ENMET Bullard AirGuard AGP User manual

AirGuardTM Operators Manual

Revision 2.08

31 January 2022

2

www.bullard.com

Table of Contents

Introduction ...............................................................................................................3

Safety Recommendations ...........................................................................................3

General Safe Use Considerations.................................................................................3

AirGuard Approvals ....................................................................................................4

AirGuard Specifications...............................................................................................5

Sensor Module Specifications......................................................................................6

Warranty ...................................................................................................................7

General Software Interface.........................................................................................8

Menu Function Interface Overview .............................................................................9

Battery Operation ....................................................................................................10

Compressor Pneumatic Connections..........................................................................11

Start-Up ...................................................................................................................14

Access Code..............................................................................................................17

Bump Test ................................................................................................................19

Sensor Menu ............................................................................................................20

Calibration ...............................................................................................................23

Settings Menu ..........................................................................................................29

Maintenance Menu ..................................................................................................31

Data Capture............................................................................................................32

Battery and Power Supply Operation ........................................................................35

Case Exterior ............................................................................................................36

ESD ..........................................................................................................................36

Air Filtration Filters...................................................................................................36

General Filter and Sample Train Parts .......................................................................37

AirGuard Parts..........................................................................................................38

AirGuardTM

3

www.bullard.com

Introduction

Thank you for selecting the Bullard AirGuard. The AirGuard is a portable breathing air system which meets NFPA

and OSHA requirements. It uses a three-stage filter system which removes contamination and odors in the

breathing air stream. The AirGuard reports both Carbon Monoxide and differential dew point values on a visible

and externally mounted liquid crystal display. It also has operator warning alarms for flow CFM (cubic foot per

minute) and calibration interval reminders. The AirGuard data log records all operational use and calibration

events for OSHA (Occupational Safety and Health Administration) compliance reporting.

Safety Recommendations

Important Reference Information

Note = Important information about use of the instrument.

Remarque = Informations importantes sur l'utilisation de l'instrument.

Caution = Affects Equipment –If not followed may cause damage to the instrument or

sensor.

Attention = affecte l'équipement - s'il n'est pas suivi, il peut endommager l'instrument

ou le capteur.

Warning = Affects personal safety –If not followed may cause bodily injury or death.

Avertissement = Affecte sécurité personnelle - non suivi peut causer des blessures

corporelles ou la mort.

General Safe Use Considerations

•AirGuard is an instrument designed for Grade D breathing air

compliance. It is important that the operator is trained by qualified

personnel to ensure proper use.

•The AirGuard is approved primarily for indoor locations and limited

outdoor use.

•Do not use the AirGuard unless you have been trained to operate the

instrument and fully understand its implementation as a health and

safety device. Inappropriate use can result in severe injury or death.

•Observe Proper Battery Maintenance and use only chargers supplied by

BULLARD to avoid battery damage and performance issues.

•Do not recharge AirGuard in a hazardous classified or environmental

location.

•Indoor recharging only.

PROOFING VIEW - SCALE: 2 : 1

LABEL, WARNING / INFO,

AIRGUARD

COMPUTER FILE NO.

04539-261_Label_Warning-Info_AirGuard.idw

DRAWING NO:

04539-261

SHEET: REV:

OF

2 2

B

UNLESS OTHERWISE S PECIFIED

DIMENSIONS ARE IN INC HES

TOLERANCES ON:

2 PLC DEC

±.03

3 PLC DEC

±.010

PG SIZE: SCALE: DO NOT

SCALE

8.5x11

ENG. APP'L:

DESIGNED BY:

1/3/2020

CREATION DATE:

PJK

NOTES: UNLESS OTHERWISE SPECIFIED:

XXX

4

www.bullard.com

•Perform a bump check before each use. Adjust the calibration if

necessary.

•After airflow is connected, check the 0.01-micron filter for a fault indication. This is displayed by

observing the bubble indicator on the top of the middle valve filter assembly when AirGuard is supplied

with compressor air.

•Should AirGuard at any time experience severe shock or impact recheck the calibration via a bump check

and adjust if necessary.

•Always have a trained and qualified person interpret the results to ensure safe operation.

Warning! California Proposition 65 Warning: Cancer and Reproductive Harm

www.P65Warning.ca.gov

AirGuard Approvals

Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use

–Part 1: General Requirements [UL 61010-1:2012 Ed.3 +R:29Apr2016]

Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use

–Part 1: General Requirements [CSA C22.2#61010-1-12:2012 Ed.3 +U2]

AirGuardTM

5

www.bullard.com

AirGuard Specifications

Enclosure:

Polypropylene case

No. of Breathing Air Lines:

1, 2, 4 or 8

Size /Weight:

1-line: 19.2 lbs, 18.7” x 13.2” x 7”

2-line: 24.6 lbs, 22.6” x 15.8” x 7.6”

4-line: 31.6 lbs, 26.4” x 19.6” x 9”

8-line: 34 lbs, 26.4” x 19.6” x 9”

Operating Environment Conditions:

Temperature - (32°F to 104°F) (0°C to +40°C)

Ambient Humidity - (10% to 95% RH, non-condensing)

Altitude Sea Level +400M

Storage Environment Conditions:

Temperature - (5°F to 140°F or -15°C to +60°C)

Altitude Sea Level +1,200M

Storage Ambient Humidity:

10% to 95% RH, non-condensing

Power Supply:

100-260 VAC 50/60 Hz (< 10 Watts average) to run unit and/or charge battery.

