M-Elec GD-5610 User manual

5-phase Stepping Motor Driver

GD-5610

Instructions Manual

(For designers' use)

MN0325-1

Please ensure to read and understand this

Instructions Manual before using the product.

Please keep this Instructions Manual at hand

so that it is always available for reference.

GD-5610

Instructions Manual

Introduction

This Instructions Manual describes the safe and proper method of handling

"5-phase Stepping Motor Driver GD-5610" with emphasis on the specifications,

assuming that our readers are engaged in designing of control devices

incorporating stepping motors.

Please ensure to read and understand this Instructions Manual

before using the product.

Please keep this Instructions Manual at hand

so that it is always available for reference.

-2-

GD-5610

Instructions Manual

Descriptions in this manual on safety matters:

This product must be operated and used properly.

Otherwise, or when it is operated and used erroneously, unforeseen accidents

may occur, causing physical injuries or property damages.

Majority of these accidents can be avoided if you are well informed of

hazardous circumstances in advance.

Consequently, this instructions manual describes all the hazardous and

dangerous circumstances and situations which can be foreseen and anticipated

as well as necessary precautions.

All the above descriptions are being titled by the following symbol-marks and

signal-words, namely:

Represents warnings ignorance of which can cause accidents

involving fatal or serious physical injuries, or death.

Represents cautions ignorance of which can cause accidents

involving minor physical injuries or property damages.

WARNING

CAUTIONCAUTION

-3-

GD-5610

Instructions Manual

Introduction

Descriptions in this manual on safety matters:

CONTENTS PAGE

1. Safety

1-1. Safety Precautions 6

1-2. Safety Information for Handling 7

Overview

2-1. Characteristics 11

2-2. Product Configuration 11

2-3. Appearance 11

3. Name and Function of Each Section

3-1. Signal I/O Connector(J1) 12

3-2. AC Input/Motor Output Terminal Block(J2, J3) 13

3-3. POWER LED 13

3-4. O.H.A LED 13

3-5.

Operating Section

14

4. Setting

4-1. Setting STEP ANGLE SELECT switch 15

4-2. Setting HOLD CURRENT SELECT switch 16

4-3. Setting DRIVE CURRENT SELECT switch 17

4-4.

Setting HOLD SWITCHING TIME SELECT switch

18

4-5. Setting ROTATE CHARACTERISTIC SELECT switch 18

4-6. Setting MOTOR SELECT switch 18

4-7. Setting PULSE INPUT TYPE SELECT switch 19

5.

Installation

5-1. Conditions for Installation 20

5-2. Mounting Method 21

6. Connection

6-1. Overview of Connection Configuration 22

6-2. Connecting Signal I/O Connector(J1) 23

6-3. Connecting AC Input/Motor Output Terminal Block(J2, J3) 24

6-4. Inputting Power 26

7. Confirmation of Setting and Connection

7-1. Check Points 27

2.

-4-

GD-5610

Instructions Manual

PAGE

8. Maintenance and Check-up

8-1. Maintenance and Check-up 28

8-2. Troubleshooting 29

9. Storing and Disposal

9-1. Storing 30

9-2. Disposal 30

10.

Specifications

10-1. General Specifications 31

10-2. Conforming to Europe standards and UL standards 32

10-3. I/O Signal

(1) Example Circuit Connection 33

(2)

Drive pulse input

(CW,CCW) 34

(3) Motor excitation stop input (M.F) 35

(4) Phase signal output (P.O) 36

(5) Overheat alarm signal output and overheat alarm LED (O.H.A) 37

(6) Step angle switch input (C.S) 38

10-4. Dimensions 39

10-5.

Applicable Motors

40

10-6. Torque Characteristics 41

The main parts which revised by this manual

-5-

GD-5610

Instructions Manual

1.Safety

1-1.Safety Precautions

(1)

This product is not designed or manufactured for application for equipment

requiring high level of reliability such as equipment related to nuclear

energy, aeronautics-related equipment, automobiles, ships, medical appliances

directly handling the human body and equipment that might seriously affect

properties.

(2) Do not use or keep the product in explosive or corrosive environments,

in the presence of flammable gases, locations subjected to splashing water,

fine particles, soot, steam, or exposed to radiation or direct sunshine.

Doing so may cause electric shock, injury or fire.

(3)

This product is designed for use within machinery, so it should be installed

within an enclosure.

Be sure to ground the protective earth terminal of the driver.

(4) Do not transport, move, install the product, perform connections or inspections

when the power is on.

