9

Figure shows left pin in good working

condition.The right pin should be

retired due to wear and detent pins not

properly working.

Textile items - Leg Restraint

Straps

The Leg Restraint Strap must be

complete with all end connections, and

must fully adjust and lock over its full

range of adjustment.

Check the webbing visually and by

passing the straps slowly through the

hands to detect damage, e.g. cuts in

the edges of the webbing, abrasion,

cuts across the face of the webbing,

softening or hardening of bres,

ingress of contaminants, broken, cut

and worn threads in the stitching. Pay

particular attention to areas where the

webbing is in contact with connectors,

buckles and the Leg Restraint Strap

Attachment Point. Check the webbing

for discolouration, which could be the

result of chemical or UV damage.

The metallic elements should be

inspected for correct function, signs

of overloading and damage, e.g. wear,

corrosion, cracking, weld failure,

abrasion, sharp edges, deformity.

Any of these defects may affect the

performance of the OBELISK.

Lubrication

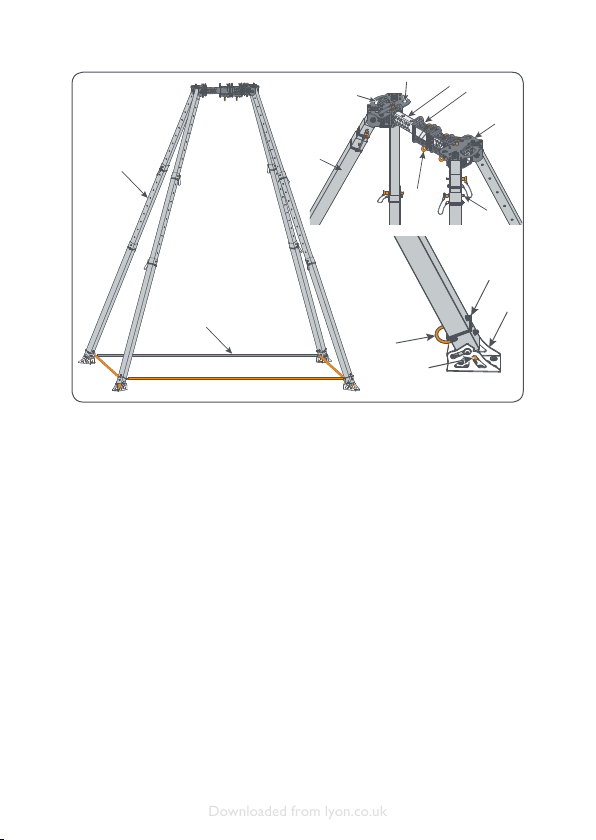

All leg hinge assemblies and Locking Pins

should be lightly lubricated after each

use. Use a liquid lubricant with good

adhesion, e.g. light machine oil.

Apply sparingly and wipe off any excess.

Chemicals

If the OBELISK comes into contact with

any chemicals or contaminants, including

biohazard, remove it from service and

quarantine.

Taking appropriate precautions, clean

the metallic parts of the OBELISK to

remove the contaminants and prevent

contamination of other items in the

safety chain.

Ensure beforehand that the cleaning

process and cleaning materials will not

damage the OBELISK.

All textile parts in contact with

chemicals or contaminants, including

biohazard cannot be effectively cleaned

and must be destroyed.

Spare parts and repairs

A limited number of spare parts are

available for user-tment. A repair

service is also offered. Contact the

manufacturer for details.

Accessories

A range of accessories are available for

the OBELISK. See www.lyon.co.uk for

information.

Materials

The body of the OBELISK is made from

stainless steel.

The legs are made from aluminium alloy.

The Locking Pins are made from

stainless steel.

The Leg Restraint Straps are polyester.

The Leg Restraint Strap quick links

are steel.

UI_LPP0003_19092.indd 9 04/04/2019 11:28:43

Downloaded from lyon.co.uk