Internal Battery:

12V / 7Ah rechargeable lead-acid, removable

Battery Life:

10 hours (typical)

Local Alarm Signal:

Color display background and high intensity audible (90 dB) horn

Remote Alarm Signal:

Remote alarm jack with 12VDC output

Pollution Degree Rating:

3

Water Resistance:

IP42

Agency Approvals:

UL 61010 (US & Canada)

Warranty:

2-years parts & labor (excluding instrument calibration and expendable parts such as calibration gas,

filters and batteries)

6

www.bullard.com

Sensor Module Specifications

Sensor Types:

Carbon Monoxide - (0 to 50 ppm)

Dew Point - (-20°F to ambient)

Flow Rate - (0 to 100 CFM)

Sensor Accuracy:

Carbon Monoxide: ±5% @ 10 ppm

Dew Point: ±2°F @ 50°F dewpoint

Air Flow Alarm Pt.:

< 5CFM ±1 CFM

Air Filter Train Filters (3):

(1) 5.0-micron filter, (2) 0.01-micron filter and (3) carbon absorber filter

Sensor response time:

< 60 seconds

Display:

Backlit, 7” diagonal color display

Keypad:

3-button, weatherproof w/ tactile feedback

Data Logging:

2 points per minute

Data Storage Medium:

USB memory stick

Calibration:

Span and Zero, Recommended Monthly, 60 Days Yellow Alert Warning, 90 Days Red Alarm Warning

AirGuardTM

7

www.bullard.com

Warranty

BULLARD warrants new AirGuard to be free from defects in quality and material under regular use for two years

from the date of shipment from BULLARD. The warranty covers both parts and labor, excluding instrument

calibration and expendable parts such as calibration gas, filters, batteries, etc.

Equipment believed to be defective should be returned to BULLARD within the warranty period (transportation

prepaid) for inspection. If the evaluation by BULLARD confirms that the product is faulty, it will be repaired or

replaced at no charge, within the stated limitations, and returned prepaid to any location in the United States by

the most economical means, e.g., Surface UPS/FedEx Ground. If a faster level of transportation is requested during

the warranty period, the customer is responsible for the difference between the most economical means and the

desirable mode.

BULLARD shall not be liable for any loss or damage caused by the improper use or abuse of the product. The

purchaser indemnifies and saves harmless the company concerning any loss or damages that may arise through

the application by the purchaser or others of this equipment. This warranty is expressly given in place of all other

warranties, either expressed or implied, including that of merchantability, and all other obligations or liabilities of

BULLARD which may arise in connection with this equipment. BULLARD neither assumes nor authorizes any

representative or other persons any responsibility or liability other than that which is set forth herein.

When returning an instrument to the factory for service be sure to include the following information.

1. A purchase order, return address, and contact information will assist in the expedient repair and return

of your unit.

2. Include any specific instructions.

3. For warranty service, include date of purchase.

If you require an estimate, please contact BULLARD AirGuard support at 877-285-5273.

