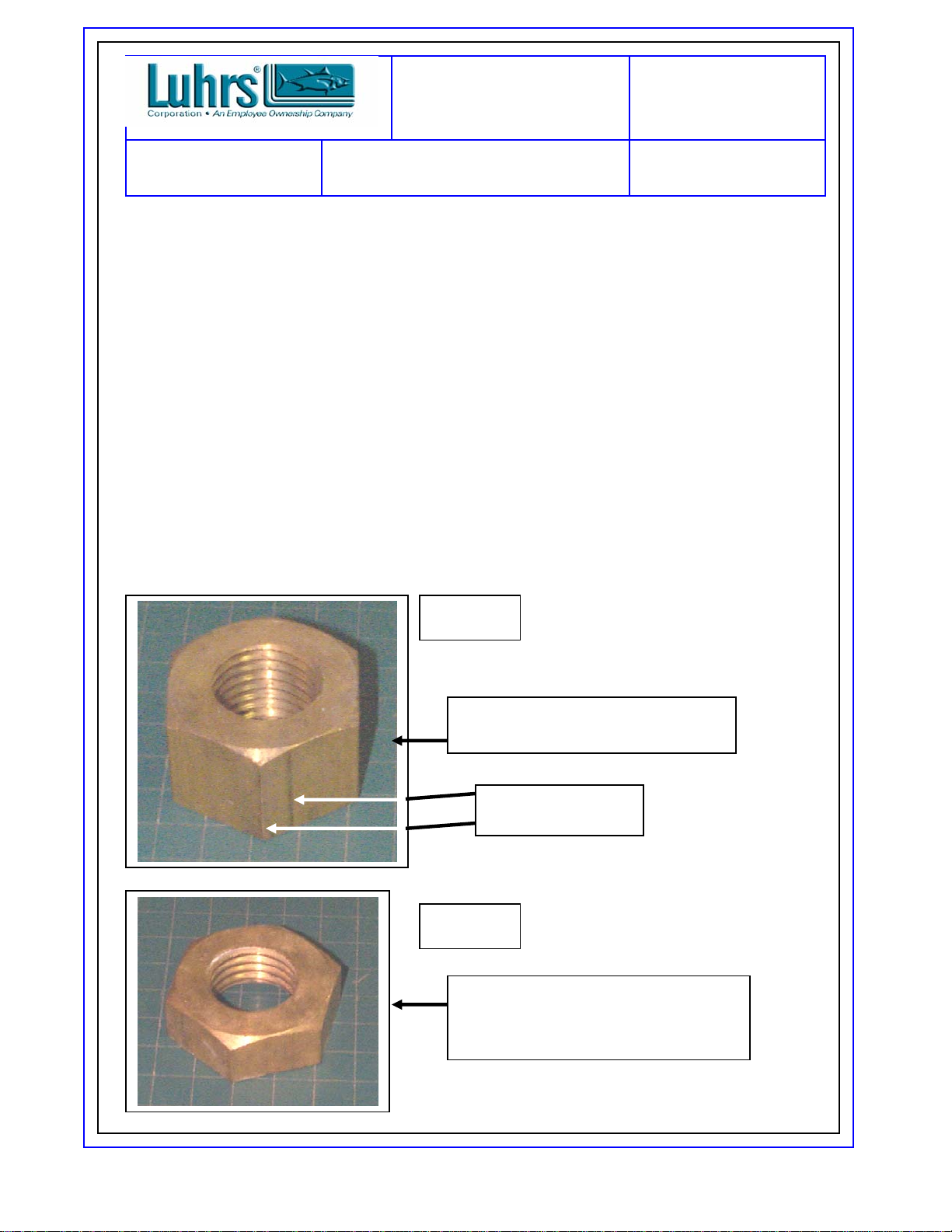

Figure: 5 is showing how to

connect the aft legs of the upper

tower to the ladder after the upper

station is in place. The outside leg

has a collar that tightens with allen

bolts and the inside tube connects

with allen bolts into each other.

