M-Power MP100 User manual

MP100

User’s Guide

Rev.F

Sep 2018

MP100 User’s Guide

1

Contents

Read Before Operating...................................................................................................................2

General Information.......................................................................................................................3

User Interface..................................................................................................................................3

Display..............................................................................................................................................4

Using MP100....................................................................................................................................5

Turn the unit on.......................................................................................................................5

Warm up sequence..................................................................................................................5

Normal mode...........................................................................................................................6

Real time reading ............................................................................................................6

STEL screen.....................................................................................................................6

TWAscreen......................................................................................................................6

Peak screen ......................................................................................................................6

Min screen (for Oxygen sensor only).............................................................................7

Turn the unit off ..............................................................................................................7

Config mode.....................................................................................................................................7

Enter Config mode..................................................................................................................7

Sensor calibration....................................................................................................................8

Calibration adapter.................................................................................................................8

Zero calibration.......................................................................................................................9

Span calibration......................................................................................................................9

Bump test...............................................................................................................................10

Change alarm limit ...............................................................................................................10

Change bump/cal interval ....................................................................................................11

Change span value ................................................................................................................12

Change display unit ..............................................................................................................12

Vibrator enable/disable.........................................................................................................12

Power on zero enable/disable ...............................................................................................13

Fast power on enable/disable ...............................................................................................13

Reset config............................................................................................................................13

Exit Config mode...................................................................................................................14

Maintenance ..................................................................................................................................14

Replace the battery ...............................................................................................................14

Replace the sensor filter........................................................................................................15

Replace the sensor.................................................................................................................15

Ordering information...................................................................................................................17

Specifications.................................................................................................................................18

Sensor configuration.....................................................................................................................19

Alarm signal summary .................................................................................................................20

Trouble shooting............................................................................................................................22

MP100 User’s Guide

2

Read Before Operating

This manual must be carefully read by all individuals who have or will have the responsibility of

using, maintaining or servicing this product. The product will perform as designed only if it is

used, maintained and serviced in accordance with the manufacturer’s instructions.

Warning

⚫Never operate the monitor when the cover is removed.

⚫Remove the monitor cover and battery only in area known as non-hazardous.

⚫Use only mPower’s lithium battery part number 1.17.02.0002 (3.6V, 2700mAH, AA size) or

part No. ER14505 cell manufactured by EVE Energy Co., LTD

⚫This instrument has not been tested in an explosive gas/air atmosphere having an oxygen

concentration greater than 21%.

⚫Substitution of components will impair suitability for intrinsic safety.

⚫Substitution of components will void warranty.

⚫It is recommended to bump test with a known concentration gas to confirm the instrument is

functioning properly before use.

⚫Before use, ensure that the ESD film on the display is not damaged or peeling.

Avertissement:

⚫N'utilisez jamais le moniteur lorsque le couvercle est enlevé.

⚫Retirer le couvercle du moniteur et la batterie uniquement dans une zone connue comme non dangereuse.

⚫Utilisez uniquement la batterie au lithium de mPower, pièce No. 1.17.02.0002 (3.6V, 2700mAH, taille AA)

ou celle de EVE Énergie Cie., Lté, pièce No. ER14505.

⚫Cet instrument n'a pas été testé dans une atmosphère explosive gaz / air ayant une concentration en oxygène

supérieure à 21%.

⚫La substitution de composants compromettra l'aptitude à la sécurité intrinsèque.

⚫La substitution des composants annulera la garantie.

⚫Il est recommandé de tester avec un gaz de concentration connu pour confirmer que l'instrument fonctionne

correctement avant de l'utiliser.

⚫Avant de l’utiliser, assurez-vous que le film ESD sur l'écran n'est pas endommagé ou épluché.

Proper Product Disposal at The End Of Life

The Waste Electrical and Electronic Equipment(WEEE) directive (2002/96/EC) is

intended to promote recycling of electrical and electronic equipment and their

components at end of life . This symbol (crossed-out wheeled bin) indicates

separate collection of waste electrical and electronic equipment in the EU

countries. This product may contain one or more Nickel-metal hydride (NiMH),

Lithium-ion, or Alkaline batteries. Specific battery information is given in this

user guide. Batteries must be recycled or disposed of properly. At the end of its

life, this product must undergo separate collection and recycling from general or

household waste. Please use the return and collection system available in your

country for the disposal of this product.

