MAC0

ALPHA

V58

26

-

33 MHZ Base Station Antenna

ASSEMBLY INSTRUCTION

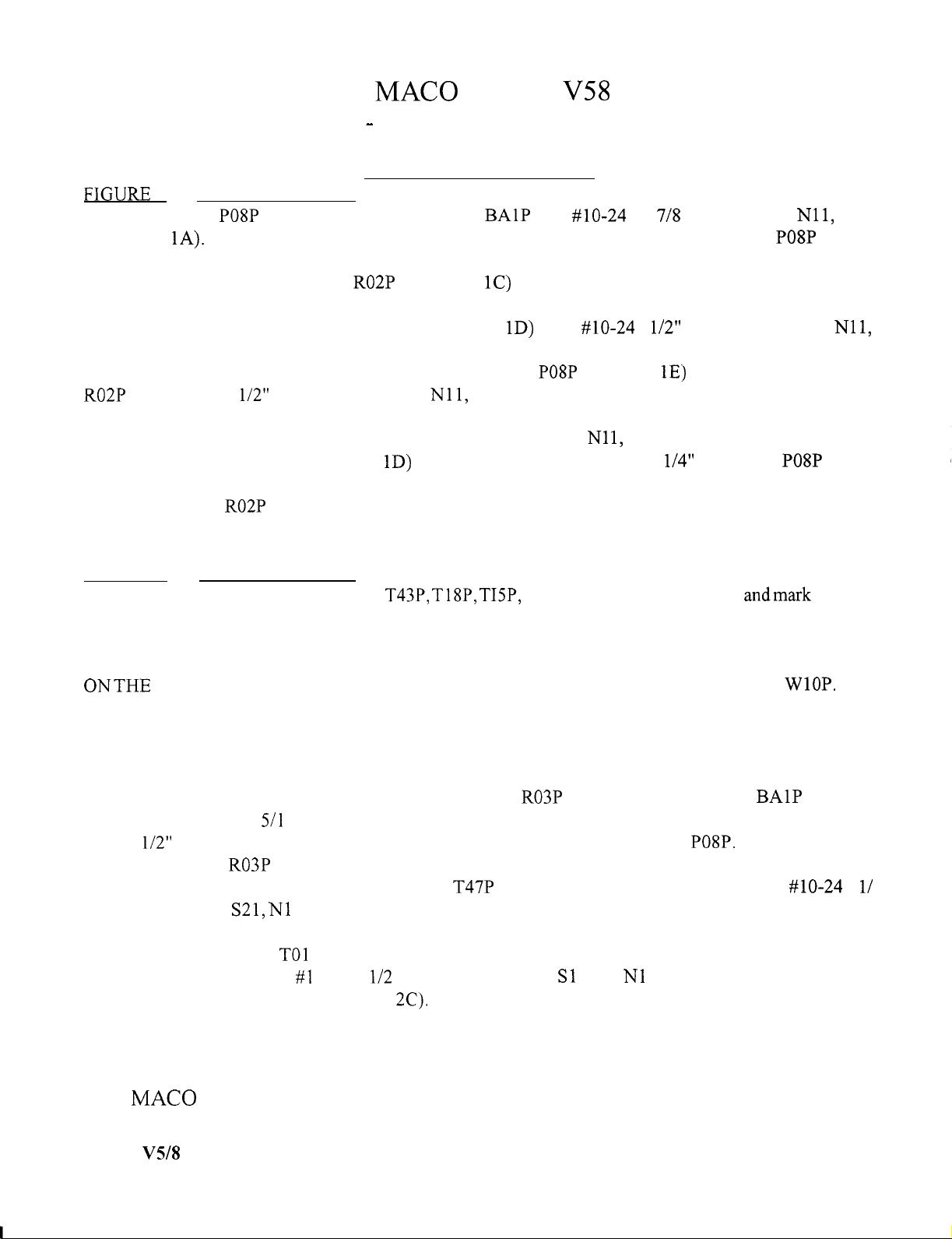

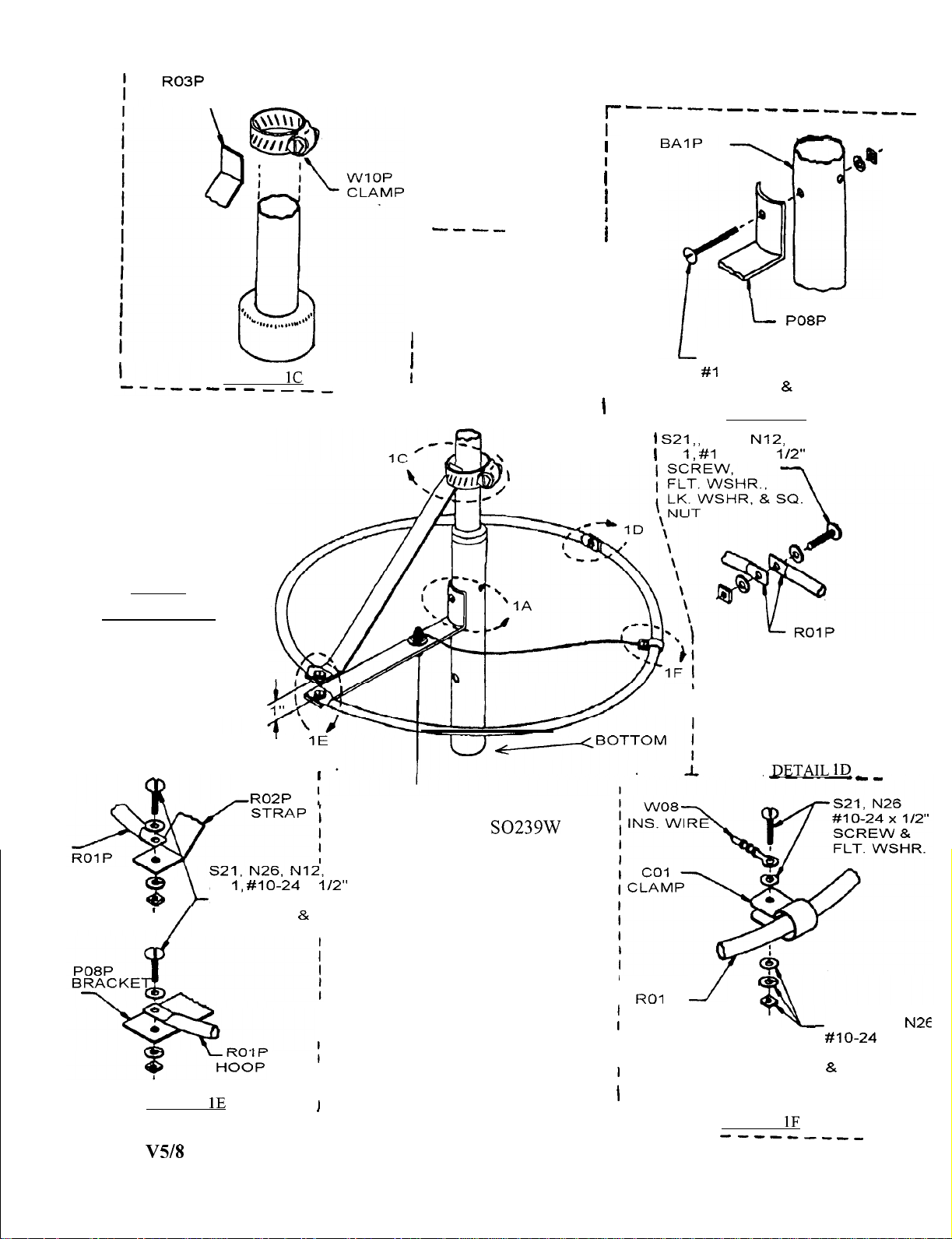

FlGURE

1

BASE ASSEMBLY

Install the

PO8P

Bracket to the base assembly

BAlP

with

#lo-24

x 1

7/8

hardware S45,

Nil,

N12

(ref. Detail

1A).

It should make a 90 degree angle with the base assembly. If not, bend the

PO8P

until it

does.

Fasten one end of the strap

R02P

(ref. Detail

1C)

to the vertical end of the base section using the

stainless steel worm drive clamp supplied. Tighten snugly but not too tight as this may have to be adjusted.

Next join the two hoop rings together (ref. Detail

1D)

using

#lo-24

x

l/2”

hardware S21, N26,

Nil,

N12.

Now fasten one end of the hoop ring RO 1 P to bracket

PO8P

(ref. Detail

1E)

and the other end to strap

R02P

using IO-24 x

l/2”

hardware S21, N26,

Nil,

N12.

Position the aluminum clamp CO 1 on the hoop ring assembly approximately where shown (ref. Detail

1 F) and attach the wire as shown using # 1 O-24 hardware S 11, N26,

Nl

1,

N12; do not tighten. Now measure

from the center of the screw (ref. Detail

1D)

around the outside of the ring 6 l/4” toward the

PO8P

end of

the hoop ring assembly until the edge of the clamp CO 1 is against the mark; tighten snugly. Now make the

final adjustment of R02P so that the distance between the ends of the rings is 1”. This is a vertical separation

of 1”. (Ignore the screws in this measurement) and tighten the clamp firmly.

