6M6LN PARTS & HARDWARE

DESCRIPTION QTY.

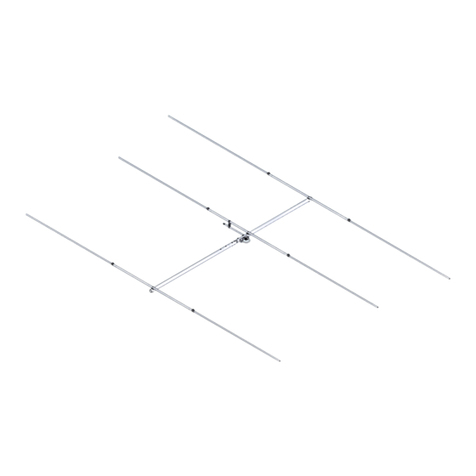

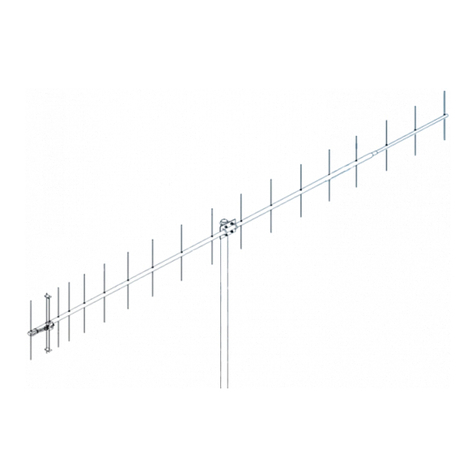

BOOM SECTION #1, 1.5” X .065” X 60”, SOE (M2ABS6M6LN-1).................................... 1

BOOM SECTION #2, 1.5” X .065” X 60”, SOE (M2ABS6M6LN-2).................................... 1

BOOM SECTION #3, 1.5” X .065” X 60”, SOE (M2ABS6M6LN-3).................................... 1

BOOM SECTION #4, 1.5” X .065” X 60”, SOE (M2ABS6M6LN-4).................................... 1

BOOM SECTION #5, 1.5” X .065” X 60” (M2ABS6M6LN-5) ............................................. 1

ELEMENT TUBE, 3/8” X .049” X SEE DIMENSION SHEET............................................. 10

ELEMENT SUPPORT ROD, 1/4” X 10” (M2AEP0060) ..................................................... 10

DRIVEN ELEMENT TIP, .375” X .049” X 6” (M2AEP0003)............................................... 2

DRIVEN ELEMENT HALF, .500” X .049” X 51.5”, TWO HOLES (M2AEP0072) ............... 2

FIBERGLASS INSULATOR, 3/8” X 10” (M2AFG0017) ..................................................... 1

HAIRPIN (M2ADP0002)................................................................................................... 1

HAIR PIN MOUNT (M2ADP0620)..................................................................................... 2

ELEMENT MOUNT (M2AEC0056) ................................................................................... 5

DRIVEN ELEMENT CLAMP (M2AEC0094)...................................................................... 1

COMPRESSION CLAMP, .500” (M2AMC0146)................................................................ 2

BALUN, 1:1 WITH SO239 CONNECTOR (FGBL0700) .................................................... 1

DACRON ROPE, 3/16” x 20’ ............................................................................................ 1

BOOM TO MAST PLATE, 4” X 6” X .188” (M2APT0022).................................................. 1

TURNBUCKLE PLATE, 2” X 4” X .125” (M2APT0102) ..................................................... 1

BALUN PLATE, 1.5” X 3” X .125” (M2APT0013) .............................................................. 1

ASSEMBLY INSTRUCTIONS........................................................................................... 1

HARDWARE

U-BOLT & CRADLE, 2" .................................................................................................... 3

U-BOLT & CRADLE,1-1/2” ............................................................................................... 4

TURNBUCKLE, 5/16”, HOOK AND EYE .......................................................................... 2

NUTS, 5/16-18, SS ........................................................................................................... 14

LOCK WASHERS, 5/16”, SS ............................................................................................ 14

EYEBOLTS, 1/4” x 4”, SS ................................................................................................. 2

SET SCREW, 1/4-20 X 1/4”, SS ....................................................................................... 1

LOCKNUT, 1/4-20, SS...................................................................................................... 2

SCREW, 8-32 X 2”, PHILLIPS PAN HEAD, SS ................................................................ 6

SCREW, 8-32 X 1-3/4”, PHILLIPS PAN HEAD, SS .......................................................... 8

SCREW, 8-32 X 1”, PHILLIPS PAN HEAD, SS ................................................................ 12

SCREW, 8-32 X 1/2”, PHILLIPS PAN HEAD, SS ............................................................. 2

SET SCREW, 8-32 X 1/4”, SS .......................................................................................... 2

NUT, 8-32, SS .................................................................................................................. 2

LOCKNUT, 8-32, SS......................................................................................................... 26

CABLE TIES, 7"................................................................................................................ 5

ALLEN WRENCH, 5/64” ................................................................................................... 1

PENETROX (SMALL CUP) .............................................................................................. 1

M2 ANTENNA SYSTEMS, INC.

4402 N. Selland Ave.

Fresno, CA 93722

(559) 432-8873 Fax: 432-3059