9

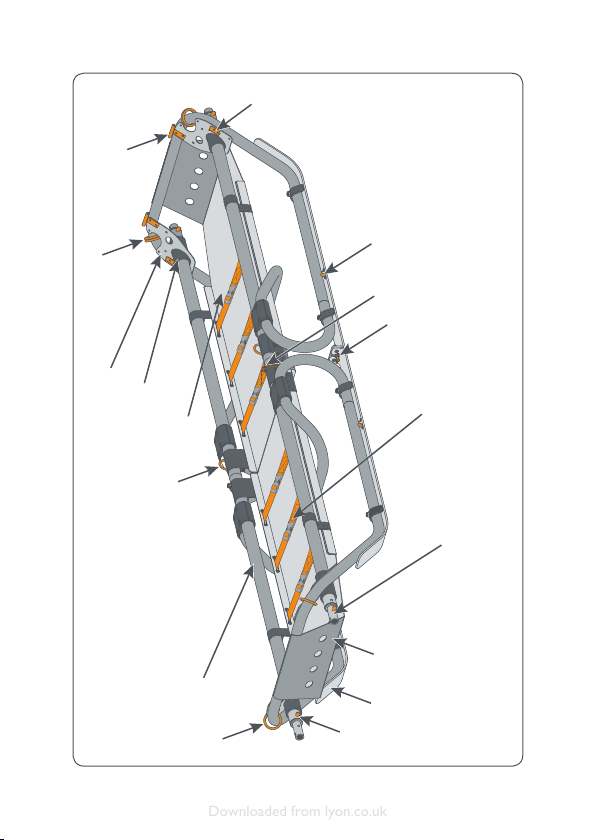

Transport of the dismantled

stretcher

A minimum of two people are required

to transport an empty stretcher. If split

into two sections for transport, each

section may be carried ‘rucksack style’

using the individual detachable pack

frames (accessory).

The pack frames may also be used as

carrying yokes when clipped to the

stretcher handles, to assist in transport

of the loaded stretcher.

The pack frame ts onto the stretcher

by placing the edge of the stretcher bed

into an alloy channel at the base of the

pack frame.This enables two alloy pegs

to enter two holes in the stretcher bed.

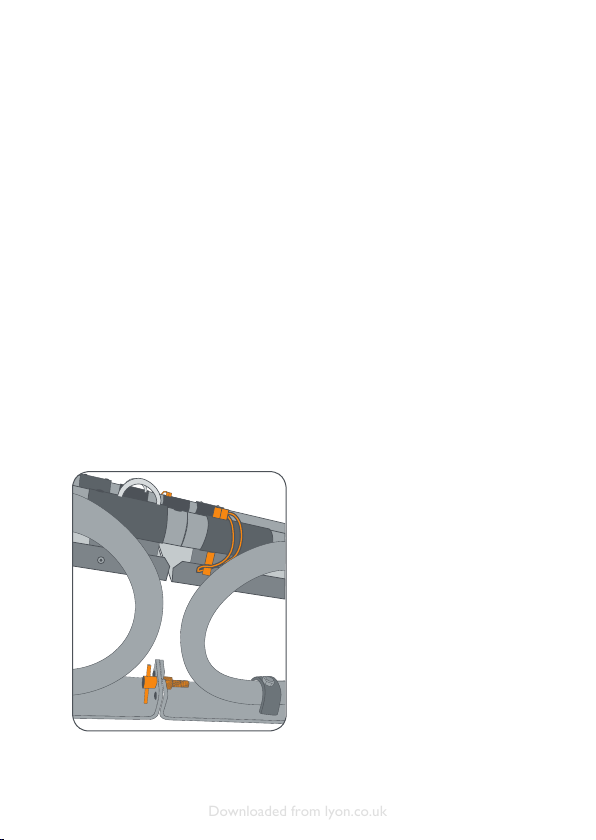

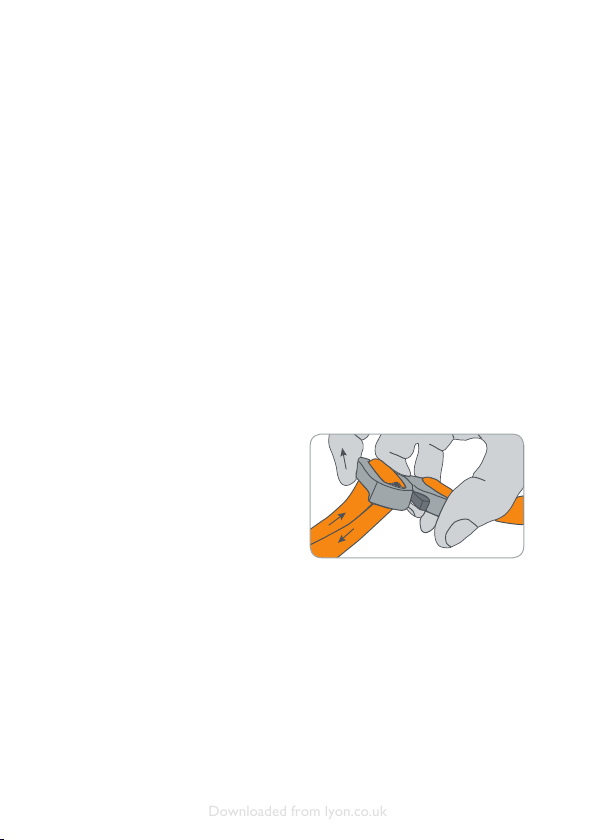

The pack frame is locked in place by

tensioning the shock cord round the

frame and attaching the hooks through

the holes in the alloy pegs.

TAKE CARE WHEN TENSIONING

THE SHOCK CORD THAT YOUR

FACE IS NOT IN LINE WITH THE

TENSIONED SHOCK CORD -

ACCIDENTAL RELEASE MAY

CAUSE INJURY.

Each stretcher section weighs approx.

9 kg. Assistance with picking up and

placing the stretcher section on the

back, and adjusting the shoulder straps

to provide a secure and stable t, is

strongly recommended.

Be aware of projections on the frame –

ensure there is adequate space around

the person carrying the stretcher

section to prevent accidental contact.

Carrying the loaded stretcher

Be aware that a loaded stretcher

(stretcher + casualty + medical

equipment) may weigh up to 136 kg.

Multiple personnel are required to

lift and transport a loaded stretcher.

Stretcher carriers should regularly

change position to reduce fatigue.Take

extra care when lifting and lowering

the loaded stretcher – training and

coordinated action is essential.

There are many methods of positioning

personnel around a stretcher to enable

it to be transported.The maximum

practical number of personnel who can

effectively share the load is eight.

Sliding the stretcher

The stretcher may be slid on its skids

over smooth surfaces. Avoid abrasive

surfaces which could damage the skids;

also avoid rocks, stumps, branches and

other hazards that could penetrate the

stretcher bed or cause discomfort or

injury to the casualty.

Lifting, lowering or suspension of

the stretcher via a rescue system

Rope rescue system anchors must be

unquestionably reliable, orientated

appropriately and of sufcient strength

for the anticipated load. Ensure all

other components in the system are

compatible and of sufcient strength.

The use of a two rope system (main

and safety) is recommended. All such

systems should incorporate a ‘fail to

safe’ principle.

UI_LMK6-ST_16347.indd 9 18/04/2019 10:57:41

Downloaded from lyon.co.uk