MP100 User’s Guide

3

General Information

UNI (MP100) is a single sensor, portable, personal toxic gas monitor. It displays gas

concentration continuously on a big segment LCD. It also monitors STEL, TWA, peak and min

(for O2only) value of the gas and can be displayed on demand.

High, Low, STEL&TWA alarm threshold values are configurable. The shell is made of high

strength, durable material. Two key operation, simple to use. Sensor and battery can be replaced

easily. Calibration is also very convenient.

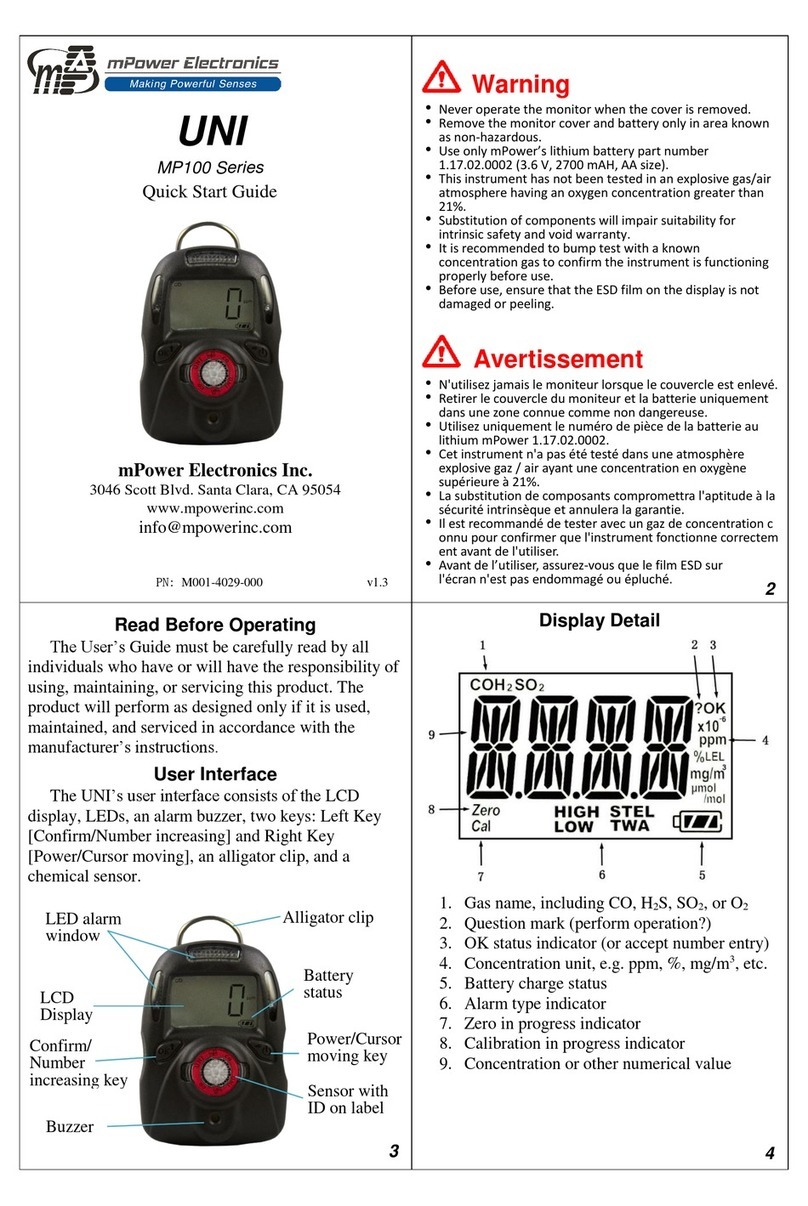

User Interface

1. AudibleAlarm Port

2. LED alarm window

3. LCD

4. Left Key (Confirm/Number increasing)

5. Right Key (Power/ Cursor moving)

6. Alligator clip

7. Sensor

8. Vibrator

MP100 User’s Guide

4

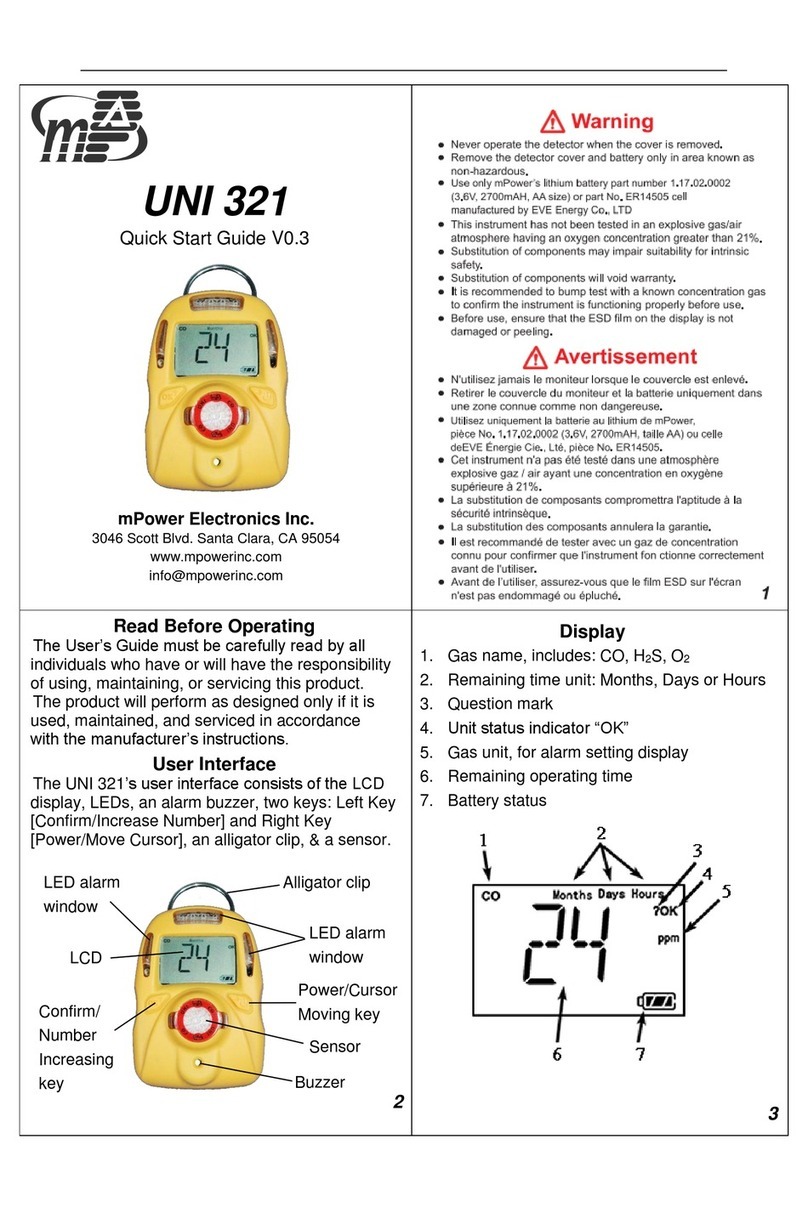

Display

1. Gas name, includes: CO, H2S, SO2, O2, VOC

2. Question mark

3. OK

4. Gas unit, includes: x10-6, ppm, %, mg/m3, µmol/mol

5. Battery

6. HIGH, LOW, STEL, TWA alarm

7. Span calibration

8. Zero calibration

9. Number

MP100 User’s Guide

5

Using MP100

Turn the unit on

Press and hold the Right Key for 3 seconds, until LCD displays , buzzer beeps,

green LED flashes, then release the button, the unit is powered on.

Warm up sequence

After powered on, the unit enter warm up and self-test sequence, show the firmware version as

follows:

If the sensor is not able to be identified by the instrument or is not installed into the instrument,

then the screen switches between and .Otherwise, the

following values will be shown accordingly:

High alarm threshold value:

Low alarm threshold value:

STEL (short-term exposure limit) alarm threshold value:

MP100 User’s Guide

6

TWA (time-weighted average) alarm threshold value:

Normal mode

Real time reading

The unit enters normal mode, start monitoring gas concentration and display on the LCD screen.

User can check some other values like STEL,TWA, PEAK, and MIN (for O2only) by pressing the

Right Key.

*Unit will return to real time reading from any other screen when there’s no key action for 60

seconds.

STEL screen

TWA screen

Peak screen

Press the Left Key to clear peak value

MP100 User’s Guide

7

Press the Left Key again, peak value is cleared.

Min screen (for Oxygen sensor only)

Press the Left Key to clear min value

Press the Left Key again, minimum value is cleared

Turn the unit off

In normal display mode, press and hold the Right Key, then the unit will display a 5 second count

down, LEDs will flash and buzzer will beep once per second.

Config mode

In Config mode, user can do calibration & change parameters for the unit. In general, use the Left

Key to increase the number or confirm, use the Right Key to move the cursor or move to the next

programming item.

