INSTALLATION / USE & CARE |7

BUILTIN INSTALLATIONS

This built-in grill is designed for easy installation into

masonry enclosures.

NOTE: Built-in grills are intended either for installation in a

built-in enclosure constructed of non-combustible materials

or for an installation in a built in enclosure constructed of

combustible material when installed with a insulating jacket).

For non-combustible applications, the grill drops into the

opening shown in the cutout detail drawing (See INDEX:

“Gas Requirements”) and hangs from its counter-top trim. A

deck is not required to support it from the bottom.

When using the insulated jacket in a combustible enclosure,

the jacket must be supported from the bottom by a ledge on

each side or a full deck beneath the jacket.

(See INDEX: “Gas Requirements”) Pay special attention to the

provisions shown for gas line hook-up.

The enclosure should have ventilation holes to prevent gas

build-up in the event of a leak. The deck ledges and counter

should be flat and level. (refer to ANSI Z21.58 Standard for

Outdoor Cooking Gas Appliances, Section 1.7 Enclosures For

Self Contained LP-Gas Supply Systems)

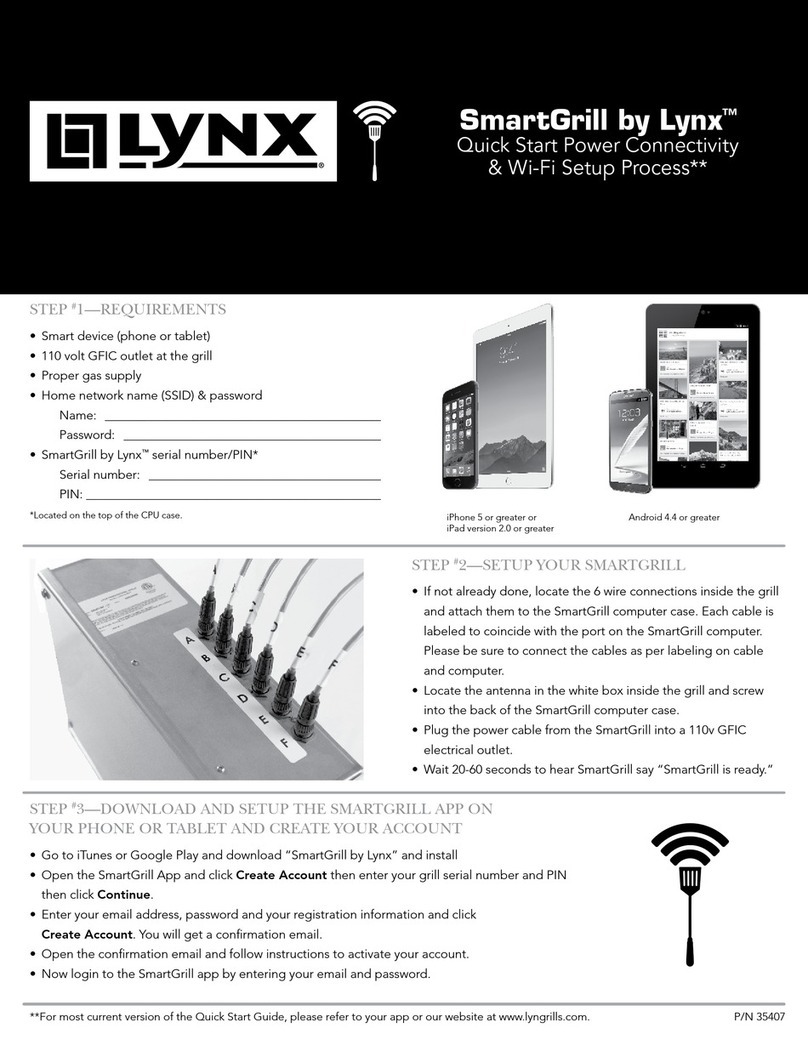

This grill requires that a 120 volt, 60 hertz, 15 amp GFI

certified outlet be installed by a qualified electrician.

CLEARANCE TO COMBUSTIBLE MATERIALS

Minimum clearance from the sides and back of the grill to

adjacent combustible construction below the counter top

surface is 12” from the sides and 6 1/4” from the back of the

hood.

Dégagement minimal entre les parios latérales et l’arrière de l’appariel et la

constructiohn combustible au-dessous de panneau supérieur de l’appariel (30 cm à

partir des parois latérales et 15.9 cm à partir de l’arrière de la hotte).

Minimum clearance from sides and back of grill to adjacent

combustible construction extending above the counter top

surface is 12” from the sides and 6 1/4” from the back.

Dégagement horizontal minimal entre les parios latérales et l’arrière de l’appariel

et la constructiohn verticale combustible au-dessous de panneau supérieur de

l’appariel (30 cm à partir des parois latérales et 15.9 cm à partir de l’arrière de

la hotte).

Do not use this appliance under unprotected overhead

combustible surfaces.

N’utilisez pas cet appareil sous des surfaces inflammables non protégées

A minimum of 6” of clearance is needed on the left side of

the grill above the counter top for the motor and skewer.

If the grill is to be placed into a combustible enclosure, an

approved insulated jacket is necessary and is available only

from your Lynx dealer. Insulated jackets have been designed

and tested specifically for your grill.

REAR HOOD CLEARANCE

A 3 inch clearance is required behind the grill to allow the

front hood to open.

The grill exhausts combustion products and cooking greases

to the back. Never locate the grill where this exhaust will be

dicult to clean.

OVERHEAD PROTECTION AND EXHAUST REMOVAL

If installed under any combustible construction the cooking

area over the grill must be covered with an exhaust hood.

The hood must provide 3 - 6” of overhange on all exposed

sides. The exhaust hood shall provide no less than 1,200

CFM for proper exhaust ventilation. The hood must be

approved for outdoor installation and provided with a

dedicated GFCI protected branch circuit.

BEF

RE Y

TART

n

in

e

Vent Hood

Overhead Construction

R

e

a

r

W

a

l

l

3” overhang on left and right side of grill

36” Minimum

6’ Minimum to

non-combustible

6 1/4” Clearance from the

grill back to above

counter combustibles

3”

Minimum

hood

clearance

12” clearance to combustibles from

surface level right/left/below

Combustible overhead

construction requires a

vent hood

Non-combustible overhead

construction a vent hood is

highly recommended

6 1/4”

Minimum

clearance

to combustibles