Doing so may cause electric shock, injury or fire.

(5) Only qualified personnel are allowed to transport, move, install the product,

perform connections or inspections.

Failure to do so may cause electric shock, injury or fire.

(6) Do not touch the driver during operation or immediately after stopping.

Doing so may cause burn on the skin due to overheating of the driver.

(7) Ensure to use this product according to the method specified

in the Instructions Manual and within the specifications.

(8) Depending on the operational conditions, the stepping motor may step out when

it is on holding-state or driving-state.

In particular, the load in transport may fall if the motor steps out on the

vertical drive (such as the Z-axis).

Start operation after test run for deliberate confirmation of operation.

(9)

Provide fail-safe measures so that the entire system may operate in a safe

mode even in cases of the external power supply failure, disconnection of the

signal line, or any failure on the driver.

WARNING

CAUTION

-6-

GD-5610

Instructions Manual

1-2.Safety Information for Handling

●Overall:

Do not touch the driver during operation.

Failure to do so may cause electric shock.

indicate terminals on which power voltage

is applied.

Do not touch such terminals while

inputting power and while POWER LED is on.

Doing so may cause electric shock.

Use only an insulated screwdriver to

adjust or set internal switches.

Failure to do so may cause electric shock.

Do not touch the driver during operation

or immediately after stopping.

Doing so may cause burn on the skin due to

overheating of the driver.

●When connecting the AC Input/Motor Output Terminal Block (J2, J3):

Turn the main power OFF.

Failure to do so may cause electric shock.

Securely ground the protective earth

Failure to do so may cause electric shock.

Do not force the power line or the motor

line to be bent or pulled or pinched.

Doing so may cause electric shock or fire.

WARNING

WARNING

WARNING

CAUTION

WARNING

WARNING

WARNING

-7-

GD-5610

Instructions Manual

Erroneous connection may result

in breakage of the motor or the driver.

Correctly connect the motor wiring.

●When setting up the MOTOR SELECT switch:

Erroneous setting may cause burn on the

skin due to overheating of the motor.

Ensure correct setting.

●When setting up the STEP ANGLE SELECT switch:

Erroneous setting may cause breakage of

the machine or injury due to unexpected

rotation of the motor.

Ensure correct setting.

●When setting up the HOLD CURRENT SELECT switch:

A high setting value may cause burn on the

skin due to overheating of the motor.

Do not select a high value beyond the

required.

●When setting up the DRIVE CURRENT SELECT switch:

Erroneous setting may cause burn on the

skin due to overheating of the motor.

Ensure correct setting.

●When setting up the PULSE INPUT TYPE SELECT switch:

Erroneous setting may cause breakage of

the machine or injury due to unexpected

rotation of the moter.

Ensure correct setting.

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

-8-

GD-5610

Instructions Manual

●When inputting the motor excitation stop (M.F) signal:

Deterioration of the holding power with

the motor may cause breakage of machine

or injury.

Check safety before inputting.

●When installing:

Overheating may cause fire.

Mount it on a noncombustible member.

Keep it away from combustibles.

●When inputting power:

Do not contact with a wet hand.

Doing so may cause electric shock.

indicate terminals on which power voltage

is applied.

Do not touch such terminals while

inputting power and while POWER LED is on.

Doing so may cause electric shock.

Unexpected behavior of the motor may cause

breakage of the machine or injury.

Maintain the state where emergency stop is

enabled at any time.

●When the overheat alarm (O.H.A) signal is output:

Overheating may cause fire.

Stop operation upon output of this signal.

WARNING

WARNING

WARNING

CAUTION

WARNING

CAUTION

-9-

GD-5610

Instructions Manual

●When the overheat alarm (O.H.A) LED comes on

Overheating may cause fire.

Stop operation when this LED comes on.

●When performing maintenance and checking:

Only qualified personnel are allowed to

perform maintenance and checking.

Failure to do so may cause electric shock.

Do not contact with a wet hand.

Doing so may cause electric shock.

indicate terminals on which power voltage

is applied.

Do not touch such terminals while

inputting power and while POWER LED is on.

Doing so may cause electric shock.

Do not replace fuse.

Do not disassemble, repair or modify.

Doing so may cause electric shock, injury

or fire.

WARNING

WARNING

WARNING

WARNING

WARNING

-10-

GD-5610

Instructions Manual

2.Overview

2-1.Characteristics

GD-5610 is a driver for a 5-phase stepping motor with single-phase 100-115V input.

Ten step angles can be selected from angles ranging from a 1/1 division to

a 1/800 division of the basic angle.

