9

D_IN4 – the application of a high state triggers the activation of the welding process according to the preset

programme, whereas the application of low state, if a high state was previously applied at this input,

triggers the deactivation of the welding process (start/stop at level). NOTE Floating output – state

should be applied between D_IN4A and D_IN4B pins with any polarity.

D_OUT1 – a closed contact indicates generator standby (power supply on, scanning completed).

D_OUT2 – a closed contact indicates that the welding process is in progress.

D_OUT3 – a closed contact indicates that the scanning process is in progress.

D_OUT4 – a closed contact indicates that an error occurred.

24 V – 24 V DC / 1.5 A auxiliary power supply output which can be used to supply an external automation

system.

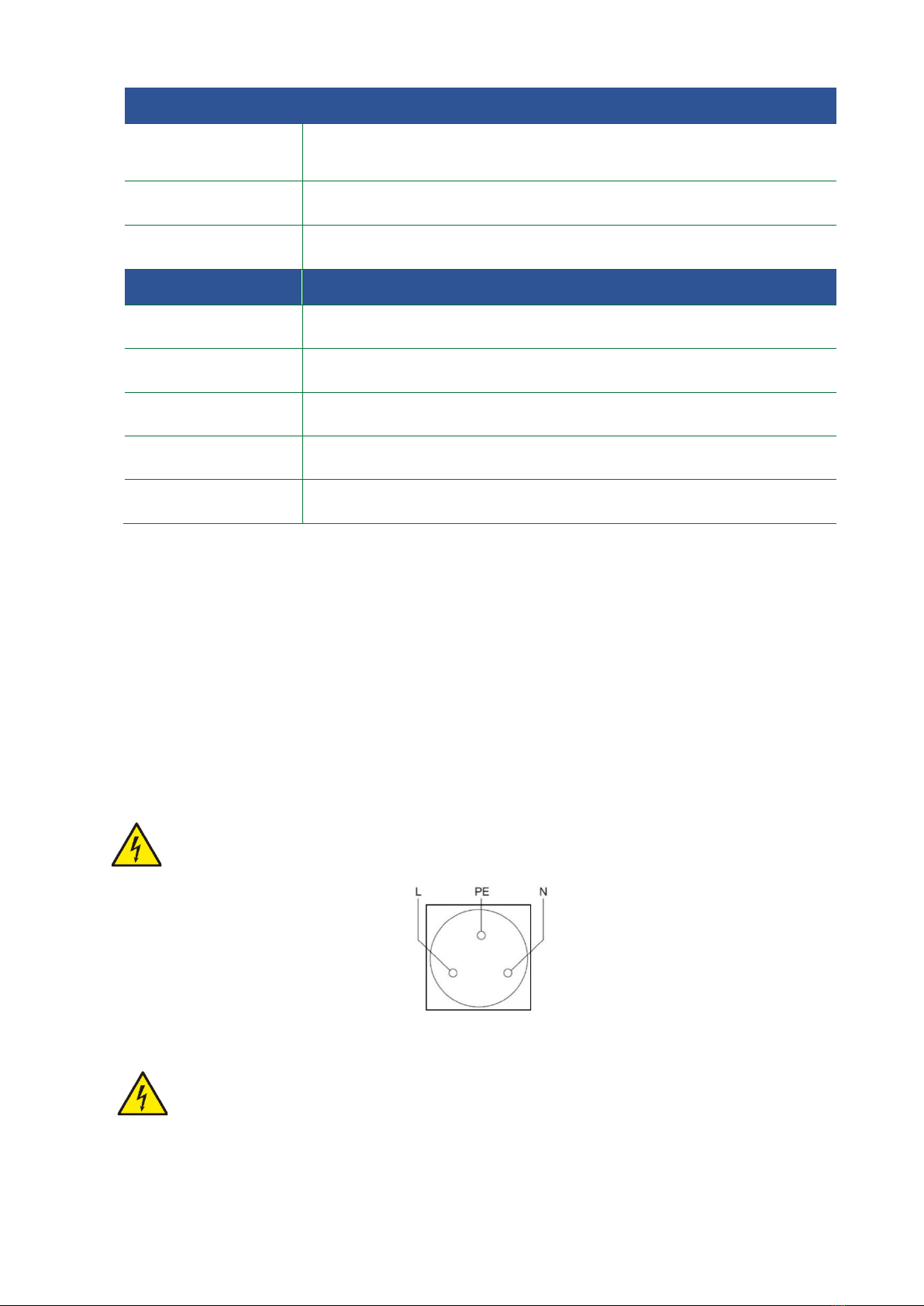

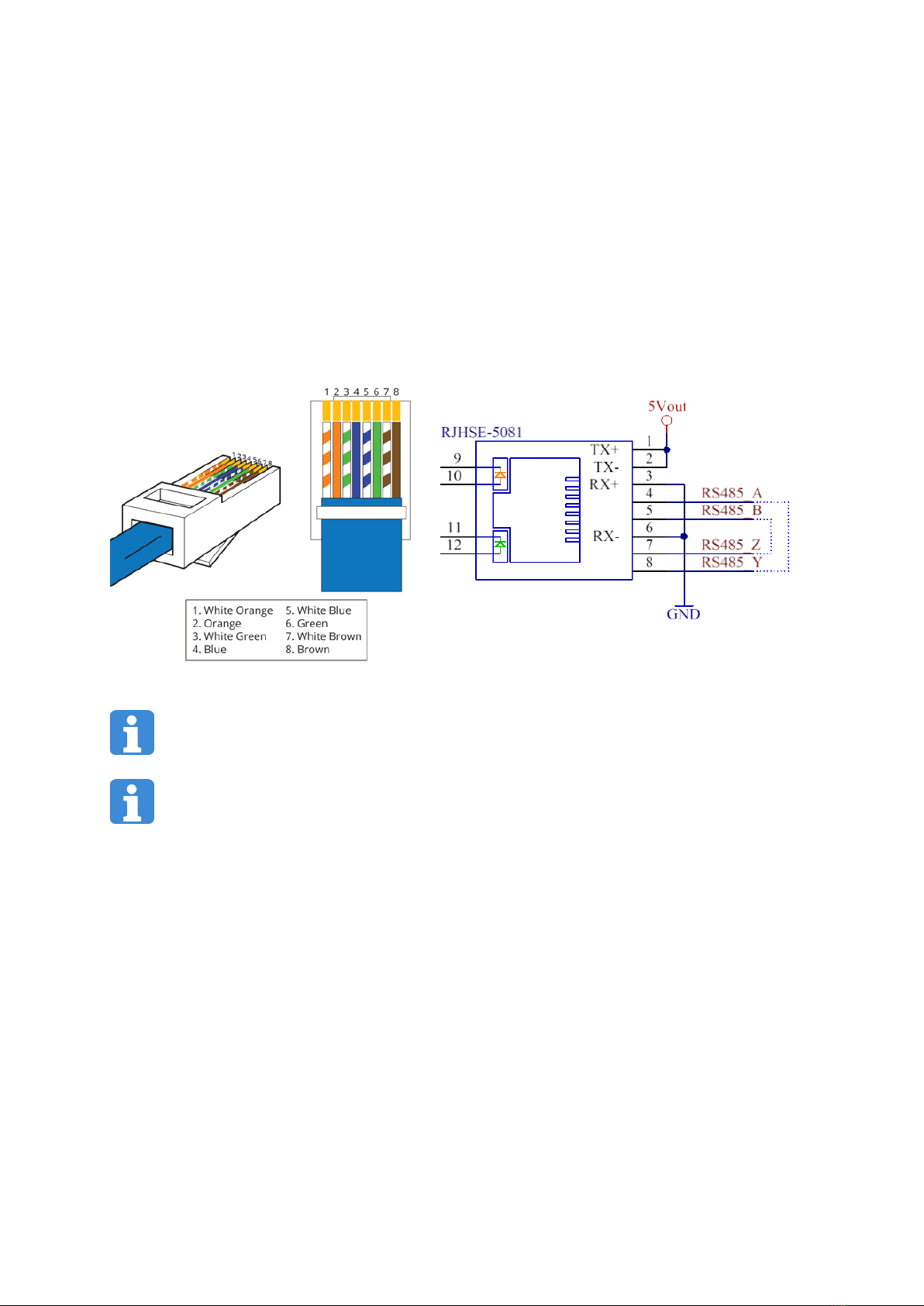

3.4. RS-485 MODBUS RTU communication interface

The generator is equipped with an RS-485 communication interface that supports MODBUS RTU transmission.

The I/O card has a RJ-45 connector, designated as RS-485. It is compatible with a UTP twisted pair. A connection

diagram is presented in Fig. 5.

Fig. 5 RJ-45 interface diagram and RS-485 interface cable and plug diagram

Transmission and reception lines are separated at this interface. To operate using RS-485, the appropriate

lines should be interconnected (as indicated with the broken line on the diagram). 5 V auxiliary output

voltage with a current efficiency of 100 mA is available at this interface.

To activate the MODBUS RTU communication unit, set the activity switch in the RS-485 position in the

SETTINGS menu to active (green) by clicking it.

MODBUS RTU:

RS-485/RS-422 transmission

Setup: 8 data bits, no parity, 1 stop bit

Bitrate: 9600 bps (to change, go to SETTINGS -> RS-485)

Generator address: 0xAA (to change, go to SETTINGS -> RS-485)

Available commands:

FC 03 – Read n setup registers

FC 04 – Read n input registers

FC 06 – Store one setup register

FC 16 – Store n setup registers

Register map:

Input registers (read-only, FC 04 command), numbers from 30001:

30001: uint16 status; status bit field: (adr:0)

GEN_IDLE 0x00 – Generator on standby, not welding

GEN_SCANNING 0x01 – Generator scanning

GEN_WELDING 0x02 – Generator welding

GEN_ERROR 0x03 – (Protection) error occurred