Both the collar and allen bolts are

provided in the loose gear kit. This

will be the same on both the Port &

Starboard aft legs.

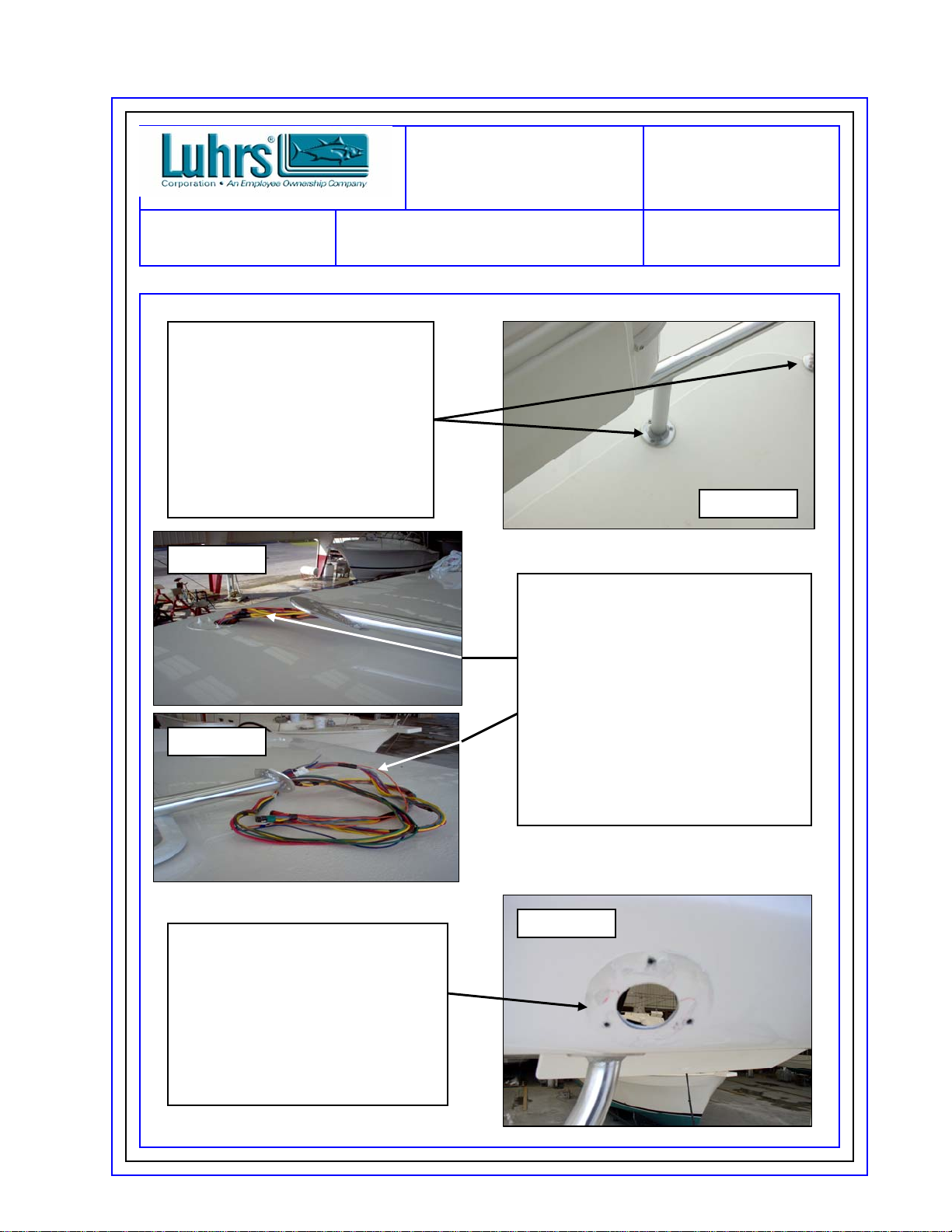

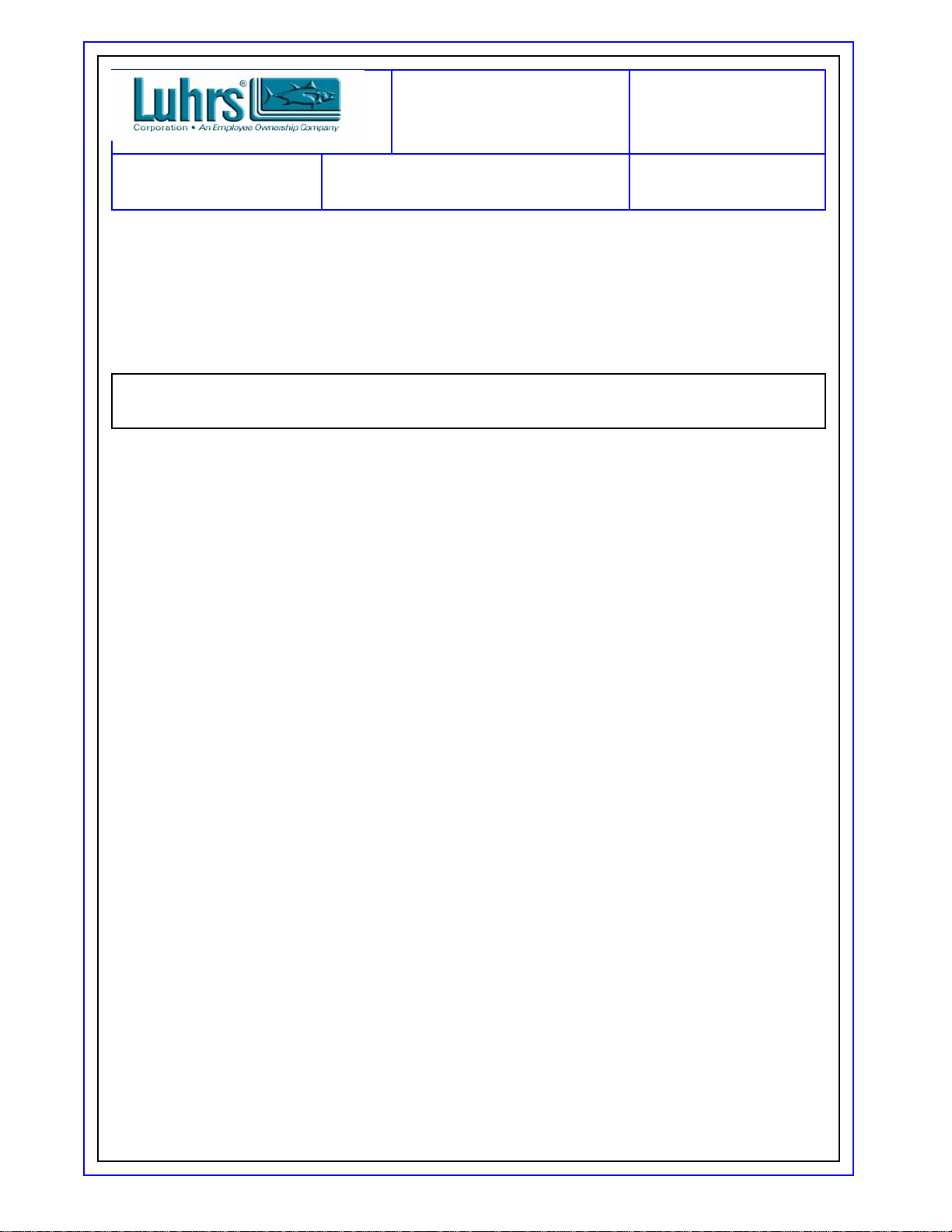

Figure: 6 is showing the base of the

seat pad. Install using ¼ x 20 x 1” f/h

screws provided in rigging kit to

secure seat. There will be pre-drilled

holes that have been pre-tapped at

the factory that you line holes in pad

up with for ease of installation. Make

sure to use 5200 sealant provided in

loose gear to get a water tight seal.

Do this with both pads that are under

upper bench seat.

Figure: 5

Figure: 6

Figure: 4