EsiWelma® s.r.l. E202.602_En Rev. 2 dated 30/11/2018 Pag. 3/4

Technical Data

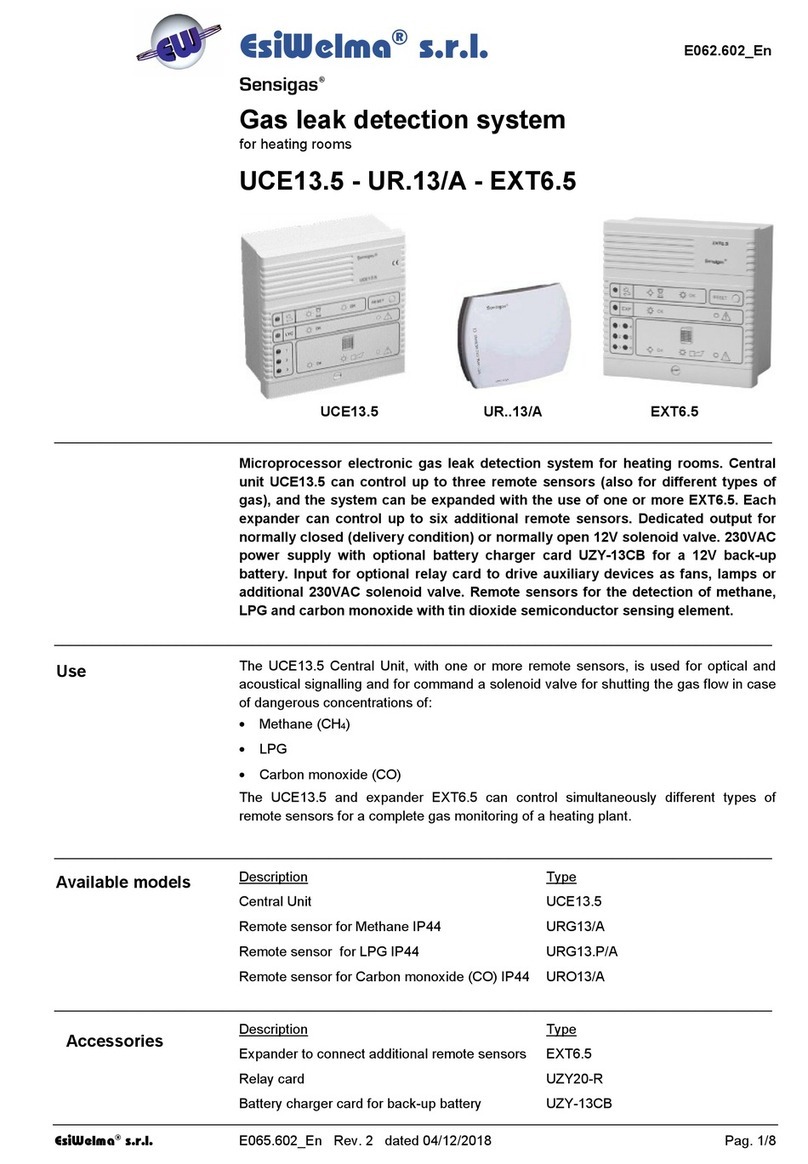

Control Unit UCE11

Power supply voltage 24VAC +/- 10%

Frequency 50/60Hz

Power consumption 21VA max (with battery under charge)

Sensor inputs 1 x UR.13/A

Control outputs - Electronic 12VDC (13W max)

- SPDT Relay 250V 5(3)A

Controlled valve type Normally Closed or

Normally Open

Operation logic positive (normally energized relay,

de-energizes in case of alarm / fault)

“VALVE TYPE” Jumper

Valve type NO = Normally Open

NC = Normally Closed

“VALVE MODE” Jumper

Valve output mode CONT = continuous

(for NO type only) PULSE = pulses (1 pulse every 10s)

Optical signals (please refer to functional tables)

Green LED Power presence / test

Yellow LED Sensor / valve / control unit fault

Red LED Gas alarm

Sensor connection length cable 1.5mm2 max 80m

Valve connection length cable 1.5mm2 max 80m

cable 1.5mm2 max 40m (13W)

