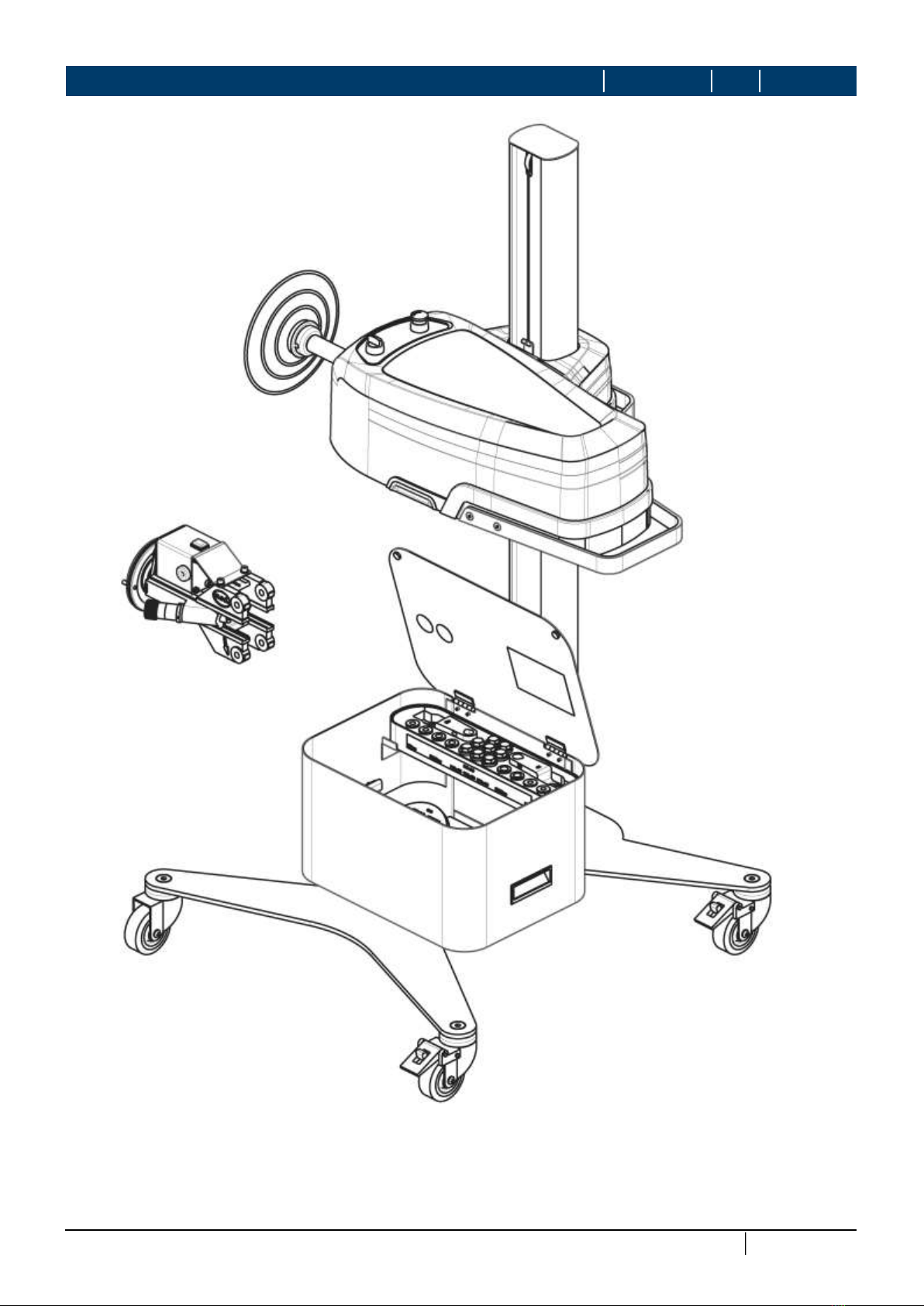

TH8750150 20-02-2015 MAD Disc Aligner

en DA87006

2. Important Safety Instructions

When using this equipment, basic safety precautions should always be followed, includ-

ing the following:

1. Read all instructions.

2. Care must be taken as burns can occur from touching hot parts.

3. Do not operate equipment with a damaged cord or if the equipment has been dropped

or damaged until it has been examined by a qualified service person.

4. Do not let a cord hang over the edge of the table, bench, or counter or come in con-

tact with hot manifolds or moving fan blades.

5. If an extension cord is necessary, a cord with a current rating equal to or more than

that of the equipment should be used. Cords rated for less current than the equipment

may overheat. Care should be taken to arrange the cord so that it will not be tripped

over or pulled.

6. Always unplug equipment from electrical outlet when not in use. Never use the cord to

pull the plug from the outlet. Grasp plug and pull to disconnect.

7. Let equipment cool completely before putting away. Loop cord loosely around equip-

ment when storing.

8. To reduce the risk of fire, do not operate equipment in the vicinity of open containers

of flammable liquids (gasoline).

9. Adequate ventilation should be provided.

10. Keep hair, loose clothing, fingers, and all parts of body away from moving parts.

11. To reduce the risk of electric shock, do not use on wet surfaces or expose to rain.

12. Use only as described in this manual. Use only manufacturer’s recommended attach-

ments.

13. ALWAYS WEAR SAFETY GLASSES. Everyday eyeglasses only have impact re-

sistant lenses, they are not safety glasses.

14. The socket-outlet shall be installed near the equipment and shall be easily accessible.

15. The machine should only be operated by persons authorized to carry out mainte-

nance on the brakes of a vehicle.

16. Do not use the equipment under the influence of drugs or alcohol, or if your judgment

is impaired.

17. Always use the disc lathe DL8704 and the drive unit DU8610 together.

18. Only use the disc lathe DL8704 and the drive unit DU8610 as stipulated in this manu-

al.

19. Do not overload the disc lathe DL8704 and the drive unit DU8610.

20. Follow the electrical specifications as stated on the information plates of both devices.

21. Keep the workplace tidy. A disorderly working environment can lead to accidents.

22. If the equipment is not being used, it should be packed away out of children's’ reach.

23. Children must be kept clear of the equipment at all times.

24. No one else should be allowed to come in contact with the equipment or cables. Keep

them clear of the working area.

25. Do not use the equipment in wet, humid environments, or where there is risk of explo-

sion.

26. Do not use the motor (DU8610) below a level of 46 cm (18 inch) above the ground.

27. Always follow the safety regulations and the (dis-)assembly instructions provided by

the car manufacturer when (dis-)assembling vehicle parts.

28. A 0.5 meter (20 inch) working area is required both next to the drive unit DU8610 and

next to the disc lathe DL8704.

Important Safety Instructions