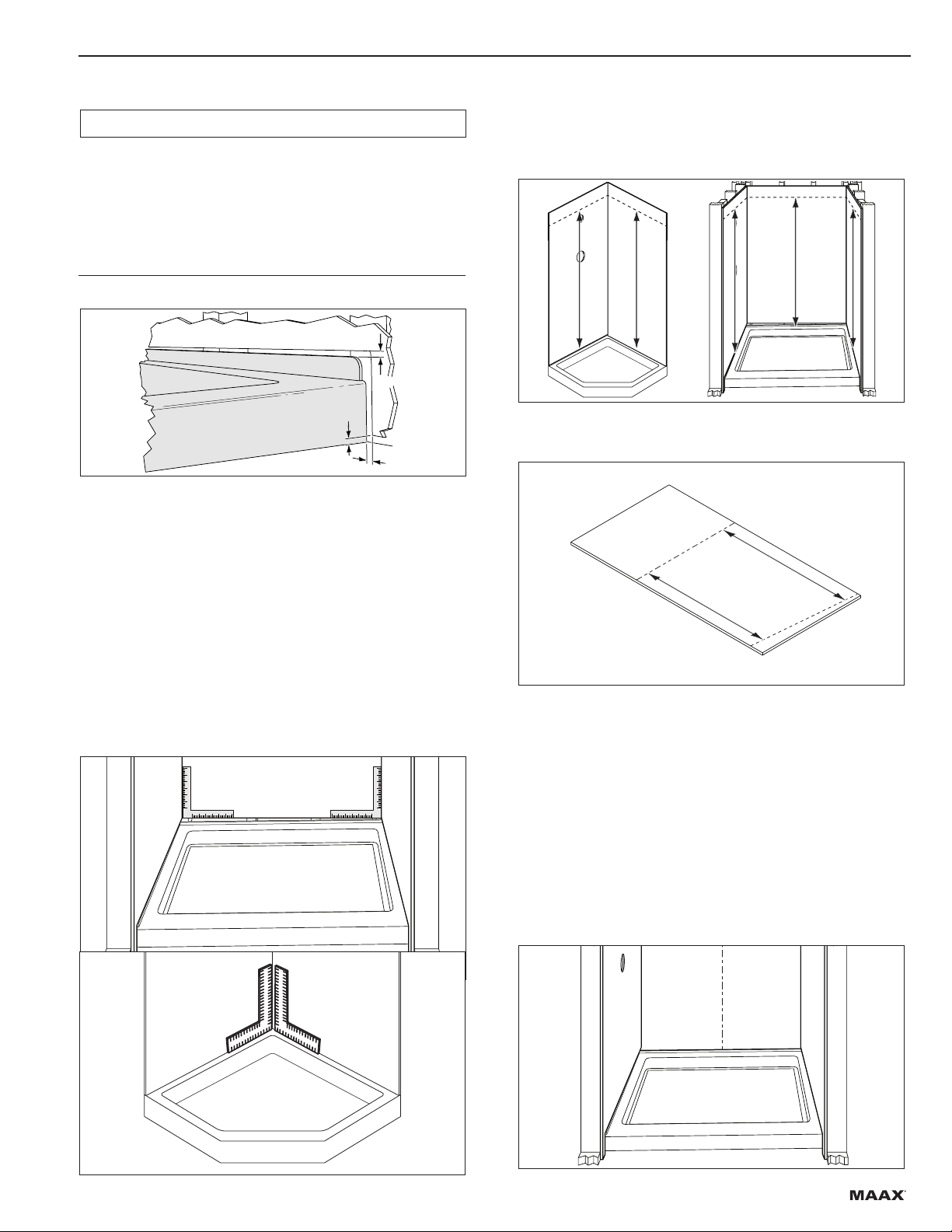

Lifting Hazard

To avoid personal injury, use two people to move

cartons weighing more than 51 lbs. The box

containing the wall panels can weigh up to 120 pounds.