HOLD CURRENT and DRIVE CURRENT can be set up.

●

Applicable motors and setting for each motor are given in the table

"10-5. Applicable Motors".

2-2.Product Configuration

The product consists of the main frame and the accessories.

●

GD-5610 One unit

(Complete with terminal block covers)

●

Housing for J1 (51103-1200:Molex) One unit (accessory)

●

Contact for J1 (50351-8100:Molex) 14 contacts (accessories,2 for spares)

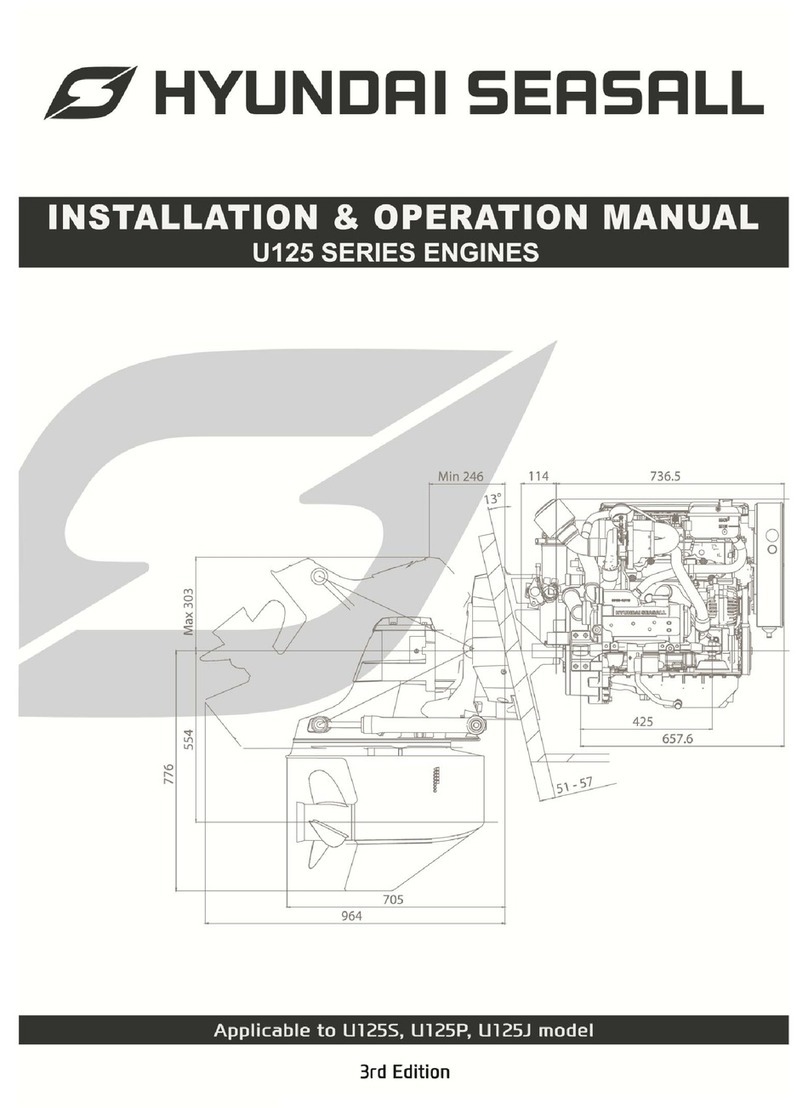

2-3.Appearance

0

F

E

D

C

B

A

9

8

7

6

5

4

3

2

1

MOTOR

!

GD-5610

J1

1

12

POWER

OHA

OP2

ON←

OP4

OP5

OP3

OP1

SPI

DRIVE

HOLD

STEP

J3

J2

3

4

5

2

1

1

2

3

L

N

115V~

100V

DHT

RC

0

F

E

D

C

B

A

9

8

7

6

5

4

3

2

1

0

F

E

D

C

B

A

9

8

7

6

5

4

3

2

1

Model Name

Mounting Section

Model Name

Signal I/O Connector

O.H.A LED(RED)

POWER LED(GREEN)

Operating Section

AC Input

Terminal Block

Motor Output

Terminal Block

2

1

J3

5

4

3

RED/GRY

VIO/BLU

BLK/YLW

WHT/ORN

GRN/BRN

GRN

BLK

BLU

RED

ORN

Protective earth

Terminal Block

Mounting Section

GD-5610

100-115V~

5.9A

1φ50/60Hz

Melec Inc.