Enter Config mode

Press and hold the Left Key and the Right Key together for 3 seconds, the unit enters Config

mode.

The Config mode is password protected, LCD displays to prompt enter

password. The screen displays , with one digit flashing.

MP100 User’s Guide

8

To input password, use the Left Key to increase the number, use the Right Key to move cursor.

Once all four digits are input, the cursor will move to “OK”, use the Left Key to finish password

input and enter the Config mode.

If the digit input is mistaken, use the Right Key to move cursor between four digits and “OK”

mark, to change the input.

*MP100 preset password is 0000

Sensor calibration

Before the unit can monitor gas correctly, it needs to know the metric, this is done by zero

calibration and span calibration.

Calibration adapter

1. Calibration adapter is used to apply gas to the unit during calibration.

2. Before span calibration (in the following section), attach the Calibration Adapter over the inlet

port on the front of MP100 by pressing it into place.

3. Open the gas cylinder valve, then press the Left Key to start the calibration count down.

MP100 User’s Guide

9

4. Take off the Calibration Adapter and complete calibration.

When monitoring, never operate the MP100 with the Calibration Adaptor attached. The

MP100’s sensor operates by diffusion. If the Calibration Adapter is attached during normal

operation, inconsistent and lower-than-normal readings will occur because of decreased

concentration of the gas being monitored.

Zero calibration

Zero calibration is to set the base line for the sensor, it is done in fresh air. When LCD

displays , press the Left Key to start zero calibration. The unit will start a 15

second count-down, after the count-down is finished, zero calibration result will be displayed on

the LCD, pass or fail .

If user does not want to do zero calibration, during the 15 seconds count, press the Right Key,

LCD displays , zero calibration is aborted.

Span calibration

Span calibration is to set the metric of the sensor to the gas, it is done with a known concentration

gas. When LCD displays , apply the known gas to the unit, then press the Left

Key to start span calibration. Unit will start count-down, the count-down time depends on

MP100 User’s Guide

10

different sensors (normally 60 seconds), after count-down is finished, span calibration result will

be displayed on the LCD, pass or fail .

If user does not want to do span calibration during count-down, press the Right Key, LCD

displays , span calibration is aborted.

Bump test

Bump test is to check if sensor and alarm devices are working properly, it is done with a known

concentration gas. When LCD displays , apply the known gas to the unit, then

press the Left Key to start bump test. Unit will start count-down, the count-down time depends on

different sensors (normally 45 seconds), after count-down is finished, bump test result will be

displayed on the LCD, pass or fail .

If user does not want to do bump test during count-down, press the Right Key, LCD

displays , bump test is aborted.

Change alarm limit

All the preset alarm limits, High, Low, STEL & TWA can be changed. When LCD displays:

, , , , press the Left Key

to change the corresponding alarm limit, the value change process is similar.

First the current setting value is displayed, with the first digit flashing: .

MP100 User’s Guide

11

Use the Left Key to increase the current digit, , cycle from 0 to 9.

Use the Right Key to move cursor to the next digit:

After all digits are done, use the Right Key to move cursor to “OK” symbol, ,

press the Left Key to confirm the changing.

* MP100 will show “Err”, if the input data is invalid as follows,

- Low alarm setting is bigger than high alarm setting.

- High alarm setting is smaller than low alarm setting.

- Input data is bigger than measuring range.

Change bump/cal interval

The bump and cal interval can also be changed. When LCD switches between:

and , and , press the Left

Key to change the corresponding interval range, the value change process is similar.

First the current setting value is displayed, with the first digit flashing: .

Use the Left Key to increase the current digit, , cycle from 0 to 9.

Use the Right Key to move cursor to the next digit:

After all digits are done, use the Right Key to move cursor to “OK” symbol, ,

MP100 User’s Guide

12

press the Left Key to confirm the changing.

* MP100 will show “Err”, if the input data is out of valid range:0~180 day(s).

Change span value

The span calibration preset value can also be changed, the change process is similar with the alarm

limit. But the new span will not take effect until user successfully completes a span calibration

next time.

*MP100 will show “Err”, if the input data is invalid as follows:

- Span setting is smaller than 5% measuring range or bigger than measuring range.

- For Oxygen sensor, span setting is bigger than 19.0 .

Change display unit

MP100 supports different gas units, to change gas unit, when LCD switches between

and , press the Left Key to change gas unit. The supported

units for current sensor are all displayed on the LCD, the current selected unit is blinking. Use the

Right Key to change unit, use the Left Key to confirm selected gas unit.

