Version 2.1, August 2005, © Machine Support B.V. page 3 of 16 Vibracon®manual, chapter 2

www.machinesupport.com

2.1 How to select the right Vibracon®chock size?

To get an indication which size of Vibracon®should be used, the following parameters will

give you an impression:

•What is the size of the bolthole in the component bed plate?

•What is the minimum distance (pitch) between two adjacent holes?

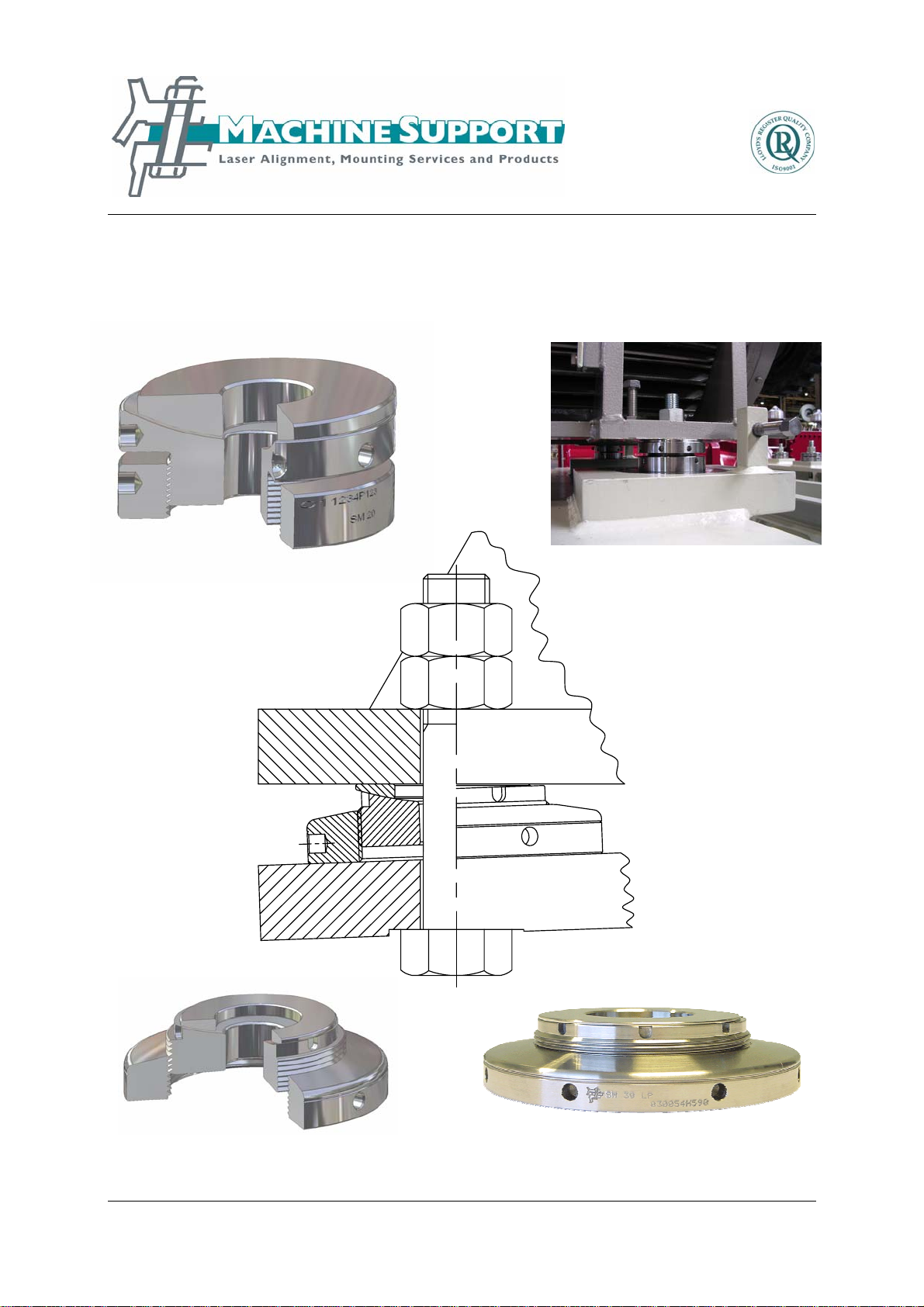

The type indication of Vibracon®is related to the foundation bolts for which they can be used.

For instance the Vibracon®SM30 is developed to be used in combination with a hexagonal

bolt M30 but it is also possible to use one size of bolt diameter bigger, in this example a bolt

M33.

2.2 How to get a Vibracon®chocking proposal free of charge?

As a part of our service, Machine Support offers you a free of charge calculation proposal for

the mounting of your component. To prepare this calculation we need information concerning

the component, the available chocking height and some information concerning the

foundation.

The fastest way to receive a chocking proposal for your application is to fill out one of the

appropriate datasheets (APPENDIX 1). The datasheets can also be downloaded from our

website www.machinesupport.com we ask you to send the completed datasheets by e-mail

to:

The used calculation software is approved by the Classification Societies involved for marine

applications. On request Machine Support will make contact with the OEM to support you

with getting an agreement on the chocking proposal.

Normally you will receive, within one day, a calculation as mentioned in APPENDIX 2.

A full proposal consists of four sheets:

•Report of all information related to the selection of the chock, including operating

forces on the chocks plus foundation hardware information;

•Illustration of the top view of the component that shows the location of the chocks, the

position of the positioning and / or collision chocks and the fitted bolts (if required);

•Illustration of the cross section of the foundation bolt in which the clamping length and

foundation bolt are specified;

•Illustration of the cross section of the fitted bolt, if required, in which the clamping

length and fitted bolt are specified.

Machine Support, upon request, will submit our report to the involved Classification Society

for approval. Costs for this service are on an as negotiated and per event basis.

ООО "Индастриал Партнер"

Авторизованный дистрибьютор SKF