8

www.bullard.com

General Software Interface

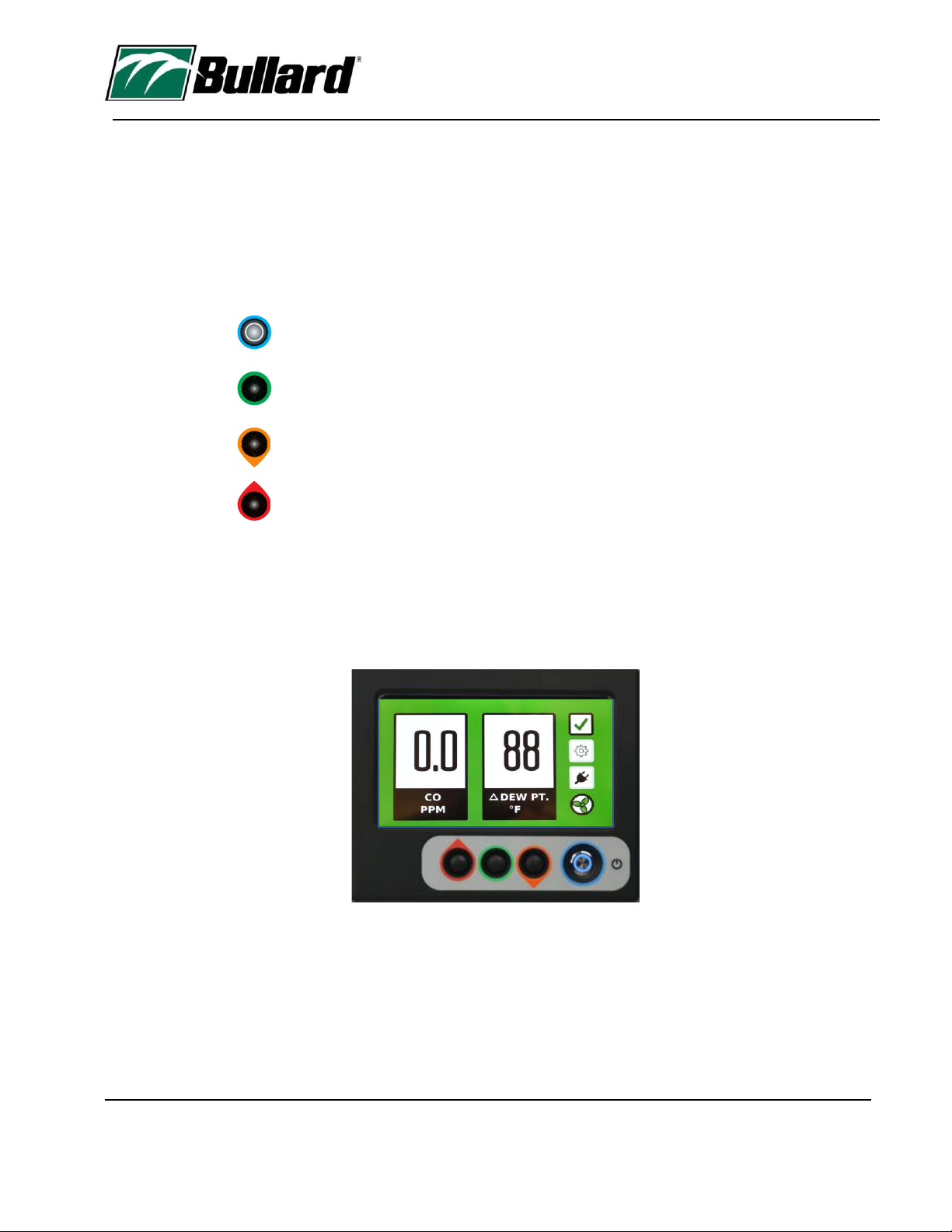

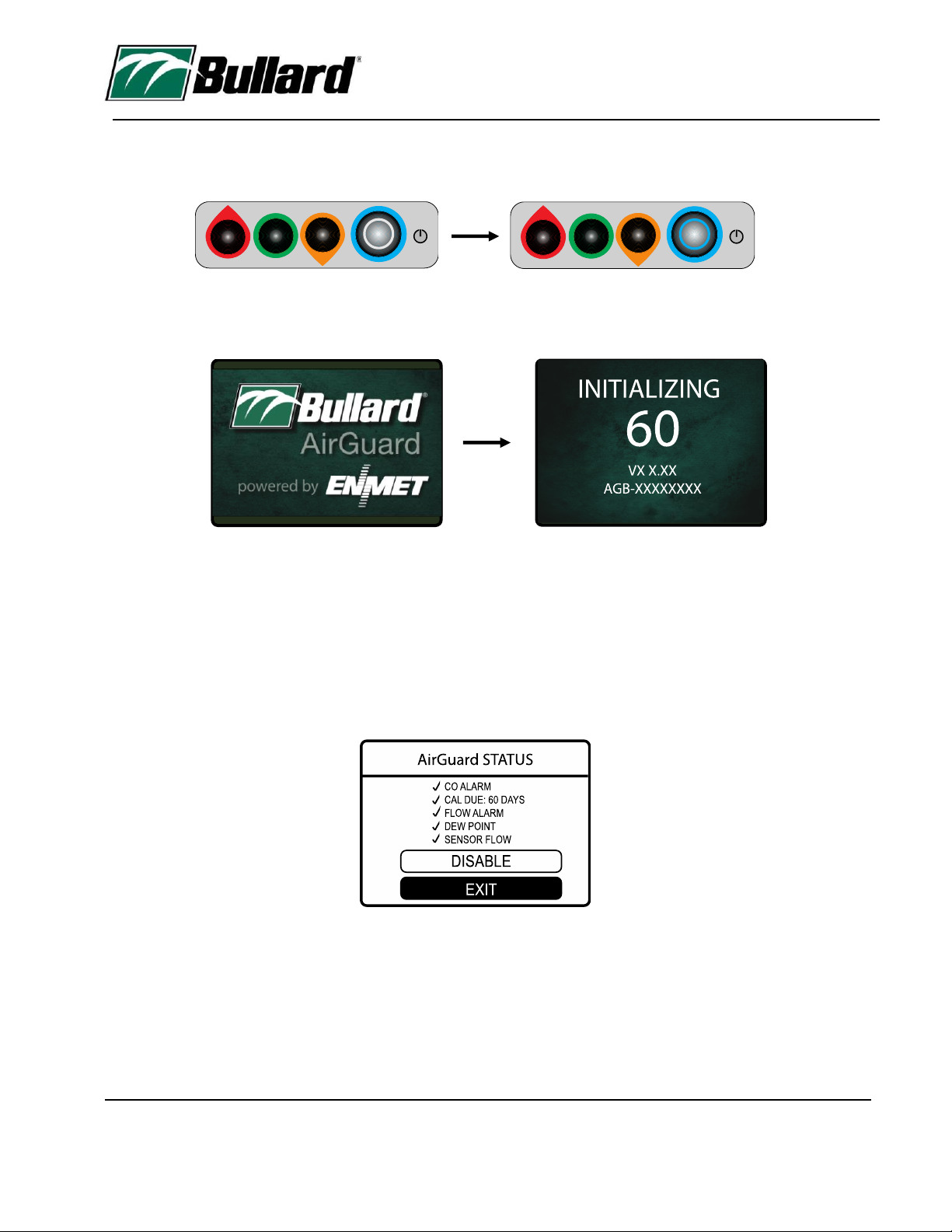

AirGuard uses a computer control menu interface which communicates using a Liquid Crystal Display (LCD). Three

buttons control this interface. These buttons toggle the menu function selection, allow the adjustment of numeric

values, and enter commands.

This three-button interface is located directly under the LCD. The buttons are color-coded, (left) red cursor up,

(middle) green enter and (right) orange cursor down. Additionally, the up-down buttons have a droplet point for

direction to assist function direction.

Power On/Off

Green Enter Function

Orange Cursor Down Selection

Red Cursor Up Selection

The main menu has three menu icons that allow access to menu functions and operational changes. From the

primary display, these icons are accessed by using the up/down buttons. The active icon selection has a black

border while the other icons will be grey. The default position is located on the check icon. Toggling the buttons

(orange button) down or (red button) up will change the icon selected position. Upon selection of the desired

function, press the middle green enter button to enter the function.