Vibrator enable/disable

The vibrator consumes a lot of power, it can be disabled to save battery power, to extend the

battery life.

When LCD switches between and , press the Left Key to

change the vibrator enable/disable status. The current vibrator status is displayed on the LCD,

switching between and if the vibrator is enabled, or

MP100 User’s Guide

13

switching between and , if the vibrator is disabled. Use the

Right Key to change the enable/disable status, and use the Left Key to confirm the change.

Power on zero enable/disable

Sensor base line may have some changes due to the environment (temperature, humidity), that will

require a zero calibration. MP100 can do zero calibration every time the unit is powered on; this

feature can be enabled/disabled.

When LCD switches between and , press the Left Key to go to

change power on zero calibrations enable/disable status. The current enable/disable status is

displayed on the LCD, use the Right Key to change, use the Left Key to confirm the change.

Fast power on enable/disable

If fast startup is enabled, the screens showing High/Low/STEL/TWA alarm threshold value will be

skipped during warm up sequence.

When LCD switches between and , press the Left Key to

change fast startup enable/disable status. The status is displayed on the LCD, switching between

and if the fast startup is enabled, or switching between

and if the fast startup is disabled. Use the Right Key to

change the enable/disable status, use the Left Key to confirm the change.

Reset config

If the unit parameter is incorrect and user does not know how to set them back, user can use reset

config to make all the parameters back to factory default.

MP100 User’s Guide

14

When LCD switches between and , press the Left Key to

enter config reset menu, press the Left Key to confirm config reset.

Exit Config mode

When LCD displays , press the Left Key exit from Config mode back to normal

mode.

Maintenance

Replace the battery

When the battery’s charge is low, LCD displays , battery low alarm will be

triggered once every minute. User needs to replace the battery.

When battery is dead, LCD displays , battery dead alarm will

be triggered once every second. User needs to replace the battery.

To replace battery:

1)Turn off the MP100.

2)Place the MP100 face down on a soft surface.

3)Use a T10 Torx screwdriver to loosen each of the four screws by turning them

counterclockwise.

4)Remove the top cover after carefully unplugging the buzzer connector.

5)Slide the battery out of its compartment.

6)Place the new battery into the compartment with its “+” end oriented toward the “+” on the

Maintenance should be performed only by a qualified person who has

proper training and fully understands the contents of the manual.

MP100 User’s Guide

15

printed circuit board.

7)Plug in the buzzer connector and reinstall the top cover.

8)Install the screws in back cover. Be careful to not overtighten the screws.

Replace the sensor filter

A “peel-and-stick” filter should be used on the MP100 in order to keep debris from fouling the

sensor. Sheets of 5 filters are available. When the filter appears dirty, replace it with a new one and

dispose of the dirty filter.

1) Turn off the MP100.

2) Place the MP100 face down on a soft surface.

3) Use a T10 Torx screwdriver to loosen each of the four screws by turning them

counterclockwise.

4) Remove the top cover after carefully unplugging the buzzer connector.

5) Peel a filter from the sheet and center it over the sensor. Gently press down.

6) Plug in the buzzer connector and reinstall the top cover.

7) Install the screws in back cover. Be careful to not overtighten the screws.

Replace the sensor

MP100 models are designed so that you can easily change the sensor.

1) Turn off the unit.

2) Place the MP100 face down on a soft surface.

3) Use a T10 Torx screwdriver to loosen each of the four screws by turning them

counterclockwise.

4) Remove the top cover after carefully unplugging the buzzer connector.

5) Replace the old sensor with a new one. Make sure the pins are not bent or corroded . Align the

pins to the corresponding holes and push the sensor straight in . The sensor should fit flush

against the printed circuit board.

6) Plug in the buzzer connector and reinstall the top cover.

7) Install the screws in back cover. Be careful to not overtighten the screws.

Sensors are not interchangeable. Use only mPower sensors, and use only

the sensor type specified for your MP100 monitor. Use of non-mPower

components will void the warranty and can compromise the safe performance of

this product.

MP100 User’s Guide

16

Caution

⚫Change battery only in area known to be non-hazardous.

⚫Use only mPower battery, PN: 1.17.02.0002 or part No. ER14505 cell manufactured by

EVE Energy Co., LTD.

Attention

⚫Changez la batterie uniquement dans une zone connue pour être non dangereuse.

