Mazda Engine Table of Contents

TABLE OF CONTENTS

General................................................................................................................................................................ 1

Description .......................................................................................................................................................... 1

Engine Removal and Installation......................................................................................................................... 1

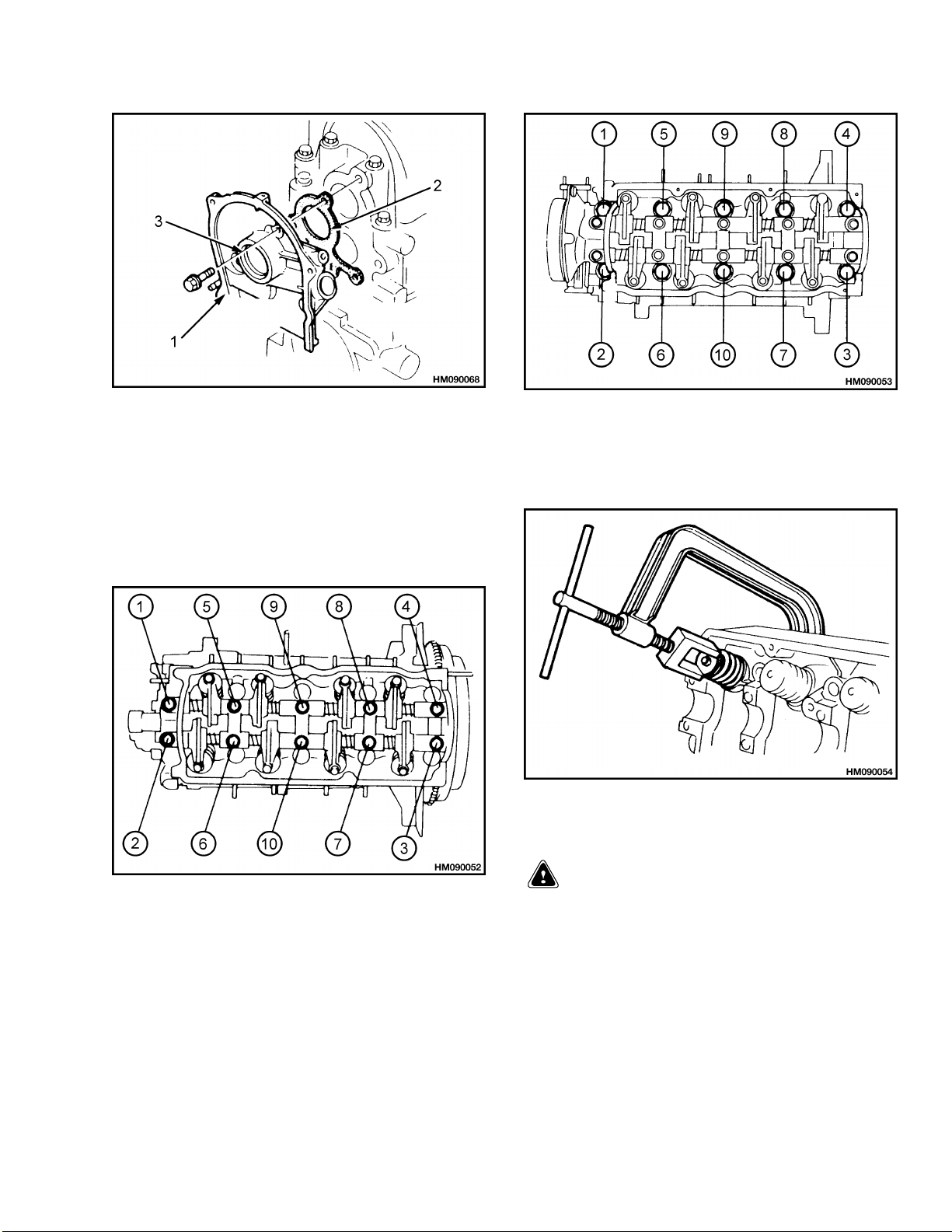

Cylinder Head, Camshaft, and Valve Mechanism Repair.................................................................................... 2

Remove........................................................................................................................................................... 2

Clean............................................................................................................................................................... 3

Inspect and Repair.......................................................................................................................................... 4

Cylinder Head............................................................................................................................................. 4

Rocker Shaft Assembly............................................................................................................................... 4

Camshaft .................................................................................................................................................... 4

Valve Guides............................................................................................................................................... 5

Valve Seats................................................................................................................................................. 6

Valves ......................................................................................................................................................... 6

Valve Springs.............................................................................................................................................. 7

Install............................................................................................................................................................... 7

Crankshaft and Main Bearings Repair................................................................................................................. 10

Remove........................................................................................................................................................... 10

Inspect and Repair.......................................................................................................................................... 10

Crankshaft................................................................................................................................................... 10

Main Bearings............................................................................................................................................. 10

Install............................................................................................................................................................... 11

Pistons and Connecting Rods Repair.................................................................................................................. 12

Remove and Disassemble .............................................................................................................................. 12

Clean............................................................................................................................................................... 12

Inspect and Repair.......................................................................................................................................... 12

Pistons........................................................................................................................................................ 12

Piston Rings................................................................................................................................................ 12

Connecting Rods and Bearings.................................................................................................................. 13

Assemble and Install....................................................................................................................................... 13

Cylinder Block Repair.......................................................................................................................................... 15

Oil Pump Repair.................................................................................................................................................. 15

Remove........................................................................................................................................................... 15

Disassemble.................................................................................................................................................... 15

Clean............................................................................................................................................................... 16

Inspect............................................................................................................................................................. 16

Assemble ........................................................................................................................................................ 16

Install............................................................................................................................................................... 17

Cooling System Repair........................................................................................................................................ 17

Thermostat...................................................................................................................................................... 17

Replace....................................................................................................................................................... 17

Fan Assembly.................................................................................................................................................. 18

Remove and Disassemble.......................................................................................................................... 18

Assemble and Install................................................................................................................................... 18

Water Pump .................................................................................................................................................... 18

Remove and Disassemble.......................................................................................................................... 18

Assemble and Install................................................................................................................................... 19

Distributor Repair................................................................................................................................................. 20

Remove........................................................................................................................................................... 20

Install............................................................................................................................................................... 20

Flywheel and Ring Gear Repair .......................................................................................................................... 21

Remove........................................................................................................................................................... 21

©2002 Yale Materials Handling Corp. i