TD-40, TD-75

SHAFT ASSEMBLY INSTALLATION:

Holding the shaft assembly by the threaded shaft only (not brass stud) install center stud spring onto shaft assembly (end opposite

pinned nut). With spring end up, insert the shaft assembly through the center tube and Tumble-Dump plate until brass stud contacts

center tube. Apply Loctite® onto brass stud and screw into center tube - approximately 4 turns - until wrench flats on brass stud are

flush with center tube. Set aside to dry.

BOWL ASSEMBLY:

Place the bowl over the center hole and screw the shaft assembly into the motor plate and back off two turns. Install bowl washer and

fasten with the 1-8 nut and tighten. With the wrench provided, tighten the shaft assembly to obtain the desired operating tightness.

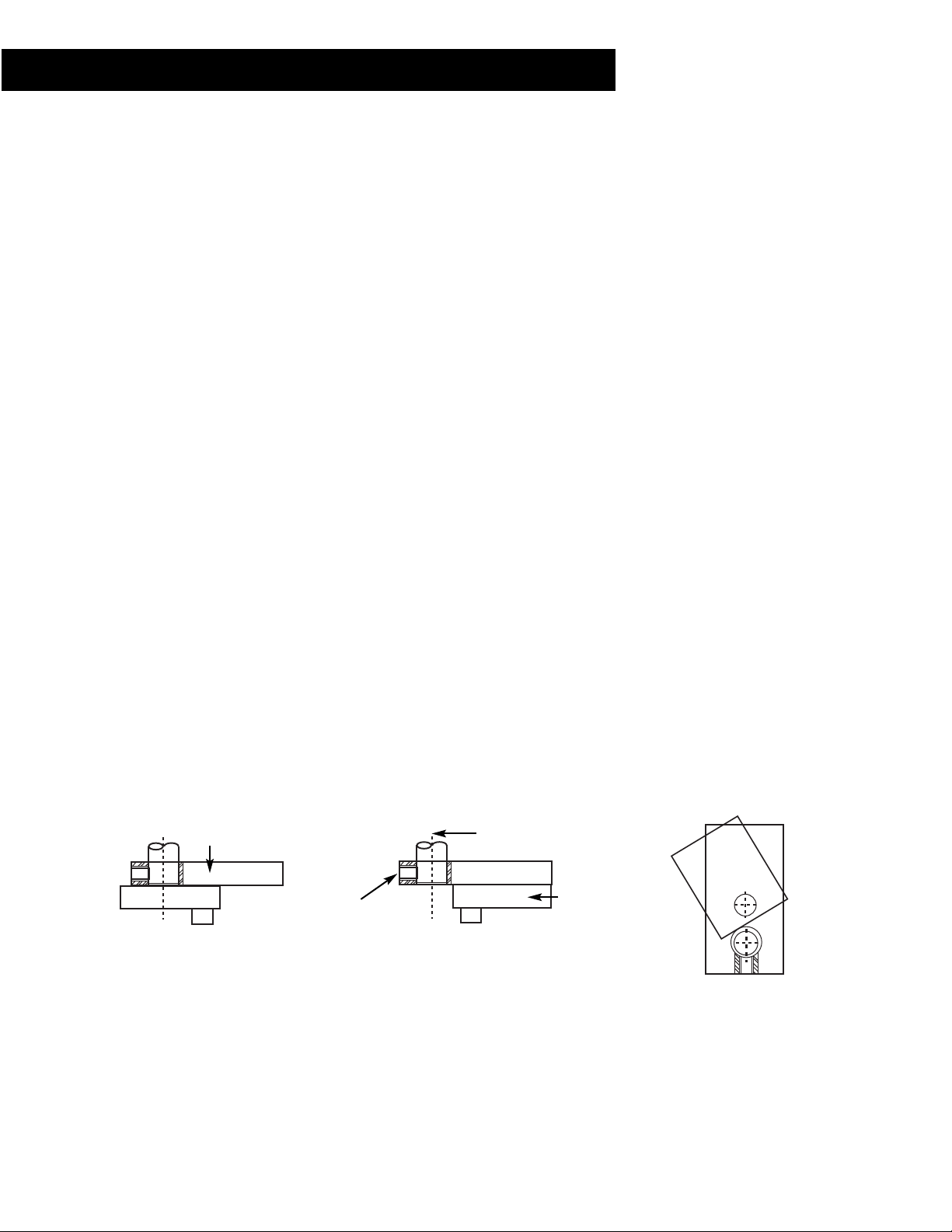

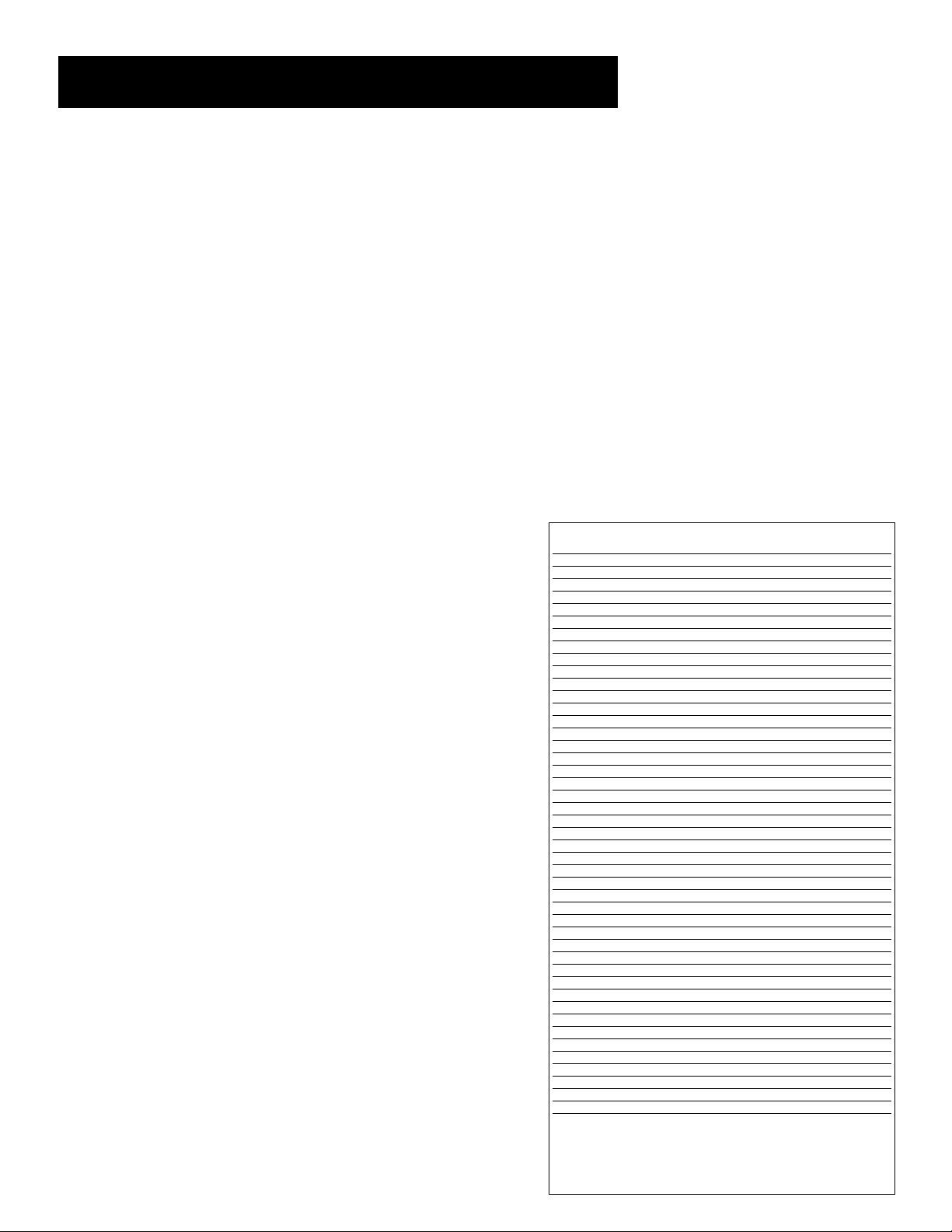

TUMBLE-DUMP FEATURE:

Raytech's Tumble-Dump models (TD-40 and TD-75) feature a built-in hinge system that allows the parts and media to be easily

removed from the machine. Used with a Raytech Separator (MS-75) the Tumble-Dump saves time and money by eliminating the

tedious tasks of unloading and separating by hand. With the special 3/4" hex wrench provided, loosen the 3/4" hex nut until the shaft

and nut spring up - approximately 6 turns. This will release the tumble-dump plate and bowl assembly from the motor plate. Raise the

dump handle to dump media and parts. To secure, return the tumble-dump plate and bowl assembly to the "run" position. With the

special wrench provided, compress the internal spring by pushing down on the 3/4" hex nut and turn to engage threads into the

motor plate. Tighten securely.

NOTE: Occasionally lubricate lower shaft assembly threads and motor plate threads with a light grease such as “Lubri-Plate.”

1

2

34

5

6

7

8

9

10

12

13

14

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

15

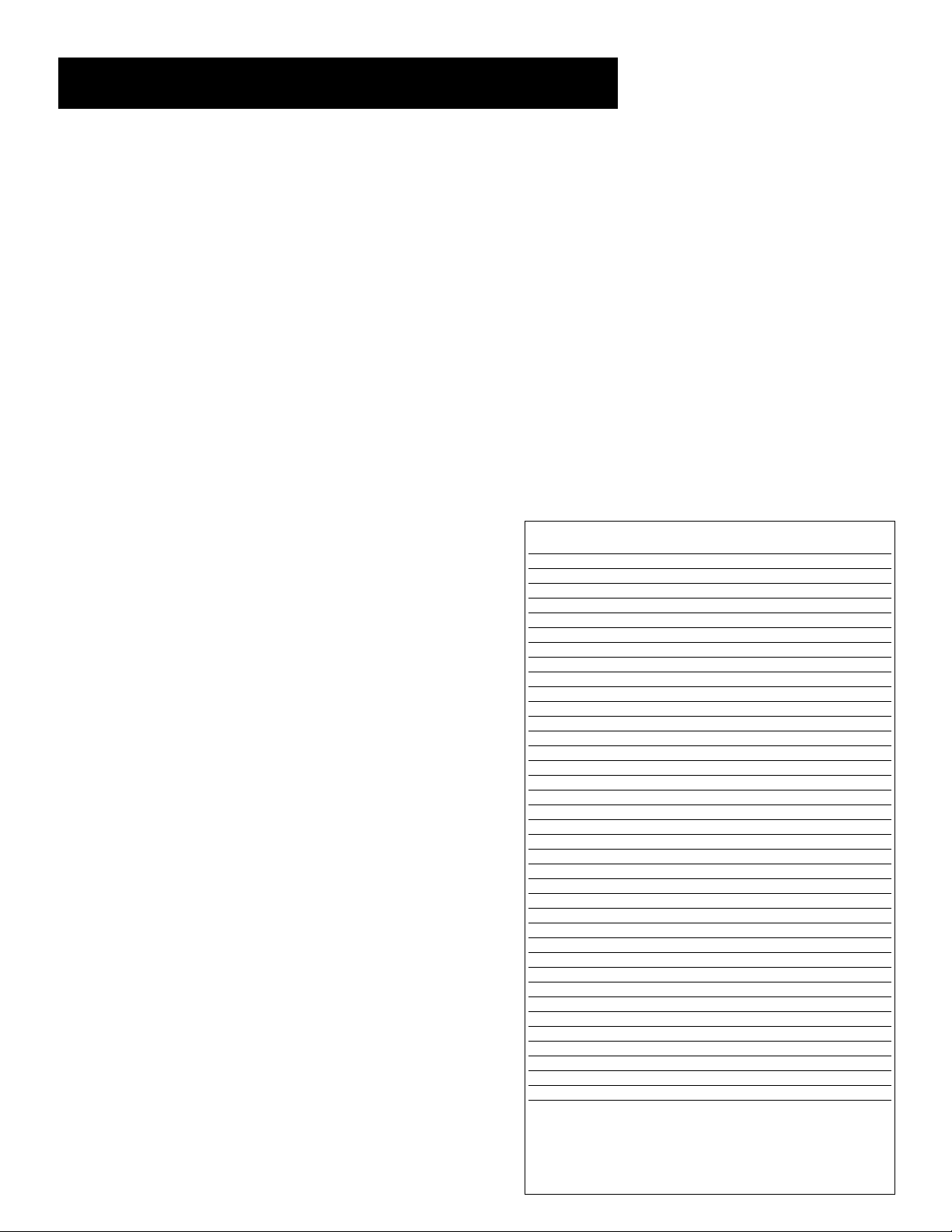

ITEM PART NO. DESCRIPTION QTY

1 07968 Shaft Assembly TD-40 1

1 07966 Shaft Assembly TD-75 1

2 07943 Cover Wing/Perm Nut Assembly 1

3* 23032 Bowl with Cover AV-40 1

3** 23046 Bowl with Cover AV-75 1

4 03376 Nut 1” -8 Hex Full Zc 1

5 07925 Bowl Holddown Plate 1