AirGuardTM

9

www.bullard.com

Menu Function Interface Overview

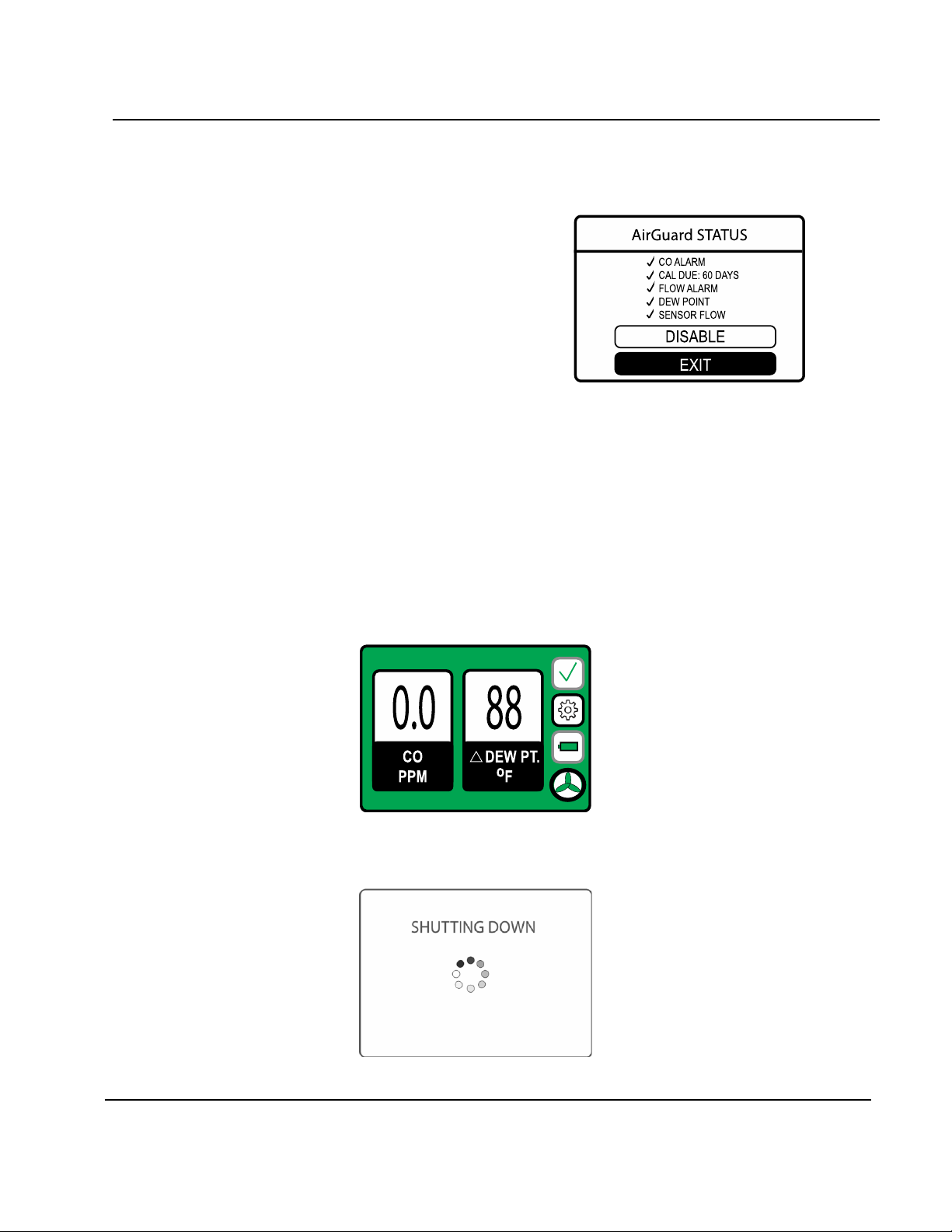

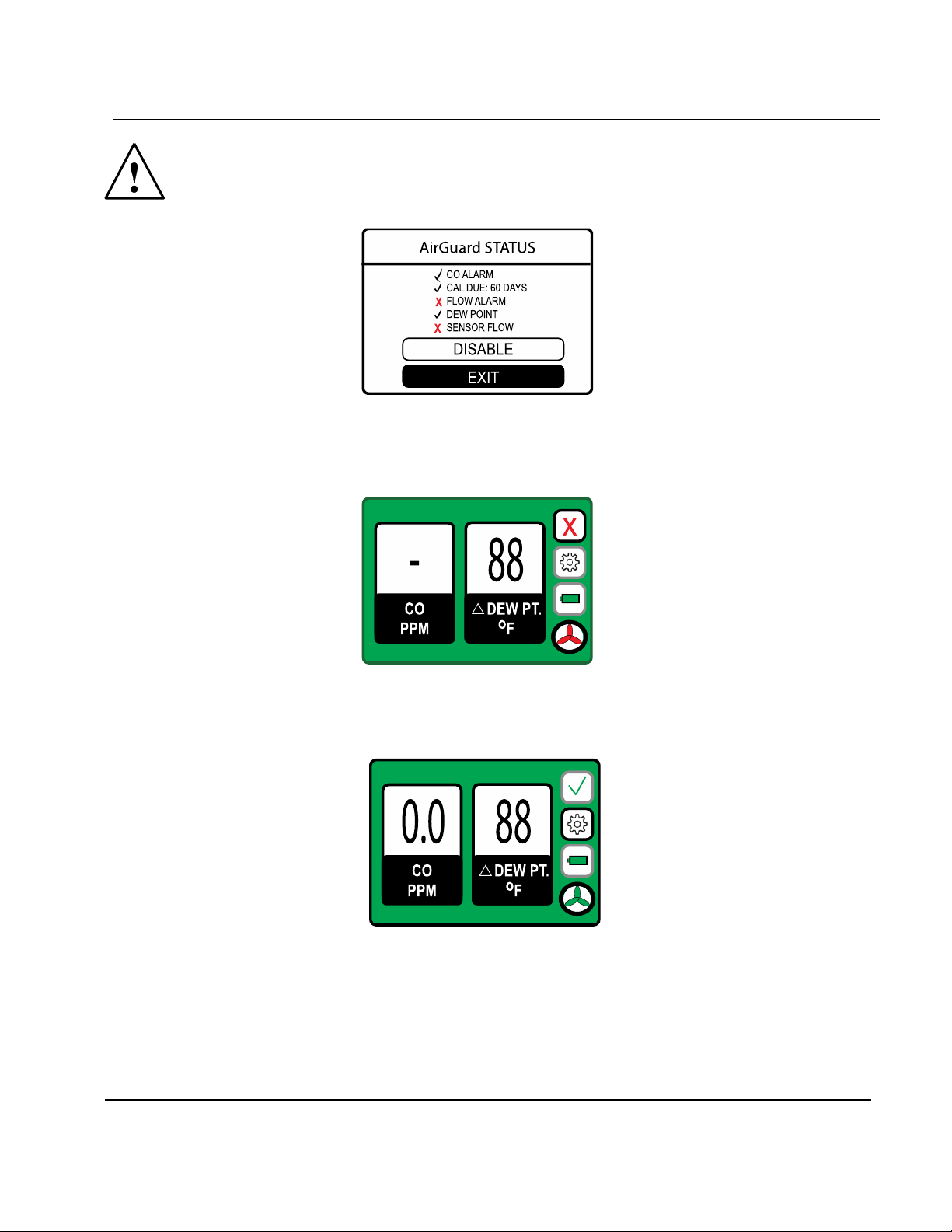

Upon powering on, the AirGuard will display a warmup screen and then “AirGuard Status” screen which

communicates the status of 5 monitored functions.

1. CO Concentration Alarm

2. Calibration Interval Day Count Down

3. CFM Flow Alarm

4. Dew Point Sensor Operation

5. Air Flow to the CO Sensor

This icon has three status functions as defined below.

1. Green Check = System Operation Satisfactory

2. Yellow Check = System Caution or Warning to which user attention is required.

3. Red “X’ = System Fault - AirGuard requires immediate calibration or service and must not be used until

the issue reported is resolved.

Should the status of the AirGuard change during operation, the AirGuard will change the green check symbol along

with the display background. When the check symbol changes color, the operator can press the enter button to

display the AirGuard Status screen which will show the warning or fault encountered.

