2

CONTENT

1. Warning ............................................................................. page 3

2. Introduction ....................................................................... page 4

3. Function ........................................................................... page 5

3.1 Construction and principal ................................................. page 5

3.2 Individual device parts ....................................................... page 5

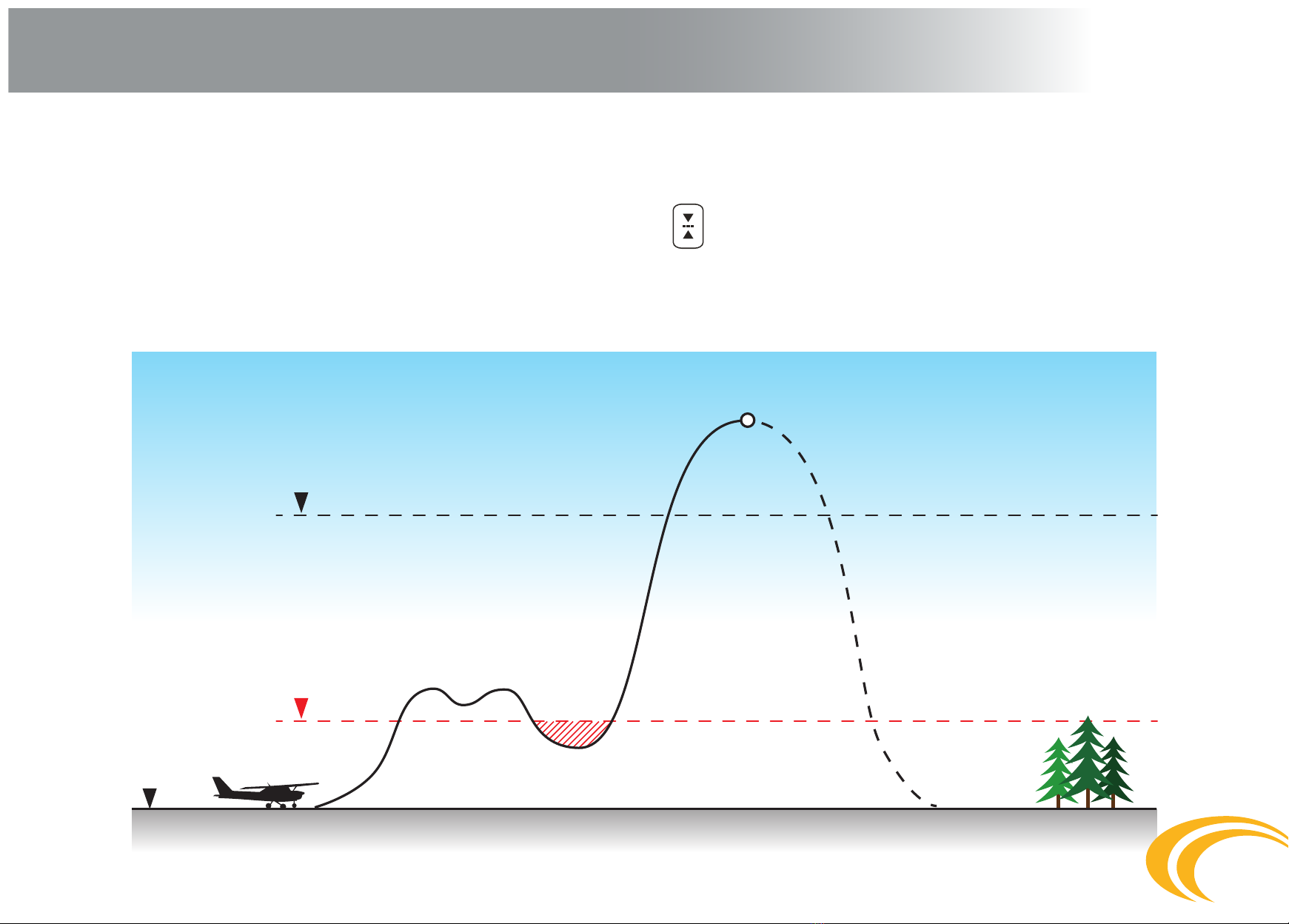

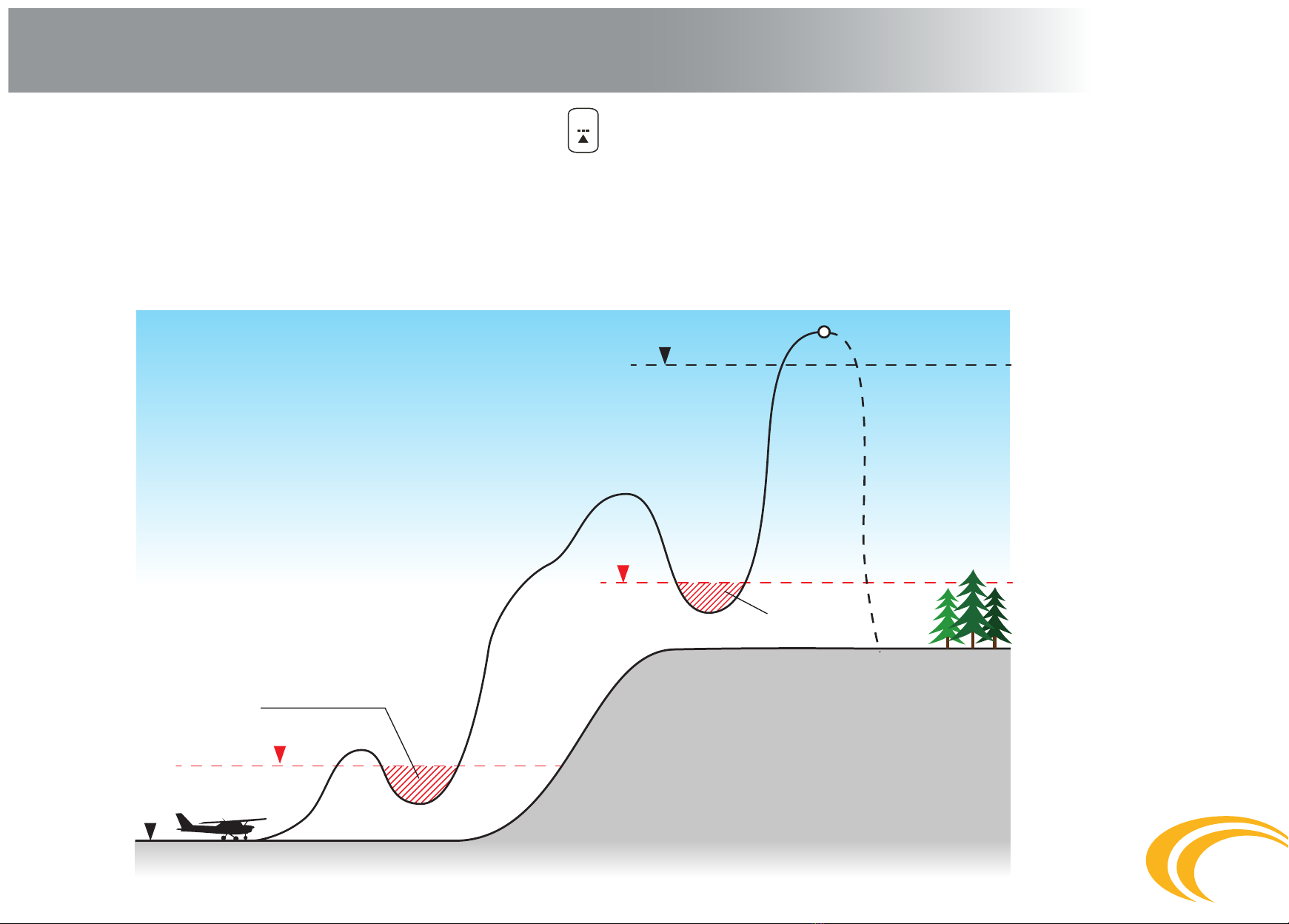

3.3 Function principle............................................................... page 6

3.4 Activation zone................................................................... page 10

3.5 Altitude lock ....................................................................... page 11

3.6 Limited speed .................................................................... page 12

4. Models................................................................................ page 13

4.1 Student............................................................................... page 13

4.2 Expert (Swoop)................................................................... page 13

4.3 Tandem .............................................................................. page 13

5. Installation ......................................................................... page 14

6. Control ............................................................................... page 17

6.1 Switching the device on ..................................................... page 17

6.2 Switching the device o ..................................................... page 18

6.3 Resetting the height of landing location ............................ page 18

6.4

Information in the device memory calibrated in meters (m)

... page 20

6.5 Information in the device memory calibrated in feet (ft).... page 22

6.6 Switching on Schema – meter version ............................... page 24

6.7 Switching o Schema – meter version ............................... page 25

6.8 Switching on Schema – feet version................................... page 26

6.9 Switching o Schema – feet version................................... page 27

7. Maintenance ...................................................................... page 28

7.1 m2release unit (cutter) replacement ................................. page 28

7.2 Filter replacement .............................................................. page 29

7.2.1 Procedure when the m2is used under water ..................... page 29

7.2.2 Procedure during the lter incorrect function..................... page 29

7.2.3 Waste disposal ................................................................... page 29

7.3 Battery ............................................................................... page 30

8. Ensuring closing loop to the washer .................................. page 31

9. Error reports ....................................................................... page 32

10. Technical data..................................................................... page 33

11. Warranty............................................................................. page 34