6 07883 Center Stud Spring 1

7 08377 Tilting Plate TD-40 1

7 07933 Tilting Plate TD-75 1

8 07796 Top Pad Cut (Not Shown) 1

8a 07779 Rubber Pad 5

9 03299 Hex Head Screw 5/16 - 18 x 1 1/2 6

10 07773 Motor Plate 1

12 07941 Compression Spring 6

13 07942 Spring Grommet 12

14 03243 Washer 5/16 USS STD 12

15 03349 Nut 5/16-18 Hex Zc 6

16 03284 Hex Head Screw5/16-18 x 1 1/4 6

17 07942 Spring Grommet 12

18 03480 Carriage Bolt 3/8-16 x 8” Long 4

19*** 30255 Motor 40/75 110V 1

19*** 30293 Motor 40/75 230V 1

20 03325 ack Nut Molly #10-24 4

21 07772 Motor Bar 1

22 03388 Nut 3/8-16 Locking 4

23 07972 Counterweight Assy 1

24 07784 Bottom Cover 1

25 03440 Screw #8 x 3/8 Typ A Pan 3

26 07882 Rubber Feet 3

27**** 07782 Base Model 40 1

27**** 07783 Base Model 75 1

28 07941 Compression Spring 6

29 03462 Screw #10-32x3/8 Pan Zc 3

30 07781 Strap for Capacitor 1

31 03928 Capacitor 115V R 1

31 03927 Capacitor 230V R 1

32 03065 Screw 1/4-20 x 1 1/4 Hex Zc 4

33 07923 Hinge Pivot Block 2

34 07770 Hinge Bar 1

35 07920 Tilting Hinge 2

36 07909 Strainer Fitting 1

37 03374 Nut 3/4-16 am Zc 1

38 03055 Screw 1/4-20 x 3/4 Hex Zc 4

39 07936 Drain Tube 3/8 LD x 30” S/A 1

*Includes 36,37,39 (Not Shown)

**Includes 36,37,39 (Not Shown)

***Includes 8,8a,9,10,13,14,15,18,19,21,22,29

****Includes 14,16,17,20,24,25,26,27

32

33

34

35

36

37

38