Use the appropriate lifting devices to move the load. Always

use two people when lifting heavy or bulky cartons. DO NOT

attempt to lift objects that are too heavy.

WHEN CARRYING A HEAVY LOAD—GET HELP!

Slipping Hazard

Do not install this product in the presence of water.

Installing this product without drying all surfaces, or in

the presence of water, could cause you to slip and fall due to

wet floors or spilled fluids. Personal injury can result from slips

or falls. Before installation, dry all surfaces, including the floor,

with a cloth or paper towel. Clean up all spilled fluids

immediately.

Tripping Hazard

Personal injury can result from tripping over power

cords, tools, or other items. DO NOT leave items laying

around the work area.

Personal Protection

Be sure to use all personal protective

equipment, such as sturdy work boots,

preferably with steel toes, gloves, and hard hat, if necessary,

to ensure your own safety. To prevent possible damage to

your hearing, always wear ear protection, such as earmuffs or

earplugs, when working around power tools.

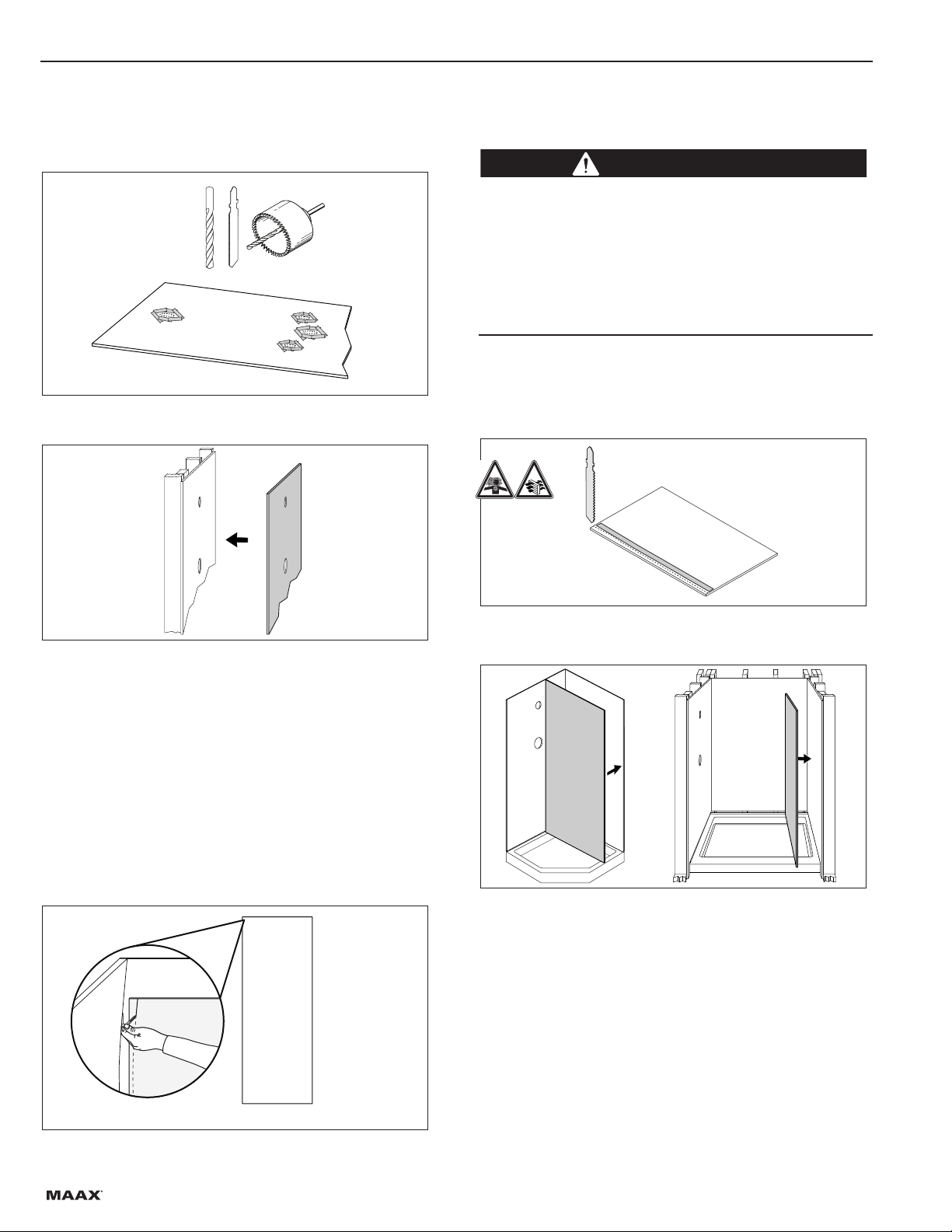

Cutting Hazard

The installation of the walls may require using power

tools. Keep hands away from the cutting edge of any

tool used in the installation of our product. Placing

fingers in or around the cutting blades could result in serious

personal injury.

Sharp Edge Hazard

After cutting the edge of a panel, it can be sharp. Wear

protective gloves to prevent personal injury.

Room Temperature

Allow the panels to adjust to room temperature

for at least six hours before installation, and

consult the 100% silicone sealant manufacturer’s

instructions for storage and surface preparation. The panels

should be installed at temperatures not less than 18°C. Panels

should not be installed in areas where the temperature may

drop below freezing. Failure to follow this recommendation

could adversely affect the silicone sealants which holds the

panels to the wall. If the panels are not correctly adhered to the

walls, they may fall off, causing possible injury to someone in or

around the shower.

Grab Bars

We recommend that shower compartments be

equipped with support grab bars that comply with the

most recent edition of ANSI-A117.1 requirements.

Grab bars must be anchored to structural support (wall studs)

behind the panels. Do not rely on the panels only for grab bar

support!

WARNING: Damage and injury can be incurred if the

instructions are not followed.

