659501-LTG-A-1010

Johnson Controls Unitary Products 5

between the mechanical cooling and economizer

operation. Independent blade design insures proper

control and less than 1% leak rate. Includes hood and

mesh bird screen filter integrated into the hood, dry bulb

sensor and relief damper. Separate field accessories of

single enthalpy and dual enthalpy are also available. A

built-in barometric relief of 25% is provided.

•Single Enthalpy Sensor - Sensor replaces dry bulb

sensor standard in economizer kit. Provides improved

economizer operation by sensing the dry bulb

temperature from outdoors plus the enthalpy content of

the outdoor air.

•Dual Enthalpy Sensor - Additional sensor to single

enthalpy sensor. Sensor senses both the return air

temperature dry bulb and humidity in conjunction with the

single enthalpy to determine the most economical mix.

Single Enthalpy sensor also required.

•Hail Guard Kit - Kit contains protective grilles made of

expanded aluminum with full perimeter frame. Sloped

hoods are also included to assure maximum protection.

•Filter/Frame Kit (Single Phase Only) - Kit contains the

necessary hardware to field install return air filters into the

base unit. Pre-cut filter racks and appropriate cleanable

standard size filters are shipped in one kit. The filter rack

is suitable for either 1" or 2" filters. (1" filter is supplied)

This kit is available for single phase horizontal or vertical

duct application only. Standard in all 3 Phase models.

•Motorized Fresh Air Damper - Designed for duct

mounted side supply/return and unit mounted down

supply/return applications. Damper capable of providing

0% through 50% of outdoor air (field supplied). Closes on

power loss, includes hood and screen assembly.

•Rectangle To Round Adapters - Kit includes one supply

and one return air rectangle to round duct adapter.

Adapters are preformed and designed to fit over current

duct openings on the base unit. Transition is from side

square duct opening to 14" round duct opening.

•Roof Curbs - NRCA approved curbs provide proper fit to

base unit for rooftop installations. Curbs are designed to

be assembled through hinge pins in each corner. Kit also

provides seal strip to assure a water tight seal. 8 and 14

inch high roof curbs are available.

•Manual Outdoor Damper - Provides 0% through 50%

outdoor air capability (field adjustable). Designed for duct

mounted side supply/return applications. Includes hood

and screen assembly.

•Wall Thermostat - The units are designed to operate with

24-volt electronic and electro-mechanical thermostats. All

units can operate with single stage heat/single stage cool

thermostats - with or without the economizer.

•Low Ambient Kit - Kit provides necessary hardware to

convert unit to operate in cooling cycle down to 0º F.

Standard unit operation 45º F.

•Transformer Kit - Kit provides necessary hardware to

provide single phase models from factory furnished 40 VA

transformer capability to 75 VA transformer capability.

(Required on installations with economizer or motorized

damper.)