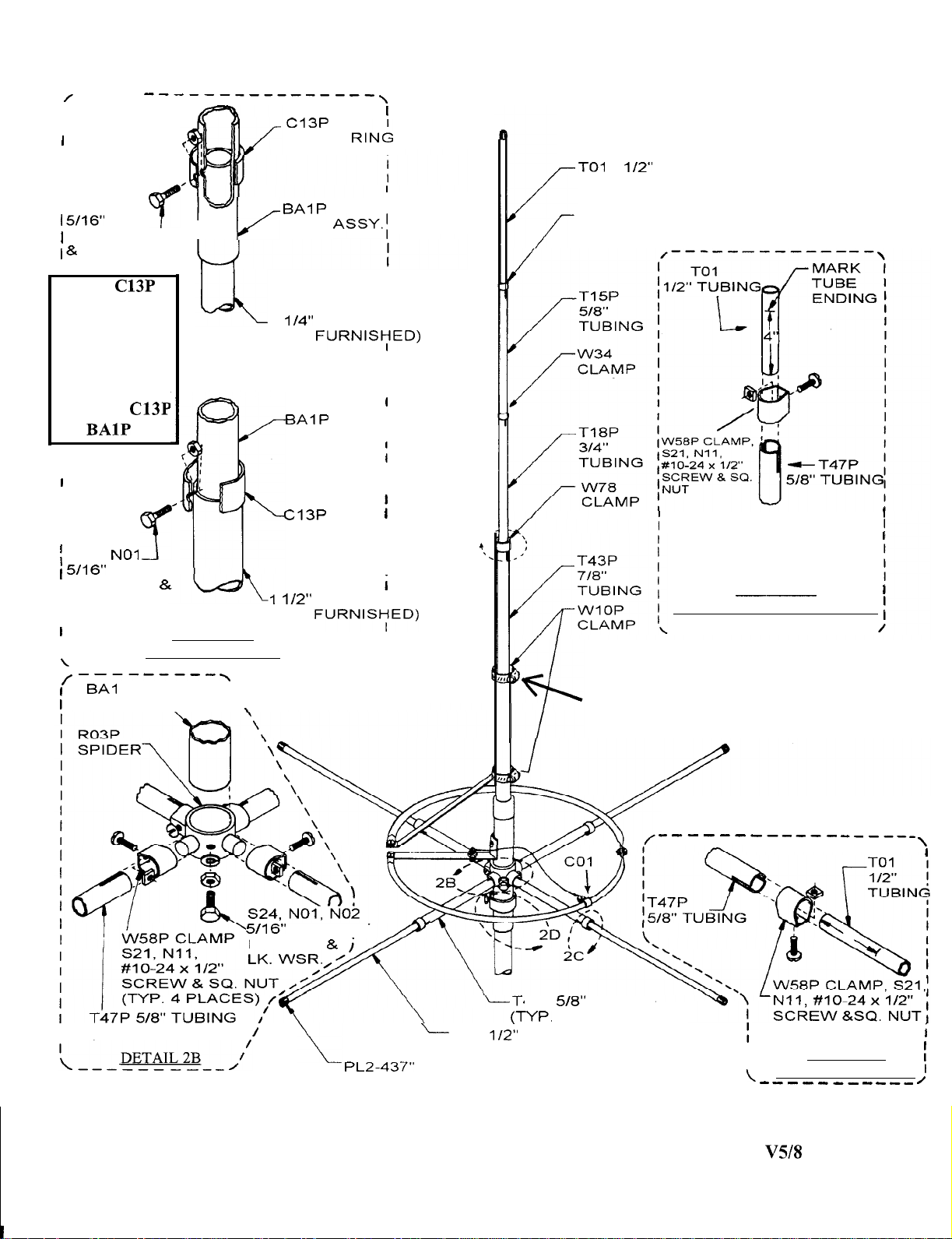

FIGURE 2 BASE ASSEMBLY

To install the vertical elements, # T43P, T18P, TISP, use a felt tip marker and ruler,

andmark

6” from

the unslotted end. Mark the TO 1 P 4” from one end. Now using the clamps and hardware as shown (ref. Detail

2A) slide the unslotted ends into the larger sections to the mark and tighten clamps. Install the plastic cap