MADE IN JAPAN

R

-11-

GD-5610

Instructions Manual

3.Name and Function of Each Section

3-1.Signal I/O Connector(J1)

GD-5610

CW+

J1

●Directs the motor to operate CW.

●Shuts off output current to drive the motor.

●Outputs the signal when internal temperature

of the driver has reached approx. 65℃or more.

1

Motor excitation stop signal input terminal

Step angle switch signal input terminal

Phase signal output terminal

Overheat alarm signal output terminal

CW drive pulse signal input terminal

●Switches the step angle by 1/20 division.

●Outputs the signal when the motor-excitation

state is the excitation home position.

CW-

CCW+

CCW-

M.F+

M.F-

C.S+

C.S-

2

3

4

5

6

7

8

9

10

11

12

P.O+

O.H.A+

CCW drive pulse signal input terminal

●Directs the motor to operate CCW.

P.O-

O.H.A-

-12-

GD-5610

Instructions Manual

3-2.AC Input/Motor Output Terminal Block(J2,J3)

Do not touch the driver during operation.

Failure to do so may cause electric shock.

GD-5610

3-3.POWER LED

POWER LED (GREEN) comes on upon inputting power.

3-4.O.H.A LED

O.H.A LED(RED)comes on when internal temperature

of the driver has reached approx. 65℃ or more.

Motor output terminal

J2

4

J3

3

2

1

5

GRN

BRN

WHT

ORN

BLK

YLW

RED

GRY

VIO

BLU

3

2

1

100-

115V~

●Outputs current to drive the motor.

AC input terminal

●Power input terminal.

The power supply is connected.

Protective earth terminal

●Protects against electric shock as connected

to the protective earth terminal of the equipment.

N

L

MOTOR

BLU

RED

ORN

GRN

BLK

WARNING

-13-

GD-5610

Instructions Manual

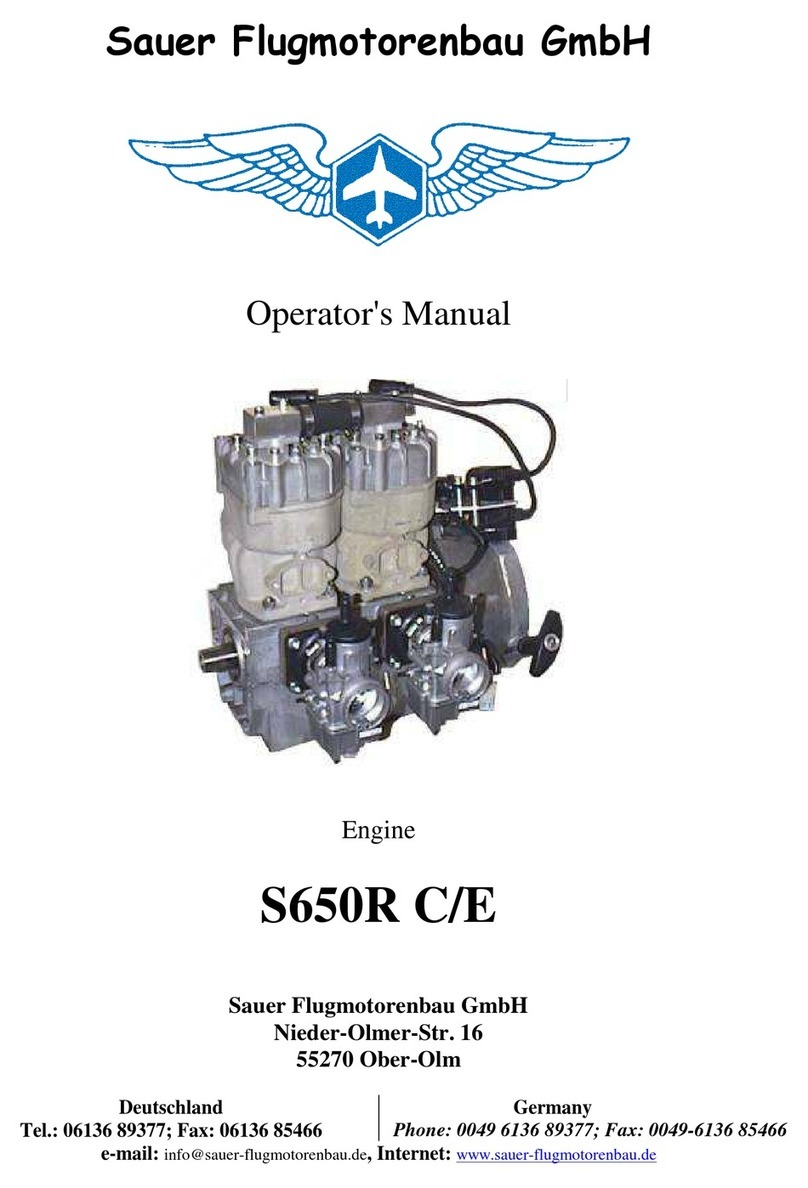

3-5.Operation Section

Do not touch the driver during operation.