Guide Specifications

General

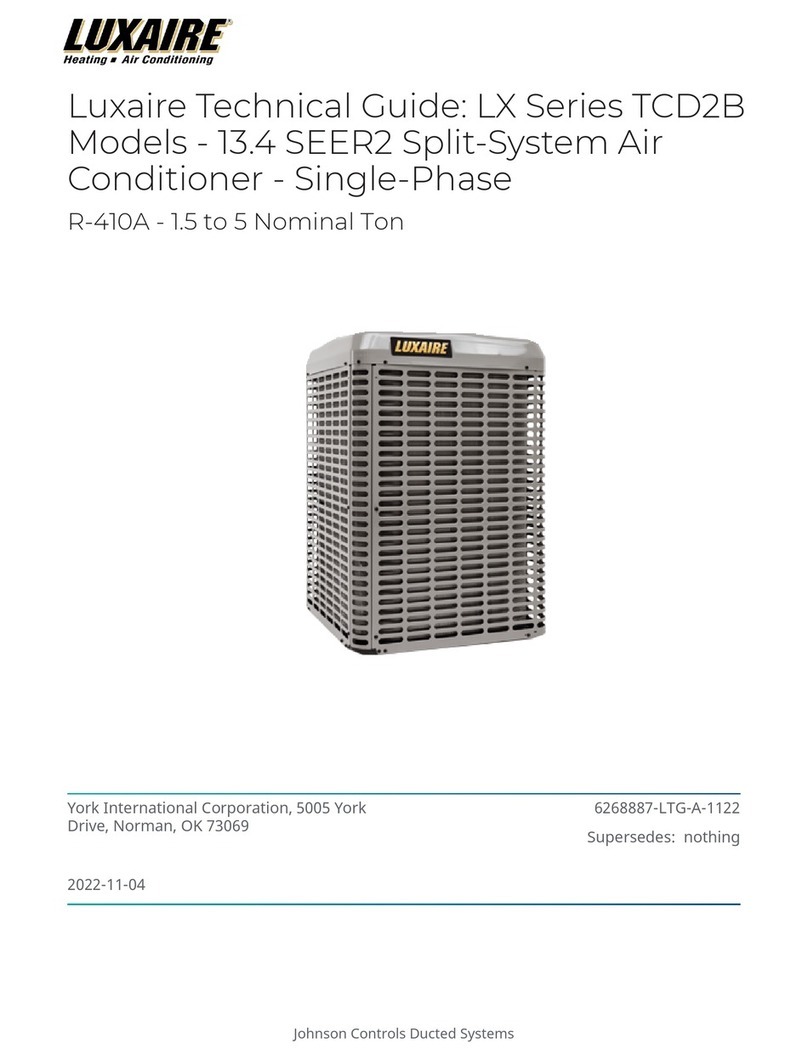

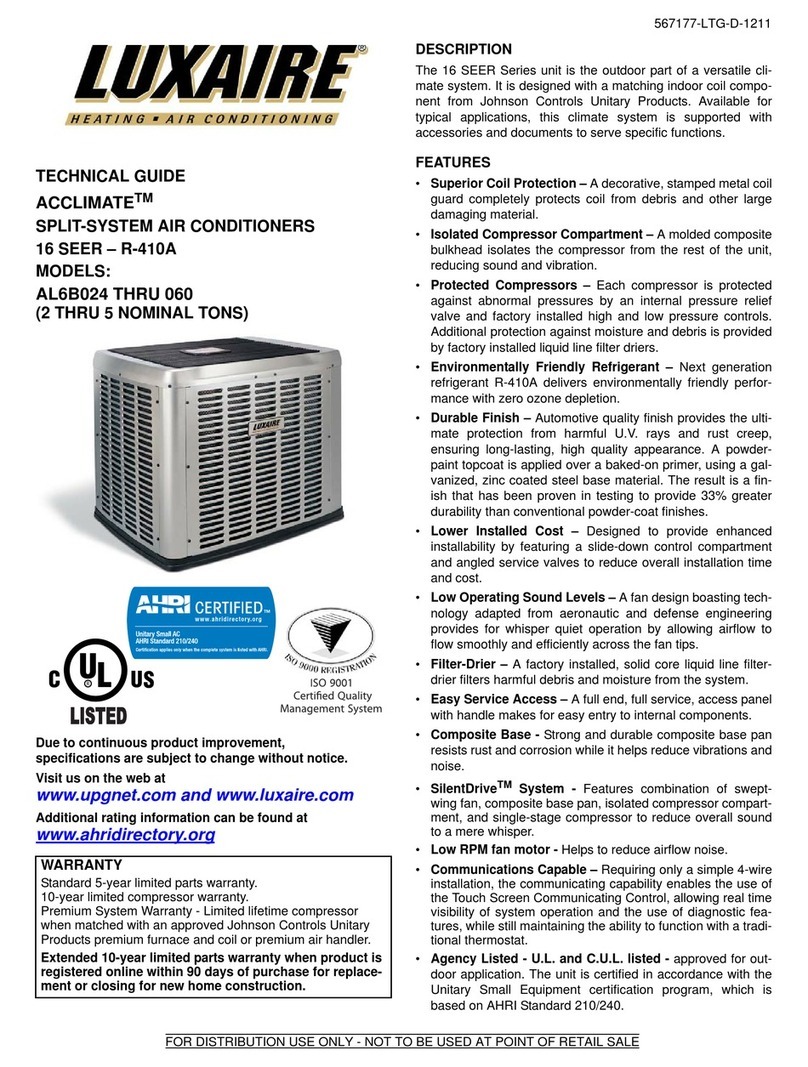

Units shall be manufactured by Unitary Products in an ISO

9001 certified facility. Luxaire Acclimate™package units give

you the flexibility and choices you need in today’s market.

These packaged cooling/heating air conditioners are designed

for outdoor installation. Only utility and duct connections are

required at the point of installation. The single or two stage gas

fired heaters have aluminized steel tubular heat exchangers

and spark to pilot ignition. They are available in natural gas with

field conversion to propane.

Description

Units shall be factory-assembled, single packaged, Electric

Cooling/Gas Heating units, designed for outdoor mounted

installation. For SEER ratings, refer to technical literature. They

shall have built in, equal size, field convertible duct connections

for down discharge supply/return or horizontal discharge

supply/return. The units shall be factory wired, piped, charged

with R-410A Refrigerant and factory tested prior to shipment. All

unit wiring shall be both numbered and color coded. All units

shall be manufactured in a facility certified to ISO 9001

standards, and the cooling performance shall be rated in

accordance with DOE and ARI test procedures. The heating

performance shall be rated to DOE and GAMA test procedures.

Units shall be CSA listed and classified to ANSI Z21.47/CAN/

CSA 2.3 standards and UL 1995/CAN/CSA No. 236-M90

conditions.

Unit Cabinet

Unit cabinet shall be constructed of galvanized steel, with

exterior surfaces coated with a non-chalking, powdered paint

finish, certified at 1000 hours salt spray test per ASTM-B117

standards. The unit top shall be a single piece “Water Shed”

design, with drip edges and no-seam corners to provide

optimum water integrity. Unit shall have a rigidly mounted

condenser coil guard to provide protection from objects and

personnel after installation. Indoor blower section shall be

insulated with up to 3/4” thick, aluminum, foil faced insulation,

fastened to prevent insulation from entering the air stream.

Cabinet panels shall be “large” size, easily removable for

servicing and maintenance, with built-in lift handles. Unit shall

be built on a formed, “Super-Structure” design base pan, with

embossments at critical points to add strength, rigidity and aid

in minimizing sound. Full perimeter base rails shall be provided

to assure reliable transit of equipment, overhead rigging, for

truck access and proper sealing on roof curb applications. Base

rails shall be removable, when required, to lower unit height.

Filters shall be furnished and be accessible through a

removable access door, sealed airtight. Units vertical discharge

and return duct configuration shall be designed to fit between

standard 24” O.C. beams without modification to building

structure, duct work and base unit. Condensate pan shall be