Eye Protection

Be sure to use all personal protective equipment to

ensure your own safety. To avoid eye injury, always

wear protective glasses with side shields when using power

tools. Also, make sure no one else can be injured by flying

particles when using power tools.

Fire Hazard

Personal injury or death can result from a

fire caused by flammable liquids or

silicone sealants. Cleaners or solvents can be highly explosive,

resulting in personal injury or even death, when not used

properly. Clean up any flammable substance immediately.

Sparks or open flames can cause flammable substances to

ignite. DO NOT smoke while working on or near any

flammable substance.

Solvents Hazard

Follow all manufacturer’s safety instructions for silicone

sealants and denatured alcohol. Alcohol vapors are

both flammable and hazardous to breathe. Silicone vapors

may irritate eyes and nose. Personal injury can result from

improperly handling or use of products, such as denatured

alcohol. Always follow the manufacturer’s recommendations for

the safe use of these products. Ventilate any work area before

beginning to apply silicone sealants, cleaning agents, or

solvents.

Fumes Hazard

The fumes from the silicone and solvents used

by the installer can be harmful if used in an

unventilated room. Always work in a well-ventilated area. To

keep the area well-ventilated, open windows and use exhaust

fans. If adequate ventilation is not achievable or practical, use

respiratory protective equipment.

Dust Hazard

When cutting or drilling the product, use a dust

collection method which prevents dust particles

from going into the air. Always work in a well-ventilated area.

Always use government health and safety agency approved

dust mask when cutting, drilling, or sanding MAAX products.

Power Tool Hazard

To prevent personal injury or possible death,

always follow the electrical safety

recommendations of the power tool’s manufacturer. Do not use

power tools in an unsafe manner. Power tools should only be

connected to a circuit protected by a ground-fault circuit

interrupter (GFI).

Shock Hazard

Never use electric power tools around water,

condensation, or other liquids. Electric shock

can cause severe burns, significant injuries, and even death. If

an extension cord is required, always use government health

and safety agency approved extension cord. Power cords

should only be connected to a circuit protected by a ground-

fault circuit interrupter (GFI).

Safety Guidelines

3