Failure to do so may cause electric shock.

GD-5610

STEP ANGLE

SELECT switch

Selects a step angle.

No.1

Selects HOLD CURRENT.

No.6

No.D

HOLD CURRENT

SELECT switch

DRIVE CURRENT

SELECT switch

Selects DRIVE CURRENT.

OFF

ROTATE CHARACTERISTIC

SELECT switch

Selects a characteristic of motor rotation.

OFF

HOLD SWITCHING TIME

SELECT switch

DRIVE/HOLD CURRENT automatic switching time

is selected.

Factory Setting

PULSE INPUT TYPE CELECT

switch

Selects a pulse input type.

OFF

OP4

OP5

Name of Operation Section

Function

OFF

OFF

OFF

MOTOR SELECT

switch

Extend functions

switch

Please use it with OFF.

Selects the applicable motor.

OP1

OP2

OP3

DRIVE CURRENT SELECT switch (DRIVE I.SEL)

DRIVE

4

3

2

1

0

F

E

D

C

B

A

9

8

7

6

5

HOLD

STEP

HOLD CURRENT SELECT switch (HOLD I.SEL)

STEP ANGLE SELECT switch (STEP SEL)

POWER

OHA POWER LED(GREEN)

OHA LED(RED)

ON

HOLD SWITCHING TIME SELECT switch (DHT SEL)

ROTATE CHARACTERISTIC SELECT switch (RC SEL)

Extend functions switch

OP4

OP3

OP2

OP1

OP5

SPI

DHT

RC

[1P - 2P]

[1s - 150ms]

[ON - OFF]

PULSE INPUT TYPE SELECT switch (SPI SEL)

4

3

2

1

0

F

E

D

C

B

A

9

8

7

6

5

4

3

2

1

0

F

E

D

C

B

A

9

8

7

6

5

MOTOR SELECT switch (OP1,OP2)

WARNING

-14-

GD-5610

Instructions Manual

4.Setting

4-1.Setting STEP ANGLE SELECT switch

Erroneous setting may cause breakage of

the machine or injury due to unexpected

rotation of motor.

Ensure correct setting.

The step angle is set up with the STEP SEL switch.

(1) Set the STEP SEL switch No. to the step angle required.

●

Relationship between the STEP SEL switch No. and the step angle.

(Factory Setting)

●

Driving with two types of step angles are provided by combining

the STEP SEL switch setting and the C.S signal.

0.0018

0.0009

0.036

0.018

0.0072

0.0036

6

7

Switch No.

1

2

3

4

0

8

9

1/

Divisions

1/1

1/2

1/4

1/10

1/20

1/40

5

1/800

Step angle(°)

0.72°motor

0.72

0.36

1/100

1/200

1/400

0.18

0.072

1/16

0.045

A

B

C

D

-

-

-

-

1/8

0.09

1/80

0.009

1/160

0.0045

E

F

CAUTION

-15-

GD-5610

Instructions Manual

4-2.Setting HOLD CURRENT SELECT switch

A high setting value may cause burn on the

skin due to overheating of the motor.

Do not select a high value beyond the

required.

HOLD CURRENT is set up with the HOLD I.SEL switch.

This sets the ratio of HOLD CURRENT to DRIVE CURRENT.

(1) Set the HOLD I.SEL switch No. to the ratio of HOLD CURRENT to

DRIVE CURRENT required.

●

Ratio of HOLD CURRENT

HOLD CURRENT

DRIVE CURRENT

(Factory Setting)

●

HOLD CURRENT changes relative to DRIVE CURRENT setting.

The ratio of HOLD CURRENT set the switch No. to [No.F]:100% represents

the same as the setting for DRIVE CURRENT.

●

The greater the ratio of HOLD CURRENT grows, the more heat the motor

generates when is on holding-state.

9

50

55

30

35

40

45

5

2

3

0

1

8

×100

Switch No.