The alarms can be disabled by selecting the disable function during an activation event.

To get to the main display, the operator must toggle to the exit function to display the main operational screen as

illustrated below.

To power down the AirGuard, press the power button, the shutting down screen will appear, the LCD will turn off

and finally the power button will go dark.

10

www.bullard.com

Battery Operation

The AirGuard is a battery-operated portable instrument and should be fully charged before use.

To charge the AirGuard, you must connect the charge connector cable to the charging inlet located on the lower

right side of the instrument. Insert the 2.5mm Ault connector into the female receptacle, secure the connector by

screwing it together, clockwise and then power the charger by connecting to main or wall power 100 to 240VAc

power.

The battery can power the AirGuard for 16 hours of operation.

The AirGuard will indicate a low battery in two ways, one through the main display battery icon turning red. The

other is a screen warning that will appear on the LCD.

If the charger is not connected the LCD will power down to conserve remaining battery power.

LED Position

Red = Charging

Green = Charged

Calibration

Connection

Charger

Connection

Remote

Alarm

AirGuardTM

11

www.bullard.com

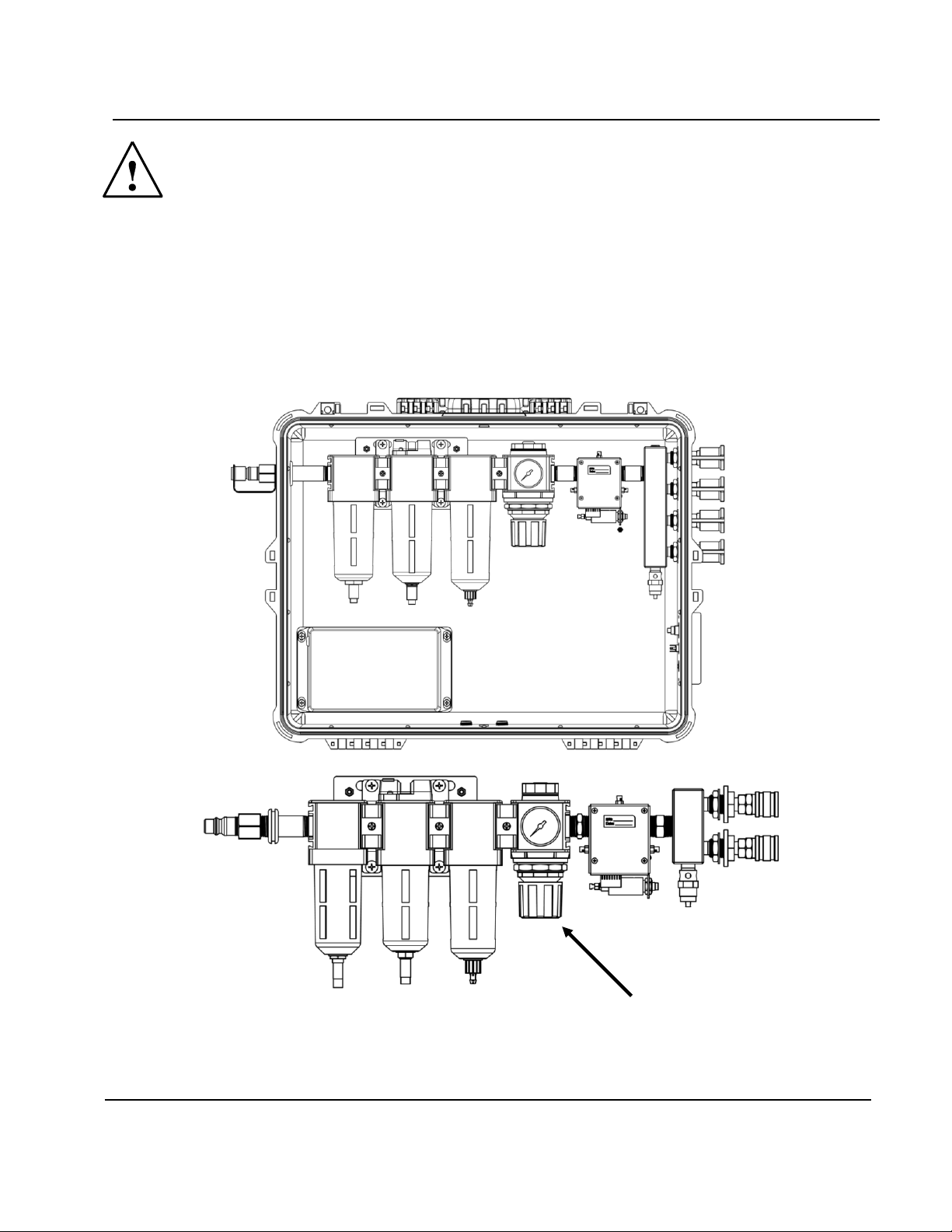

Compressor Pneumatic Connections

Prepare to connect the air supply from the compressor to the AirGuard inlet located on the left side of the

instrument.

Caution! 150 pounds is the maximum inlet pressure

Attach the pneumatic hose from the compressor to the AirGuard.

To connect to the AirGuard inlet pull the outside ribbed ring away from the end of the compressor hose and push

the connector into the receptacle port. Release the ribbed connector to complete the connection. Make sure the

connection is secure.

Follow the same process in reverse to disconnect the hose.

