48.5-4 ASSEMBLY MANUAL

NOTE: A cup of zinc paste (PENETROX, NOALOX, OR equivalent) has been provided to enhance the quality

of all the electrical joints in this antenna. Apply a thin coat wherever two pieces of aluminum come in contact.

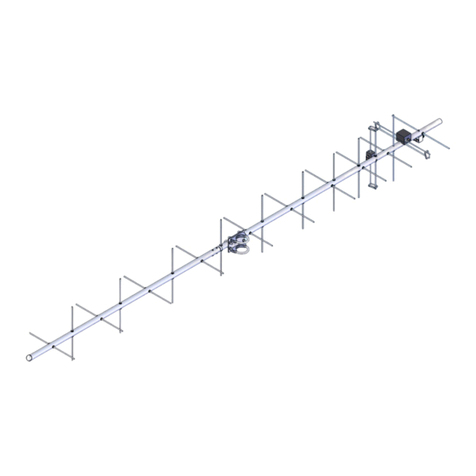

1. Refer to the Dimension Sheet. Note the different boom sections and the approximate position of each

element. Slide the 2” RING CLAMP into their approximate positions on the boom sections. Note One section

also has a 1/4” hole (for “T” match block) and ALL SPACING DIMENSIONS ARE REFERENCE FROM THE

DRIVEN ELEMENT. Accuracy at this pint is unnecessary as the boom must be assembled before exact

element spacing is set. Spread the ring clamp fingers with a flat blade screwdriver if necessary to ease

movement on boom. Loosely and a 1/4-20 x 1” bolt and locknut to fingers of all clamps.

2. Return to the rear boom section. Mount the “T” MATCH ASSEMBLY BLOCK to the 1/4” hole with a single

1/4-20 x 2-1/4” bolt (make sure the Driven Element ring clamp is to the rear of the “T” match block). Orient the

two balun connectors to the front. Now slide the ring clamp up against the “T” Match block and rotate until the

element channel is on the opposite side of the boom from the “T” Match block. Tighten the 1/4-20 x 1” bolt and

locknut to hold the clamp in position.

3. Select a 7/8” x 15” CENTER SPLICE and insert a 3/4” x 36” tube section halfway into butt end. Line up

holes. Push a 1/4-20 x 1-3/4” bolt through this hole and add the second 3/4” element section. Add another bolt

and place this assembly into the Driven Element ring clamp channel. Add the 1/4” locknuts and tighten.

4. Slide the SHORTING BARS onto the swaged outer ends of the 3/4” sections and onto the 1/4” “T” Match

rods. Position them per the DIMENSION SHEET. The measurement is between the outer face of the “T” Match

block and the inner face o the shorting bar. Wipe PENETROX on the element and “T” Match rod at the correct

spot. Slide the shorting bar to this spot. Add the 8-32 x 1-1/2” screw and locknut and ALIGN the rods parallel

with the element sections and tighten the hardware. Wet the two 8-32 x 1/4” set screws with Penetrox and

thread a pair into each shorting bar. A 5/64 Allen wrench has been provided for tightening the set screws.

5. Now assemble the boom sections using the 1/4-20 x 2-1/2” bolts and locknuts. Install the BOOM TO MAST

PLATE at about 66” from the rear at this time. This plate can be clamped in a vice, turned flat and laid on a

work table or clamped to a short mast providing a good working height for the balance of the assembly.

6. Assemble the remaining 3/4” element sections and 7/8” x 15” sleeves and mount to the ring clamps as in

step #3.

7. Pair up the 1/2” tip sections by length. Install the longest pair into the REFLECTOR (rear) element. NOTE: If

you have received tips with no holes predrilled at the factory, position the 1/2” tip at the proper dimension and

drill through the holes into the 1/2” tube using a #17 (.173 dia.) drill bit. Secure with 8-32 x 1” screws and

locknuts. Repeat for all elements, using the shorter lengths forward. See the Dimension Sheet for EXPOSED

TIP LENGTHS.

8. Now adjust ELEMENT SPACING ACCURATELY following the Dimension Sheet. Since the Driven Element

is fixed, use it as the primary measurement reference. Dimensions given are “center to center”, but can also be

used for edge to similar edge measurement. After setting spacing, align elements parallel with the Driven

Element and tighten the 1/4-20 x 1” bolts in each ring clamp.

9. Install the “F” connector SEAL NUTS on the two female “F” connectors on the “T” match block. The black

neoprene seal should face out. Attach the balun to the two “F” connectors on the “T” match block. Finger tight-

en and then gently final tighten with a 7/16” end wrench. Then run the SEAL NUTS up against the face of the

male connectors and tighten gently about 1 turn with a 1/2” end wrench. Attach the coaxial PHASING LINE “N”

connector to the “T” match block and route the coax forward to the boom to mast plate. Secure the main feed

line and the coiled balun cable as required with large black cable ties or equivalent. (ties should be snug, but

not crushing cable). It is your option to further seal the “N” feed connector and balun connectors with Coax

Seal or equivalent. NOTE; The balun cable does not have be coiled up to be effective. It can be uncoiled and

secured cleanly along the boom if desired.