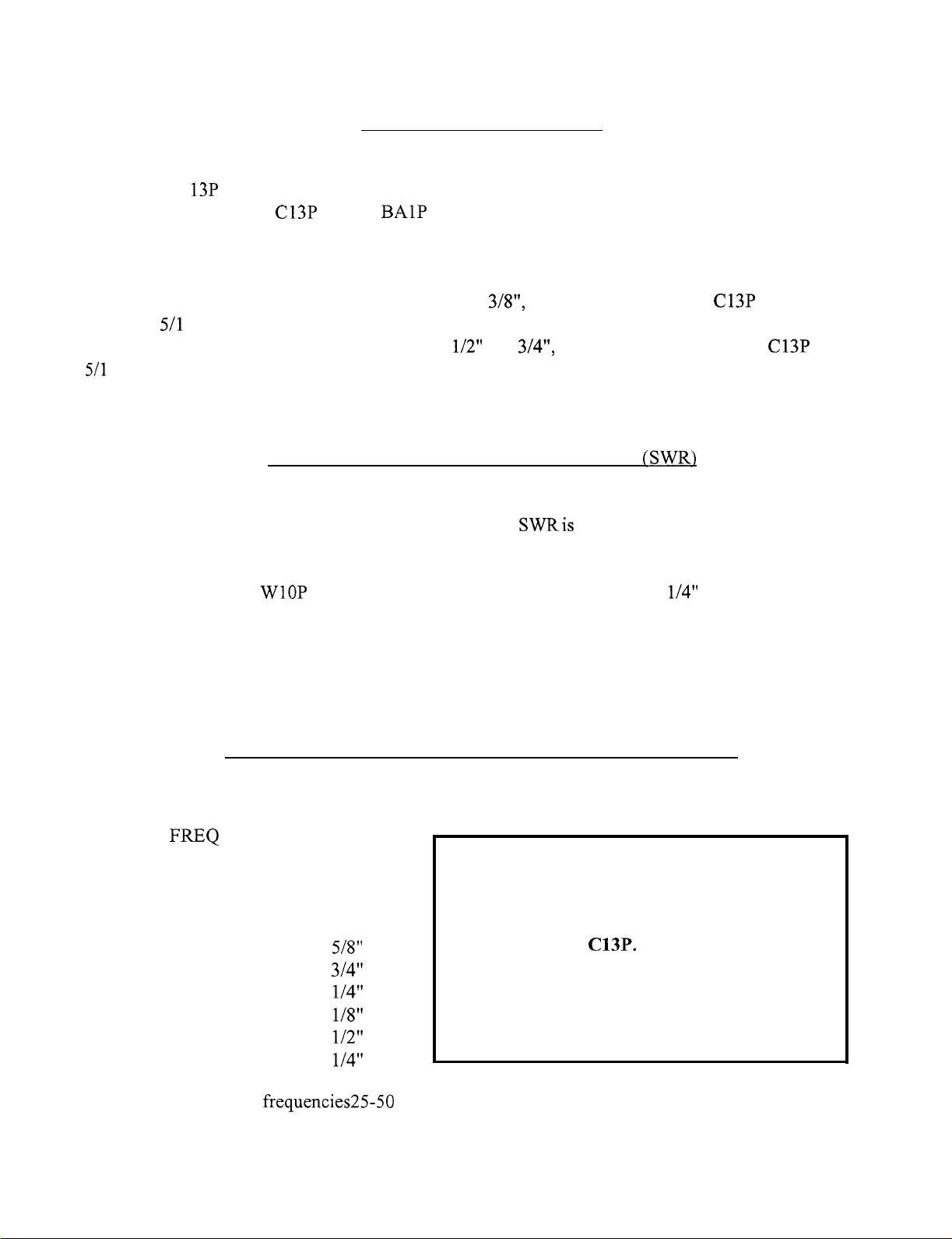

PL2 on the top. THE OVERALL LENGTH MUST BE SELECTED FROM THE FREQUENCY CHART

ONTHE NEXT PAGE AND ADJUSTED TO THIS MEASUREMENT. Shorten at top Clamp

WlOP.

This

is important to assure low SWR; however, the chart length is not sacred and may be changed to allow for

objects close enough to the antenna to cause the SWR to be affected. For frequencies falling between those

shown on the chart, it is suggested that interpolation be used to get the starting point for adjusting. Note:

The bottom means the very bottom!

To install the radials, first put the aluminum bracket R03P spider on the base section

BAlP

as shown

in Detail 2B. Install the 5/l 6 x 1 hex bolt,, nut, and washer in the bracket. The bracket is positioned so that

there is

l/2”

clearance between the top of the spider and the bottom of the bracket

PO8P.

This position puts

the top edge of the

R03P

spider just where the base section stops tapering and gets back to full size. Now

tighten the bolt and lock nut. Next take the four

T47P

radials and the four clamps W58 with

#lo-24

x

l/

2 screws, hardware

S21,

Nl

1; and place the clamps with hardware installed over the end of the tubing up

on a bracket stub and tighten. Now repeat with the other three radials.

Next take the four

TO1

P radials and using a marking pen, mark 4” from the end on all four radials.

Now using clamps W58 and

#l

O-24 x

l/2

screws with hardware

Sl

1 and

Nl

1; insert the marked end to the

mark and tighten the clamps (ref. Detail

2C).

Install the four Black

Plastic Caps PL2 on the ends. Exact length is not critical.

MAC0

MANUFACTURING, 4091 VISCOUNTAVE., MEMPHIS, TN 38118

For parts or information call (901) 794-9494.

V5/8

2