Inlet Connection

12

www.bullard.com

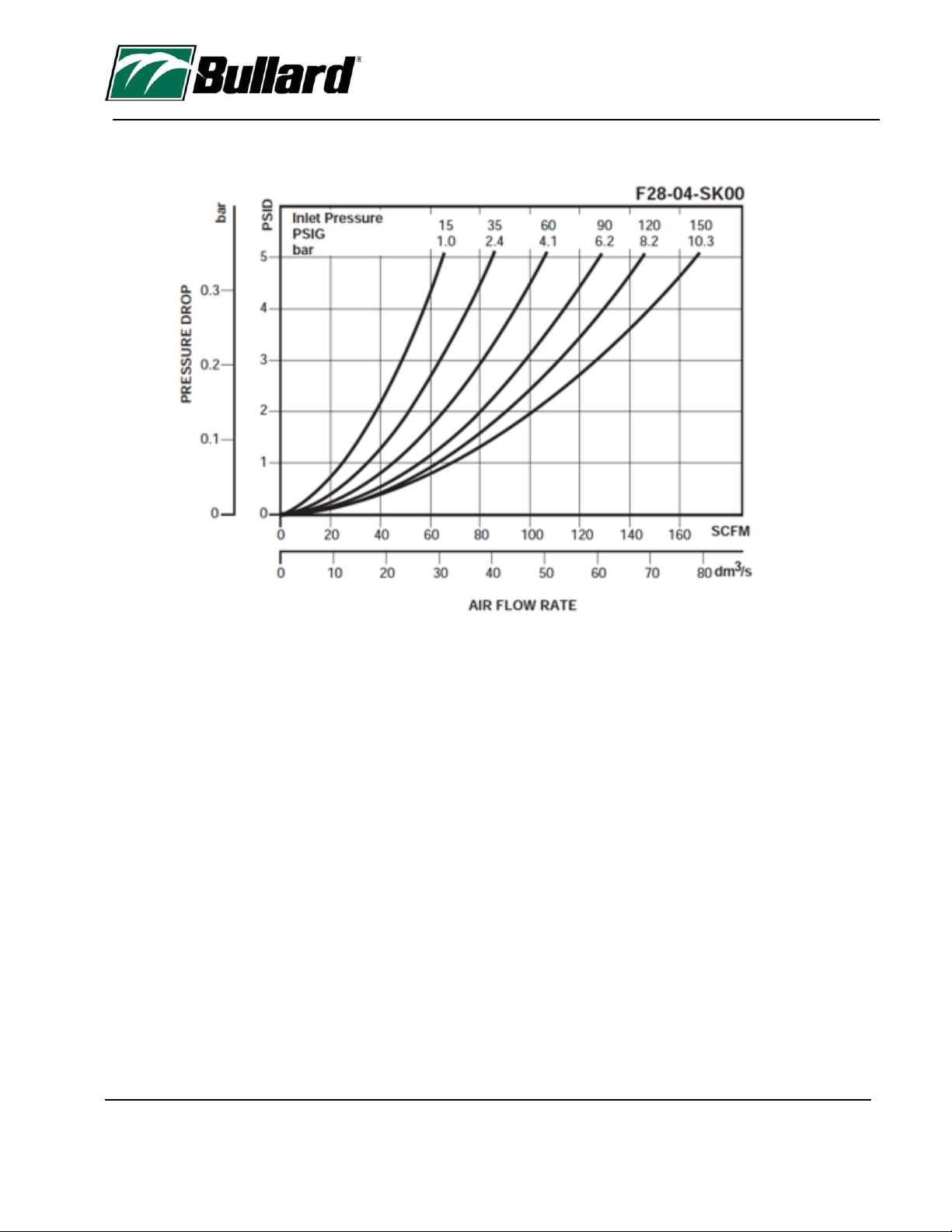

The following chart illustrates the CFM delivered at different inlet pressures.

AirGuardTM

13

www.bullard.com

Warning! Maximum Supply inlet pressure cannot exceed 150psi

Review the personal protective equipment instructions to be used with AirGuard. You need to know the pressure

setting required for the correct flow.

Open the enclosure and adjust the delivery pressure by turning the regulator adjustment to the desired pressure

to deliver required SCFM as per the NIOSH approved respirator being used. Clockwise increases the pressure value.

Regulator

Adjustment

Knob

14

www.bullard.com

Start-Up

To turn on the AirGuard, you must press the power on button.

Once pressed, it will illuminate light blue.

During this time the main LCD will activate in ≈ 30 seconds, and the main warm-up in progress screen will display.

After warm-up functions are finished the AirGuard status screen will display a report of 5 key metrics of operation.

1. CO Alarm

2. Calibration Due

3. Flow Alarm

4. Differential Dew Point

5. Sensor Flow

All parameters with a green “check”are satisfactory.

A red "X" will report an unsatisfactory operational status which will need to be corrected or cleared before use. A

yellow “check mark”will appear if there is a caution or warning condition that may require action.

AirGuardTM

15

www.bullard.com

Warning! Below is an example of an AirGuard Status Screen fault message due to no

compressor flow.

After toggling to the exit function, the main operation screen will appear. Under this condition the main screen

will display a dash (-) in place of the carbon monoxide reading. This is a safety measure to ensure the AirGuard is

operating under the correct conditions of compressor flow

Once compressor airflow is established the carbon monoxide value will appear.