⚫Utilisez uniquement la batterie au lithium de mPower, pièce No. 1.17.02.0002 (3.6V,

2700mAH, taille AA) ou celle deEVE Énergie Cie., Lté, pièce No. ER14505.

*Filter need to be replaced when it becomes discolored, clogged with particles or draws in liquid,

otherwise it will contaminate sensor and void warranty.

MP100 User’s Guide

17

Ordering information

Kit Package

⚫MP100 instrument (with sensor, AA size lithium battery and alligator clip)

⚫Quick start guide

⚫Calibration adapter

Calibration Kits(Optional)

⚫Test gas (for sensor as specified)

⚫Gas regulator with flow controller

⚫Hard transport case

⚫Multi-unit charging and calibration station

Year of manufacturing

To identify the year of manufacturing, please refer to the serial number of the instrument.

The fifth to sixth digit in the serial number indicates the year of manufacturing. 00~99

indicates the manufacturing year is 2000 to 2099.

MP100 User’s Guide

18

Specifications

Size

3.46 x 2.44 x 1.3 in.

(88 x 62 x 33mm)

Weight

4.4 oz. (125g)

Temperature

-4℉~ 122℉(-20℃~ 50℃)

Humidity

5 ~ 95% relative humidity(non-condensing)

Alarm type

High alarm, low alarm, STEL alarm & TWA alarm

adjustable.

Over range alarm, battery low alarm.

Alarm signal

Audible: 90dB @ 30cm

Visual: Bright red LED

Sense: Built in vibrator

Calibration

2 point calibration, zero and span, power on zero (need

user confirm).

Event log

Up to 10 alarm events

Response

time(T90)

20 seconds(only for CO/H2S/O2)

IP rating

IP67

EMI/RFI

Compliant with EMC 2004/108/EC

Certifications

Intrinsic Safety:

UL/CUL:

Class I, GroupA, B, C, D

Class II, Group E,F,G

Class III ,Hazardous Locations

T4, -20° C≤ Tamb≤ +50° C

Battery

Replaceable AA size Lithium battery,

3 years if used within specs

Sensor

CO/H2S expected operating life 5 years in air, others 2

years

Warranty

2 year warranty for CO, H2S, O2and SO2, 1 year for

the others.

MP100 User’s Guide

19

Sensor configuration

Sensor

Range

(ppm)

Resolution

(ppm)

Span

(ppm)

Low

(ppm)

High

(ppm)

STEL

(ppm)

TWA

(ppm)

Panel

Ring

T90(s)

CO

0-1999

1

100

35

200

100

35

Red

20

0-1000

1

100

35

200

100

35

20

0-500

1

50

35

200

100

35

20

H2S

0~50

0.1

25

10

20

15

10

Light

Blue

20

0-100

0.1

25

10

20

15

10

20

0~200

0.1

25

10

20

15

10

20

0~1000

1

25

10

20

15

10

30

NH3

0-50

1

50

25

50

35

25

Orange

150

Cl2

0-10

0.1

10

0.5

5

1

0.5

Orange

30

ClO2

0-1

0.01

0.5

0.2

0.5

0.3

0.1

Orange

120

HCN

0-100

1

10

4.7

50

4.7

4.7

Orange

200

NO

0-250

1

25

25

50

25

25

Orange

30

NO2

0-20

0.1

5

1

10

1

1

Orange

30

PH3

0-20

0.01

5

1

2

1

0.3

Orange

60

SO2

0-20

0.1

5

2

10

5

2

Orange

15

ETO

0-100

0.1

10

1

5

5

1

Orange

120

0-200

0.1

10

5

10

5

1

Orange

120

O3

0-1

0.02

1

0.1

0.2

0.1

0.1

Orange

60

HF

0-10

0.1

6

2

6

6

3

Orange

90

HCl

0-15

0.1

10

2

5

5

1

Orange

90

CH3SH

0-10

0.1

5

0.5

5

0.5

0.5

Orange

35

C2H4O

0-20

0.1

5

2

10

5

2

Orange

120

Sensor

Range

(%)

Resolution

(%)

Span

(%)

Low

(%)

High

(%)

STEL

(%)

TWA

(%)

Panel

Ring

T90(s)

O2

0 - 25

0.1

18

19.5

23.5

-

-

Dark

Blue

20

0 - 30

0.1

18

19.5

23.5

-

-

20

Caution

Use only mPower sensors.

Call forAvailability.

Table of contents

Other M-Power Gas Detector manuals