Battery protection fuse T3.15A 250V 5x20

Dimensions 130 x 106 x 56.5 mm

Protection IP20 – EN60529

Room temperature 0…50°C

Room humidity Max 90% R.H. non condensing

Sensor UR.13/A

Sensing element Tin dioxide semiconductor

URG13/A 20% LEL methane (10000ppm)

URG13.P/A 20% LEL LPG (3720ppm)

URO13/A 200 ppm CO

Protection IP44 (if correctly installed)

5 years from installation date

Room temperature 0…50°C

Room humidity Max 90% R.H. non condensing

Built-in relay

Operation Positive logic (normally energized).

de-energizes in case of alarm / fault

Changeover contact Voltage free 250VAC 5(3)A

Built-in battery charger

Charge voltage 13.8VDC

Charge current 0.5A max

Battery 12VDC 4÷6 Ah (not supplied)

Automatic intervention and current limit

Conformity

Regulations Low Voltage 2014/35/UE

Electromagnetic Compatibility 2014/30/UE

Standards EN50194

EN50270

CAUTION

Lifetime of sensors URG13/A, URG13.P/A e URO13/A is 5

years from installation date. It is necessary to substitute

them systematically before the end of the 5th year of use.

Average lifetime of sensors has been calculated considering a typical

usage in an environment free of pollution substances (gases,

solvents, etc.). A frequent presence or high concentration of these

substances may accelerate normal oxidation process of the sensing

element and consequently shorten its decay time (lifetime).

Functional tables

LEDs status

Functions

Green LED

Yellow LED

Red LED

Sensor preheating ph. (1 min) Flash 1Hz ON ON

TEST phase (3 min) Flash 2Hz ON ON

Normal operation ON ON ON

Gas alarm ON ON Flash 1Hz

Valve fault (*) ON Flash 1Hz ON

Sensor fault ON Flash 1Hz OFF

General fault ON OFF OFF

Output status

Functions

output

EV

(NC valve)

relay

output

Sensor preheating ph. (1 min) Voltage absence De-energized

TEST phase (3 min) Voltage presence Energized

Normal operation Voltage presence Energized

Gas alarm Voltage absence De-energized

Valve fault (*) Voltage absence De-energized

Sensor fault Voltage absence De-energized

General fault Voltage absence De-energized

(*) A valve fault is detected by short circuit (normally closed valve) and open

circuit (normally open valve).

Simultaneousness of 2 or more events causes a combined manage-

ment of LEDs and outputs in accordance with a defined priority.

IMPORTANT

IN CASE OF ALARM FOR GAS LEAK OR CARBON

MONOXYDE PRESENCE ACT AS FOLLOWS:

Cut off all free flames and all gas-supplied devices

Do not switch-on or switch-off electrical lights or any other

electrically-supplied appliance, in order to avoid the

sparkling (cause of explosion for explosive gas)

Close the main valve of gas network or of LPG gas bottle

Open windows and doors to ventilate the rooms

Look for the cause of the alarm, and eliminate it. If you are

not able to find and to eliminate the cause of the alarm,

leave the building, and, from the outside, call for emergency

aids.

Environmental compatibility and disposal

This product was developed and manufactured using materials and

processes which take full account of environmental issues and which

comply with our environmental standards.

Please note the following for disposal at the end of the product life, or

in the event of its replacement:

For disposal, this product is defined as waste from electrical and

electronic equipment (“electronic waste”); do not dispose of it as

household waste. This applies particularly to the PCB assembly.

Observe all current local laws and regulations.

Always aim for maximum re-use of the basic materials at

minimum environmental stress. Observe any notes on materials

and disposal that may be attached to individual components.

Use local depots and waste management companies, or refer to

your supplier or manufacturer to return used products or to

obtain further information on environmental compatibility and

waste disposal.

The UCE11 shipping case can be recycled. Retain it for future

use or in case of product return to the manufacturer.

C NC NO

M