Website: www.luxielectronics.com

Phone: +1 (949) 654-2047

Address: Irvine, CA, USA

Document name: HHT-100 user manual Revision: 1.01 Date: 8/29/2012

Specifications are subject to change without notice

Thank you for purchasing the Luxi Electronics HHT-100 HDMI

cable tester. Please read through this manual before using the

product.

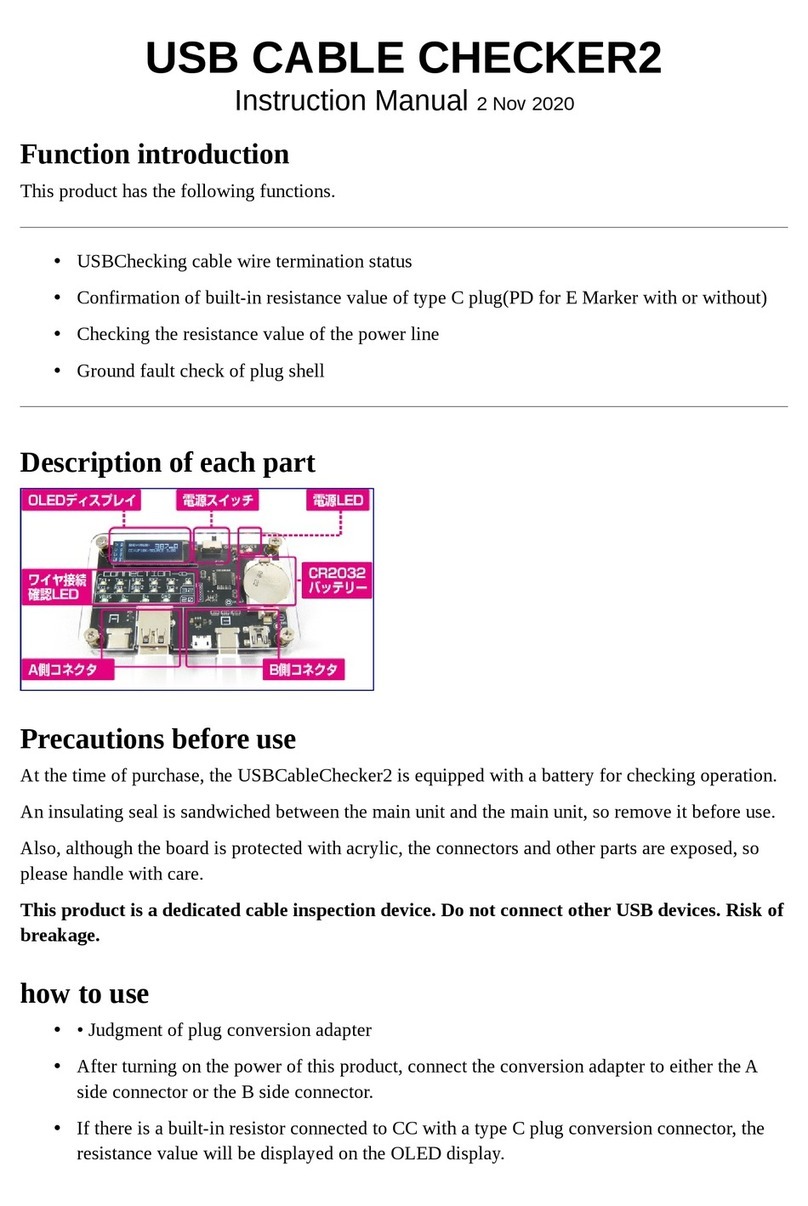

Product overview:

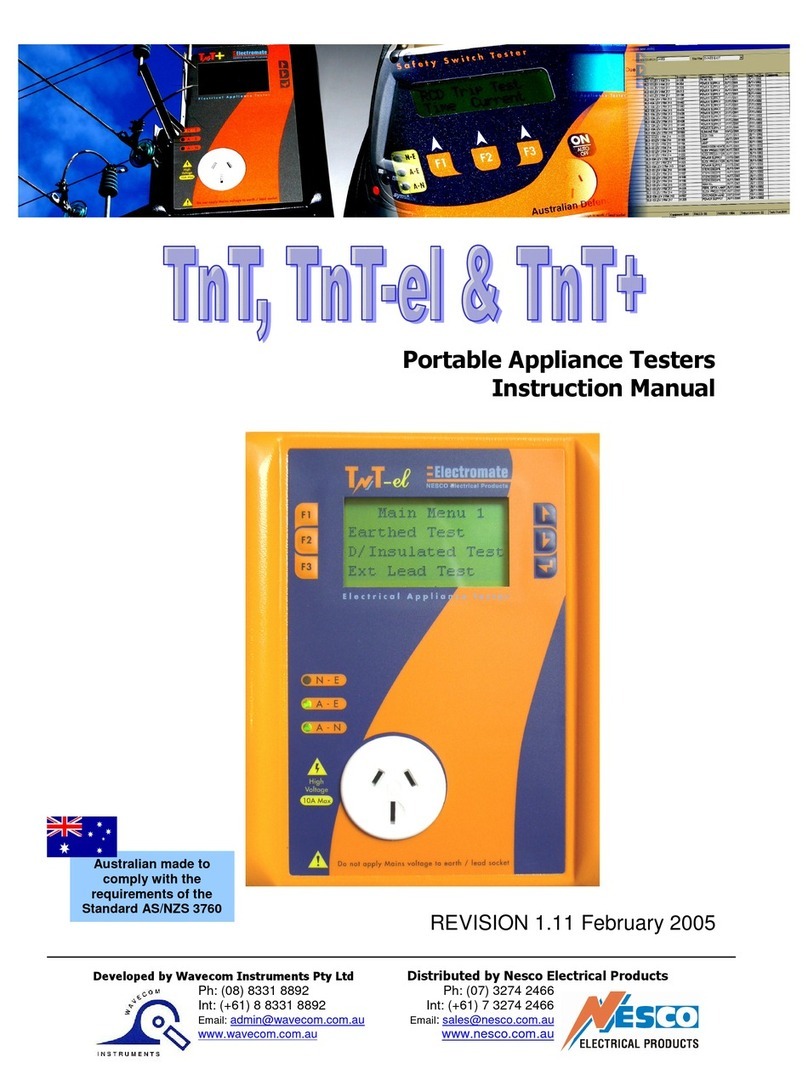

The HHT-100 is an HDMI cable continuity tester designed for

quick and easy test in the field. It can be used for other purposes

as well. The HHT-100 consists of a transmitter (Tx) unit and a

receiver (Rx) unit. This two piece design allows the test of the

long HDMI cables installed in the wall or in other places where

the two ends of the cable are not in the same place.

Battery installation and replacement:

Two AA batteries (not supplied) are needed in the Tx unit; no battery needed in the Rx unit. If the LEDs

on the Rx unit become dim during the test with a known good cable, it’s time to replace the batteries.

To install/replace the battery, make the back side of the Tx unit facing you and the battery cover on top,

stretch the orange rubber jacket over the two corners of the Tx plastic body to clear the battery cover

slide path, then slide the battery cover up to remove it. Install the batteries with the negative side first

compressing against the spring in the compartment. Replace the battery cover and the rubber jacket.

How to test the HDMI cables:

Simply plug one end of the cable to the Tx unit and the other end to the Rx unit; if all 9 LEDs light up,

the cable is good. If certain LED does not light up, refer to the clearly marked function of each LED for

troubleshooting. This tester can test HDMI Type A to A, A to C and C to C cables; just plug one end of

the cable following the clearly marked blue connector arrows on the Tx unit, and the other end to

whichever connector on the Rx unit that fits.

How the product functions:

The Tx unit sends DC voltage through every one of the 19 wires inside an HDMI cable; the Rx units

detect these DC voltage and display the open/connect status via the 9 LEDs.