Ratio of HOLD CURRENT (%)

10

15

20

A

60

B

65

Ratio of HOLD CURRENT(%)

=

25

6

7

4

E

90

F

100

C

70

D

80

CAUTION

-16-

GD-5610

Instructions Manual

4-3.Setting DRIVE CURRENT SELECT switch

Erroneous setting may cause burn on the

skin due to overheating of the motor.

Ensure correct setting.

DRIVE CURRENT is set up with the DRIVE I.SEL switch.

(1) Set the DRIVE I.SEL switch No. to the setting specified in the table

"10-5. Applicable Motors".

●

Relationship between the DRIVE I.SEL switch and DRIVE CURRENT.

(Factory Setting)

Switch No.

F

2.0

1.8

1.7

1.6

2.1

3.0

1.5

1.4

2.9

2.3

2.4

2.5

2.6

A/phase

2.2

2.7

2.8

4

5

6

7

0

1

2

3

C

D

E

8

9

A

B

CAUTION

-17-

GD-5610

Instructions Manual

4-4.Setting HOLD SWITCHING TIME SELECT switch

DRIVE/HOLD CURRENT automatic switching time is set up

with the DHT SEL switch.

(1) Set the DHT SEL switch.

4-5.Setting ROTATE CHARACTERISTIC SELECT switch

ROTATE CHARACTERISTIC is set up with the RC SEL switch.

(1) Set the RC SEL switch to the specified in the talbe

"10-5. Applicable Motors."

4-6.Setting MOTOR SELECT switch

Erroneous setting may cause burn on the

skin due to overheating of the motor.

Ensure correct setting.

The OP1 and OP2 switches is turned to the setting

corresponding to the motor in use.

(1) Set the OP1 and OP2 switches to the specified in the talbe

"10-5. Applicable Motors."

(Factory Setting)

Hold Switching

Time

DHT SEL

1s

150ms

ON

OFF

CAUTION

-18-

GD-5610

Instructions Manual

4-7.Setting PULSE INPUT TYPE SELECT switch

Erroneous setting may cause breakage of

the machine or injury due to unexpected

rotation of motor.

Ensure correct setting.

2-pulse input method / 1-pulse input method are

set up by the SPI SEL switch.

(1) Set the SPI SEL switch.

●When the motor is operated with two pulse signal inputs of CW and CCW,

set the SPI SEL switch to [OFF].

●When the motor is operated with the pulse signal and direction signal

input, set the SPI SEL switch to [ON].

●In the case that 1-pulse input method is selected, the CCW terminal becomes

direction signal input designating the direction of the motor rotation.

Drive pulse set to the CW terminal(CW+,CW-).

●The input timing is same with 2-pulse input method and 1-pulse input method .

As for input timing, refer to "10-3. (2)Drive pulse input(CW, CCW)"

(Factory Setting)

SPI SEL

Input type

1PULSE (1P)

2PULSE (2P)

ON

OFF

CCW terminal(CCW+,CCW-)

direction set

Photo-coupler OFF:CCW direction

Photo-coupler ON :CW direction

CAUTION

-19-

GD-5610

Instructions Manual

5.Installation

5-1.Conditions for Installation

Mount it on a noncombustible member.

Keep it away from combustibles.

Overheating may cause fire.

(1) Designed for incorporating into equipment used indoors, this product requires

to be installed in the following environment:

●

Area that is free of explosive, corrosive or inflammable gas

●

Indoors (Area not exposed to direct sunshine)

●

Area that ambient temperature and humidity are controlled within the range

set out in the specifications

●

Area protected from dust, salt or iron particles

●

Area not subject to direct vibration or shock

●

Area not subject to splashing water, oil or chemicals

(2) Install the driver at least 10mm away from other equipment.

However, please be installed to a distance of at least 15mm from the

heating element.

●

Please contact us if you are not installed to a distance of at least 15mm

from the heating element.

(3) Considering heat release, control the ambient temperature around the driver

within the specified value.

●

Take measures against accumulation of heat such as allowing generous space

ようにする。

around the driver or installing a fan so that heat release is taken care of.

●

Install the driver securely in contact with metal or other substance with

adequate heat conductivity.

(4) In the case that an overheat alarm signal is output, perform the cooling measure of

the mounting plate is enlarged or compulsion air cooling etc.

Use the driver on the condition that an overheat alarm signal is not output.

(5)

Do not allow standing or placing anything heavy on the product.

WARNING

10mm or more

10mm or more

15mm or more

Driver

10mm or more

Driver

10mm or more

heating

element

-20-

Table of contents

Other M-Elec Engine manuals