Bulletin281-167 Page 2

PLEASE READ THESE INSTRUCTIONS

CAREFULLY.

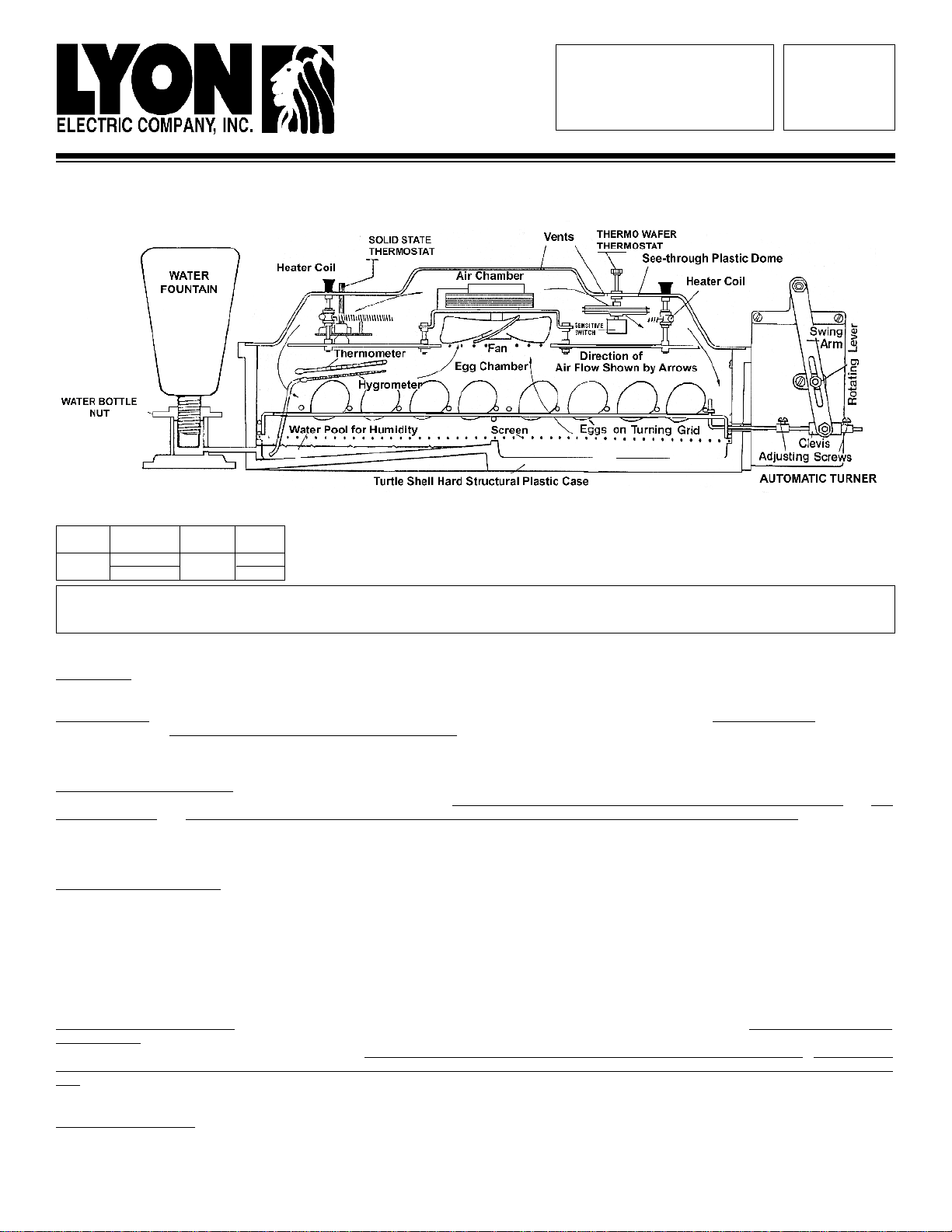

Position the Roll-X in front of you so that the water fountain is to the

back and on your left side. This will aid you in adjusting the Roll-X.

Materials needed to assemble the Roll-X:

Small flat head screwdriver

Crescent wrench

UNPACKING T

HE RX-2

1. Carefully remove and identify the following as you unpack the

Roll-X.

Clear plastic dome ( packed upside down)

Grid assembly (for packaging purposes the grid assembly is

shipped upside down)

Screen mesh

Blue Plastic base

Water fountain kit

The thermometer/hygrometer kit in plastic bag which includes:

One flat washer

One wing washer/nut

One long bolt

(3) hex nuts

One mercury thermometer with a wick attached to the

end of the thermometer (wet bulb),

One regular thermometer (dry bulb),

The L-shaped turning pull rod with black screw on cap

2. IFTHE UNIT IS AUTOMATIC,THEFOLLOWING ITEMS

AREENCLOSED:

Automatic turner (available in 110VAC and 220VAC)

Two (2) screws and two (2) washers

L-shaped turning pull-rod with two (2) adjusting screws and collars.