16

www.bullard.com

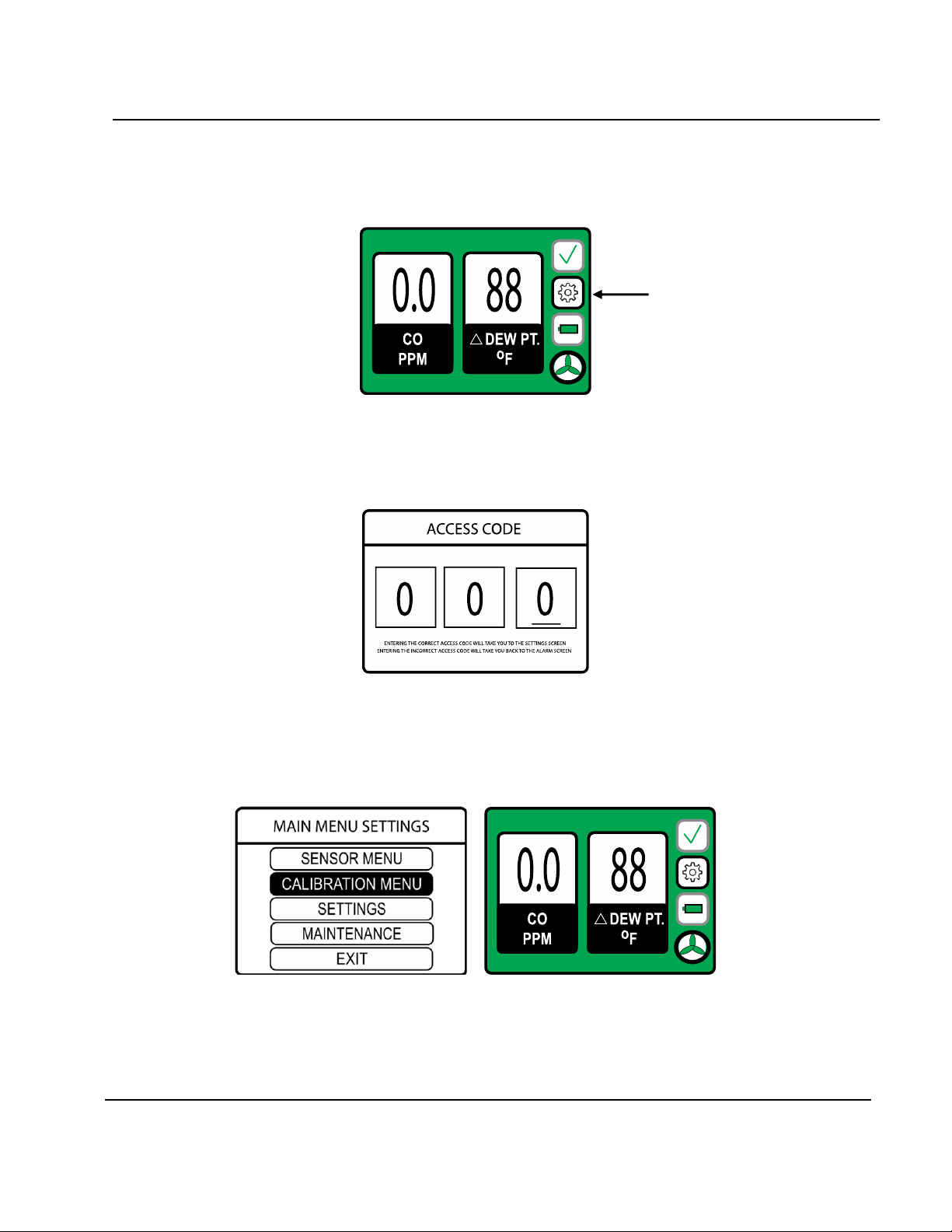

Upon each power up the operator must acknowledge the "AirGuard Status" report before the instrument is ready

for operation. To begin active operation, the user must toggle down to the exit function and press enter.

Next, the main screen will appear indicating the current CO concentration (ppm) and the differential dew point

value in degrees Fahrenheit when connected to compressed air supply. To change the unit to centigrade, refer to

page 22.

Upon display of this screen, the AirGuard is now in normal operational status.

AirGuardTM

17

www.bullard.com

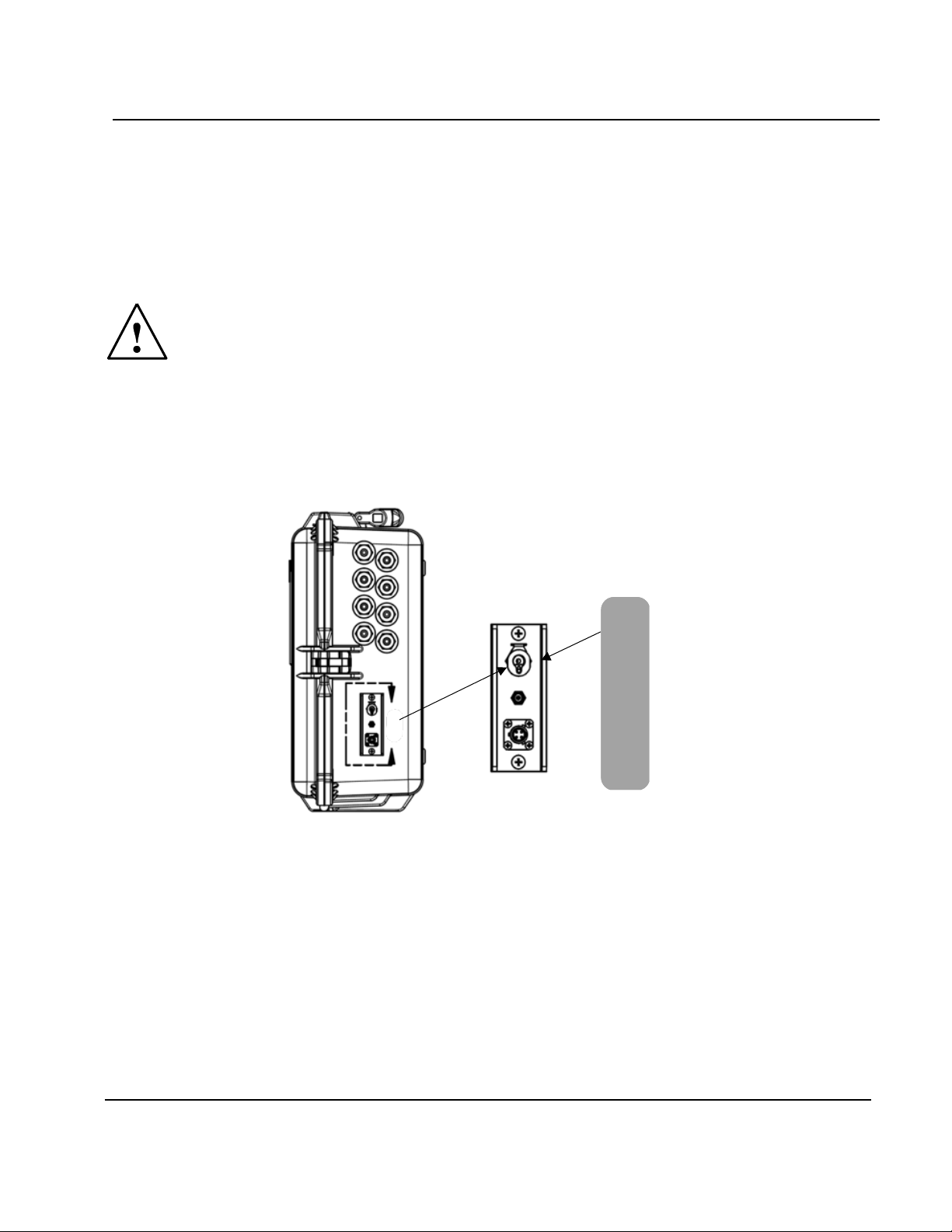

Access Code

To modify the AirGuard functions you must enter an access code.

Toggle to the gear icon by using the down or orange code button. The gear icon outline will appear black and

press enter (green button).

The Access Code Screen will appear.

Enter the assigned access code, the factory pre-set is 2 - 7 - 0.