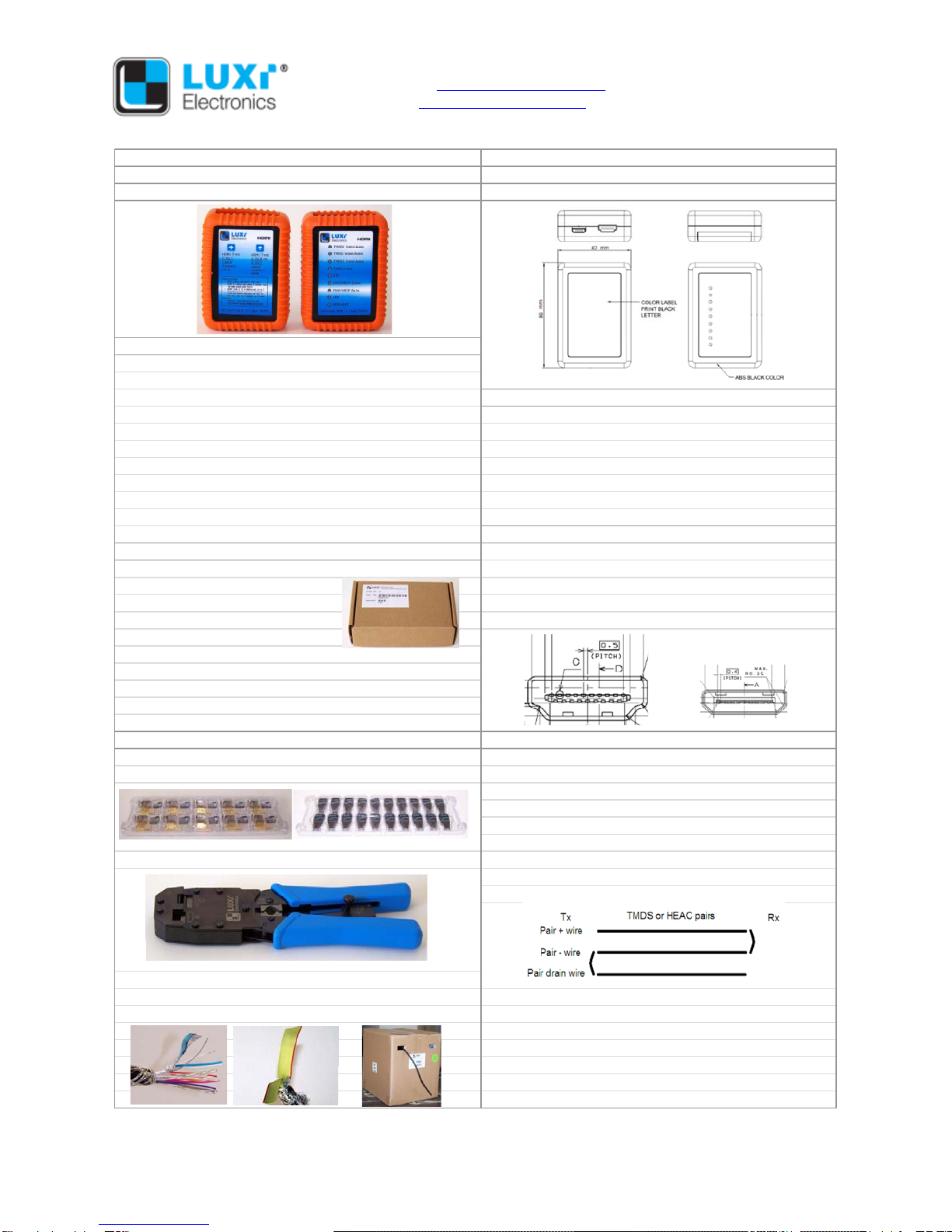

There are 5 twisted pair (4 TMDS and 1 HEAC) wires

inside an HDMI cable; each pair consists a “+” and a “–”

wire, and a shield drain wire. This tester connects these

3 wires in the pair in series and tests them as if it’s one

long wire; see the schematic on the right. This allows

using 9 LEDs to test all 19 wires.

Know limitations:

This tester is designed for quick and easy field test, not a complete electrical lab test. Here are some

minor limitations:

1) Because the drain wires in the 5 twisted pairs are part of the test circuit, if the drain wires in certain

cables are connected to each other and to the overall ground, the LEDs for the corresponding pairs

may not light up; but the cables may still work normally and pass an HDMI signal.

2) It only tests the wire continuity in DC; it does not check high frequency performance. Thus an

HDMI cable tested OK with this tester may not work properly with an HDMI signal. This usually

happens to the HDMI cables where the cable length is too long for the HDMI signal.

3) It only tests the individual wire’s open/connect status; it does not test the short circuit between wires.

Thus an HDMI cable tested OK with this tester may not work properly if there’s a short circuit

between wires.

Support: Please contact your reseller directly for local support; or to Luxi with the contact info above.