3. Assembling the Roll-X2: (see ADJUSTING AUTOMATIC TURNER).

SKIP THIS INSTRUCTION IF YOUR ROLL-X IS MANUALLY OPERATED.

Remove the grid assembly and screen mesh from the inside of the blue

base. Take the automatic turner and match the two holes in the blue base

to the two threaded inserts on the side of the turner. Put the two screws

with the washers on them through the wall from the inside of the incubator

base. Place the turner against the base and tighten the screws. Do not

overtighten the screws. From the inside of the blue base insert the L-

shaped turning rod through the hole of the blue base wall. The short end

should remain on the inside of the base. Place one set collar and adjusting

screw on the L-shaped pull-rod located on the outside of the incubator.

Run the rod through the clevis hole on the bottom of the swing arm of the

turner and attach the second set collar and adjusting screw to the pull-rod.

Do not tighten the adjusting screws onto the pull-rod at this time. Final

adjustments will be made later.

4. SKIP THIS INSTRUCTION IF YOUR ROLL-X IS AUTOMATICALLY

TURNED. Insert the L-shaped turning pull-rod from the inside of the blue

base with the short end remaining on the inside of the base.

5. Place the mesh screen directly on the bottom supports of the blue

base, with the notched out corner where hole for water bottle is located

(And the thermometer kit attaches). Place the grid assembly (plastic coated

side down, bright plated side up) over the screen. Be sure the guide rollers

are connected between the plastic coated and bright plated grids. The

grid assemblies should be resting against each other firmly but move freely

without friction against the walls of the blue base.

NOTE: If the grid assembly appears to "climb the walls” it is upside down.

Connect the turner pull rod Inside the base with the small plastic loop on

the end of the removable grid. (Make sure the notched corner of the grid

assembly

is on the opposite side of the blue base from the turner.)

INSTALLING YOUR THERMOMETER KIT

6. Locate the hole on the back side of the base next to the water

fountain. From the inside of the base, insert the thermometer assembly

and apply the washer and wing nut to the exterior of the blue base.

Tighten the wing nut snugly, but do not over tighten. (The

thermometer assembly should extend to the right with the wick

hanging down to the front right corner).

The bulbs of the thermometers should slant downward but still clear

the eggs to be set. Extend the wick of the wet-bulb or hygrometer

through the grid notch so that the end will rest on the bottom of the

base.

INSTALLING EXTERNAL WATER FOUNTAIN

7. To install the external water fountain:

A. Insertthe threadedhose barbfitting intothe threaded hole provided

in the bottom blue base corner where the Thermometer/

Hygrometer kit is mounted. Tighten enough to prevent leaking.

B. Push the hose piece provided onto the white hose barb that is

screwed into blue base.

C. Push the hose barb on the water fountain base into the hose.

D. When ready the water fountain bottle height (and thus the water

height in the incubator) is adjusted by raising or lowering the nut on

the neck of the water fountain bottle.

8. NOW PLACE ROLL-X DOME ON BLUE BASE

Plug the long cord from the dome into your electric power source. If

you have an Automatic Turner, plug the Automatic Turner cord into

the electrical receptacle on the dome (Remember: it is only for the

automatic turner).

ADJUSTINGTHEAUTOMATICTURNER

Skip instruction if your RX is manually turned.

CAUTION: Do not tighten the adjusting screws on the L-shaped turning pull

rod until they are in the proper position. The incorrect positioning may cause

the turning grid to be forced against the walls of the incubator and break

either the automatic turner or the connections to it.

Lift the Dome and move the grid to the left (away from the automatic turner)

to within 1/4" of the incubator wall. Press the red button on the top of the

automatic turner. This will activate the automatic turner and cause the lever

to move either to the right or left. Observe the lever as it moves to the left.

At this point when the lever reaches the maximum position to the left re-

move your finger from the red button and tighten the adjusting screw against

the clevis at the left and tighten the adjusting screw against the clevis at the

right.

SETTING TEMPERATURE CONTROLS

Theincubatorwastestedandthe temperature regulatedto100°Fbeforeitwas

shippedtoyou. Due tohandling in shipmentor the environment itis used in,it

mayrequirefurtheradjustment. Temperatureadjustmentis made according to

thetypeofcontrolorderedwith the incubator. Theyaredescribedinthe follow-

ing paragraphs. Watch the thermometer as the temperature in the incubator

rises. The indicator light should go off at 100°F. After the set temperature is

reached the light will go on and off at short intervals. This on and off of the

indicatorlightand a constantthermometerreading of 100°Findicatesthether-

mostatiscontrollingtheheat.