Entering the correct code will take you to the “Main Menu Settings”screen, if an incorrect code is entered the

main alarm screen will appear.

Gear Icon

18

www.bullard.com

When powered in a no flow condition, the AirGuard will report a system fail “X” and a red fan icon. Additionally,

the system status screen will indicate a flow alarm and sensor flow failures. Once flow is re-established from the

compressor the system status will return to a green check and fan will turn green. The AirGuard system status

screen will display updated information clearing the flow alarm and sensor flow failures to green checks.

Once the gas flow is started, it will take about 4 minutes for the LCD to report the measured gas concentration.

The range of acceptance on a 10 ppm CO standard is 9 ppm to 11 ppm. If the gas concentration is outside of these

values we recommend a complete two-step calibration be performed. Refer to page 23 for step by step calibration

instructions.

AirGuardTM

19

www.bullard.com

Bump Test

It is recommended that the AirGuard is bump checked before use to ensure proper response to a known

calibration standard. Should the reported test values from the bump check not meet the calibration standard

value, ±10% of the reference value, it should be recalibrated.

BULLARD provides a calibration kit for the AirGuard with all the components to complete this test.

(Part Number: AGDCK)

Warning! To perform a bump check, the AirGuard must be disconnected from the

compressor air supply.

Calibration cylinder must be connected to a pre-determined or fixed flow regulator assembly, with a male quick

connect fitting and tubing attached to the regulator.

The calibration cylinder assembly tubing is then attached to the female calibration connection located on the right-

hand side of the instrument and the cylinder is turned on to initiate gas flow.

Calibration

Connection

Charger

Connection

Remote

Alarm

20

www.bullard.com

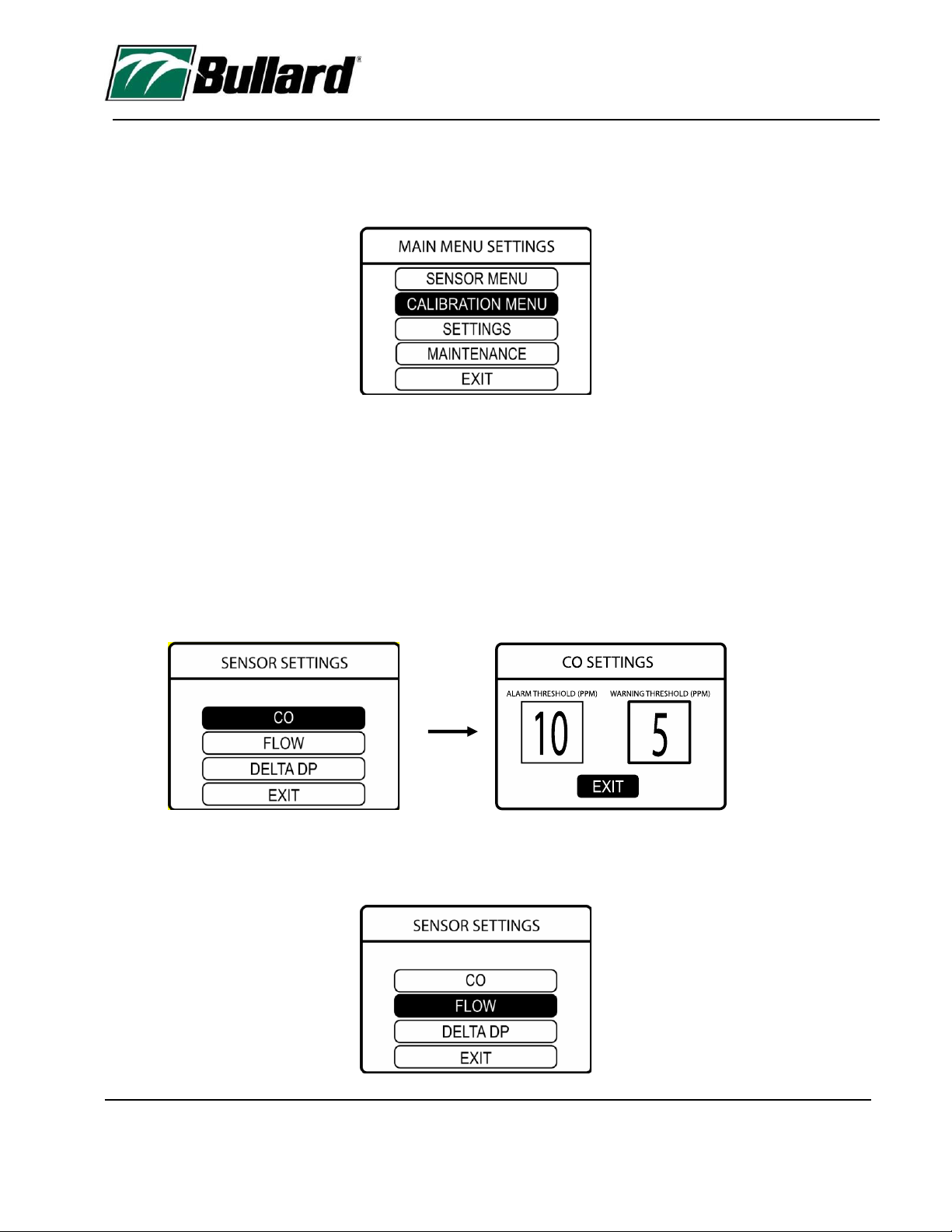

Sensor Menu

The sensor menu allows the operator to adjust function parameters. This includes CFM (flow) alarm and warning

values as well as the audio alarm horn.

The Sensor Settings menu allows adjustment of Air Guard set points such as alarm values, CFM flow value and

delta dew point units.

For the adjustment of number values, the active box containing the number will have a bold border indicating it is

active. To adjust the values, you must use the up and down buttons below the display. You will move to the next

value entry by pressing the enter button or going back to the previous menu.

1. CO (Carbon Monoxide) displays the preset alarm values. These values are user adjustable. The maximum high-

level alarm setting is 10ppm. A value setting higher than 10ppm cannot be entered as per OSHA requirements. A

CO warning alarm (yellow alert) can be set to any value, but cannot be set to the alarm level value.

2. Flow settings adjust both the horn and visual alarms.

Table of contents

Other ENMET Gas Detector manuals